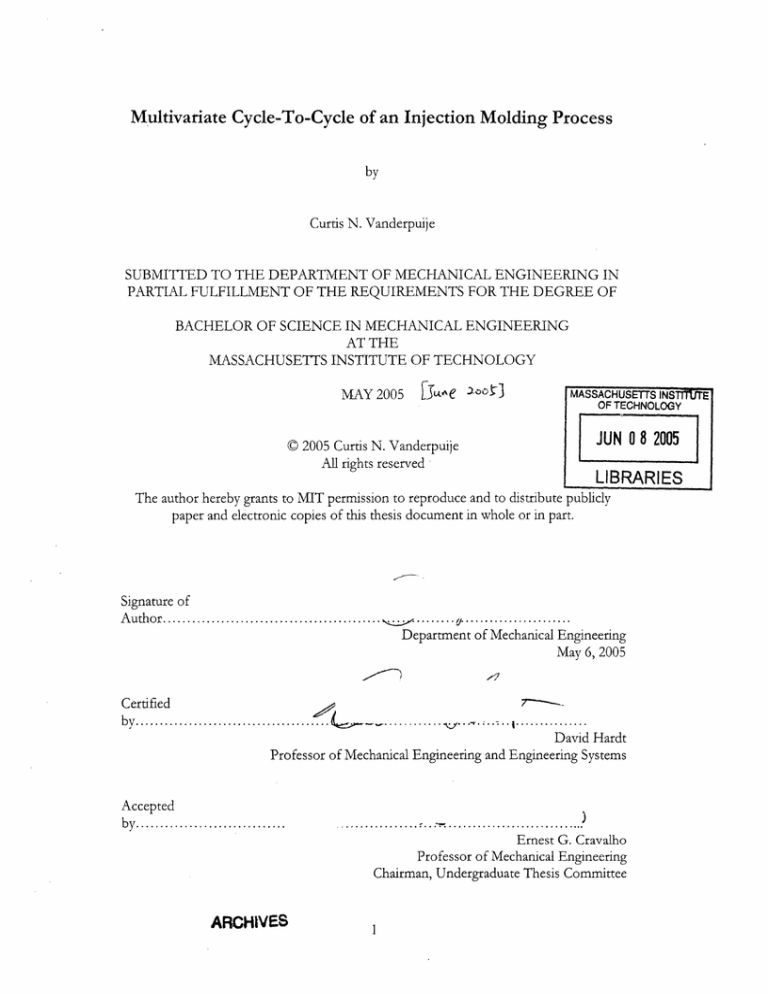

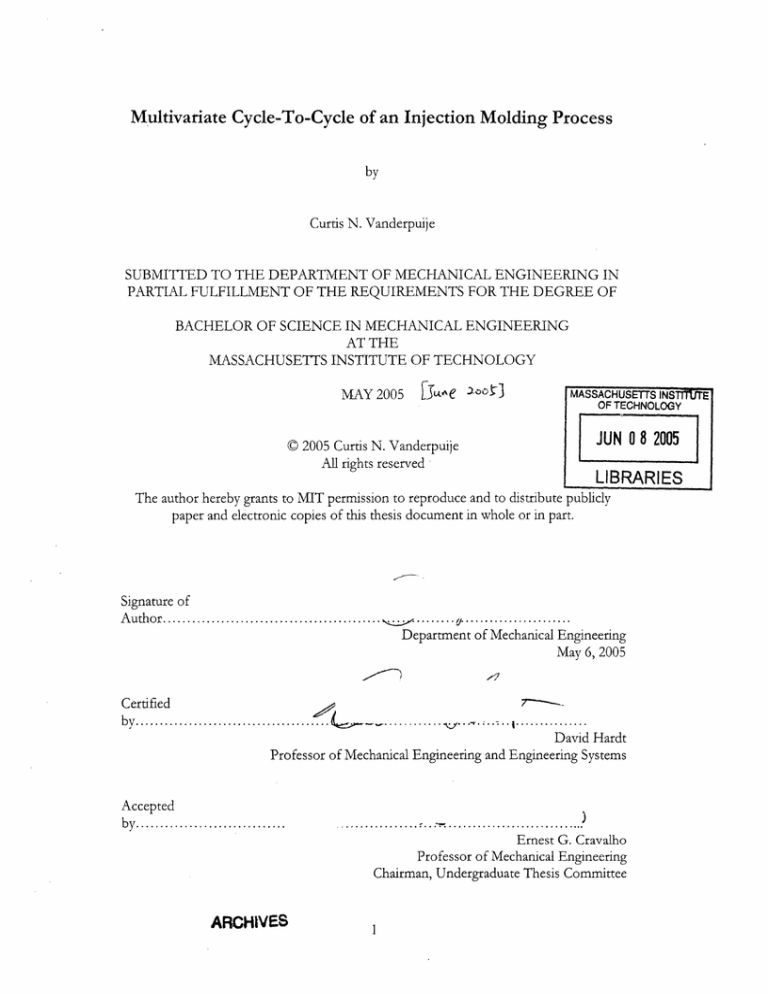

Multivariate Cycle-To-Cycle of an Injection Molding Process

by

Curtis N. Vanderpuije

SUBMITTED TO THE DEPARTMENT OF MECHANICAL ENGINEERING IN

PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE DEGREE OF

BACHELOR OF SCIENCE IN MECHANICAL ENGINEERING

AT THE

MASSACHUSETTSINSTITUTE OF TECHNOLOGY

iJSLe aoor73

MAY 2005

~MASSACIiHUSt"S INS'TIT"E

OF TECHNOLOGY

F.

