DEC OF TECHNOL LIBRAR

advertisement

\dS.

OF TECHNOL

DEC

2 1960

LIBRAR

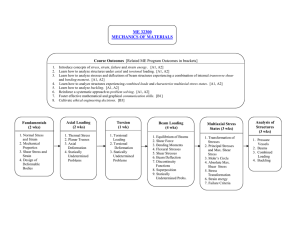

BUCKLING OF CHANNEL FLANGES DURING

BENDING IN THE WEAK DIRECTION

.by

RICHARD C' HASKELL

BE-CE

University of Southern California

SUBMITTED IN PARTIAL FULFILLMENT OF THE

REQUIREMENTS FOR THE DEGREE OF

MASTER OF SCIENCE

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

August 1960

.........

,

..

...

Signature of Author........

Department of Civil and Sanitary

Fngineexing, August 22, 1960

Certified by. ..

/Thesis

Supervisor

Accepted by.....

t7

i............

Chai7 an,

Graduate

Qmmittee on

s

~2

ACKNOWLEDGEMENTS

The author would like to express his

sincere thanks to Professor J. M. Biggs, whose guidance

and patient advice made this thesis possible.

Appreciation is

also extended to Don Gunn for his pre-

paration of test specimens and Saul Nuccitelli for his

advice on strain gage techniques.

ABSTRACT

BUCKLING OF CHANNEL FLANGES DURING

BENDING IN THE WEAK DIRECTION

by

RICHARD C. HASKELL

Submitted to the Department of Civil and Sanitary Engineering on August 22, 1960 in partial fulfillment of the

requirements for the degree of Master of Science.

The problem of channel flange crippling during

bending about an axis parallel to the web had been given

very little treatment since it did not occur too often

in practice. One rigorous analysis and three approximate

analyses of determining critical flange stresses were

discussed, and experiments were performed to spot check

these theories.

A method of determining the ultimate failure

moment for channels was investigated from a semi-empirical approach.

Thesis Supervisor.:

Title:

J. M. Biggs

Associate Professor of Structural Engineering

TABLE OF CONTENTS

Page

Summ

...

ry....

...

...

...

...

1

..

Work...................

2

1.0

Previous

2.0

Theoretical Approaches.............

3

2.1

Method (a)........ ...............

Assuming an Infinitely Long Uniformly Stressed Hinged Flange

7

2.2

Method (b)...................

.

.

Assuming an Infinitely Long Uniformly Stressed Partially Restrained

Flange

7

2.3

Method (c).........

Bijlaard's Theory Assuming a

Uniform Stress Coefficient of

Restraint

8

2.4

Method (d)........................

Bell Aircraft Solution of Channel

in Bending about Axis Parallel to

Web

12

2.5

Ultimate Strength Considerations...

14

3.0

Procedure............

.

15

3.1

Method ofAttack...................

15

3.2

Description of Apparatus...........

17

3.3

Description of Procedure...........

17

3.3.1

Tests to Determine Material Propert ies............................

17

3.3.2

Tests of Channel Sections..........

17

3.4

Methods of Making Computations and

of Plotting Curves.................

l8

3.4.1

Determination of Material Prop ert ie s............................0 0 0 0 0

18

3.4.2

Plotting Values of k vs. bw/bf.....

19

3.4.3

Design of Channel Sections.........

19

.

......

Page

Calculation of Section Pro

perties using Actual Channel

Dimension.................

21

Predicted Buckling Stresse s

using Actual Dimensions...

21

3.4.6

Reduction of Channel Test Data. .

24

3.4 .7

Determination of k at

cr ......

27

3.4 .8

Ultimate Moment.................

28

3.5

Sources of Error................

28

4.0

Results...........

33

5.0

Discussion of Results...........

63

5.1

Critical Moment.................

63

5.2

Ultimate Moment.................

63

6.0

Conclusions.....................

67

6.1

Cbitical Moment.................

67

6.2

Ultimate Moment.................

67

7.0

References......................

69

8.0

Appendices......................

70

3.4.4

3.4.5

...........

List of Figures

Figure

No.

1

Title

Page

Tensile Testing Apparatus............ 71

2

Tensile Testing Specimen in Machine ......

71

3

Channel Test Sections Showing Strain

Gages...........

.. .

..............

72

4

Channel Section in Testing Machine ....... .72

5

Channel Section and Strain Indicator ..... .73

6

Balancing Strain Indicator ............... 73

7

Channel Testing Apparatus................ 74

8

Tensile Specimen ............

9

Channel Section.....

..

75

............. 76

10

Table of Calculated Buckling Stresses

from Actual Channel Dimensions ........... .24

11

Table of Percent Error between Plotted

Elastic Stresses and Calculated Elastic

Stresses ................

29

Table of Percent Error between Calculated

Stress Diagram Moment and Actual Applied

Moments..................................

30

Table of Percent Error between Calculated

Critical Stresses and Experimental

Critical Stresses........................

32

Channel Dimensions and Section

Properties...............................

34

Tensile Test Log Sheets

Specimens 1, 2, and 3...........------

35,36

Tensile Test Log Sheets

Specimens, 4, 5 and 6...................

36,37

Tensile Test Log Sheets

Specimens 7, 8, 9, and 10................

38,39

12

13

14

15

16

17

18

Tensile Stress-Strain Curve

Specimen 4.............................. o

19

20

Page

Title

Figure

No.

Tensile Stress-Strain Curve

Specimen 5............................

.41

Tensile Stress-Strain Curve

Specimen 6............................

42

21

Tensile Stress-Strain Curve

Specimen 7............................... 43

22

Tensile Stress-Strain Curve

Specimen 8.............................

44

Tensile Stress-Strain Curve

Specimen9...........................

45

Tensile Stress-Strain Curve

Specimen 10..............................

46

Channel Buckling Test Log Sheets,

Channel #1...............................

47

Channel Buckling Test Log; Sheets,

..............

Channel #2........ ...

48

Channel Buckling Test Log Sheets

Channel #3..............................

49

23

24

25

26

27

28

Channel Buckling Test Moment-Strain

Curves: Channel #1,

29

0D ,3

,and(.

Channel Buckling Test Moment-Strain

Curves: Channel #1,

30

Gages

Gages

O

3

.--.

Channel Buckling Test Moment-Strain

Curve : Channel #2, Gages

,5,

and.

............................

..-

31

Channel Buckling Test Mome t-Strain

Curves: Channel #2, GagesQ(

}, and

32

Channel Buckling Stress Moment-Strain

Curves: Channel #3, Gages Q,

}

...

0........ 0.

6

33

34

35

36

50

5

52

,

54

Channel Buckling Stress Mo ent-Strain

Curves: Channel #3, GagesQ9 and 0 )....

55

Table to Plot Stress Distribution Curves

from Moment-Strain Curves................

56

Channel Buckling Test Stress Distribution

Curves, Channel #1-.......................

57

Channel Buckling Test Stress Distribution

Curves, Channel #2......................

58

Figure

No.

Page

Title

37

Channel Buckling Test Stress Distribution

Curves, Channel #3 ....................... 59

38

Check of Stress Distribution Curves by

Area and Moment Balance..................

60

39

Values of k vs. bW/bf from Test Results

and Theoretical Methods (a), (b), (c),

and (d).................................. 61

40

Table of Percent Error between Actual

Ultimate Moment and the Predicted

Ultimate Moment..........................

67

41

Table Calculating k Values for Methods

(b) and (c)............................... 62

42

Illustration of Stress Distribution

Factor, OC................................

77

Illustration of Stress Distribution in

Channel Section..........................

77

Notation for Analysis of Flange by

. .

....

. . ..

Method ()...

78

43

44

45

...

Theoretical Ultimate Moment Stress

Distribution.............................

78

1

Summary

The object of this thesis was to spot check

various theoretical methods of determining critical

buckling stresses, and to formulate an approach to finding the ultimate moment a channel can resist when loaded

in bending in

the weak direction.

