Document 11264103

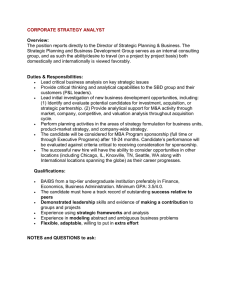

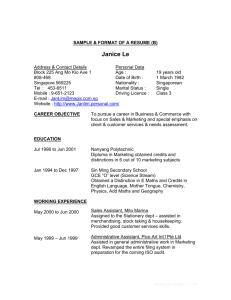

advertisement