© 2005 Curtis N. Vanderpuije

All rights reserved

N 0 8 2005

LIJ

LI[3RARIES

The author hereby grants to MIT permission to reproduce and to distribute publicly

paper and electronic copies of this thesis document in whole or in part.

Signature of

Author

......................................... ......

- ......................

Department of MechanicalEngineering

May 6, 2005

Certified

-

by

.........................................

. . . xzI..........

....

David Hardt

Professor of Mechanical Engineering and Engineering Systems

Accepted

by...............................

... . . . ......

. . ........

-)

Ernest G. Cravalho

Professor of MechanicalEngineering

Chairman, Undergraduate Thesis Committee

ARCHIVES

1

Multivariate Cycle-To-Cycle of an Injection Molding Process

by

Curtis N. Vanderpuije

Submitted to the Department of Mechanical Engineering

on May 6, 2005 in partial fulfillment of the

requirements for the Degree of Bachelor of Science in

Mechanical Engineering

ABSTRACT

Cycle-to-Cycle (CtC) feedback control has been studied extensively with increasing

demands on the precision and quality of manufactured parts. Single input-Single output

has been studied as the basis of CtC feedback control. In the manufacturing sector,

processes consist of many input parameters and critical outputs. Multivariate CtC seeks

to extend the findings of SISO CtC to more accurately reflect real world processes.

Multiple input-Multiple output CtC feedback control is applied to an injection molding

process to verify the effects on quality of the parts produced. A design of experiment is

used to determine the gains of the process, regression models are developed and integral

feedback control is applied. The process is actively driven to meet specific target outputs.

Minimal mean errors and variance ratios ranging from 0.14 to 0.57 are observed

indicating an improvement in quality.

Thesis Supervisor: David Hardt

Title: Professor of Mechanical Engineering and Engineering Systems

2

ACKNOWLEDGEMENTS

I would first like to thank my advisor, Prof David Hardt for being a great advisor all four

years of my undergraduate education. He always made time when I needed to meet him

to discuss important issues and was always full of great ideas. You have been an amazing

thesis advisor - giving me the requisite guidance for this thesis project, explaining

concepts and methods effectively and very understanding during difficult times in the

semester. I really appreciate it all.

I also want to thank Dave and Pat for being very understanding about scheduling, for

being eager and ready to help out always and for the expert advice on injection molding.

Lastly, I would like to thank Adam Rzepniewski for explaining aspects of his work to me

that were relevant to this project.

3

TABLE OF CONTENTS

1.0 INTRODUCTION AND BACKGROUND...........................................6

2.0 THEORETICAL BACKGROUND....................................................

2.1 Cycle to Cycle feedback control ..................................................

9

9

2.2 The Integral controller ............................................................

11

2.3 Multiple input-Multiple output Cycle-to-Cycle feedback control .............

13

2.4 Design of Experiments ...........................................................

15

3.0 MIMO APPLICATION IN AN INJECTION MOLDING PROCESS............

16

3.1 Description of Injection molding process .........................................

16

3.2 Part selection for MIMO CtC feedback control .................................

17

3.3 Experimental Approach ............................................................

18

4.0 RESULTS AND ANALYSIS .............................................................

21

4.1 The 22 full factorial experiment and gain determination .......................

21

4.2 Multiple input-Single output CtC feedback control ............................

24

4.3 MIMO CtC feedback control .....................................................

30

5.0 CONCLUSIONS...........................................................................

4

36

LIST OF FIGURES

Figure 1 - Graphical representation of a process in Statistical control .....................

6

Figure 2 - Examples of different Cpk ..........................................................

7

Figure 3 - A simple MIMO system ...........................................................

8

Figure 4 - A simple model of CtC control .....................................................

9

Figure 5 - A CtC feedback control system .....................................................

10

Figure 6 - A CtC feedback integral controller showing the gains ...........................

12

Figure 7 - A schematic of injection molding ...................................................

16

Figure 8 - Part chosen for research ...........................................................

17

Figure 9 - Distinct output measurements for part ............................................

18

Figure 10 - 22 full factorial design ..............................................................

19

Figure 11 - 'Correlation' graphs for outputs ...................................................

22

Figure 12 - Graphical representation of MISO system .......................................

23

Figure 13 - Open and closed loop run charts for diameter parts in MISO ................

25

Figure 14 - Open and closed loop MISO runs for thickness and height ...................

27

Figure 15 - Open and closed loop run chart for height of parts ............................

29

Figure 16 - Schematic of MIMO CtC feedback control .....................................

31

Figure 17 - Runs for height and thickness of cold parts in MIMO .........................

32

Figure 18 - Run charts for height and thickness of hot parts in MIMO ...................

33

Figure 19 - Run chart for the thickness in MIMO with small variance reduction ......... 35

5

1.0 INTRODUCTION AND BACKGROUND

The manufacturing industry has made much advancement in production and quality

control over the last fifty to sixty years. The demand for manufactured parts have

increased steadily as specification limits are continually made smaller and processes are

adjusted to meet tight specification limits. Precision parts have moved from the

millimeter scale level to the micro and even nano-scale levels. Given these advancements,

the challenge to reach specific quality targets remains arduous.

