MASS PRODUCED BUILDING SYSTEM FOR UNSKILLED ... By: Angelo Petrozzelli, Boston Architectural Center,

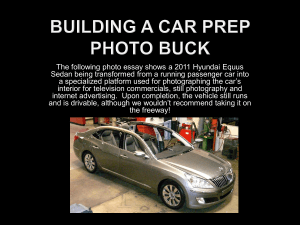

advertisement

MASS PRODUCED BUILDING SYSTEM FOR UNSKILLED LABOR By: Angelo Petrozzelli, Boston Architectural Center, Certificate of Architecture, 1966 A THESIS SUBMITTED IN PARTIAL FULFILLMENT OF THE REQUIREMENT FOR THE DEGREE OF MASTER OF ARCHITECTURE AT THE MASSACHUSETTS INSTITUTE OF TECHNOLOGY June 1972 Department of Architecture, May 12, 1972 esis Superv 6r Chairmnan, Depar aent Oominittee On Grad e Students Rotch JUN 27 1972 MITfibraries Document Services Room 14-0551 77 Massachusetts Avenue Cambridge, MA 02139 Ph: 617.253.2800 Email: docs@mit.edu http://libraries.mit.edu/docs DISCLAIMER OF QUALITY Due to the condition of the original material, there are unavoidable flaws in this reproduction. We have made every effort possible to provide you with the best copy available. If you are dissatisfied with this product and find it unusable, please contact Document Services as soon as possible. Thank you. The images contained in this document are of the best quality available. 405 Saratoga Street East Boston, Massachusetts 02128 May 12, 1972 Dean William Porter School of Architecture and. Planning Massachusetts Institute of Technology 77 Massachusetts Avenue Cambridge, Massachusetts Dear Dean Porter: In partial fulfillment of the requirements for the degree of Master in Architecture, I hereby submit this thesis entitled. "Mass Prod.uced. Build ing System For Unskilled. Labor". Respectfully yours, Angelo Petrozzelli Enclosure ABST RACT A Strategy For Developing A Mass Produced Building System For Unskilled Labor by Angelo Petrozzelli Submitted. to the Department of Architecture on May 12, 1972 in partial fulfillment of the requirements for the Degree of Master of Architecture. It should. be noted that this thesis is a continuation of an .earlier submission by the office of Imre and Anthony Halasz, Inc. and. various other participants. This submission was part of the H.U.D. Operation Breakthrough Program RFP No. H-55-69. The reason for selecting the development of a mass produced build.ing system for unskilled. labor is my reaction to presently available housing systems that by their size and. complexity create a physical and human strait jacket Ill suited. to user participation in any stage of its development or existence. This thesis prepares the ground. work for a building system sympathetic to this need and applicable in the immediate future at minimal cost. It is the hope that this thesis will stimulate a research program to d.evelop a full-scale model to test and. improve the system. The illustrations shown in the text deal with housing, but the system is not limited to this use. It seems to adapt well to other building types with similar clearance and span requirements. Thesis Supervisor: John Steffian Associate Professor of Architecture iI ACKNOWLEDGEMENTS I wish to express my deepest gratitud.e to Professor John Steff ian and Professor Waclaw Zalewski for their participation during this unselfish study for my graduate work, and I wish to include in my thanks the many faculty members and staff of the Department of Architecture. I wish to thank my associates within the staff of the archi- tectural office of Imre and Anthony Halasz, Inc. especially Imre and. Anthony Halasz for giving me the opportunity to complete my work at the institute and for their contributions to my academic enrichment. I also wish to thank them for the personal relationship which has developed not only during this experience, but also within the last five years since I have known them. My gratitude extends to Mr. Frank Ransome of the Wheeling Steel Corporation, and Mr. Kenneth Sisson of American Architectural