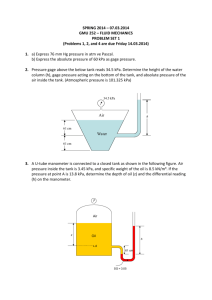

by

advertisement

Steam Bubble Collapse, Water Hammer and Piping Network Response Volume II. Piping Network Response to Steam Generated Water Hammer by R. Gruel, W. Hurwitz, P. Huber and P. Griffith Energy Laboratory Report No. MIT-EL 80-018 June 1980 IIMII IllIgiI lM H1ih N11 - l, I Steam Bubble Collapse, Water Hammer and Piping Network Response Volume II. Piping Network Response to Steam Generated Water Hammer by R. Gruel, W. Hurwitz, P. Huber and P. Griffith Department of Mechanical Engineering and Energy Laboratory Massachusetts Institute of Technology Cambridge, Massachusetts 02139 sponsored by Boston Edison Company Consumers Power Company Northeast Utilities Service Company MIT'Energy Laboratory Report No. MIT-EL 80-018 June 1980 -2- Foreword Work on steam bubble collapse, water hammer and piping network response was carried out in two closely related but distinct sections. Volume I of this report details the experiments and analyses carried out in conjunction with the steam bubble collapse and water hammer project. Volume II details the work which was performed in the analysis of piping network response to steam generated water hammer. Table of Contents Volume II Piping Network Response to Steam Generated Water Hamer Page Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . I. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . II. Experimental Apparatus . . . . . . . . . . . . . . . . . . . . 2 3 5 III. Experimental Procedure . . . . . . . . . . . . . . . . . . . . 12 IV. Theoretical Analysis . . ..................... .. Wave Propogation Model ... ............... . Governing Equations . . . ................ . . Formulation in Finite Difference Form . . . . ... 13 14 14 15 Representation of Piping Network . . . . . . . . . Cavitation Model . . . . . ................ . . Boundary Conditions . . . . . .............. . .. Deflection Model . . . . . . . . . . . . . . . . . . . 16 19 23 24 Bubble Collapse Model . ....... 35 V. Results . . . . . . . . .......................... . 38 Wave Propagation Experimental Resuls .... ....... Wave Propogation Theoretical Resu s . . . . . . . . Displacement Experimental Results . . . . . . . . .... .. 38 .. 44 Displacement Theoretical Results VI. ............. Conclusions 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 58 111 I N ., 4,11111 -3I Introduction Conventional and nuclear power steam systems require the transport of high pressure, high temperature steam and water through complex piping networks. During transient phases of operation, steam and subcooled water can be present simultaneously in a variety of piping and reservoir configurations. Under certain conditions, instabilities in the two phase flows can give rise to water hammer events. Most notable are the water hammers experienced in the feed pipes to steam generator spargers in pressurized water nuclear reactors. Little is currently known about the mechanisms involved in the evolution of water hammer. Creare (1977) offers a possible description of how instabilities in the feedwater pipe of a PWR steam generator can lead to the formation of an isolated steam bubble between two columns of subcooled water. Under such conditions, the steam inside the bubble rapidly condenses, causing bubble collapse and impact of the two water columns. This leads to the formation of high amplitude pressure waves which propagate through the piping network, causing deflections and possible damage to the pipes and their supports. This study combined with the work done by Gruel (1980) attempts to analyze the events which occur after the formiation Of an isolated steam vapor bubble. Experimental and theoretical models are developed to investigate the condensation process leading to steam bubble collapse, the mechanisms involved in the propagation of pressure waves through pipes, and the resultant fluid-structure interactions. The focus of this study is on experiments run with a small scale water hammer generator (Gruel 1980) which can be used to form an isolated steam bubble between two columns of water under stable conditions. By -4opening a valve, the steam is brought into contact with cold water. steam bubble collapses and a water hammer transient results. The The sub- sequent wave propagation and structural interactions can be measured in a length of pipe connected to the water hammer generator. Three theoretical models are developed to help understand three separately defined processes involved in the experiments. The first is a model of the condensation and initial collapse of the steam bubble. Gruel (1980) uses this model in the analysis of data taken for this phase of the study. The second model uses the method of characteristics (Wylie & Streeter 1978) to describe the propagation of pressure waves through the experimental piping network. Finally, a simple deflection model is used to help understand the fluid-structural interactions associated with the water-hammer transient. -5II Experimental Apparatus The experimental apparatus consisted of two components. was a water hammer generator (Gruel 1980) (fig. 1). The first The second component consisted of a freely supported U-shaped section of pipe (the test section), connected horizontally to the base of the water hammer generator (fig. 2). The overall network represented a system in which water hammer transients could be generated by the water hammer generator and subsequent system responses could be measured in the test section. The properties for all of the materials used in the network are listed in Table 1. The details of the water hammer generator (fig 1.) are fully described by Gruel (1980). The main features include the cold water reservoir, the steam ports and the quick action pneumatic valve. Immediately prior to each test, steam was circulated through the steam ports in the section of pipe below the cold water reservoir. was isolated by closing the input and output valves. The steam Activating the pneumatic valve initiated the water hammer transients by bringing the cold water in the reservoir into contact with the hot steam. The steam bubble rapidly condensed resulting in a depressurization of the vapor cavity. A column of water from the reservoir accelerated into the network and generated high pressure transients on impact with the stationary steam-water interface. These pressure transients propagated through the test section where the network responses were measured. Three geometrically identical test sections, (fig. 2) built from three different materials (see Table 1): 3/4" carbon steel pipe, 3/4" copper tubing and 3/4" CPVC pipe, were used in the experiments. Pipe unions were incorporated for the easy instalation of the test sections -6- Pressure Ports for Operating Piston Reservoir Pressure Port Water Inlet * Cold Water Reservoir 4-Pneumatic Valve Water Level 0 Piston .23m Steam Pressure ' Gage T2 Thermocouple Port .65m Steam Inlet Valves TI Thermocouple Port Steam Outlet xan Section .27m .20m Steam -Water Interface _I .02m Pressure Transducer P2 -Outlet to Test Section Pressure Transducer P Fig. 1 Water Hammer Generator Fig. 2 Piping Network Test Section Table 1: Properties of Materials Used in Piping Network Test Sections Water Hammer Generator 6" steel Reservoir 1 1/2" Steel Pipe 1 1/2" Lexan Pipe 3/4" Steel Pipe 3/4" Copper Tubing 3/4" CPVC Pipe .1778 .0483 .0444 .0267 .0222 .0267 Inner Diameter (ID) (m) .1524 .0407 .0381 .0208 .0189 .0188 Wall Thickness (e) (m) .0127 .0038 .0032 .0029 .0017 .0039 Elasticity Modulus (E) (kPa) 207 x 106 207 x 106 2.76 x 106 207.0 x 106 119.0 x 106 2.9 x 106 Material Density (p) (Per Unit Length kg/m) 51.4 4.033 0.490 1.683 0.954 0.490 (7.806 x 103 ) (7.806 x 103) (1.200 x 103) (7.806 x 103) (8.908 x 103) (1.55 x 103 1360.5 1368.4 456.6 1390.9 1318.0 "682.9 Outer Diameter (OD) (m) (kg/m 3 ) *Wave Speed (c) (filled with water) 0: oo (m/s) Pwater -1/2 1000 kg/m Cwater = vTT + = 1440 m/s C. water Pwater Ee ID) M I 1III il II I III l1 II into the network. inmEE~ hIYInIYInmIIIYY m __ -9The copper and CP.VC test sections were supported vertically at the end of the "U's" to prevent them from sagging under their own weight. To minimize the effect on horizontal displacements, the support was provided by attaching a long thin wire from the ceiling to the "U". Pressure waves propagating through the test section created unbalanced horiztonal forces when they passed by the two elbows of the "U" (see deflection model). Resultant displacements of the pipe were measured at the two locations indicated in fig. 2, one at the end of the "U" (x = L) and the other at the halfway point (X = L/2). In addition the pressures were measured at two of the three pressure ports provided in each of the test sections (fig. 2). Instrumentation The instrumentation used in the experiments. consisted of devices for measuring the temperatures, pressures and displacements of the piping network. Two types of measurements were made; first the steady state initial conditions and then the transient responses due to water hammer. The initial steam and cold water temperatures and pressures were recorded immediately before each test. Two iron-constantan thermocouples were used