Four theoretical buckling analyses were discussed, and tests were run on three different channel

sections.

Critical buckling moments and ultimate

moments were determined by observation of specimens

and analysis of strain gage data.

Of the four methods shown in figure 39, it

was found that method (a) was the best method of predicting critical buckling stresses for materials with

proportional limit below 18.0 ksi.

For material with

a higher proportional limit method (b) was used to be

conservative.

Methods (c) and (d) indicated large

errors on the conservative side, especially at the low

buckling stresses.

A semi-empirical method of predicting ultimate

strength was discussed, and formulas were developed.

How-

ever, the results were inconclusive and more test data

was required to substantiate the theory.

A conservative

formula for predicting ultimate strength was

Mult

'( crb2t

(19a)

2

1.0

Previous Work

A search of the literature showed that very

little work had been done on this subject.

Tne people

most interested in formed sneet metal sections were in

the air frame industry and these people were usually

concerned with minimum weight design.

For this reason

it was found that a channel section in bending about an

axis parallel to the web was rarely employed in practice.

There were two theoretical approaches to finding

the critical buckling stress of these channel flanges

which had been presented to date.

The first approach

was derived by Bell Aircraft Corporation in an unpublished

report with the aid of references 2, 3, and 4.

The results

of this report were shown in a graph in reference 1.

Another study which is analogous to the problem

was done by Bijlaard and presented in reference 5.

Bijlaard derived formulas for critical compressive stresses

of hinged and fixed flanges under a linearly varying

stress.

The critical stress for a partially restrained

channel flange was somewhere in between the cases of

pinned and fixed flanges.

Since the available methods

of arriving at the amount of restraint were approximate

the Bijlaard theory did not seem as accurate as the

graph used by Bell Aircraft.

Another approach to flange buckling problems

which was often used by aircraft designers was based on

ultimate strength theory.

A semi-empirical method that

gives good results for uniformly loaded flanges was given

in

reference 9.

However, for the case under consideration

another ultimate strength approach was developed.

There was no previously available test data

on either critical buckling stress or ultimate strength

which could be found.

2.0

Theoretical Approaches

A firm understanding of plate buckling theory

was necessary to analyze this problem correctly.

The

basic formulato determine the critical crippling stress

in plates or plate elements with various compressive

stresses was

klT2 YV

cr

E

12(1 - V 2)

2

($)

where:

V/=

Poisson's ratio

UCr = critical compressive crippling stress - ksi

t = plate thickness - inches

b = plate width - inches

= plasticity coefficient used in reference 2

for stresses in the inelastic range

7= Et/E where Et = tangent modulus, the slope of

the stress-strain curve at any particular point.

k = constant which is dependent on the restraint

of the plate along its unloaded edges and the

distribution of the stress across the width

of the plate.

4

The basic differential equation for instability

of plates in the elastic range was

Et3

t72

12(l -1)

d 4w

4w

Wa

(. 4 +2 j

dx dy

J

4w

+ )+i

c y

C)2

x

t

2

o

(2)

whereDT

w

* stress in the direction of loading

* plate displacement perpendicular to the plane

of the plate

For the case of stress in the inelastic range,

equation (2) was modified.

different modifications.

Different authors gave

Probably the most widely ac-

cepted plasticity hypothesis was derived by Stowell in

reference 8, but the results were far too complicated

to be used in design.

A more simple approach was given

by Bleich in reference 2, and was sufficiently accurate

for practical purposes.

'Whenthe buckling stress exceeded the proportional limit of the material, Young's modulus, E, no longer held.

Bleich assumed that when

exceeded pro-

portional limit, the tangent modulus, Et was effective

in the direction of loading and Young's modulus, E,

was effective in the direction perpendicular to loading.

In equation (2) the three terms in parenthesis were

noted.

The first term corresponded to bending of strips

parallel to the x axis.

These strips were stressed

by the longitudinal force, rext.

modified to read

<)x(

This term was then

In the same manner the third

5

term corresponded to strips in bending perpendicular

to the x axis which were free of externally applied stresses.

Therefore this term remained unchanged.

The middle term

in parenthesis was associated with the distortion of a

square plate due to twising moments on the element.

This term was effected by plastic action in a complicated

way, and was multiplied by a coefficient having a value

somewhere between 1 and 7.

what arbitrarily.

Et3

2

-

12(1 -V

) (7'

C

Yx

The value V-7 was used some-

This equation (2) became

w

+2 2

M4

)X

+

w

by

-4)+

dy

w

024

Ix

(2a)

Poisson's ratio:, /

,

was effected slightly in

the inelastic range, but since the effect of if on equation (2a) was small, the change due to inelastic behavior

was ignored.

Solution of equation (2a) resulted in the

algebraic plate crippling equation, (1).

It was known

that the plasticity coefficient lay somewhere between

Es/E and Et/E where Es was the secant modulus.

was a conservative value and was con-

value of

sidered as a lower limit for most cases.

7

Bleich's

Bleich defined

as follows(3)

~cr

Et/E _ (Fy ~ cr)

(UOy Up)OC'p

''

material yield stress - ksi

Cr-=

y

=7

material proportional limit

-

ksi

6

It was noted that since 7' was dependent upon

r-'cr,-a trial and error solution of (1) was necessary.

This was avoided by algebraic manipulation of (1) to read

r2

k 7722

12 (1 -1/ 2)

CFyc

Tables were available to determine

values of OrcVr

(tW2

(la)

b

Orcr from corresponding

for various materials.

For the case of a sheet metal channel in

bending in the weak direction the only unknown in (1)

was the constant, k.

Four different methods of deter-

mining k were considered, and were presented in figure 39,

as a function of (web depth/flange width).

These methods

were summarized as follows+- (a) An infinitely long

hinged flange under uniformly distributed stress was

assumed.

(b) An infinitely long partially

flange under uniform stress was assumed.

restrained

(c)

(Bijlaard's

analysis) The flange was assumed infinitely long and

under a linearly varying stress.

A coefficient of

restraint proportional to the coefficient for a uniformly

distributed stress was used.

(d) (Bell Aircraft graph)

The actual case of a channel loaded in bending in

the

weak direction was assumed.

This paper was only concerned with the most

common case where the web thickness equaled the flange

thickness and the unsupported flange length was great

compared to the flange width.

--I1

7

2.1

Method (a):

Assuming an Infinitely Long.Uniformly

Stressed Hinged Flange

Solution of equation (2a). using the boundary

conditions of method (a) for an infinitely long hinged

flange under uniform stress led to the basic algebraic

equation (1) for crippling of plates.

In this case the

value for k was .425 as shown by the straight line in

figure 394,

This well known salution was presented by

Timoshenko in reference 7.

2.2

Method (b):

Assuming an Infinitely Long Uniformly

Stressed Partially Restrained Flange

The case of method (b)

for a restrained flange

was solved by Bleich in reference 2.

Bleich introduced

the concept of the coefficient of restraint, ef,

determine the value of k.

to

The coefficient of restraint

expressed the amount of fixity provided to a plate

element, by the adjoining plate elements.

It depended

upon the cross section dimensions and the stress distribution.

For the case of a channel under uniform compres-

sive stress, the coefficient of restraint for the flanges

was

tf3

bw

tw 3

bf

1

1

.106 (tf/tw)2 (bw/bf)2

-

where:

t

=

flange thickness

-

inches

tw = web thickness -inches

b

= flange width -inches

bw = web width - inches

8

This equation was valid for 9.4 (tw/t9) 2 (bf/bwfel.0.

When

the above value was less than 1.0 the web plate crippled

at a lower load than the flange,

so the flanges then pro-

vided restraint for the web.

To determine the value of k the following

equation was used:

kr=

2

+ .65)2

(5)

where:

kr = k for the restrained case under uniform load.

For the case being considered where t

= t wk

was found as a function of bw/bf in

Figure 41 and plotted

in figure 39.

