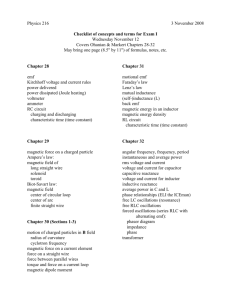

V P M

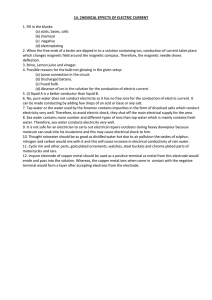

advertisement