for the temperature measurements (fig. 1). Initial pressures were measured with two bourbon pressure gages, one located in the steam line (fig. 1) and the other (not shown in the figure) behind the reservoir. The transient pressure and displacement histories of the test sections were recorded in each test, using three piezoelectric pressure transducers and one displacement transducer. Two of the pressure transducers were -10- used for high pressure measurements and were located at positions P 1 and P3 (fig. 2). The third, a low pressure transducer was used to record the steam bubble depressurization history (P2 % fig. 2). The displacement transducer was located at either of the two points (D1 or D2 ) shown in fig. 2. The pressure and displacement signals were led through various signal conditioners to a storage oscilloscope. All oscilloscope traces were recorded using an oscilloscope camera. Table 2 gives a complete list of instrumentation used in the experiments. A total of 5 different transients (PlA' P2' P3 , Dl and D2 ) were recorded for each set of experimental conditions. However, the oscillo- scope was only capable of recording two traces at a time. This required the repetition of tests under identical conditions to compile one complete set of data. For each run, the pressure P1A was recorded along with one other variable. This provided an unambiguous "time scale" reference as well as an assesment of the run to run repeatability of the pressure transients (which was, overall, very good. See results). nl ilmmm Moll ",Ill l. . . . Iii -11 Table 2: - Instrumentation Pressures 2 Kistler Type 6606A5000 Piezokompac Pressure Transducers: scale factor = -1mv/psi, Range = 0-5000 psi Response time = 3 -is 1 Sundstrand Model 206 Piezotron Pressure Transducer: scale factor = 96mv/psi, Range = 0-80 psi Response time = 3 ps Temperatures 2 Omego Type J 3/16" Iron-Constantan Thermocouples 1 Omega Type MCJ-J Electronic Ice Point Displacements 1 HR-DC 500 Shaevitz Displacement Transducer 1 R-C filter for filtering high frequency noise 1 PSM120 DC Power Supply (For transducer) Recording Hewlett Packard 3440A Digital Voltmeter W/Amplifier Tektronix 434 Dual Beam Storage Oscilloscope -12III Experimental Procedure The method outlined in Gruel (1980) for operating the water hammer generator was followed. Before each experimental run, the reservoir and steam initial conditions were carefully monitored. All of the experimental tests in this study were run with the steam pressure (Ps) set at 170 kPa absolute (10 psig). In each case, saturation conditions were met, corresponding to a steam temperature (T1 ) of 115 0 C (239 IF). The water temperature of the reservoir (T2 ) was maintained by circulating water through the piping network between runs. Due to the day to day changes in the water supply temperature, the reservoir temperature varied between 20 - 300 C. Three different reservoir pressures (back pressure P ); 170 kPa, 240 kPa and 310 kPa, were used in the experiments. The back pressure was regulated by pressurizing the reservoir with nitrogen. Together with the 3 different test sections, a total of nine experimental conditions were run. each of the cases. the oscillograms. Appendix A contains some sample oscillograms for Appendix B contains the numerical data obtained from II *mmIImIII.YmIi nIa -I I1111 .1,1 I,1111 111 , 11 14 111 1111 -13-13- IV Theoretical Analysis The analysis of water hammer in the piping network has been divided into three parts. The first involves an evaluation of the processes involved in the initial depressurization and collapse of the steam bubble. At the end of this section, a numerical model is proposed that can be used to determine the time dependencies of the governing parameters. Gruel (1980) uses this model in an evaluation of his experimental data collected on steam bubble collapse. The second and third parts of the water hammer analysis involve a study of the pressure wave propagation and structural responses that occur after the initial bubble collapse and water column impact. These are considered separately below. The wave propagation model assumes that the structural response excited by the pressure transients does not significantly affect the wave propagation mechanisms. The deflection model uses the output from the wave propagation model to predict the deflections of the test section. This proceudre should be accurate when the pressure transients occur over a period that is short compared with-the vibration period of the excited structure. This was the case for the conditions of the experiments, which can be