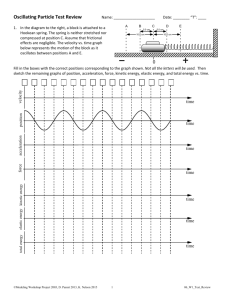

Experiments in Heat Transfer Under Conditions of Oscillating Pressure and Flow

advertisement