Most processes are characterized by deterministic changes and random disturbances that

affect the output.

Manufacturing processes become random processes if all the

deterministic disturbances are found and eliminated. Such a process is said to be in

Statistical control [7]. A graphical representation is shown in Figure 1.

I

Figure 1: Graphical representation of a process in Statistical control

In manufacturing, this process is usually left untouched until a drastic change is noticed.

However, in cycle to cycle (CtC) feedback control, the process is actively controlled to

attain specific mean values and to minimize variations in the process. In CtC control,

output parts are measured between cycles and used to adjust the inputs of the next part

to be produced. As a result, the process can be controlled to attain specific target values

6

for the parts produced, thereby improving quality. Quality in this case is characterized by

the ability to reach target specifications.

The quality of the process can be measured by the process capability, Cpk. The process

'3r

capability compares the effect of the offsets from the mean value using the specification

limits and the 3a limits for the process. This is shown in equation 1.

USLCpk mMin(

3o=

.A- LSL

(1)

where USL represents the upper specification limit of the part, LSL represents the lower

specification limit of the part, pt is the mean and

is the standard deviation. Ideally, the

larger the process capability, the higher the quality of the process as it ensures that

almost all the parts produced will fall within the specification limits. Figure 2 shows some

examples.

rem

I

~ill

2:

USL

Cpk= 2

Cpk=

Figure

I

LSL

LSL

·

Examples of different Cpk values showing the ease of attaining target

specificatio ns

Extensive work at MIT has been done in single input-single output (SISO) processes in

which CtC feedback control was used to improve quality. Many manufacturing processes

however, consist of systems with multiple inputs and multiple critical outputs. The

outputs could be dependent on independent input factors or a combination of input

7

factors. This system is slightly more complicated than the SISO system but can be

tackled with the same techniques found in the SISO system. Hardt and Rzenpniewski [1]

actually extend the findings of CtC control in SISO systems to MIMO systems.

Figure 3 shows a simple schematic of a MIMO system.

Y1

X1

,Y2

.=:: --------------

Yi

X2

Figure 3: A simple MIMO system

In the system shown in Figure 3, one can notice that input factor X1, can either affect

output Y1 only, or both outputs Y1 and Y2, ditto for input factor X2.

The main objective of this thesis is to improve the quality of an injection molding

MIMO process using the theoretical findings of Hardt and Rzenpniewski. A design of

experiment (DOE)

is carried out to understand

the process. Linear models are

formulated based on the results of the DOE to identify the gains in the system. The

gains obtained are used in a MIMO CtC feedback control system to run production and

to test the improvement in quality of the parts produced.

8

2.0 THEORETICAL BACKGROUND

2.1 Cycle to Cycle feedback control

Cycle to Cycle feedback control as the name suggests makes changes between

subsequent cycles. Input parameters are changed for the production of a subsequent part

based on the difference between the part produced and the target specifications. CtC is

therefore a discrete control process with a one cycle delay. Figure 4 shows a simple

representation of the CtC control model.

Inpui)

Input (ui 1)

Process

(Kr)

Process (Kp)

Output (yi)

Figure 4: A simple model of CtC control

Hardt and Siu [2] show that the discrete nature of this process leads to a very simple

process model in which the process gain relates inputs to the outputs. This process can

be modeled as

yi

Kpuil-i

(2)

where yi represents the ouput of the process, Kp is the gain of the process and ui-i is the

input of the current cycle (the output of the previous cycle). This equation does not

include the randomness of the process which is modeled as the disturbances in the

process and is not shown in Figure 4. These disturbances change the model to

yi

Kpui-l + di

9

(3)

where di is the noise factor. These equations can be simplified by using the Z - transform

to model the equations in discrete time. In this case, z = eTs, where T is the time to

complete a single cycle. Equations

(2) and (3) become

Y(z) = Kp U(z) z- 1

Y(z)

(4)

Kp U(z) z- 1 + D(z)

(5)

respectively.. Given the process model established, controllers can be included to give an

actual representation of a sample manufacturing process. Figure 5 is a representation of a

CtC feedback control system.

disturbance

TUired

Figure 5: A CtC feedback control system

The controller, Gc can be either proportional or integral. Hardt and Siu [2] show that Gc

for the proportional controller is

Gc(z) = Kc

(6)

Gc(z)=KZ-1

c-

(7)

and Gc for the integral controller is

10

in the Z-transform. The integral controller would be used in this project for reasons that

will be specified in the next section.

2.2 The Integral controller

The integral controller is simply a running sum of the all errors in the process. It is able

to remove the steady state error from step disturbance within the system enabling the

system to reach its target specifications. It has been proven by Hardt and Siu [2] that to

implement this scheme of discrete feedback control, this is the right controller to use. In

recursive form it is expressed as

ui+

=

ui + Kcei+l

(8)

where ui+i represents the input for the current cycle, ui represents the input from the

previous cycle, Kc is the controller gain and ei+l is the error from the desired output.

