Volume II Appendix D.3 Fault Tree Closure Summary COLUMBIA

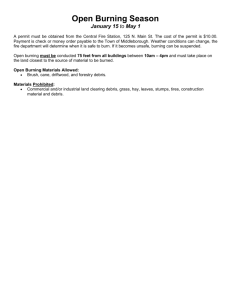

advertisement