verified by the oscillograms. IIIIIYY -14Wave Propagation model The method for analyzing the propagation of pressure waves in liquid filled pipes are well documented (e.g. Wylie & Streeter 1978). To model wave propagation in the experimental network, a finite difference form of the method of characteristics was used. Pressure and fluid ve'ocity histories were calculated at various locations in the network, for times after the initial steam bubble collapse. The following sections will describe the pertinent details of the model including the governing equations, the nodal representation of the piping network, the model for cavitation and the treatment of the boundary and initial conditions. Governing Equations The governing equations for compressible flow through constant area ducts can be written as follows (Wylie & Streeter 1978): ; + V. x + Dt continuity: momentum: 9V + V 3V _ 3t ax aP eq. of state: where p V= 0 x aP p x (1) fVV(2) 2D = (3) P = fluid pressure V = fluid velocity p = fluid density f = Darcey-Weisbach friction factor D = pipe diameter S= bulk modulus of elasticity With the proper stress-strain relationships for a thin walled elastic 11.1 ~ 1011111111 JI julYY I__ ~ __ liffi -15pipe, the continuity equation can be rewritten as: 1 p + V P + C2 V = 0 ax p ax p Bt 1 with 2 C2 where 1 1 /p Ee/pD (4) (5) C = wave speed of fluid in pipe E = pipe modulus of Elasticity e = pipe wall thickness (A linearized analysis of eqs. 1-3 demonstrates that C is the fluid wave speed corrected for the elasticity of the duct (Wylie & Streeter 1978). Formulation in Finite Difference Form The momentum and continuity equations (Eqs. 2, 4) represent two quasi-linear hyperbolic equations in two unknowns. For liquid flows, one can assume that V << C, and can therefore neglect the convective acceleration terms in equations 2 & 4. By choosing the proper trajectories (or characteristics) in space and time, the characteristic equations are formed as follows: 1 dP pC dt for d + - 0 dx = C (6b) dt 1 dP pC d+d dV + f v V = 0 and dt pC dt for dx - (6a) 20 dt 20 C (7a) (7b) dt The values of +C (wave speed) represent the slope of the characteristics in the x-t plane on which the corresponding compatibility equations are vaild. With the addition of the boundary and initial conditions, -16- equations 6 & 7 can be solved numerically in finite difference form. Representation of Pipe Network Fig. 3 and Table 3 outline the procedure for developing a nodal representation of the experimental network, with the steel test section, usedin the finite difference calculations. Each element, located between two nodes (fig. 3c) representsa constant area segment of the piping network and has a constant wave speed. The wave speed and area, however, are allowed to change from element to element. There- fore, a series of identical elements represents one uniform section of pipe in a network. The representation of a network composed of many sections of pipe can be simplified if sections of pipe with similar properties are represented by "equivalent" sections (fig. 3b). The wave transit times and the overall fluid momentum are properly accounted for by defining "equivalent" wave speeds and pipe diameters: L. n, L C_ = E 3 i L. L 2 3 where L (8) 1 nj nJ LLi i D.2 (9) 1 = length of jth equivalent section representing n actual sections. The values for the "equivalent" wave speeds and diameters can be readily calculated if the actual lengths of the sections are maintained (see Table 3). The number of computational elements in the piping network is determined from the "equivalent" representation. Continuity in the calculations is maintained by choosing the elements such that the -17H I W II SZ.02 ,. x -= L 13 6 (a) ACTUAL L =.104 |.0 PIPING NETWORK L i® 1 I I ® I I x r =.136 I (b) EQUIVALENT NETWORK -C-=. L "IO4 Reservoir End ~ ~ 12 3 2 Pressure Transducer P (x/L=.172) IA I i I 10101 ( I I I 1 15 i16 17' 18 19 201 10~I 12. 