DEVELOPING METRICS FOR CONCURRENT ENGINEERING AT ... COMPANY'S SURFACE RADAR GROUP by

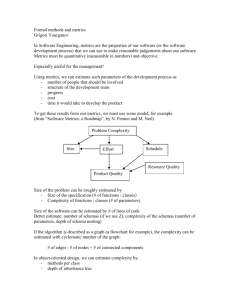

advertisement