Iron, for help in obtaining the structural members and universal connection development. Finally, family, my deepest gratitude to the members of my immediate especially my parents, for understanding and unfailing support over the number of years it has taken me to complete my education. done. Without their support I do not know what I would have I also wish to thank my personal friends who have encouraged me to continue with my studies. III TABLE OF CONTENTS TITLE PAGE ABSTRACT 11 ACKNOWLEDGEMENTS 111 TABLE OF CONTENTS iv PART 1: PART 2: PART 3: GOALS AND DESCRIPTION OF THE SYSTEM a. General b. Architectural c. Structural d. Interior Work e. Mechanical, Electrical f. Foundations SYSTEM ADAPTABILITY a. Housing Types and Scope b. Climatic Areas c. Geology and. Soils d. Site Topography e. Site Size f. Site Situations g. Changes h. Regional Application 10 SYSTEMS COMPONENTS 15 (Introduction of system as related. to housing) iv PART 4: PART 5: MODULAR STUDIES (System Applications) a. General Site Matrix b. Diagrammatic Layout of Housing Matrix DIAGRAMMATIC EXAMPLES OF HOUSING TYPES a. Row House using a 20'-0" Matrix b. Row House using a 32'-0" Matrix c. Townhouse 33 39 PART 6: PHOTOGRAPHS OF MODEL 75 PART 7: BIBLIOGRAPHY 80 PART 8: MECHANICAL SYSTEM DIAGRAMS 63 V GOALS AND DESCRIPTION OF THE SYSTEM ~ -l1- A. BUILDING SYSTEM CONCEPT 1. GOALS AND DESCRIPTION OF THE SYSTEM a. General The basic rationale underlying the concept of this proposed building system-is that the system should not only fulfill the needs for shelter but also should. become a source of employment, primarily for the unskilled of our society. The essential feature of this system is simplicity, based on the following objectives and solutions. 1. Participation by the unskilled or semi-skilled members of society, erect, who would be able to and maintain the system with minimal training and. supervision. ii. Minimal capital investment for production and construction so as to allow immediate application in any volume, anywhere and throughout the country. iii. The use of available commercial products in order to minimize new building components. A few of the system components may be especially fabricated., but the parts will be standard. It is hoped that these components will be stocked in local outlets. -2- iv. Shop fabrications should be done with minimum investment on the part of the supplier. Fab- rication of some of the components may be accomplished on the site at first in order to keep investment to a minimum. V. The components shall be of a size and weight that can be handled. manually by two people. This will result in components. modest spans and small Small component size will allow greater individual freedom for different assemblies and will allow the system to be adapted to a wide variety of needs. vi. Simple mechanically fastened joints are intended for the entire system without using special equipment and skilled. labor. vii. A universal joint is proposed. at all inter- sections of structural members. viii. The system will expand or contract in every direction due to the use of the universal joint. Change and. growth can occur without disruption of the finished spaces already occupied.. viiii. The system will take advantage of readily available components from other systems that are practical and usable. -3- x. High standards of quality, low cost, easy adaptability to individual preferences, com- bined with the consumer's possible involvement in the production and marketing process, should assure his acceptance and identification with the housing product. Following this logic the system consists of a series of independent replaceable infill structural frames with panels that constitute all finished surfaces. Prefabricated mechanical units will form an integral