13 13l4, 7~II 3 5 , I g" g00ei0g l IIl I -1= 1. L .I, I I 1* I I I I 0*0*0*01 I i I I I I .104 IP, x = IA I I I I I I I I I I I I I I t IIi I I I I I i I , I I I Closed End I I *I*I*iII@*I01*1I**1 Section I ' 31 I I NODAL REPRESENTATION Fig. 3 Development of Nodal Representation (steel test section) I I I I iI 0101016*I I II I L1.0 Elbow (A= 646 L I 3233134 35 3 Pressure Traonsducers and P2 (x/L=.160) (c) I 2 12/ 2312425126!27l28 29,30 I I I Section # I Section #2 x I, Elbow =.558) L Pressure Tronsducer P -18Table 3 Development of Nodal Representation (steel test section) Actual Piping Network (Overall Length = 8.43m) Pipe Section Length (Li) (m) 1 2 6" Reservoir 1 1/2" Steel 3 4 1 1/2" Lexon 1 1/2" Steel 5 3/4" Steel .23 Wave Speed (ci) (m/s) 1361 .65 diameter (d i ) (m) .1524 .0407 1368 457 .27 .51 6.77 1368 .0381 .0407 1391 .0208 Equivalent Piping Network Section Pipe 1 Reservoir & 1 1/2"Steel 2 Lexan 3 1 1/2"Steel & 3/4" Steel Length (L.) Wave Speed (c.) (m/j) 3 8) I .88 1366 .27 7.28 diameter (dj) .0467 457 .0381 1400 .0214 Nodal Representation Section Length (L.) Pipe Adjusted Diameter (d.) wavespeed (m) Steel Lexon Steel .88 .27 7.28 L. J = 0002 s At N. C. 33J At= (m) (m/s) .0467 .0381 .0214 1460 445 1400 # Divisions (Ni) -19wave transit time across each is a constant: L. At = = constant --- (10) N.J C. J N = number of elements in "equivalent" section J. where Since the N 's must be integers, it is unlikely that suitable values can be found to satisfy eq. 10 exactly for all sections, given that the L.'s and C 's are fixed. This problem is avoided by modifying the wave speeds by small amounts (say less than 10%) to assure that equation (10) is satisfied. The constant value for At is chosen by taking into account both physical and computational factors. The final representation of the piping network has nodes located between each of the representative elements and at the system boundaries. This results in a total of N. 3 + 1 nodes for each "equivalent" section In addition, each junction between sections is represented (fig. 3c). by two nodes. As the calculations proceed, the pressures and velocities are determined at each node by the appropriate characteristics from the bordering elements. At the system boundaries, a boundary condition is substituted for one of the characteristic equations. Cavitation Model In its pure form, the method of characteristics predicts negative as well as positive absolute pressures in the piping network. Realistically, cavitation nust occur when the absolute pressure in the fluid drops below the vapor pressure. This state is identified and accounted for in the wave propagation model by using a form of the continuity equation. In the calculations, when cavitation is indicated at a node (P < Pvapor ), the pressure is artificially set equal to the vapor pressure, -20which then serves as an internal "boundary condition" for the rest of the system. Growth and collapse of the cavity is calculated using the following equation: = E (Vu - V) A At (11) t where -V = cavity size Vu = upstream velocity at the cavitating node V = downstream velocity at the cavitating node A = area of pipe The upstream and downstream velocities are calculated from their respective characteristics and the summation is taken over all time for which the cavity exists. can be calculated in two ways. The time at which cavitation vanishes Observations of the experimental water hammers suggest that two types of cavitation must be considered. The first type of cavitation involves the separation of the water column and the formation of a vapor void over the entire cross section of the pipe. For this case, the disappearance of the cavity is cal- culated to occur at the time when the cavity size, V, vanishes. At that instant, an accoustic overpressure is produced of amplitude: AP = pc (Vu - V) (12) A second type of cavitation consists of a distributed void, without localized separation. The void volume is again calculated using eq. 10 and in addition, the characteristics solution for the nodal pressure is continued. The cavity is taken to vanish when either the computed cavity size, f, goes to zero, or when the pressure at the cavitating node is calculated to be greater than the vapor pressure, AMIII III Al1 ll llm lIMINIM M Ill, 11Al - . whichever occurs first. -21This second type of cavitation models the formation of a void consisting of very small vapor bubbles distributed uniformly throughout the "cavity". In this case the characteristics solution is still valid, although the calculations will be somewhat in error because they fail to account for the change in wave speed caused by the presence of the vapor bubbles. This error is equivalent to an unaccounted for increase in the length of the piping network. If the cavitation region is small in length, compared to the overall length of the system, the error will be small. For better accuracy, Wylie & Streeter (1978) outline a procedure which accounts for both variable wave speeds and column separation at all computational modes in the network. The cavitation model is completed by specifying where to allow for column separation and where to assume "bubbly" cavitation. Fig. 4 illustrates some of the numerical results for the model calculations corresponding