2.3

Method (c):

Bijlaard's Theory Assuming a Uniform

Stress Coefficient of Restraint.

Mothdd (c) 6d finding 0-cr of a channel was

taken from Bijlaard's paper, reference 5. BiJlaard

analyzed hinged and fixed flanges of infinite length

subjected to a stress that varied linearly with flange

width.

An energy approach was used and the equations

were solved by a method of finite differences.

The flange

was assumed to buckle in the shape of a sine curve in the

longitudinal direction for both the fixed aid pinned

cases.

In the lateral direction, for the fixed case the

deflection was expressed in terms of the normal mode of

vibration of a cantilever beam.

For the hinged case the

9

flange deflection was assumed to increase linearly

with the distance from the hinge.

For application to

the case under consideration, two modifications were

made.

To arrive at a plasticity factor,

',

Bijlaard

published graphs that expressed a plasticity constant

in terms of Es/E at the edge of highest strain.

This

constant was then plugged into an equation to determine -,

and this factor,

in place of

r

i[, was

in turn used in equation (1)

to find rcr.

The advantage of

Bijlaard's plasticity factor was that the graphs were

applicable to all materials, but values of Es/E

were not readily available for various materials.

Also

the method involved a trial and error solution because

was dependent on c'cr.

Since values of Es/E vs.

stress

for mild steel sheet could not be easily plotted, and

since Bijlaard's method involved a great deal of arithmetic, it was decided to use Bleich's

coefficient,

f,rin place of 7.

plasticity

The error involved

was slight.

The second modification to Bijlaard's theory

was the determination of a proper coefficient of restraint.

The procedure was to find values of k for

Bijlaard's hinged and fixed cases, and then determine

an intermediate value proportional to the intermediate

value for the case of a uniformly stressed channel given

10

in reference 2.

This gave results which were generally

conservative as expected, since a web in tension during

bending supplied more restraint than a web in compression

during axial loading.

Values of k vs. bw/bf were plotted in figure 39

(b), and

and compared to values obtained by methods (a),

(d).

These values were determined by the following al-

gebraic manipulation of Bijlaard's equations, and appeared

in figure 41.

In reference 1, k for the fixed and pinned cases

was expressed as a function of

M, where O is an ex-

pression for the linear stress distribution as shown in

Figure 42.

ah (compressive stress

oC = 1 - w

=

+

)

(6)

where:

=

stress at hinged or restrained edge

-

ksi

= stress at free edge -'ksi

To express

OC

in terms of bbf, it was

necessary to locate the elastic neutral axis, y, of the

channel.

A

A

From figure 43,

bf(bf/2) + (b12)bf

+b/2

bf

(b

(bf + bw)

2+b

1

/bf

11

= -(b

- Y)

.. [b

b + b

- 2 +bV /b

b

+ b/br

+ bw

2 + b /b

2 + b/bf

bb

2b

=

-

+ b

bf

h 1

=

+

bf + b

b

w

+ bw

(6a)

It was then possiole to solve for oC knowing

o/or.

In reference 5, the value of (kg)h for ninged flanges

was

16.8

(ks3

(8)

77 2 (4 -OL)

h

where

(k

in

was Bijlaard's constant, k, for hinged flanges.

For fixed flanges (kB f vs. o( is plotted

gure 9 or reference 5, where (kB4

constant,

was Bijlaard's

k, for fixed flanges.

Using equations (4)

and (5)

values of kr were

determined for restrained channel flanges when the channel

was under uniform stress.

The proportioned k value for

moment loading was found by the following equation:

12

k

-k

kf

kh

Bh

B'h

where.

kr

=

k for uniformly loaded restrained flange

kh

=

k for uniformly loaded hinged flange

k

= k for uniformly loaded fixed flange

=

=

.425

1.277

(kB)h =k for Bijlaard's hinged flange under linear

stress distribution (reference 5)

(kB)

=

k for Bijlaard's fixed flange under linear

f

stress distribution (reference 5)

2.4

Method (d):

Bell Aircraft Solltion of Channel

in Bending about Axis Parallel to the Web

Method (d) of determining the plate buckling

factor, k, was a method derived by Bell Aircraft

Corporation in an unpublished report with the aid of

references 2,

3,

and 4.

The results appeared in

a

graph in reference 1 which was reproduced in Figure 39.).

An energy approach was used in conjunction with an

application of the moment distribution method explained

in reference 4.

Figure 44 was considered.

The stability condition was

T = V

and V 2

(10)

where.,T

= work done by external compressive forces

V

= strain energy in the plate

V2

= strain energy in the elastic restraining medium

13

(J )

to-

T =/

dx dy

42 w

b 2

Et3

V1

2

2 x 12(1 - 1/2)

+ 2 (1 -V)

(11)

+

2w

2

7of-2

(

22

j~

)

2

Idx dy

(12)

dx

2~~

2

V2

(13)

So = stiffness per unit length of elastic medium or moment

for 1/4 radian rotation

The proper boundary conditions from Figure 44

were

(14a)

(w) Y= = 0

Et3

32"

12 (1 -V

Ey2

-

=

4x2y=0

(4

12 (1 - V

12 (1

)

4s (

)O

y=0

(14b)

2W

Et3

Et

+1

2

'V2)

)

2

7

+ (2

y =b

- y(

Y7

(14c)

0

=

-

W

y

laxy) y=b.

(14d)

where (14b) and (14c-) expressed the moment condition

at points y=O and y=b respectively, and (14d) expressed

the shear condition at y=b.

14

The assumed deflection was

w

A

=

+ B

(Y)5 + ai(Y)4 +

a2( ) + a() ]os

(15)

where A and B were arbitrary deflection amplitudes.

When A = 0 the edge was clamped, and when B = 0 the

edge was pinned.

The assumed deflection inaequation (15)

was a sine curve in the direction of length, and the sum

of a straight line rotation deflection and cantilever

beam deflection in the direction of the width.

Method (d) above was a rigorous solution of

the problem of a channel in bending in the weak direction.

Methods (a), (b), and (c), demonstrated conservative

approximations which might be used by designers if more

accurate data were not available.

2.5

Ultimate Strength Considerations

Determining ultimate strength of compression

flanges was a very complicated mathematical problem,

and empirical or semi-empirical methods were usually

used.

Gerard in reference 9 had developed a method that

seemed to work for plates and flanges under uniform load.

His method assumed that after tha flange buckled at the

free edge, the member continued to take load until the

yield point was reached at ithe flange-web connection.

the present case this theory did not hold up, since the

connection area between flange and web carried small

stresses at ultimate load.

In

15

A theory of predicting ultimate moment was

discussed in paragraph 5.2 of this thesis.

It assumed

a particular stress distribution at failure, which

varied with cross section dimensions.

The method was

semi-empirical in nature, and much more test data was

necessary before it could be considered accurate.

3.0

Procedure

3.1

Method of Attack

The purpose of these tests was to spot check

the theoretical methods of determining critical buckling

stresses, and to formulate an approach of finding the

ultimate moment a channel could resist when loaded in the

weak direction.

The first step in testing was to determine

the material to be used and its properties.

Cold

rolled annealed mild steel strip was selected because

of its thickness tolerances (+.002"),

its freedom, from

residual stresses, and its linear stress-strain curve.

Tensile tests were run on specimens cut from the same

strip as the channel sections,-and stress-strain diagrams were plotted.

From the stress-strain diagrams.'

average values of proportional limit, yield point, and

Young's modulus were found.

Using the Bell Aircraft curve in figure 39,

three channel test sections were designed and constructed.

16

The material used was the same thickness throughout,

and the width of web was held constant.

The flange

width was varied on the three sections to give

critical crippling stresses (1) below the proportional

limit, (2) at the porportional limit, and (3)

inelastic range.

in the

The channels were all the same

length and were all loaded in pure bending at the

same loading and support points.

Sheared edges were

ground off to eliminate strain hardening.