part of the system. b. Architectural The architectural i. character of the system. Additivity One of the chief dangers generated by prefabricated and preassembled. industrial systems is that they often eliminate flexibility. This system, both in the relationships of its components to each other and themselves, is based on the principle of additive flexibility. ment, be it settlement, in the components The resulting environ- an individual house or a complex can be molded. and. articulated according to specific need.s and human desires rather than forced. into an imposing preconceived industrial strait jacket. 11. Component Parts The principle of additivity is maintained by the relatively small size of the basic floor and wall panels between the structural frames. Since the assembly of the components is designed for the utmost simplicity, the number of joints does not adversely influence cost. spans, However, by virtue of modest small components, freedom of different and. great individual assemblies the system can adapt itself to a wide variety of needs. Old. systems based on large component parts often offended. our sense of human dignity by limiting additive modulation. The selec- tion of the smallest component parts, readily available through the regular channels of the construction industry has its not only in cost, easy handling, advantages self-help, etc., but chiefly in that the small component parts enable the user to contribute to the form of his environment, and initiative, exercise choice and. thus restore his pride in his place of living because he can adapt the system to his specific needs and requirements. -5- ii1. Diversity Since the system consists of relatively small components and. a very large degree of additive flexibility, it can adapt itself to different housing densities, site conditions, and. individual needs. Since the wall panels are designed for additive flexibility, can adapt to different they climatic conditions, as well as various zoning and building code requirements. The main test of every contemporary system is its growth. behaviors in terms of change and The proposal allows change and growth on different levels. It can most easily expand. in every direction by virtue of the universal joint. It permits the alteration of the standards of housing units themselves, even in higher d.ensities, by exchanging components without interfering with the rest of the units. Since the proposal d.oes not concern itself with a building as a product, but with an additive process it will change itself through field experience, demand., research and human ingenuity. -6- The ease of assembly implies the ease of dismounting. Change and growth demands addition as well as removal of parts in relation to the whole, c. without disruption. Structural 1. Low-rise Construction The basic structure consists of a light gauge metal frames and infill form all finished panels that surfaces. A prefabricated "universal" which is at every intersection be- placed joint piece, tween frame members, allows simple attachment of column and. beam units. exceeds 150 pound.s in weight. connections bolts. in No element All frame the field are by high tensile Details are such that while all the frame parts will be prefabricated in a shop, all assembly will be handled. by unskilled labor, without any hoisting equipment. All panels, for floors, walls and. partitions, exterior and interior are of standard manufac- ture and are set into the frames by simple connections. devices is The use of advanced. fastening contemplated to assure easy, and safe assembly. rapid Fairly large tolerances O-7- are employed to avoid the need for exacting precision. designed to withstand The frame structure is all vertical loading and the effects of wind. or earthquake