In Z-transform space, equation (8) is expressed as

zU(z)

U(z) + IKzE(z)

(9)

which gives the transfer function

G, (z)

U z)K

E(z)

z

Z

(10)

These new equations are incorporated in the block diagram shown in Figure 5 to give a

complete block diagram for the CtC feedback control system which is shown in Figure 6.

11

disturbance (di)

Figure 6: A CtC feedback integral controller showing the gains

The disturbance is usually modeled as a normally identically distributed independent

noise (NIDI) with mean

, and variance a2 - di - NIDI(p , a 2 ) when the noise is

uncorrelatecd. It can therefore be modeled as a constant step disturbance.

Assuming r = 0, the block diagram in Figure 6 leads to the transfer function

z-1

Y(z) =

z-_I+K

D(z)

(11)

Kp

In continuous time space this results in

yi+ + yi(1 - KCKp) = di+l- d i

Since the disturbance is constant and at steady state yi+l = yi

(12)

y the disturbance terms

at the right side of equation (12) go to zero and equation (12) simplifies to

y-(2 - KcKp) = 0

(13)

Showing that the steady state error has been eliminated using the integral controller.

12

The output can therefore be related to the input simply by going through the block

diagram in Figure 6, but without the disturbance. This leads to

Kc

(R(z)- Y(Z) =U(z)

z

z-1

(14)

In time space, this can be rearranged and expressed as

=

ui+

i + Kc (r- yi-)

(15)

where r represents the output desired as shown in Figure 6, and yi-1refers to the output

of the previous cycle. As can be noticed, this is of the same form as equation (8). This

can simply be extended for the MIMO system.

2.3 Multiple input-Multiple output Cycle-to-Cycle feedback control

MIMO CtC feedback control is a simple extension of the models presented for the SISO

CtC feedback control. Though these models are simple in the SISO system, they can

become quite complex in the MIMO system when they involve many inputs and outputs.

In such cases, some higher order terms would probably have to be approximated as it

becomes too difficult and probably too expensive to run all the tests needed for an exact

model. These approximations will probably be effective enough for the process under

consideration. Hardt and Rzepniewski [1] show that for a system with n2 inputs and n2

outputs, n4 coefficients are required to satisfy the matrix form of the CtC model

expressed in equation (2). For a simple 2 input - 2 output system, the gain matrix is

simply a 2x2 matrix. The gain matrix Kp becomes

KP=(16)

I[k" k,]

z

k21

k22

13

Hardt and Rzepniewski[1] also show that for best performance of one time step settling,

total loop gain K (which is the product KcKp) must be equal to 1. As a result, for the

MIMO CtC feedback loop

KcK = I

(17)

where I is the identity matrix and Kc is the controller gain matrix

=

k clI

kcl2

kc21

kc22

(18)

Equation (17) therefore expands to

k1 l

k

k2 1

k 22 1

1 2

k,

1,

Lkc2 1

k,

k,

12

1

22

(19)

L

1

The controller gain, Kc is simply the inverse of the process gain Kp when Kp is invertible.

Given these further developments, the model in equation (15) can be altered to represent

the MIMO C(tC process to give

1+

Fu U i iF(u

Fk

IU+i

UiuiL2I

Luj+

J

Uj

k

1

k c12 i [e i

eli

1

2k k,22

c22ej e~j

(20)

Equation (20) is the fundamental equation used to determine the effects of varying

inputs on critical outputs in the MIMO experimental process in this thesis. The

controller gain matrix is determined by using a DOE.

14

2.4 Design of Experiments

A design of experiment is a series of tests carried out on a process by changing input

factors and recording the corresponding effects on the outputs of the process. It gives a

better understanding of the important input parameters of the process and enables one

to perform an active control of the process by adjusting inputs instead of the usual

passive form of statistical process control. This is essential because for a process in

statistical control, passive observation would yield few results whereas active control can

sometimes make a significant difference.

In this research project, two input factors will be used in a series of tests to determine a

model for the injection molding process. The model coefficients will give the process

gain parameters for the 2x2 Kp matrix. The model is expected to take the form

A

y

1

= ? 0 +,6 1 x +,

12x 2

+i14 12xx:

(21)

A

Y2 =

i 20

+

42, x ,

+

4 22 x 2 +,/

for each input and output parameter tested. The

212 xIx 2

(22)

o parameters represent the means for

the outputs, and the remaining s represent the coefficients for the specific input factors.

The gain of the process becomes

L2 I

11 of

gain Kp becomes the inverse

d the controller

A22 ]

.

and the controller gin K becomes the inverse of Kp.

15

(23)

3.0

MIMO

APPLICATION

IN

AN

INJECTION

MOLDING

PROCESS

3.1 Description of Injection molding process

Injection molding is a process that is used to make many plastic parts in the

manufacturing industry. It is a relatively quick mass production process and lends itself

to the study of feedback control in manufacturing. This process also has a variety of

input parameters that are easily altered during production to attain specific output

targets, hence is very suitable for the study of MIMO CtC feedback control.

Figure 7 shows a schematic of the injection molding process. The hopper holds plastic

pellets that drop into the barrel. These pellets are then moved by the screw towards the

heating area labeled in the diagram. They are heated into molten plastic and shot into the

mold through the nozzle. The shot size, injection pressure, cooling time in the mold,

hold time in the mold amongst other parameters are all preset through the control

system of the injection molding machine. The part is then ejected after the cycle.

PART

v.