The 20 inch span between load application was

ground down to assure the highest stresses occurred

in

this area and not at the point of load application

where shear stresses were present.

Care was taken to

avoid any pounding or straightening which might work

harden the material in critical areas.

A mathematical check was made of channel #3

to determine if the channel would fail by lateral buckling

below the ultimate load.

It was found that later.all

bickling was not critical.

Strain gages were located on the channel at

midspan to determine the stress distribution at various

applied moments.

Gages were located as shown in

figures 28, 30, and 32.

The double gages were placed

on both sides of one flange and connected in series to

eliminate any effects from the flange bending out of its

plane.

Since no eccentric load occurred in the web single

gages were adequate there.

The single gage on the opposite

flange was to indicate if the channel was loading

17

concentrically.

The double gage nearest the web was

located at the elastic neutral axis to note at what

moment the neutral axis started shifting.

3.2

Description of Apparatus

Photographs of the tensile testing and channel

testing apparatus were shown in figures 1 through 6.

A sketch of the channel testing apparatus was shown in

figure 7, and sketches of tensile specimens and

channel sections were shown in

3.3

figures 8 and 9.

Description of Procedure

3.3.1

Tests to Determine Material Properties

Tensile specimens were made from the strip

used to form the channel sections.

These specimens con-

formed to the standard ASTM specifications for tensile

testing sheet metal as described in reference 10 and

figure 8.

The specimens were measured with micrometers

and tested in a 5,000 lb. capacity Baldwin tensile

testing machine, using a Metzger extensometer with a 2 inch

grip reading to .0001".

Incremental load and deflection

readings were taken as shown in figures 15, 16, and 17.

3.3.2

Tests of Channel Sections

-

Three sheet metal channel sections were formed

as shown in figure 9.

Baldwin A-7 120 ohm, 1.96 gage factor

strain gages were attached as shown in figures 28, 30,

and 32.

Double gages were connected

18

in series.

The resistance changes were read with a

Baldwin SR-4 strain indicator which read strain directly

to the nearest 0.1 microinch.

The channel sections were

measured using micrometers and placed in a 10,000 lb.

capacity hand operated beam testing machine as shown

in figure 7.

Loads were applied incrementally as

shown in figures 25,

26, and 27.

The loading machine

was accurate to the nearest two pounds and strain

gage readings were recorded at each incremental load.

On channel #1 loads were increased on up to failure, but on channels #2. and #3 the load was applied,

released and reapplied alternately.

The loads causing

crippling in the extreme fibres and ultimate failure

were noted.

3.4

Methods of Making Computations and of Plotting Curves

3.4.1

Determining Material Properties

The data from the tensile specimens was reduced

in the usual manner and plotted as stress vs. strain

in figures 18 through 24.

The yield point was determined

by the .2% offset method as shown on the graphs.

The E

value was taken as the initial straight slope ofthe curve.

The porportional limit, which was difficult to obtain

consistantly, was taken as the stress at that point of the

curve which first deviated from a straight line.

Due to

initial unrecorded stresses which were unavoidable,

each curve had a small offset stress from the zero point

which was compensated for in the calculations.

Material

19

properties for each specimen were calculated on the

stress-strain curve, and the sum was averaged to determine the yield point, proportional limit, and Young's

modulus of the material

Ultimate strengths were re-

corded.

3.4.2

Plotting Values of k vs. bv/bf

Four curves of k vs. bl/bf were computed in

figure, 39 and plotted in accordance with methods (a),

(b),

(c), and (d) of paragraph 2.0.

The computations

for these plots were as follows.

Method (a) k = .425

3.4.3

(straight line)

Method (b)

k from equation (5)

(see figure 41)

Method (c)

k from equation (9)

(see figure 41)

Method (d)

k from reference 1.

Design of Channel Sections

Channel sections were designed using equation (1)

and the Bell Aircraft curve reproduced in figure 39.

Material properties as found in paragraph 3.4.1 were

used in the calculations.

For each channel the follow-

ing dimensions were constant:

Web thickness = flange thickness = .0625"

Web depth = 4.00" (outside dimension)

Channel span = 40.0"

Distance between load points = 20.0"

Bend radius = .062"

The flange widths were varied to give crippling stresses (1) in the elastic range, (2) at the

20

proportional limit, and (3) in the inelastic range.

Assume flange width = 4.00" (outside dimension)

Channel #1:

ff

e

=

Cr-

k17 2E

E- )

12(1 -1/ )

t f2

f

(1)

t

= .0625"

b

= 4.00 -

.06/2 = 3.97"

b

= 4.00 -

.06 = 3.94"

v

= .30

E = 28.6 x 103 ksi

P.L.= 17.7 ksi

From figure 39, method (d):

b/bf

3.94/3.97

. . k = 1.30

.994

=

0625)2 =

1-30T 2 x 28.6 x 10

12(l -. 350'

c,:I

8

.35ksi< 1 7 7

= 8.35 ksi

r

Assume flange width = 2.50" (outside dimension)

Channel #2:

b

=

bf

4.0

-

.O

=

1.60

.*.

1.157 2 x 28.6 x 103

12(1 - .302)

.S-r

18.0 ksi

.k= 1.15

-

o65 2 = 19.0 ksi =l17.7

21

Channel #3:

bw/bf

3.4.4

4.00 _ .06

=

=

Ei29.0 ksi

1.00" (outside dimension)

.

4.10

= .96r2 x 28.60 )10

rl

*

Assume flange width

k = .906

0625 2 =97.1 ksi>l7.7

(slightly less than yield point)

Calculation of Section Properties Using Actual

Channel Dimensions

The following section properties of each channel

were calculated using the measured dimensions of each

section and material properties found in paragraph 3.4.1.

When the two flange dimensions varied the least of the

two was used.

Refer to figure 14.

y = neutral axis ibacation - inches

S = section modulus - in. 3

I = moment of inertia - in.4

3.4.5

Predicted Buckling Stresses Using Actual Dimensions

The extreme fibre buckling stresses were

calculated using the actual measured cross-section

dimensions.

When the two flange dimensions varied, the

least of the two was used.

22

Method (a)

Channel #1:

4.00 x 4.01 x .o61o

-= 1.0

tf

LFcr

12 (1 -I

')

k772 (1) x 28.6 x 103

12 (1 - .302)

(tf

bf

2

= 25.9 x 103 k

b/bf= 3.94/3.98 = .990, .'.

Ucr

=

25.9 x 103 x 1.300('

Channel #2:

b

b

k = 1.300

8)

= 7-91 ksi

4.00 x'2.49 x .0618

= 3.94/2.46 = 1.60

k = 1.152

25.9 x 1.152 ('0 6)8=

(try ~0cr)g-r

(30.0

18.8 ksi > 17.7

'r) C~cr

(30.0 - 177.)

Solve by trial and error

_

17.7

I

I

30.(Cq

218

- Ur

2

23

1

U'r

2

Ucr 2

5

4

3

3o04

-

3

2

6

7

4/218

YT.

1813

335

549

214

. 982

.991

18.~6

18.5

342

555

213

.978

.988

18.6

I Ucr

Channel #3:

ksiI

3.99 x 1.00 x .0628

b/b

= 18.5

= 3_93= 4.05

.97

1

.'.

r=25.9 x 10(068

cr/

..

1

2

O~cr Ocr

4

3

2

97

5-

30Tcr

2

> 17.7

= 98.6 ksi

5

7'

6

4/218

k = .910

7

r VI-qr/

29.5

870

885

15

.0689

.263

26.0

29.3

859

880

21

.0964

.310

30.5

I

-'r

= 29.4 ksi

24

In a similar manner Ccr was solved using

methods (b), (c), and (d).

The results were summarized

below in figure 10.

Method

Channel

k

(a)

(1)

1.300

(2)

1.152

18.8

18.5

(3)

0.910

98.6

29.4

(1)

1.260

(2)

1.026

16.7

16.7

(3)

.702

76.3

28.6

(1).

