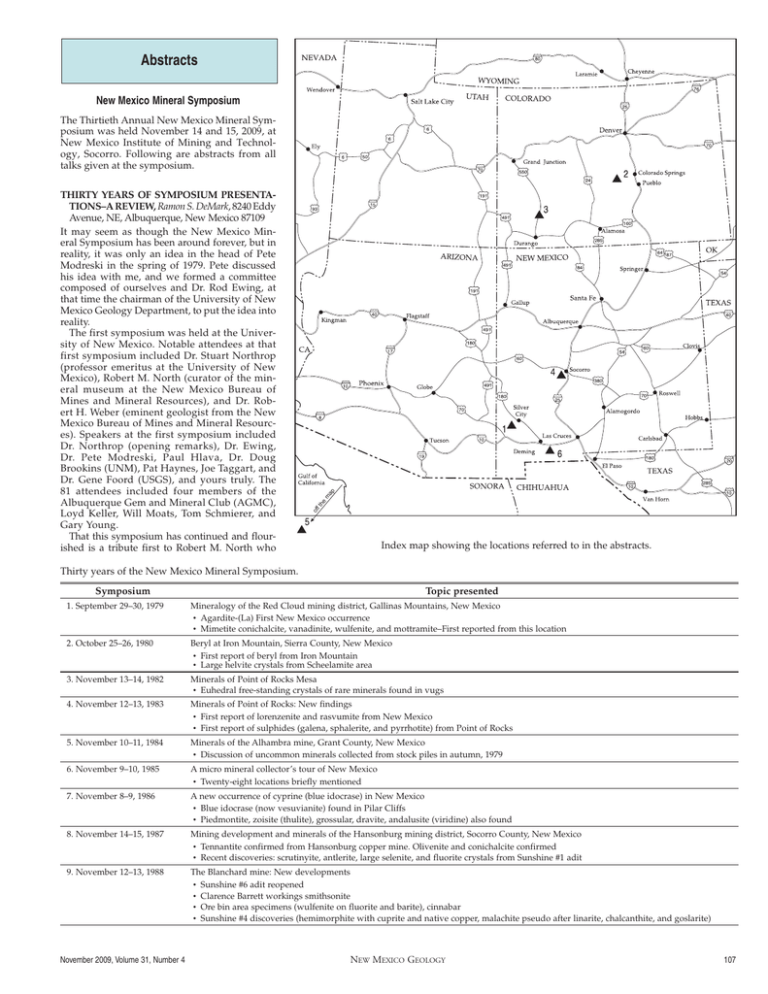

Abstracts New Mexico Mineral Symposium

advertisement