-

Dclam

Figure 7: A schematic of injection molding [3]

16

3.2 Part selection for MIMO CtC feedback control

The injection molding process yields many input parameters as has been previously

mentioned. Siu [4] and Manoosingh [5] show that cooling time, hold time and injection

boost pressure (referred to as pressure henceforth) are among the most significant of the

input parameters for variation in output parts. The part chosen for this study was

selected based on the expected effects caused by varying cooling time and pressure.

Cooling time is known to have a significant effect on the shrinkage of the part after it is

ejected from the mold. Pressure is known to affect how well the part fills up the mold

specifically small crevices or corners. This is however dependent on shot size as well

which is kept constant in this research project.

The part chosen for this research project was a yo-yo part from a previous

manufacturing class. The part was chosen based on the fact that it has several distinct

dimensions that can be measured as outputs. The part is shown in Figure 8 and Figure 9

shows various potential measurements (outputs) for the part.

Figure 8: Part chosen for research

17

Figure 9a

Figure 9b

Figure 9c

Figure 9: Distinct output measurements for part

In the first picture of Figure 9, it can be noticed that there is the possibility of measuring

several diameters of the part. The triangle vertices for instance are potential reference

points.

3.3 Experimental Approach

Six different dimensions on the yo-yo part were chosen for initial study. These included

4 diameters - 1 at each of the vertices of the embossed triangle, 1 diameter slightly off (200 counterclockwise from the position shown in Figure 9a), the height of the triangle,

also shown in Figure 9b and the thickness of the embossed triangle as shown in Figure

9c. The outputs are listed in Table 1 as a reference. Figure 9 can also be used as a

reference.

Table 1: Outputs in DOE

Output(y)

Location in relation to part

Y1

Diameter

Y2

Diameter 200 counterclockwise from yl

Y3

Diameter 1200 counterclockwise from yl

Y4

Diameter 1200 clockwise from yl

Y5

Height of triangle as shown in Figure 9b

Y6

Thickness of triangle as shown in Figure 9c

18

as shown in Figure 9a

In order to determine the gains for the process, a 22 full factorial experiment with 2 input

factors each at 2 levels with 15 replicates was carried out. The input factors were cooling

time (factor xl) and pressure (factor x2) and the design geometry is shown in Figure 10.

b -

oh

'"U

0

Factor B pressure

0

Factor A cooling time

a

Figure 10: 22 full factorial design

Pressure was varied from 500psi to 1000psi and the cooling time was varied from 10s to

40s. These input parameter ranges were found to be suitable for the purposes of the

DOE after initial experimentation.

These experiments led to linear regression models like those shown in equations (21) and

(22). These models were found for both the hot and cold parts (a total of 12 linear

regression models). This is actually a very interesting characteristic of injection molding

in regards to the approach taken in this research project. The parts shrink and have

different dimensions or outputs from the cold state as compared to the hot state.

However for CtC feedback control, it is only pragmatic to use the regression models

developed for the hot parts since it takes an extensive amount of time to do so with the

cold parts as one would have to wait for each part to cool. Interestingly, the cold parts

are the final products and are of more significance than the hot parts. This approach

which utilizes the linear models of the hot parts can therefore only be justified if a hotcold part correlation (henceforth referred to as 'correlation') is found between the cold

and hot parts. A graph is therefore drawn after both hot and cold parts have been

19

measured to determine if a 'correlation' exists. This is further discussed under the Results

and Analysis section.

After determining the loop gains, the controller gain is found using equation (19). An

algorithm is then developed to utilize equation (20) in a production run. The process is

rerun with the CtC feedback control for the specific outputs chosen to determine if

quality can be improved via the MIMO CtC feedback control process. The expected

results are to achieve zero mean error and a reduction in variance of the parts produced

when the closed loop MIMO process is run.

20

4.0 RESULTS AND ANALYSIS

4.1 The 22 full factorial experiment and gain determination

The results of this experiment led to the development of regression models for all 6

outputs.

The models were found for both the hot and cold parts as stated in the

previous section. Though the models for the cold parts were not used for CtC feedback

control, it was done to find out if there was a noticeable relation simply by inspection.

This was however not the case and the models were found to vary. The models obtained

for the hot parts which are relevant for this research project are shown in Table 2. The

coefficients of the varying factors represent the gains for the process and will be used

together with equation (19) to determine the controller gains.

Table 2: Regression models for hot parts

Regression models

yi

1.645 - 0.00268xi + 0.00125x2 + 0.000275xlx2

y2 1.643 - 0.00375xi + 0.00162x2 + 0.000308xlx2

y3= 1.644 - 0.00062xi + 0.00172x2 + 0.000158xlx2

y4-

1.643 - 0.00095xi + 0.00105x2 + 0.000075xlx2

y5

0.8225 + 0.00237xi + 0.00013x2 + 0.000383xlx2

y6 0.0539 - 0.00207xi + 0.0012x2 - 0.0003xlx2

Graphs were plotted for the hot outputs versus the cold outputs to determine if there

was any 'correlation' and R2 values fitted. It was noticed that the 'correlation' for the

triangle height output was 0.55 and the 'correlation' for the triangle thickness was 0.29.

The 'correlation' for the diameters were however much smaller; the best was 0.025 and is

suggestive of little or no 'correlation' between the parts. The 'correlation' graphs

obtained for outputs yl, y5, and

y6

are shown in Figure 11.