.854

5.19

5.19

(2)

.702

10.44

10.44

(3)

.425

46.1

27.2

(1)

.425

2.58

2.58

(2)

.425

6.94

6.94

(3).

.425

(b)

(d)

(d)

Figure 10-.

CFc

ksi

7.91

7.65

46.1

76r (ksi)

7.91

7.65

27.2

Table of Calcnlated Buckling Stresses from

Actual Channel Dimensions

3.4.6

Reduction of Channel Test Data

Graphs were plotted of applied moment vs. strain

for each strain gage of each channel,

and were shown in

figures 28 and 29, 30 and 31, and 32 and 33 for channels

#1, #2, and #3 respectively.

Strain gage locations for

each channel were shown in figures 28, 30 and 32.

25

By studying the moment-strain curves and

the log sheets, the critical crippling moment and ultimate

moment were established for each channel section.

Stress

distribution curves were plotted to scale for the Mcr, Mult,

and two other significant moments in figures 35, 36,

and 37.

Stress was determined from the strain readings

by use of Young's modulus

C~ (ksi)

=

E(ksi)

x

E(microinches)

It was noted that gage

©

= 28.6 x strain

and gage

©

plotted different moment-strain curves which indicated

that the channel was being loaded eccentrically.

error was particularly pronounced in channels #(l)

#(2).

At lower loads gage @1

This

and

read a greater amount

When a certain irtermediate load was

of strain.

reached the channel had deformed sufficiently to fit

the loading appartatus, and from that point on each flange

took the same amount of strain.

from gage 0

At higher loads readings

became insignificant due to high bending

strains as the flange assumed its buckled shape.

This eccentric loading was compensated for

in the following manner as shown in the table of figure 34.

In the range of lower loads, before the flanges were

accepting an equal amount of applied moment, the actual

strain was taken as an average of gages Q

and 0

.

This averaging method was used up to the point where the

26

channel had warped sufficiently to no longer load

Further incremental loading applied equal

eccentrically.

At this point gage

stress to each flange.

a higher strain in

that flange than gage

(Q) showed

(j.

Half the

difference of these two strains was subtracted from the

strain readings of gage

intermediate moment.

0

(D

at all moments above the

-Strains from gages

(Q} ,

(}

, and

were all adjusted in a proportional manner, depending

on the distance from the neutral axis.

The intermediate moment for the different

channels was:

Channel #1

2,000 inch lbs.

Channel #2

2,000 inch lbs.

Channel #3

1,000 inch lbs.

The following checks were made of the stress

distributions:

1.

Using the formula C'=

4,

the extreme fibre

stresses were calculated for moments in the elastic range

and compared to the measured stresses.

2.

(see figure 11)

The area of compressive stress equalled the

area of tensile stress since thickness was a constant.

(see figure 38)

3.

The area of compressive stress x flange

thickness x moment arm between compressive and tensile

27

area centroids equalled the applied moment.

(see

figures 38 and 12)

In the case of channel #3 where the flange

strain exceeded the yield strain, the points of stress

were plotted in figure 37 as if the material was

infinitely elastic.

These points were connected by the

dotted lines, but the actual stress distribution was

shown by the cutoff at (Ur.For the 1,000 inch lb.

unloading moment the stress diagram was found by subtracting half of

1,000 inch lb. loading moment dia-

gram from the 1,500 inch lb. diagram.

The 1,500

inch lb. diagram was shown dotted.

3.4.7 Determining k at Ucr

The values of Mcr were established by

studying the test data and moment-strain curves.

Test

values of k were determined as follows, and plotted on

figure 39.

Channel #1:

Dc

Mcr = 3,750 in-lbs

M - 3.75 = 7.78 ksi

k=r12(1 -V2)

72E

b 2

tf

2-=71 28

25.9 x 10

0610

28

Channel #2:

-

Mcr = 3,750 in-lbs

=

9

r

19.05 ksi

try -crh)

~

k

(y

p

-

cr~

Up

(2 46

19.4

_

-

.1(30

-

19.05) 19.05

1(30 - 17.7)

17.7

2

25.9 x 10 (.9 8 )b-

Channel #3:

U'cr

Mcr

=

1000

(30.0

30.0

1000 in-lbs

28.3 ksi

-

28.3) 28.3

1-7.7) 17.7

28.3

k

25.9 X103 x (.470)

.470

.969

(.0628

2

) =.554

3.488 Ultimate Moment

A semi-empirical method of predicting ultimate

moment was presented in paragraph 5.2 of this report.

3.5

Sources of Error

The chief source of error in the results was

the variation of strain gage readings due to eccentric-.

loading.

Other sources of error were variations in

material thickness, initial eccentricities in flange

straightness, inaccuracies in load application at low

loads, differences from critical moment in an infinitely

=

-

29

long channel and a finite length channel,

variations

in channel material properties from the tensile test

results, inaccuracies in gage and instrument readings,

and inability to detect the exact critical load.

It

was extremely difficult to calculate the exact percent

error due to each of

these factors.

However, it was

possible to check the final results in several ways to

find the overall percent error.

The.rmain error due to eccentric loading was

compensated for by the method explained in paragraph

3.4.6,

By comparing the stresses on the plotted

elastic stress distributions (figures 35,

the calculated stresses a

36, and 37) to

percent error was

determined in figure 11.

Channel

Applied Mom.

(in. - lbs.)

Calc. Max.

Plotted

M

Max.Stress(ksi)

Stress = g(ksi) (Figs.35,36,

and 37)

% Error

#1

2,000

4.15

3.7

-1o.8

#2

1,000

5.08

5.0

-

#2

2,000

10.16

9.3

-'8.

#2

3,750

19.0

18.3

-

#3

1,000

28.3

30.0

+ 6.0

Figure ll-.

1.6

3.7

Table of Percent Error Between Plotted

Elastic Stresses and Calculated Elastic Stresses

This error indicated the difference from theoretical elastic stress and strain gage readings.

Positive error

30

indicated the plotted stress was higher.

To determine the percent error in the inelastic

stress regions, the applied moment was compared to the

moment of the stress distribution diagrams.

This was

done in figure 38 and summarized in Tigure 12.

Positive

error indicated the stress diagram moment was higher.

Channel

Applied Mom.

(in.

- lbs.)

Stress Diagram

Moment, (in9lbs)

% Error

#1

3,750

3,390

-.9.6

#1

5,000

4,650

- 7.0

#1

7,000

7,260

+ 3.7

#2

4,750

3,770

-20.6

#3

1,500

1,630

+ 8.7

#3

1,000 (unload)

1,000

0

#3

1,550 (reload)

1,620

+ 4.5

Figure 12-.

Table of Percent Error Between Calculated

Stress Diagram Moments and Actual Applied

Moments

The 20.6% error in channel #2 was probably

cde to an erroneous strain gage reading at the extreme

fibre,

since this

recorded strain was actually lower than

the strain at lower moments.

The above errors repremnted differences from

applied moments and strain gage readings.

To detect the

error in the moment at which buckling occurred was more

difficult, and the value could vary as much ae 10%.

This

was especially true in channel #3 which buckled in the

inelastic range.

Due to dimensional differences and

31

eccentric loading one flange always buckled at a lower

load, so it was necessary to interpolate between to get

the actual critical moment.

The percent error between the calculated critical

(b), (c) and (d); and the

stresses of figure 10 using (a),

test results were summarized in figure 13.

In the inelastic

range it was noted that a large variation in the value of k

had a small effect on the critical stress.

Positive error

indicated the test results were higher.

Error in the critical stress due to the flange

not being infinitely long was approximated from the case

of a uniformly loaded hinged flange.

Reference 6 gave for

this case the following formula for k;

k = .456 + (b)

(16)

where:

a = distance between simply supported loaded

edges of flange

b = flange width

For the worst case of channel #1 assume

b = 4.oo" and a = 24.0"

k = .456 + (4)2

=

.485

% Error = .485 - .456

6.4%

.456

This estimate was high since the linear varying

stress and flange restraint tended to reduce the effective

value of b.