to the steel test section. If column separation is allowed to occur everywhere in the network (Nseparation = 33), the solution in fig. 4a results. The pressure spikes occuring after the second depressurization represent the random collapse of the cavities formed at nodes throughout the piping network. By allowing column separation only at a few nodes in the region of the initial column impact, the solutions in figs. 4b, c & d result (Ns = 8, 4, 1 respectively). High speed films taken of several water hammer events (Gruel 1980) show that column separation does in fact occur in this region. Comparison of the experimental results with fig. 4 suggests that allowing column separation elsewhere in the system model does not accurately represent the actual events. 4000 iI I , lI . i , g 3500 3000 AC a- 250 11 WJ2000L) i-i, Lu 1500 1000 C1 a1000 500 " 0 0.00 0 500002 0 04 0.0G 0.09 0.10 TIME 0.12 0.1e 0.20 ~~ALA& 0.00 0.02 0.04 0.06 0.06 010 (S) (c) NS = 4000 0.14 0.16 TIME (b) 33 0.2 044 0.6 048 AB . 0.20 CS) N =8 r 3500 - 3000 a 2500 W 2000 (i 1500 0.00 0.02 0.04 0.06 0.09 0.10 TIME 0 12 0.14 01G 0.18 0.20 0.0 0.02 0.04 0.06 08 CS) (c) Ns= 4 00 TIME (d) Fig. 4 Numerical Results with Column Separation at Ns Nodes. (steel Wee!tes, test secti.on; P = 310 kPa) s%-.tio; P0 =30ka 2 CS) Ns= I 04 0.2 -MI iE1 INWil H I -23Boundary and Initial Conditions At the ends of the piping network, boundary conditions are substituted for one of the characteristic equations. For the closed end, the boundary condition is zero fluid velocity. At the reservoir end, kinetic energy losses are taken into account. For flow between the piping network and the reservoir, the effects of convective acceleration and friction on pressure are: po Pe Pe where = o ( + K) pV2 (13) (V > 0) (V < 0) (14) Pe = Pressure at entrance to piping network P = Reservoir pressure V = fluid velocity out of reservoir K = entrance loss coefficient. The transient calculations begin at the instant of the initial column impact (t = 0), following steam bubble collapse. The initial conditions for the model correspond to the system pressures and velocities at that time. The pressures are set equal to the experimental initial conditions for the reservoir (P ) and steam (Ps). The fluid velocities are everywhere zero, except for the velocity of the water column at impact. This velocity is computed from the experimental results, using Eq. 6 in the following form: V21 impact pcT (15) I = impulse of initial pressure spike T = time duration of initial pressure spike Appendix B contains the necessary data compiled from the experimental runs. -24- Deflection Model Many structural codes have been developed to determine piping network responses to specified forcing functions (see, for example NUPIPE and PIPERUP). The model developed here is not intended to duplicate or improve the work done in these codes, but instead is to provide the basis for a simple analysis of pipe deflections in the experimental network due to water hammer tests. In the experimental network, the unrestrained "U" shaped pipe (fig. 2) is modeled as a pair of cantilevers joined at the free ends. The end shear created by the cross piece is neglected (an assumption justified by the small lateral displacements) as is the added mass of the cross piece (which is small compared to the total mass of the test section). The forces producing lateral displacements of the test section result from unequal pressure forces acting at the two elbows (fig. 2). The magnitude of the forces are equal to the pressures inside the pipe at the elbows, less the atmospheric pressure outside, multiplied by the pipe cross sectional area. Since the pressure forces at the elbows act in opposite directions, no unbalanced forces, result when the elbow pressures are equal. For a given time, the total force on the test section is written as: F(t) = [(PA(t) - PB(t)] A where PA and PB refer to the pressuresat elbow A and elbow B respectively (see fig. 2). By convention, forces and displacements in the direction of elbow A have been defined as positive. The forces acting at elbow A are then always positive and the forces on elbow B are always negative. -25Due to the presence of the cross piece, F(t) is evenly divided between the two cantilevers. It is assumed that the two cantilevers vibrate in phase, therefore the displacements can be determined by looking at a single cantilever excited by a force of F(t)/2 concentrated at the end. The governing equation and boundary conditions for a cantilever beam are: y + Wx1 2 at2 a ax with and f(xt) (17) El a2 = EI pA (18) Y(x=O) = 0 --Y (x=L) = 