21

Correlation for trianglethickness

..

r, ,-,

U. UZO

.

.....

..

_

.

.

.....

_.

..

.

o

.

.

.

..

0.057

0.056

02

r't

0

= U./OO

0o5

' 0.055

E

T 0.054

*

*

4W

*

c 0.053

a)

E 0.052

;i

X

0

-

0.051

0.05

*#

I7 r

*

*

r

-

0.049

0.048

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

Cold part measurements

Figure 11a: 'Correlation' for triangle thickness (output

Correlation for triangle height

U.821

0.821

0.82

c 0.819

E 0.818

T

' 0.817

X

' 0.816

E

, 0.815

AL

z

0.814

0.813

0.812

0.811

0.818

0.819

0.82

0.821

0.822

0.823

0.824

0.825

Cold part measurements

Figure 1lb: 'Correlation' for triangle height (output

22

y5)

y6)

1.648

......

....... ..........

..

Correlation for diameter (yl)

1.647-

*

c 1.646

*

E

E~~~~~~ * *

, 1.645

(U

*

*

U)

E 1.644 -

* -*

-

*

* *

*

*

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~id

*

**

2f 1.643

* * * -*

1.642

1.641 .

.*

2

R = 0.0252

.

1.631 1.632 1.633 1.634 1.635 1.636 1.637 1.638 1.639 1.64 1.641 1.642

Cold part measurements

Figure 11c: 'Correlation' for triangle diameter (output yi)

Figure 11: 'Correlation' graphs for outputs y1, y5 and

y6

The lack of 'correlation' was noticed for all diameter measured outputs. This can be

attributed to the fact that the measurements were very sensitive to the time that

surpassed before the measurements were taken. The first measurement of output yl was

taken 10secs after the part was ejected from the injection molding machine. However, in

order to obtain an accurate measurement, it was sometimes necessary to re-adjust the

digital calipers taking more time for some parts than others. This definitely affected the

diameters due to their time sensitivity in regards to shrinkage while exposed to ambient

temperature.. Based on the 'correlation' figures obtained, it can be concluded that the

diameters were more sensitive to time exposed to ambient temperature than the triangle

height and triangle thickness outputs. The 'correlation' values obtained also determined

the final outputs that would be investigated in the CtC feedback process - outputs

yI,

ys,

and y6, henceforth referred to as diameter, height and thickness. The difficulty of

measuring the diameters also suggest that the model obtained for the diameter output

will be the least accurate.

23

4.2 Multiple input-Single output CtC feedback control

A Multiple input-Single output (MISO) analysis was done on the 3 outputs using the

coefficients in the regression model shown in Table 2 as the gain terms in the gain

matrix. The multiple inputs were the input factors xl and x2 and the single outputs were

the diameter, height and thickness, each tested independently. The equation used in the

algorithm for feedback control was a slight deviation from equation (20). The process

gain was therefore expressed as

K1

[-0.002681

K =Lfl2 2 ]=L

0.00125

(24)

for the diameter (simply a matrix of the coefficient terms in the regression model for the

diameter).

The controller gain Kc was simply found by using the relation KcKp

1

equivalent to the relation expressed in equation (17). The process was therefore run

using the equation

L iF:x

1

t F-370.371r

i+I xiI+

Xi2+L]x

2

- 370.37 [e]

76 9 23

.

[e]

(25)

where x represents the cooling time input parameter and i2 represents the pressure

input parameter.

This was done for the height and thickness as well and yielded very

favorable results.

Graphically, this MISO process is shown in Figure 12

24

Figure 12: Graphical representation of MISO system

Though the models used were for the hot parts, run charts were produced for both the

hot and cold parts. Figure 13 shows the run charts for the diameter and height outputs.

The figure Shows a run chart of the open loop process and shows a change to the closed

loop CtC feedback control using the models established for CtC feedback control and

gains found in this thesis.

Diameter- same meanhot

-~S~~__

__~~~__

__~~~

_~_~~S.~__

1 ~As_.

1.641

1.64

--- Open loop

E 1.639

--

M

Closed loop

1.638

1.637

1.636

0

10

20

30

40

50

Runnumber

Figure 13a: Open and closed loop run chart for hot diameter parts - closed loop target is

1.64 inches

25

Diameter - same mean cold

1

Role

---------I

-111111-1-11.. ....

''I-I-111,11111--."--,""-,.,.,-""-.

-- - - - - -------

1.6385

1.638

1.6375

E

-- Open oop

1.637

l

Closed loop

1.6365

1.636

1.6355

1.635

0

10

20

30

40

50

Run number

Figure 13b: Open and closed loop run chart for cold diameter parts

As can be observed from Figures 13a and 13b, the improvement in quality is seen in

both the hot parts that are actually actively controlled by the CtC process and in the cold

parts. Even though no 'correlation' was found between the hot and cold parts, these two

figures suggest a strong 'correlation'. Interestingly, there is a mean shift in the cold parts

produced through the closed loop CtC process. Table 3 summarizes the improvement in

quality for this output.