The effect of the flange length not being in-

finite was neglected.

Channel

Critical Crippling Stresses (ksi)

% Error

Experimental

Mcr

Met.

Met.

Met.

Met.

Met.

Met.

Met.

Met.

(a)

(b)

(c)

(d)

(a)

(b)

(c)

(d)

#1

7.78

7.91

7.65

5.19

2.58

-1.7

+1.7 +33.3 +67.9

#2

19.05

18.5

16.7

10.44

6.94

+2.9 +12.3 +45.2 +63.6

#3

28.3

29.4

28.6

27.2

Figure 13

27.2

-3.9 -11.1 + 3.9 + 3.9

Table of Percent Error Between Calculated Critical Stresses

and Experimental Critical Stresses

\AJ

I')

335

4.0

Results

The results of this experiment were presented

in the following log sheets and graphs1. Channel dimensions and section properties (figure 14).

2. Tensile test log sheets (figures 15 through 17).

3.

Tensile stress-strain curves (figures 18 through 24).

4.

Channel buckling test log sheets (figures 25 through 27).

5. Channel buckling test moment-strain curves (figures 28

through 33).

6. Table to plot stress distribution curves from momentstrain curves (figure 34).

7.

Channel buckling test stress distribution curves

(figures 35 through 37).

8.

Check of stress distribution curves by area and

moment balance (figure 38).

9. Values of k vs. blbff from test results and theoretical methods (a), (b), (d), and (d) (figures 39

and 41).

34

Channel #1

Channel #2

Channel #3

4.o1

2.49

1.00

4.01

2.49

1.01

tL

.0622

.0620

.0628

tR

.0610

.o618

.0628

b

4.00

3.99

2.65

1.762

.810

3.99

A

.734

.555

.376

I

1.278

.348

.0287

.197

,0354

S

Figure 14.:

Channel Dimensions and Section Properties

35

F/6U

e

- L

_

/5

o

/_

__

ii

/45,

oZo

o

o

_

_''7_____a

"

/,

_0-0

II,

,Ann

O

3______

\

7

71

!ro p

Sn//

inp

-r

3 -o 9

9/5'

/

ro

;A..

k

-41r

q -r

--

r

~

'I

20''

n .k

4:\~

9

ls

4 *0

Y-sL 0

p

i

-n6

n

/,-. 9

ge''t/

/:3;.

71>,- 9

/,no

:Ln

/1

~

.-

A1

/O2-

9

le

3"oimn

US

n 10 Technology Store

9

tr

-/n

7I

3

,M

ts

7. 7/1n /

.2-

-/

.

5'm

9-00zr

4

19<

0

'

10Tchooy

qnp

\

::L4-

N

15/.

(/1

ntl

/li3

5U .-

z,4

35'

35'0

r

2- 0

_t.io1

36

F/bu~/5'

