The Mitchell Framing System

advertisement

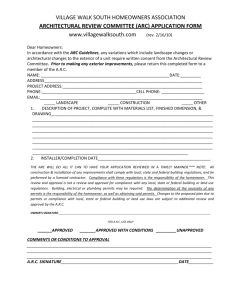

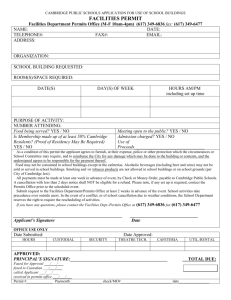

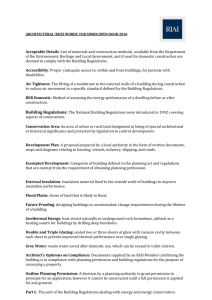

THE MITCHELL FRAMING SYSTEM A building system that encourages homeowners to have a direct involvement in driving building growth and expansion Neal Mitchell Associates 1041 Sutton Street Northbridge, MA 01534 Tel: 508-234-8646 E-mail: nmitchell2@aol.com WHY US ? • • • • • • • • • Low Cost Materials Low Cost Equipment Expands Using Local Capabilities Encourages Growth Of Local Businesses Same Components for 1 to 4 Story Buildings Flexible Architectural Solutions Flexible Architectural Unit Planning Ability To Create Entire Cities Ability To Put Lots Of People To Work The Basic Frame Is Made With 4 Elements • • • • Column Beam Tie Beam Slab The System Uses A Steel Jig To Accurately Locate Footings Components Can Be Easily Lifted And Carried By Two People Components Are Easily Assembled By Unskilled Workers Component Erection Component erection can be labor intensive when people need jobs, or when lifting equipment is not available. Components can also be erected using small scale and inexpensive hydraulic lifting equipment. Generally a small truck with an extending boom crane has been efficient for this work. The Frame Has Been Designed So that It Can Be Easily Expanded In The X, Y, And Z Direction Beams Can Be Lifted By Hand Labor To Upper Floors HOUSING GROWTH New frames can be added at any time so that the buildings can grow with the availability of homeowner funding. This permits possible expansion for up to four floors. Architectural designs are available for single unit buildings up to four story apartment buildings. The structural frame for buildings for the poorest members of the society must be designed to carry the same loads as those for the richest members of the society, so the investment in the frame becomes a permanent asset. CONNECTIVITY The Design of the beam/column connection involves a bolted connection between steel plates. The plates are rigidly attached to the forms during component casting so exact location is insured. All vertical connections are steel-to-steel connections so vertical heights are fixed. Frame Construction Accuracy of ¼” is insured in all directions by the fabrication process. Building Permits Frames To Grow Together And To Grow Up FRAME UNDER CONSTRUCTION This picture illustrates a basic frame before the infill walls have been added. This demonstration project illustrates a one, two, and three story building attached together to produce row housing for a small city. Note that the three story unit has a two story living room. The other holes in the slab are for the various utilities for the prefabricated kitchen and bathroom units. Frame Construction Permits The Use Of A Variety Of Different Local Wall Materials LOCAL MATERIALS LOCAL SKILLS A feature of the system is the use of locally available skills, and locally available building materials. In this case, the wall system is using field cast concrete blocks. In the Middle East these are commonly referenced as “Yemeni Blocks” because of their low strength and minimal use of cement. We coat these non-structural wall panels with an elastomeric skin coat for proper weather resistance. The Building Frame The frame can be in-filled with standard panels using various materials. The modular dimension of the frame allows the owner to bolt standard prefabricated panels for use as the building face. These panels can be unbolted and recycled when the owner wants to change the window location or size. The frame permits both easy growth and fenestration change as the owners income permits. TYPICAL LOW-INCOME UNIT PLAN TYPICAL FINISHED UNITS These demonstration Units for Lancaster provided one, two and three story units with wood framed walls. The single story house was built in Austin and it won a competition for design and minimal construction cost of $7,500. The house, built to American Standards, had two bedrooms, a kitchen, a bathroom and a dining/living room along with heating and air conditioning. Typical Mid Rise Buildings Low Cost Mid-Rise Apartments Unit plans are available for a large number of different designs for one to four story buildings. Flexibility of infill walls between the frames permits designers to apply a broad range of different elevation solutions. This architectural flexibility permits a rich variety of building elevations. Self Help Housing In Vietnam TWO STORY HOUSE This house used wall components that were purchased in the existing market. However, these wall components could not be manufactured in sufficient quality or quantity to satisfy an expanded market demand. We helped the owner apply new technology to the manufacturing process for these wall screens, and then purchased the existing output from this small shop. The business owner used the technology that he received from us to improve his product , and the money that he made from our order to increase his capacity. The Design Of Human Spaces Architectural Spaces Using Standard Components Low Cost Does Not Mean Low Quality Interior View – Low Cost House USER NEEDS FOR LOW COST HOUSING By using large space modules it is possible to tailor housing unit design to the specific needs of a family. Flexible wall treatments coupled with the ability to easily expand units puts the growth of housing in any area in direct relation to available funds and needs. Papers On The Technology Have Been Published By The United Nations THE FRAME HAS BEEN STRUCTURALLY TESTED This was the first full scale structural building system that was tested by the National Bureau of Standards. The building system resisted four times the required ultimate load with about ½” member deflection due to vertical and horizontal loads. At this load the NBS testing frame failed. The structural tests resulted in over 40 new additions to the building code. What We Offer Unit design, unit clustering design, urban design, plant design as well as technology transfer for the construction of various building components that will support the growth of a local building component industry.