Table 3: Quality improvement summary for diameter output

Part

Hot

Loop

Hot

Cold

ClClosed

_

Mean

error Steady-state

(inches)

Variance (xlO-6)

Open

1.64

1.034

Closed

1.6425

0.4998

Open

1.63679

1.6381

1.6381

0.8299

0.1156

0.1156

~~~Closed

Variance ratio

0.48

0.14

Similar graphs were obtained for both the height and the thickness and are shown in

Figures 14a and 14b. However, there was no noticeable shift in the mean.

26

Height - same mean hot

U. 01

0.818

0.817

0.816

-*-Open loop

.2 ().

0.815

|

Closed oop

0.814

0.813

0.812

0.811

10

20

30

40

50

Run number

Figure 14a: Run charts for open and closed loop MISO runs for height. The closed loop

target for the hot part was 0.814 inches

27

Thickness- same meanhot

Ub/

0.056

0.055

10.054

-- Open loop

I-- Closedloop

*.- 0. 053

0 052

0.051

0.05

0

10

20

30

40

50

60

Runnumber

Thickness - same mean cold

U.U

Ob

(0.055

(0.054

o (0.053

I--

-- Openloop

-- -Closed loop

(.052

0.051

0.05

0. 049

0

10

20

30

40

50

60

Run number

Figure 14b: Run charts for open and closed loop MISO runs for thickness. The closed

loop target for the hot part was 0.0524 inches

The purpose of CtC feedback control is also to attain specific target values besides a

reduction in variance. This was tested for the outputs as well and the results are shown

for the triangle height in Figures 15a and 15b.

28

Triangle height - adjusted mean (hot)

0.824

0.822

0.82

0.818

- 0.816

-a--Open loop

|

Closedloop

._M

I 0.814

0.812

0.81

0.808

0.806

0

10

20

40

30

50

60

Run number

Figure 15a: Open and closed loop run chart for height of hot parts with a target mean

value of 0.82

Triangleheight - adjustedmean(cold)

rn R9 ..-Uo . ..

...................

.......................................

0.82

0.818

-

-Oe

loop

--4&-Open loop

0.816

0.8140812

0.81

--*-Closed loo

--

.

_._.

-

-1.__

-

0808

.

0

10

20

30

40

50

60

Run number

Figure 15b: Open and closed loop run chart for height of cold parts

The gains for the height appear to be quite accurate as the production quickly shifts to

the new target specifications. It was observed that the gains were most accurate for the

height output. For the diameter output, it took more runs to attain the target values. This

was expected as the problems associated with the diameter output suggested that it

29

would have the least accuracy. A summary of the quality improvements are shown in

Tfable 4.

T'able 4: Quality improvement summary for height output with shift in target mean

Part

Loop

Mean error Steady-state

(inches)

Variance (xO1-6)

0.8142

2.723

Closed

Closed

0.8200

0.4679

Open_

0.8155

1.464

0.8185

0.2294

Open

Hot

Variance

ratio(reduction)

0.17

Open

Cold

0.16

Closed

The variances listed represent the last 14 points after the process reaches its target value

so that it is not affected by the transitional parts as the process moves towards the target

value. As can be observed, there is a significant improvement in the quality as the

variance is reduced.

4.3 MIMO CtC feedback control

Based on the observations from the run charts, the height and thickness outputs were

chosen for the 2x2 MIMO CtC run since they were the most dependable outputs in

terms of 'correlation' and measurement accuracy. It should be noted that the thickness

was sometimes slightly defective such that the embossed triangle was sometimes warped

due to the thermal strains. As a result it could not be fully concluded whether the error

from warping was more

significant than the measurement

error or vice-versa.

Nevertheless, it still seemed more feasible to use than the diameter output.

30

The MIMO CtC feedback control process was based on the models shown in this thesis

and the algorithm was based on equation (20). Graphically, the MIMO process can be

represented by Figure 16.

Figure 16: Schematic of MIMO CtC feedback control

KIcand Kp represent 'black-boxes' that are modeled simply in Figure 3.

The coefficient for the pressure factor, x2 was approximated as zero as it was a

magnitude smaller than the other coefficients and was deemed insignificant. This was

'because the initial run proved problematic as the second gain term seemed to cause

conflicting changes during the production run. The process gain found was

l,

PLk2

k,2

k22

0.002367

0 l

[-0.002067 0.00120

eading to a controller gain of

kcl I

kcl 2

[422.53

k,21

kc 2 2

727.7

31

0

833.3

Once again, graphs were drawn for both the hot and cold parts since the cold parts are

actually the significant or useful parts under production. The graphs for the cold parts

are shown in Figures 17a and 17b.

Height - same mean (cold)

U.1

b

0.8145

0.814

0.8135

0.813

s 0.8125

* Open loop

I 0.812

-a-

0.8115

0.811

Closed loop

[_

0.8105

0.81

0.8095

0

5

10

15

20

25

30

35

40

Run number

Figure 17a: Open and closed loop run charts for height

Thickness- same mean (cold)

U.UU

0.0545

0.054

0.0535

U)

0.053

0) 0.0525

-Open

0.052

----

loop

Closed loop

0.0515

0.051

0.0505

0.05

0.0495

0

5

10

15

20

25

30

35

40

Runnumber

Figure 17b: Open and closed loop run chart for thickness

It is obvious from the figures that the process is improved after the closed loop process

kicks in. It can be clearly seen that the variance reduces drastically for the triangle height.

32

It decreases for the thickness as well but not as much. A summary of the quality

improvement is show in Table 5.

Table 5: Quality improvement summary for height output for cold parts

Output

Mean error

Loop

Steady-state

Variance

Variance (x10-6)

ratio(reduction)

0.8129

1.459

0.8118

0.8281

0.0531

0.9428

Open

Height

0.57

Closed

Open

Thickness

0.45

Closed

0.0552

0.4277

The graphs fior the hot parts with an adjusted mean are shown in Figures 18a and 18b.

Triangle -adjusted

U.0I

mean (hot)

-

0.8150.814

0.813* 0.812

s Open loop

-*_ Closed loop

._0)

I~0.81 1

0.81