F/

7~7-

Src____

,s

-soo

=

og

,o si

Si

y

ii

,s

su

-

j

3_00|ti

15

SPD

/1

~~~

/

) n-

r/

U/

'&1

7-n

/1

11/

2272f

'D

/4

0/

7'.

7?S ??2

91e

L'/

~

~

4

-274n

14.Za

,p-aQ

pp

2.,.2

.17-a

2 3, pp p

240 77'60ea 1V

3f90

90

.7

XL

n1.4

2-4/Of

n

1,2.r0r

2-1/

/VSo

;Lr

1Y

.o

9sno

.{/-Z

e,.~

1-V

-

Technology Store

0

s6

no

-42Y9

r

7

90

f

g

10

~-2

5:2A/0L

>

7 D

50~4

-37

4

.

/

4S

61

F-,4,

5"e-

(/-A n(o

75~

'd

-3

z4

- Z7

-

/9T

____

1l;1

- 2r>-

I# -/4-n ----. -

-.. ,

p

/

n p~J~--

/6i

.. 5 1-1A'F' 7('

/.

0

/

6-V4

AOOG

-7,

--

47 5n

-77

__>

37

S,

m 10 Technology Store

/ 6

38

Fi&v&.

7T

IA5142IL F

A =

Ac_ M,

/7

r

X ,062

2

~

0~~~

Q.b

z

476

D~

3 DO

2!n;,

4,5SaoU

7 51

9l

4 -f2

5M40

Z /3X

690 S

Z

950

32-5''

2,yO

42

/,70

p

-1pf

70O

suo

/ 4,ov

/72690

75

3 !70

XZWO,5

39

-

34,o

4,/D

g

iip

Z ago

4, 9 p

___

5vo

/X(a

4-7 n

tip

h,/

to

24

/0/0

Aex

A45- ;;oL - 71,4p9

1i09 z.9,Lp

pI5-

00

q1 n

e4n7-,!r

to

'723

VL7~-

/l~ x2 an

w

/2

7 k

106S

/(){,3-.

.

.0

41r

0..

y

/.13-0

23

10 Technology Store

400

ta.

aV

0

-1O

35a,2

go

9'~3,on9,TA

W45

.0_/

-- 70O

4,4

4

A

0

02D

6

-' -,

2503d

9Z.2

J1/0

320

-

/

9 6*0

2..3L

Z

4 2.

nt

A-S-D

4s-

O

goo

9 35

/ - ~

-&0

-O

IV

___D____A zL

Al51

04,

9b.D

//62-AD

/0g

/;;4/S,

/go

9w9

AQmp?__Da

-72

3:D2~7-,0,

fra

___

-

&sr

SaM

//

Z

'4

=,4,9*

03/

4,006

/0~D

43

.Oo&-

41p

/07_<

/7/a

______J4474

--_00_0

AA

7o0

X47<

'3",ai

3000

31,40n-

1O

4.3o.-1-:1

3 2, 2p

3 9nr/

3,400

A. Yp

3 4,- pp

iR~D

34,100

A/47;

/,7

39

/-7

F)c"'/

7~

_7

(/hs

4QzAmi

/>,2ne'

'kS7-

_A _5

,0,_

(P

REA

L

O

I4g

/50

0

0

v

53

400

4&oD

32?L

-NI

7g

IO

3

3to

71ro

7;

(n&D75"

/i-669

I-p

7<n

-

on

LL 4 0

4

-1

L/g bn

/ 1nn

1 'D 4 570

720/no

93

9;660

m 10 Technology Store

OO

L

0,0

f9F

100 6 9

/;O

00

332O

on

on

/.

2/

4

X2-a

3Q

.Z5:

X200-

41-

X42

M

77

Th

41

bL

5n

|o9

/31

7t2

on

po

44

12

92-

99z

Mo9<

>,4o/43

U

/=1

/

4ag

9,69

5~

1?

/2

/Z1?0

/--1

-9y, 2

9,

ro ?v1,-900

FL4, 95aa

240

X2aO

4 0

9

/4On

77 o

/2eo

-

Ebz-

-3-

324L<_ _A2K

nno-9

4,s0

43474

O0

40

16T

s

(ps,

in/>x9

'75V269

2o

r

LepJ7i

z oo

4I/h r132n i .29,~p

/47o

fierAy

190

1510

IIZ/O

7 (in

M

19eut

-)44

'zs

JJ,1-9(

3_--

1

00

'47 a1p

30 ou

__

/z

47

~-

g

_;140D

9

--GA2p

30000

4 3-03000

V

--

t-

±

14

-t

q1*

p

-+

[_ T

44

-

4-

+

-

I- -T_

-- 7--

-

-T

-

I

I

-

i

41t

-

7

-

LLLL

ELI Ll 17-

Figure 18

1

;-

L

- - -4

N

STRESS

*

1

+t

-

1

-

I

441

-n

p-

Isi

-11d4

J-

-

-1$

#-

4

-

L

4i

-4t4'V

:{

tr T--

I

0

-

t: 4#mrn4tt*

A I-A-L'.

4 4

ii!1

4 44++TJ_

irl

i4iL 44

:

4

44

-- T +-

-

-

-

-ii 4 4+14-4

!IiE

L

-4-

! m+

t__;tt -It_1-i-tr4441t-

-

T-

TI

-

0

7Y

AS

-4--

4

-

T

J

40

+I--H

H

+46

SIJ

I I

--

el

o

o

I

t

TT

T -

4

T -- -.

1

-A-

1. 1. . I I

-

$

+ -1-

-

7 ,T

Llt

2T

t4-T-H l ;H-

IPt

t 1 1-1 1 11

#W

#411 -+

Li Ll.

±1 1 .HHHH++

1 , 1 1.

i4t:

1 . 11

-tti th-ttit

-

-

-7

-

--

Q

T

,t-~

-

-

-

1

-4-

-7

K/AS//N

-1

-

Q

-L

l

t

--.

f7R4

-

--

-'

t--

LiiE±EE±ftJ±i±t±zH -LI- -,_ItQH~~L+4±iL"1 '~A

. ...

1 . 11 -

Figure 19

4-F-

-p

Th4

~,

it

--

- I-

---

4- -L I -+-i +. .

p-

-L

T1

±P441-4j

-'-

-1-7-

1-4

-

S

1 4 i ! i i i i ll. I I I ' ' .

--

t

-tt

'd-

L---

-

1

44

4

TTT-t

-

F$

'+

#4441

1 3 . 1 4 ! ; . 1 ; 1 1 1 1 1 1 imm!

--

-ft-

-7

44

tt

r~

STRESS

41

4

2-+t

t

---

-

JiJ

-I

-

222

-4-+

_A..4

--

77

-R

iK

7T

1

411

---

-

-

Ot

-

HH4-iH +1H-H

2

4-

I

Figure 20

t-

-

-t

$

'~L

H+1+4+1-

-

-

Itiam~

}{21j

ti

- t

-

-

ES

-1

4 i 4'

'111i11in

V

p

Hl

TI441

4

1

£2444

4L*pp

I-H iHi+I

14

kiA-

-

T i IT

-- T-1

-L-

471

-

S

v

f

-

It

4

4-I-

I-

/N

--

4

T

t

-

. 11lI

l1

-

--

-V

4--

- -_

--

/

I

r

;

4

q

-

C

H

jj--

--

-

-

H -

-

t+H

II II

-

+ ,

-4

, II

1--

t-

i

1

it

4/~

IL;

t

--

II~dA~J

7-T1

r

---

-

--

-

--

-

-

42

i+"

-

--

-

-

p

-

-

-f

--

I

I

-

0

II

AJt

-- -

-

lIT

_d

Tij -

-

-

T_

-T-

-T-

T

1-4

3

a:

4

C0

-

--

+ -

--

--

-

-

-

-

-w

-

.

4

-

-

1

lilA

.-

J

2--- -r-H-

4

-i-i

-17

4-

Iiviv-j~-

~

+

+

V.J414

4--

a I-I

t_

I M 1JH+

3

P

-

-f--

44

. .. . -

I-

*

-V

-.

_

;1

1

.7

-

-

_

~j7-~- K

It~14~

-

-

I T,

0

]Liit

-t-ti 111

4- -1

1-1 11 11

H4

ii

-

i7z?8I

- K<PS //N.a

A-1

-

ll4I

- -

N -1

-- -

Figure 21

I~

-[

+ - --

It

----

-

4- 4

0

N

S TRE SS

43

- +-

-

4-t '

-4-

-

:-2

-

-

-- - -

-

0

9

--3--

--

tr

-

T-4

T

44-

41

-

-

-

-

--

-

I

-

-

-

-

T+t+t T.

T

-4

-4

T4+1+

-

4+14H-

tml±Thzi2t

44-4-

4--

2 -K

1-7

1-

KPS/ INt

t

-H11 ! 111 i

i 1 1 1 1 1 i 1 1 1 1 1 1 1 1 i 1 1 1 1-+-+-++-4-4

-4-

Figure 22

.4H

LL

L

-

--TT

T

TT

1

-L

STRESS

1

tTI

1

~

I

I

I

;

I

I

I

.

4-4~4

-

44

t-

4

1

+

-4- i

a i I I-%

CPA

-

M

-

1

- -- -.

i

2

77

111JE-1-

L --

T

. .. .. . .. ..

4

-4-4-1

III, - - I -I '

-

_'444-+

H

1

-I1

0

44

t

T--

t}

--

t-ITT

-4

t~i-

--

i

I

I

4

-7T-

-

T

~-

Neu.

-ft

ti11

T-tt

InI

t

; -T

-

-p-

t~-jK

I

--

- -

-

-r!-

i I II I

-

a

~

-+ .

7

fl-t

1il

+---

4

7 1t

-

t1

,Nl

_

i i i !

.4

--

kl

qy~

11

il-Ill'

4 >

.

T n<

i

4 14-; W-'44-' -11 - I-VIF,

1 11 1 11 11 1 11 i H

X/P35/

--

4F

L'Lr--

IIII

Figure 23

ILL

-

t-

ST7-R ESS

-

-R

-7-1-

-t

45

+-

J-d+H+

ii ii ! iiI

1

$

-C

-

-

-4-4"

ii T1

4r~

4

4

4 -

i

-

--

'

T_

i

-±

--

Ill-

-

c7

- -4

--

4,4

-

.

L

T

-

- - -

-

--

T

-

-

4-

i

H-

--

-4-

- - --

-----

Tr----

n

1-44-

4+

±"$

27

+-

T,

if

KIPS//N

T

7t t-

4-

- -

Figure 24

F$"

-

TT

i

2++

fit

1-17±

ifx

F-

iiiijilmmT11

._ __.......

.............. .............

fl4

+

;- -Lt

t4

-t

-TRESS

I-

KI

I

H

4141

4

if

---

-

,144

4

.,

hiA.

,

0

2

fit I

444:

i-4

+

:44.

tt

T-

a

4r

v-4.

riM

1

F

--

-

4

t

46

4UA

L

______

&

_____

_____

G6s4 :

L~4 P

F-

as

tt

_____

R

x.5-

4-00

5'377 -

100

,geXs

Iz~z

(D

1IA~~)

/

-7674

,~ ...., 7

1599 II

-a'7

5::97

-1-9 7r

-

7 (f

A~h7LA

41

Lcn 09s

-STAA-S/

-767/4

3-ib

4! 5-4

LA

n

:7 f.

S~2 9 I

5-;-W 7-

-o

.1 7692.

RSA&%f-

.4930

10

7

4-92.-1

'tA

47

O0

4xo

-jA-7-A

S

4.0/

0

7 67:3

-- 424-

/2

529

130t)

-7

Z 100

00 Q

.4 41

e/

--+/4

--

S&

691&

6 *9

757/

RCA3

712.

4>>iq

____

I

_____

I

I'll

0V

n 10 Technology Store

-

D.O

m--

I

I

48

F~~4'L8

/

J

-'

L/ b-

C---A=--

-~

a~

/1",

C

.

--

--

.

I

zr I

z~zI

I~z5

z~jz

-4

/5o

75

1991

7(0

/

3

73rS -

37T-2

4ep 3.L

4-S-2.

0 hn)ySo

0

95n

47I2z

44493 0

4-4

!mg-3

2,6n

61-

9

49

407

K&

,/--v9

-A/04--

-'31--

4499 t

4,5Z 9

swa-

40A 35

4W29

4Z-

45

_5-

9

-

rz.

5fm

1.0

TcnlgStr

I

_______

J -______________

/0

0

I"*"

49

FlG r e

a7

',"

Wh(7)

$)

(00)0(-)

A)

45 _2.,r419-- 4936

n3

n40

_ _j

4,

/-

0

.{

0

_

40

-ro

:.-?

rno

0

o pnn

.m

10 Technology

Store

7

/12/0

3

722-9- 49/Z9

779/

4 909

4A30

4493

470-L ...

4_

9

-1922

71 F

74'

AJOn

3r9A

32./

449X1

9

543

-/3

/4-00

/Ao D

3429

z..43

34/

&-r2..

7931

47

2.-

-2-/

o/.

7 7 2-2-.

7?47

1 7 3-13

?,73L

24

-12,97

7"r

XX 0,

/500

2go-

O-

n_

77,02-b

7 Ar-2.;

-7|49 37

1

6378

4/4 9 - k2.1

1649

- W

727 /1 6/02

:270L

603k2 .67|

4

200 A39 494

19 1

9 00 4 /5-

20 ___z000

_

75E7

4 93 2

D 44//437

OO

,0oL,

4;29 4!9'7

4;24!9 49 33

/n700

LO

i

-. /

A337

3

2 4. 9

.2 710

'790

2. /

;2!fe1292.0

2.03

2.g??

2

;//

_7

7

e-

H1

&I4'All t"T

~f4f~Tf~FTh 4~

*F-

i4

-H-

-F-

1idH

{11

$

*4l

A,

7_7

-iiW±~±44HThztdz1

41*

t~ijT77i~i-V7177I7Ij~ Af

1T L

7000

1

ti

44-Th-Th't'1

-

360W0 p

tt

-H-H i

1H

............

III1

_~j~

tt

hVt1

-4-

ti

iT4+M

H

-w

-!

I

ft- r ++ --H

- -4 -

I

-t

-

4_1 1 .1,.,

7T17t

~40W

-i I-

HI ~

W+4#Ith

-H

H-

i

11--11H

-4.444

4

H-4Af' -4Ih---

# t

-

- -

-41

-

4

---

4-1-

C

-

,

-

-

-

-

- 12

'U

-44-.-

~oo4

000

IL

44

-

-

t4

-fFr

Li

Fs1+1

H-

1 -4

42l

414

I

4

T-

-

--

'I: 4

1

I 1

t

jg

1 !

ut

-1

4

1

T:4,

-

-j 11

1

o

50

jI

- u',

14

1

T T

'-V71 7V71771

/00

5YRAIN

150

-

. .......

tj

1

r L

'1

~~A

444

I 4

A-

-

-

oo

MICROINCHES

-4

--4

tj! -t±I.,

-

Ii

250

PER

~jj1j®

1.

350

300

INCH

--

-I-

r~i~ I

444

-if

i4-

t

I:

I-I

I I-.

-

-

1227

.1,

4

-

~T22

Figure 29

-

I

__

I

2~2j:2

.14' I~i Li

* 1222.

-

T1q

I

TT

2:

-

.

4

222

-

I

.

i~ItT4j

- - -J- --

-4 -I-F

4~

I t

- 4

'0

-

/NcH

. 1-16 6

--

IitL tLi

'14:IL'~~ J-L

:1

7

_-1 I'll

7T.-:2

7777

2

9

FA

SA4oMENIT

-

4--

JTI

--

.

7221

I

.

0

.

4

~--t~

V

POUADS

S

Tr

_I-.

-

0

0

w.

-F

o]

C3

03

(t)

51

0

-110

Q

Figure 30

*1a

OMEN'T

I

*I;Q

**i*

04

- INC/- POUNDS

C,

t

C.)

()

:3:

uJ

V

(I)

1~C)

2

N

0

0

0

52

I

TI,

--

vI-,

-T~-

]

7,

p

4 - - -J

t

14

- -

-T

-

tt

7u

4

-

-

-- 4414

t-T - -

L

u

--

tI

-

-

-F

-

- -

-~~

--

4

--

-+-

T-

--

-

H

4

4.

-

--