forces. ii. High-rise Construction The system is adaptable to any building height with the provision that it becomes a subsystem in a megastructure whenever it exceeds four stories. In such a case a basic concrete frame, consisting of columns, core walls and. floor slabs at four-story will be constructed. a four-hour fire intervals The structure serves as barrier, both in vertical and. horizontal planes, in addition to its load bearing function. gauge steel frames and The low-rise light infill panels will be plugged into the megastructure, with provisions for fire protection. While the megastructure will demand labor, all the infill skilled. structure will be manufactured and. assembled exactly as the low-rise units. d. Interior Work Prefabricated assemblies of stairs, cabinets, -8- partitions and closets are introduced into the system, at a wide variety of possible modular applications, allowing any pattern of growth and. change, e. Mechanical, Electrical The general approach, here as well as in the structure, is based on the following premises: i. Simple mechanical installation by unskilled labor. ii. Individual control of the mechanical system in each dwelling and independence from occupants of other units. iii. Possibility to change, remove or upgrade the mechanical installations. A suggested outline specification has been developed for some housing units investigated. These are included in the Appendix. f. Foundations The system is points, designed to be supported at discrete the cases of the frames. As such, it is applicable to practically any soil condition. The flexibility of the steel frames and the tolerances between infill panels make the system relatively insensitive to minor differential settlements of the supports. -9- SYSTEM ADAPTABILITY -10- 2. SYSTEM ADAPTABILITY a. Housing Types and Scope The proposed system will allow maximum freedom of choice and degree of self-participation at densities up to 15 units per acre. At these densities the capacity for growth and change can be employed to a very large extent. Simple family detached or attached homes can expand in all directions in small or large increments by the use of building components (stair, mechanical unit) and by use of columns, universal joints and panels. The limit of the proposal serving as a primary system is in the range of 40 dwelling units/acre. The accompanying illustration assumes the following restraints: 100% parking on-grade parking limited walking distance from car to units walk-up with maximum two flights of stairs emergency and service traffic only within the residential matrix no more than four stories (possible duplex on top) Residential densities higher than 40 u/a will adapt the proposed components as infill or -11- secondary systems. These densities will change the rationale of parking relationships and circulation considerations in general. The attached. site application addresses itself to the upper limits of the system in terms of its residential densities as demonstrated in the This type of site utiliza- general site matrix. tion is a long neglected. prototype for urban housing. The well known later d.ay prototypes in the lower and upper extremes of urban residential densities did. not fulfill the aspirations and promises of their urbanistic conception. Not only did they stereotype their architectural presence but a noncompromising social segregation followed.. The careful study and revitalization of middle density housing is system is most timely and necessary. The proposed best suited. to such middle density appli- cations while still in effective all other types of residential development. b. Climatic Areas No restriction. Steel frame is designed to resist zontal and vertical load. such that any insulation Infill any specified