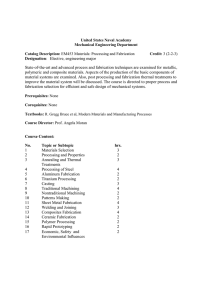

Molding and Filament Winding of ... Graded Material Properties through Computational Design

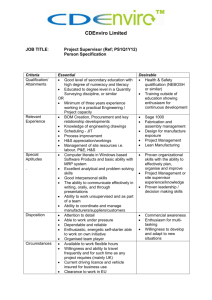

advertisement