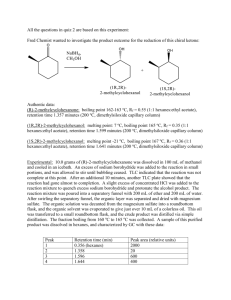

Studies Toward the Synthesis of

advertisement