horiconstruction is value is attained by using an appropriate insulating blanket. -12- c. Geology and. Soils usable on soils with poor natural The system is d.ue to the relative drainage and unstable soils, flexibility of the structure which is capable of adjusting to differential excessive stress. settlements without All infill panels allow minor distortion without damage to them. d. Site Topography footings with piers of adjustable At sloping sites length will allow the use of the system both in the same form as on flat the introduction of partial e. as well as with lower levels. Site Size adaptable to any site The system is f. sites size. Site Situations The basic concept of the system, in its simplicity the use of unskilled. labor and finished light materials that are available anywhere, renders it applicable to any site situation and. basically independent of local labor and material supplies. The presence of existing or removable structures d.oes not restrict g. the applicability of the system, Changes All components are removable or can be added on, as desired.. Thus the standard. of surface finishes, cabinets, etc. can be improved at any time by simple exchange of panels. Expansion and re- arrangement are handled. similarly. In many cases the frame may be erected. at the time of construction, to serve as porch or terrace, and. later enclosed by snapping the finished panels into the frames. h. Regional Applications No restriction. -14- SYSTEM COMPONENTS -15- PREFABRICATED FLOOR PANEL -'7 7' 7 - BEAMS 6-COLUMN TYPE: B N CANTILEVER WITH CONNECTOR ATTACHED ISOMETRIC OF TYPICAL COMPONENTS 0 K 2 4 8 I2GA.JOIST HANGER COLUMN SLEEVE ELEVATION OF UNIVERSAL CONNECTOR: TYPE A 0 1 2 -SLEEVE COLUMN ;D I JOIST HANGER C-' PLAN OF UNIVERSAL CONNECTOR: TYPE A 0 1 2 I I. T 474k 'II. I. 10"-12GA.BEAM 6-COLUMN 0 SECTION AT TYPICAL INTERIOR JOINT 1 2 id"LJ.""""" l0'-2GA.BEAM PLAN OF TYPICAL INTERIOR JOINT 0 1 W"6.rmm7 2 f I. I I I I I. ~ I. -- ~ ----.- .- - -. .-- BUILDING PAPER PREFABRICATED t-R PANEL '---I I -- 3A8'PLYWOOD -I u~ - - - I- - -I cc17 2 ~c7 I-, £~ ) - V 1 (C ~IZ§. cEZT' I %~ -I - - -i S.111e1 0 6"u CLOSURE I f -1-. - - SECTION AT TYPICAL INTERIOR JOINT 0 1 2 121-/""""" -~ .-... 9- 9.9 - - PREFABRICATED FLOOR PANEL 1~ ~~~1 - --- 4. -I lIFI IZIZIL- -7 Z-------- V L .L1Th I I - I -1 ---- 4-----I 1L ,, W~rF1 ,~jII1 x x IA ~~1~ - I II iii I -U ii I - II I. I-III ii ii I' -- ' -I- ii, \) K -- III :K I - - I - --- 4IXDBVWflflfl ~ - I I- . I ............... I- I JIlL - - 2 - Fri Mi I I - I - I - PLAN OF TYPICAL INTERIOR JOINT 0 1 LJ"LJ"""""" 2 - r a I C I C PLATE INSULATED PANEL |TRANSLUCENT WALL EXTERIOR WALL SECTION 0 Ll"l 1 2 """""" I OR 3 4 - - - - - - - - - ~~1 -I I. 1 _-z -7--- 7 ~zjI '4. _______ i -~-1 t *i I 1 1: ~~~1~ '4, ~~~~1 -. 1 t - 4 - / I - ~~~~1 -I COVER PLATE AT CONNECTOR --- ~----I - 7 - I - ~iL ~' I/I r \ ;\~ 1\\' ~' II I ~ ~ ~ TRANSLUCENT WALL -I "' 7 - -x A- 0 PLAN OF EXTERIOR CORNER 1 2 Lfl-/"""" *1* - 7 * A / - -t I. -I I.. ~1: 1 KN A- -I -I. I PLAN OF EXTERIOR CORNER AT FOUNDATION I 0 1 2 - se e- -.- Z-- - s- - - - k I -I ~di *1. -i 1- - iA~ ~4j .1 7: A I 717 '7 K. ~~t~iI "N .1 N ''It * -* * \\ . . - - I .'' I.. \\* --I- ) i (i- EXTERIOR WALL SECTION AT FOUNDATION - - - EXTERIOR WALL SECTION AT ROOF ~Lr~9 "2" - * 10%2GA BEAM PLANS OF UNIVERSAL CANTILEVER CONNECTOR JOINT TYPE: B h"jW ? 4 W4J V, 4 /4"A 141 I iv F4 N'___ kl '---' _____ It I I II I I II * ii I. 4 IT I OPEN I I I I I -I I I I I I I I I I I I E-.JOIST HANGER I I I I. I I I II a I I I 1~' Is II 0; I I I 8 1.-i I I I I. * r- I ii - Je" I i~ II I I - 2x6COLUMN 11 I I It I.o I SLEEVE 4.