~~~~

~~~~t

-

-

~ ~

--

---

---

- ---

~

---------

--

--

~ ~ ~~

-

-

-it--

-64-

I---

-

---

-t

-

-t-14

-

-7

-

-

-

-

-

j

--

-

-

-

--

--

it

--

_

-

i-

----

_7

-

--

--

-

-4--

-

----

4-

-------

pm

1

-100

0

100

Zoo

STRAIN

300

400

- MICROINCHRES

--

700

So

PER INC 1H

*-P +

11

-

oo

1~

o

~

(v,

'~

0

0

0

32

Figure 32

Figure

I

('4

I

o0

o0

o

MOMENT - INCH POUNDS

N

8

8

*1

+

U

LtJ

UI)

t4

:t

Qo

54

54

I

if

---

±1< V&I~Az>

A1±+~K~~t~&uhH

I"i~~t'-i~L

I-

I

I

IL

IO

:

40

7-21-- 1:17

-;

iI-

H

.4

T

i-L

I00

jj~

__

I..

KZT

-

t

I I I1

.. 1wI:.

-

Z.-:-

Wm

ap

z400

i

2'II

-f

1~*

.

.

.

.

V K1717T~:K7

it

I..

f 4-

.

121

.

I.

L..

.

.

(n 200

0

!

lit

ii. ~ i'7~

~80

'

IL ~

7717PE

*.

.

ill

C~AMS

-4

0

200

400

,STRAIN

600

800

- MC/INCHES

/000

PER

1400

//NC H

-+

/600

I.

/800

Strain att outer fibres

Moment

Gage

Gage

Q~©Modi.

Strn.

Gage

Modi -

fied

Strain,

0

-Strain

Factor

Stress

2000

E = 28.6 x 103

(ksi)

Factor

Gage

Gage

-Modifled

Strain

Gage

ge

' I

ress

(ksi)

Strain

Factor

ModiGage

fled®U "

Strain

Stre

Gage

(ksi)

Strain

0

Factor

Modified

Strain

Gage

0

©)

Ga e

Stress

(ki)

ksi

o4

(-.65)

121

3.46

275

-66

-

209

5.98

170

5000

306

-66

-

240

6.87

216

7000

294

-66

228

6.52

338

3750

Strain

0~-

-66

54

fld

Gage

Strain 9tress

(ksi)

Gage

factor

#1

Gage 1.

Gage

00tGage

u©

CHANNEL

©

;Gag~

56

68

1.95

0

0

0

0

-36

134

3.83

9

0

9

.27

,-36

180

5.15

54

0

54

1.54

302

8.63

228

(.72)

68

1.95

17

(.72)

12

(.65)

cr

CHANNEL

#2

0

228

E= 28.6 x 103 ksi

1000

217

94

-61

(w72)

156

4.46

95

2000

411

186

-112

(.73)

299

8.55

182

(.73

133

.81

30

(.73)

22

3750

673

561

-112

-

617

17.65

319

49

270

7.72

25

-8

17

349

9.98

-8

-84

cr

4750

65

-

65

1.86

95

(.72)

68

1.95

.63

131

-

131

3.75

18o

(.73)

123

3.52

.49

274

-

274

7.84

303

-57

246

7.04

433

12.38

298

-57

241

6.90

228

(.90)

205

5.86

-23

425

12.16

317

9.07

495

14.06

(compr)

546

CHANNEL

1000

859

1500

1000

-112

-

#3

E

-

=

434

12.40

398

-49

-76

-2.4

433

28.6 x 103 ksi

9

.23

(.90)8

237-237.6..79

- 92

(.90)

1777

- 92

-

1685

48.2

2,36

-1

235

6.73

410

410

11.72

448

1316

- 92

1224

241

-1

240

6.87

293

8.39

340

35.0

293

-

2378

- 92

-

2286

65.5

35.8

.-1

357

10.2O

493

493

14. 09

518

675

767

(unload)

1550

6.52

21.9

-23

(reload)

Figure 34.:

Table to Plot Stress Distribution Curves from

Moment-Strain Curves

--

-

--

-

--

4t

-t

-

-

-

-

-

~

-

-WE

u

t

LLM

_-

I-t---+-

.1:

-

-