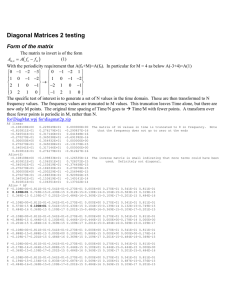

Steel

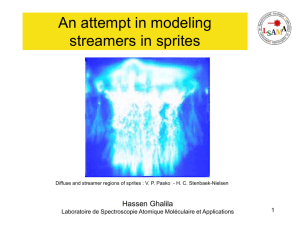

advertisement