~~~~~

0.812

-.-- Open loop~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

C0.809

0.808

C0.807

0

10

20

30

40

50

Run number

Figure 18a: Open and closed loop run charts for height for hot parts with a target mean

of 0.809

33

Thickness - adjusted mean (hot)

U.Ub05

/

0.056

0.055

Open loop

0X

Closed loop

(0.053

I--

0.052

0.051

0.05

0

10

20

30

40

50

Run number

Figure 18b: Open and closed loop run charts for thickness for hot parts with a target

mean of 0.56

In the case o(f the adjusted mean, the data shows that the process does not move to the

new target specifications as quickly as it did in the MISO system. However, it eventually

gets to the target values or close to the target values and stabilizes. The quality

improvement is summarized in Table 6.

Table 6: Quality improvement summary for height output for hot parts with adjusted

means

Output

Loop

Mean error

0.8126

Steady-state

Variance

Variance (xlO-6)

ratio(reduction)

1.638

Open

0.51

Height

Closed

0.8093

0.8391

0.0540

1.145

Closed

Open

0.465

Thickness

Closed

0.0556

0.5329

34

In order to show the actual effects of the improvement, the values for the closed loop

system used are the last 12 data points. This is because the gradual process which drives

the process to target specifications would throw the data off. Ideally, this should not be

the case as gains are expected to move the process to target values within 2 time steps at

best. This discrepancy can be accounted for by the fact that the Kp is not always exactly

known hence the product

Kl

#I

therefore the process might not be at its best

performance state.

The model was not always very robust. In one of the runs in which the target thickness

was the same value as the mean thickness in the open loop run, the usual reduction in

variation observed during the closed loop run was hardly noticeable. Figure 19 shows the

results obtained for the run.

Thickness - same mean (hot)

t rnc"

U.56

0.056

0.055

(0

X

0.054

-.- Open loop

--= Closed loop

M 0.053

0.052

0.051

0.05

0

5

10

15

20

25

30

35

40

Run number

Figure 19: Open and closed loop run for the thickness during a MIMO feedback control

run. The target value for the thickness was 0..

Interestingly, zero mean error was observed for this run. However, the variance hardly

decreased and changed from 1.14e-6 to 1.007e-6 - a variance ratio of only 0.88.

35

5.0 CONCLUSIONS

The experimental application of MIMO CtC feedback control has been thoroughly

explored in this thesis. The gains were determined through a DOE and MISO and

MIMO CtC feedback control process were tested. It has been shown that the SISO CtC

can be successfully extended to the MIMO system and achieve similar improvements in

quality. The variance ratio

(closed

oop/Gopen

loop)

was found to be as low as 0.14 for the

thickness in the MISO system and was found to be as low as 0.51 for height and 0.45 for

thickness in the MIMO system. Mean error was minimal and was almost zero in certain

cases. This proves that the MIMO process can indeed be used to drive a process to a

specific target values whiles simultaneously reducing variance. These decreases in

variance and low mean error would improve the values of Cpk hence improve the quality

of the process.

During experimentation, it was noticed that the uncertainty in measurement could be

quite high. A slight change in measurement location was enough to throw the data off. It

was also difficult to assess the effects of warping on the part as it varied from part to

part. It was difficult to conclude whether or not warping played a significant role as the

data sometimes appeared to be affected by other factors besides the changes in the input

parameters. It was concluded that these external factors were all a part of the random

error of the process. It was noted that these errors probably accounted for the slow

settling times that were observed especially in the case of the triangle diameter.

Future research in this area should be very critical of the part chosen for investigation. A

part with dimensions or outputs that are very easy to quantify should be used to alleviate

measurement uncertainties.

36

REFERENCES

[1] Hardt, D.E. and Rzepniewski, A. "Multiple Input-Multiple Output Cycle-to-Cycle

Control of Manufacturing processes

[2] Hardt, D.E. and Siu, Tsz-Sin. "Cycle to Cycle Manufacturing Process Control"

[3] Injection molding schematic.

http://islnotes.cps.msu.cdu/trp/images/video3/video3-2.jpg,

(Accessed on May 3,

2005)

[4] Siu, Tsz-Sin. "Cycle to Cycle Feedback Control of Manufacturing Processes". SM

Thesis in Mechanical Engineering, MIT, 2001.

[5] Manoosingh, R. Sasha. "Cycle to Cycle Feedback Control of Manufacturing

Processes" BS Thesis in Mechanical engineering, MIT, 2003.

[6] Hardt, D.E. MIT Course 2.830J lecture notes. Spring 2005

[7] Montgomery, D.C. "Introduction to Statistical Quality Control" Fifth edition, John

Wiley & Sons, 2005

37