-J II r A. ~1 ELEVATIONS OF UNIVERSAL CANTILEVER CONNECTOR: TYPE B 0 1 2 LM'.2"""""" L 2 SIDE ELEVATION-TYPE B CONNECTOR END ELEVATION 0 1 2 EXANSION 1 MINIMUM UNIT 2 1 BEDROOM UNIT 4 3 BEDROOM UNIT ADAPTED TO SLOPING SITE SELECTIVE SEXPANSION 3 VERTICAL 3 BEDROOM UNIT STRUCTURAL ADAPTABILITY / % / N 'I 4C / / / II / / N ) / N 110 FLOOR PLANS %A SYSTEM APPLICATION -.33- Construction Cost ($/L.U.) Environmental Cost (S/L.U.) 0O I -o Proposed system primary Max. possibility for self-help Adaptability and change And growth for each Living Unit 1-2 stories .detached Proposed System Primary 1-3 stories attached -.-.-- - 1~ Establishes a Range of I. possibilities for self-help, Adaptability and change and growth for each Living Unit CD 3-4 stories attached / L Ca r__ Proposed System subsystem of High Density 4;r 0 'Structural Matrix. Limited possibility for self-help -Adaptability and change and growth,for each living unit SYSTEM APPLICATION DIAGRAM C VWV I I I :Z ct\ - SYSTEM APPLICATION DIAGRAM This diagram is a generalized illustration of the relationship between cost and type of housing development. divided into three categories per acre. in Housing is terms of number of living units These categories and. the implications of the pro- posed structural system for each category have already been discussed. The solid-line curve in the diagram represents the relationship between construction cost and density of housing. dashed-line The curve represents the relationship between environ- mental cost and intensity of land use, i.e., the environmental factors, or costs, necessary to develop a socially and economically successful community. The underlying assumption is that the success of a housing development depends not only on the comforts provided by the living unit itself, These services range from services available to the community. utilities, open spaces, but also on the parks and recreation areas, schools, shopping centers, community centers, transportation networks, etc. to more abstract benefits which determine the quality of socio-economic life. Based on past experience with housing types and community development, it is assumed that the cost per living unit of these supporting services decreases as the intensity of land use, hence the sharing of facilities by larger numbers of living units, increases. -35- However, this relationship is not directly proportional. The diagram indicates that the benefits of increasing land use intensity grow in smaller increments as increasingly high densities are reached. These considerations led to the selection of the 15-40 living units per acre density as the area of intensive study; shaded area in diagram). because it (the This type of housing was selected represents the low to medium range in terms of construction cost and promises better environmental benefits with increasing land. use intensity. The 15-40 living units per acre d.ensity was selected for intensive study because it appears to be more economical in terms of construction cost and of environmental cost, and also offers a desirable range of possibilities for self-help, adaptability, and change and. growth for each living unit. The proposed construction system may be used to develop a wide range of site plans at a density of 15-40 living units per acre. The "General Site Matrix" and the "Diagrammatic Layout of Housing Matrix" illustrates a possible application of this system. -36- LiLLLIfltI ~LIfl~114~41ILi~i1i~1 LLLLLL --. - .......-:.......; -- - - --- - LLi -. .... .-... - ., -mmI om- -- *om' Ii - _- _ _ _.- -- ..-.. s LL* f housin 167 F _ _ - i -- -i ix - t el sch.j1K ~-~It SITE MATRIX jL -f~ - h el sh GENERAL -- rFir CO 0 Com Com -.. PARKING FEEDER ROAD POSSIBLE CENTRAL PEDESTRIAN ROUTE TO COMMUNITY FACILITIES PARKING FEEDER ROAD PARKING PEDESTRIAN OCCASIONAL SERVICE ACCESS PLANTED SPACES BETWEEN BUILDINGS THIS DIMENSION EXPANDS WITH INCREASE IN HOUSING UNITS THIS DIMENSION IS DETERMINED BY QPTIMUM WALKING DISTANCE THIS DiMENSION EXPANDS WITH INCREASE IN HOUSING UNItS DIAGRAMMATIC LAYOUT OF HOUSING MATRIX DIAGRAMATIC EXAMPLES OF HOUSING TYPES: 20'-O"MODULE UNITS -39- E VEXP IB 2B IB 3B IB 2B 3B -7 i~~1 IB B (.EXPI- POSSIBLE FAMILY GROUPINGS 20' UNIT MATRIX LEGEND E EFFICIENCY APARTMENT , 1B ONE BEDROOM APARTMENT 2B ~TWO BEDROOM APARTMENT 3B THREE BEDROOM APARTMENT C CLOSET [SHADED AREAS INDICATE POTENTIAL EFABRICATED COMPONENTS io 0 -I74 - - - -9 - 04 .9 -~-. -. -. IZV - -~- - - .8/1 - 119 .9 ,~I 1,9 i I-= 0 U. E&1B FLOOR PLANS ,7 (C4 '0 sk - I- 0 ..J 2B&3B FLOOR PLANS 2B IB E SECTION 3 STORY -Jt V 3B 2B IB E SECTION -4 STOR Y DIAGRAMATIC EXAMPLES OF HOUSING TYPES: 32a-O''-MODULE UNITS -48. SPACE STANDARDS It is suggested that another method. of reducing costs in housing units is by examining present-day space standards. Significant savings in low-cost housing can be achieved by a reasonable reduction in these standards. The following plans are based on English space standards currently recommended as minimum standards. IB E IB E 2B 3B EXP EXP L L1 -- E E IB IB IB 2B EXP EXP POSSIBLE FAMILY GROUPINGS 32' UNIT MATRIX 60412@ 6 B' 6,4z121 T1 6ON -4 40 4 STRUCTURAL LAYOUT 1---tas LIV.-DIN. LIV.-DIN -SL. K K BR. STOR. 1B&E FLOOR PLANS I 2 4 4 'I, 4' t 4 4 C~4 4, c~4 -4 -. 4 --- iv~7C 4' STRUCTURAL LAYOUT 1B&2B FLOOR PLANS E&3B FLOOR PLANS 2B-IB IB-28 E-IBCINSO SECTION 3 STORY - E-3B IB-2B IB-E E SECTION 4 STORY DIAGRAMATIC EXAMPLES OF HOUSING TYPES: TOWNHOUSE MODULE UNITS -58- ii- 1ST FL. SECTION 2 ND FL. 2B 1ST FL. SECTION 2 NDFL. 2B 1ST FL. SECTION 2 ND FL . 3B 1ST FL. SECTION 2 ND FL. 3B APPENDIX 1 MECHANICAL SYSTEMS DEVELOPED FOR ILLUSTRATED HOUSE TYPES HEATING PLUMBING ELECTRICAL PLUMBING The basic design of plumbing is in accordance with the "Recommended Minimum Requirements For Plumbing" (Hoover Report) as published Commerce. by the United States Department of Consequently, all sanitary piping is not only inexpensive, but, as can be observed by inspection of the drawings, also lends itself tion by unskilled labor. and where there is in its simplicity to installa- In single family isolated units, no incentive towards inclusion of hot water, individual hot water heaters are installed in each unit. Hot water heaters may be gas or electric as dictated by fuel and energy costs at each specific location. rent inclusion of hot water is permitted Where in multiple occupancy units, further economies can be realized by providing one hot water heater per building in lieu of one hot water heater per dwelling unit. ferrous, nonferrous metal, Piping materials can be or synthetic as indicated at each location by availability, adaptability, acceptance, and cost. HEATING AND VENTILATION Heating of each apartment is accomplished by a warm air furnace located in each unit and discharging directly into a ceiling plenum. The plenum is fabricated under the general construction, thus avoiding sheet metal work. The system can utilize fossil fuel or electricity as a source of heat as dictated by economic analysis at each location. The system requires no skilled labor to assemble in the field. Techni- cians are required only during initial firing where fossil fuels are incorporated. and. not at all utilized. Interior where electric heat is Each apartment will have its own thermostatic control. bathrooms are exhausted. through shafts constructed. in the general construction and topped by wind-driven turbine exhausters. Interior stairways are also similarly ventilated. bymeans of wind-driven turbines at the top of the staircase. Both.avoid expensive wiring, fans, and. maintenance. Accordingly, installation of the heating system consists primarily of setting a single factory assembled warm air place. heating unit in Sheet metal duct work is almost non-existent. heating system lends itself The readily to rent inclusion of hot water or to individual metering as may be desired. It also lend-s itself to future installation of mechanical cooling. -65- ELECTRICAL All wiring conforms to the requirements of the National Electrical Code. Individual fuse boxes in each apartment permit convenient servicing of the system by each tenant as well as individual or master metering of electrical consumption. Cooking can be electric or gas. Branch wiring is inexpensive aluminum not metallic sheathed cable. Telephone system can be readily prewired in the construction. -+ 14J PNA-tQQo r UtVT 7VJiIly A 0 , A~ I -VA e. T4~- PI (A* Se _:, ~E~TiQt~-4 - 5V-AIE E7 LAETPk L 7- ~i-p <'I' m I' A-1\ -. CLA, LE - V4!'- I'- 0 " ThV-LP- Y .11'11 ___________ QG V 6Q IJ%- ,-j ~C(~ A -PLIEN4U &~A " 1 t, IE cc)vi 60~c~.~ wA~C.e t-.?F % ~ E I lcT to wJ §1 ILL -A 9IL \L '-p V4 \f%.1 - - .0 0 - -- z e~ L M 011T -rO V::' F L Q-Pk E T ALuPE tTO 5 0 Ck, is N=7% VA 0 0 C:> C> R 46 1: N Fu~wNc-L~ 0 VA vv -" E 1,.-t E-t L. ... 0t. T-i v-> r - T TO j A ~C) -- T7 L wo 0 T- lati 6 R A% CE t C U3 (9 &rtA ~TE b. TM cik% DI pics\L- .AL LCt~ S q_ AI T W4 O~~1 P~pJ~S~A. _______c. "AOT WPTR No ~ \V-s 30 GA L GA 5 HL0H E%. tRCTc OE.CTCQIC, T-- pi "FL 0 0 r. PL u 3 CA L >I cK) , '-: '/6--l'-o'' Ok. H 4- }4"VTC~.. 2VF~- I - - 4. PPow5 4 it c.o 2, P> N V-4 C.O'. Kv& w t. -v ,R1<> EP - C O., ~ c W-. C=)%JT L/T A~~~ P. AT vA W W -r -- TL C\ C, W W- 00 CvW. t D IPcxA xJ - '' fVT rZ AC, Ac- A C- 'Vt Is'- - ~.P-*?~ P-I '2' i AC-- I 9 I" -W 21 A e A c. n.- Ac PF-I ?-2. P-4-- P-2 P.-J4 IT, Ac.. '' AL Ac- P-4 e-3 AC. p~3 P-3 U] "M RveWz EA/ NA/R ja \d E \/ D IA C b AT - 5 COLO - - - \/TZ H 6 C.O0. " w H to A T a W \/ EQ \ C- >P. j!TT VENT TrW /-4 2007 Wo 0SE- e.. %;!>e, C-- A u w TkAE ?--\.A P-3 L -.4 A c.. AT/ P.. 0E~4 LAVATOLARrZ %4 A T C T- U- t:> I A I r> c p A Mil EE, A CVW .. a H A, 'T c-s k4 kw Au na T E Tr. ER a J. 5E~. P,mF'A t.--A 4;-%WGLC- F-0 TY T-.-- Ict -L 9CLe U6WTIQC> OU17LC-.*A eA6.%JC-->FPUL u cHxjtj FLo c)1;;> 5C-ALC-: 'vs ""If-C)" F,L A, V.-I S',*417C" MTe,.) PHOTOGRAPHS OF MODELS -75- I e- -- - - - -BIBLIOGRAPHY -80- BIBLIOGRAPHY Thomas Schmid/Carlo Testa, SystemsBuild.ing--An International Survey of Methods, Frederick A. Praeger Publishing Company, 1969. "Aesthetics and. Technology of Preassembly", Progressive Architecture, October 1 9 64. "Metals Review", Progressive Architecture, October 1969. Don Raney and Suzanne Stephens, "Operation Breakthrough--Operation P/R", Progressive Architecture, Pagesl20-137, April 1970. Wells and Koetter, "Modular Housing System", Progressive Architecture, Pages 86-87, January 1971. Helmot E. Schultz, "Structure for Change and Growth", The Architectural Forum, Pages 60-63, March 1971. Special Issue on Build.ing Subsystems, Building Design and Construction, September 1971. "Building Systems", Engineering New Record, McGraw-Hill Publishing Company, October 22, 1970. "Housing Systems Propoposals For Operation Breakthrough", U.S. Department of Housing and. Urban Development, U. S. Government Printing Office, December 1970. "Modular Assembly (The Art of Design with Standardized. Parts)", Progressive Architecture, November 1957. N ~0* "Britain's Clasp System", The Architectural Forum, Pages 116- 123, November 1961. "Unskilled Mass Production of Housing Proposed For Type B Contract", submitted. in response to RFP #H-55-69 for Operation Breakthrough H.U.D. Proposal prepared. by Imre and. Anthony Halasz, Inc. and various other participants. "Wheeling Steel Framing", catalogue of structural framing by Wheeling Corrugating Company. Stressed Skin Panels, catalogue of plywood components by Plywood Fabricator Services, Inc. Strong Tie Connector, Structural Design and Load Values, Simpson Company. -82-