0 ax xx=o) ax where 0 -Y ax (x=L) = 0 (19) E = modulus of elasticity I = cross section moment of inertia p = material density A = cross section area f(x,t) = forcing function in x and t Since the pipe was filled with water, the product pA was taken to be equal to the sum of the masses of the pipe and the water, per unit length. Damping effects are neglected, a simplification which appears to be consistent with observations made during the time periods of interest (the first few cycles of vibration). The solution to eq. 17, for forced vibrations, can be expressed as a series expansion of the normal modes of Vibration (Graff 1975): -26Vn(x) 2 Y(x,t) = n) 'n pLn=l where iI Yn(u)du n0f j f(u,T) sin cn (t-T) dT (20) Y (x) = normal modes of vibration n = natural frequencies of vibration Fig. 5 illustrates the first four modes of vibration for a cantilever beam. The corresponding frequencies of vibration are given by: n where the = aB n2 (21) n's are solutions to the frequency equation: cos nL cosh BnL = -l (22) The first few roots of eq. 21 are: 6 L = 1.875 a3L = 7.855 (23) 2L = 4.695 84L = 10.996 Given that the forces on the test section are concentrated at the ends of the cantilevers, they can be represented, consistant with eq. 16, as f(x,t) = F(t) 6(x-L) where (24) 6(x-L) = 1 for x = L = 0 for x L Substituting eq. 24 into eq. 20, the solution becomes: Y(x,t) = 2 pAL nl Y (x) Y (L) ft n n(L) F(T) sin w (t-T) dT Wn n (25) By specifying F(T), eq. 25 can be solved to obtain the transient pipe deflections at any position x. The forces on the test section, given by eq. 16, can be determined 2.0 1.5 1.0 0.5 0.0 -0.5 Z -1.0 - -1.5 - -2.0 0.0 0.1 0.2 0.9 0.4 0.5 0.6 0.7 0.9 X/L Fig. 5 Normal Modes of Vibration for a Cantilever Beam 0.9 t0 -28from the pressures calculated from the wave propagation model. For the nodal representation of the steel test section, elbow A is represented by node #22 and elbow B is represented by node #25 (see fig. 2 and fig. 3). Fig. 6a shows some sample pressure histories computed at these nodes from the wave propagation model. The very short duration of the pressure spikes (compared with the natural period of vibration of the test section: Eq. 21) suggests that the pressures can be accurately represented by a series of impulses. The trapezoidal rule was used to integrate the pressure histories, in time, to obtain the impulse representations. Fig. 6b illustrates the impulse representations for the corresponding pressure histories in fig. 6a. The magnitudes of the impulses are equal to the areas of the pressure spikes they represent and the application times correspond to the midpoints of the integrated time intervals. The reference pressure for the calculations was chosen so that only the high pressure spikes were included in the integrations. The large magnitude pressure spikes contribute to most of the force applied to the pipe structure. Numerically, the reference pressure is immaterial since the force on the test section is proportional to the difference in the elbow pressures and not their magnitudes. The magnitudes of the initial pressure impulses are actually little changed (-10%) for reference pressures chosen between 100 kPa (atmospheric pressure) and 500 kPa. When higher reference pressures are used, the times of application of the impulses shift closer to the time of maximum pressure for the pressure spikes. It is apparent that the impulse representation becomes more inaccurate for times after the initial pressure spikes when the pressure fluctuations are of the same order of magnitude as the system natural frequencies. However, only the first few pressure spikes Elbow (8) Elbow (A) r% EL2500 a- 2500 (a) W 2000 W-2000 n (I) u 1500 a. Lu 1500 Er Er a- 0.00 0.02 0.04 o0.06 010 0.12 0.0. TIME 0.14 0.16 CS) 0.18 0.00 0.20 (0) 0.02 0.04 0.06 0.0 0.10 0.12 0.14 Elbow PressureS 16 0.19 0.20 CS) TIME 7 (b) 0.00 0.02 0.04 0.06 0.09 0A0 0.12 0.14 0.16 0.19G 0.20 0.00 0.02 0.04 0.06 0.09 0.0 0.2 0.14 0.6 0.19 0.20 TIME CS) TIME (S) (b) inteqgrted Elbow Pressures Fig. 6 Reduction of Pressures to Impulses (Steel Test Section; Po = 310 kPa) Preference = 500 kPa. -30- have a significant effect on the subsequent test section deflections. For a single impulse of the form F(t) = F6 (t-T) (26) applied to the end of a contilever, eq. 25 becomes: Yn(L) -oY n(x) An=l n F Y(xt) = (27) sin wn (t-r) (A factor of 2 has been removed from the numerator to account for the fact that the forces are evenly divided between the two cantilevers.) Eq. 26 can now be summed over all of the impulses occuring at the two elbows to obtain the test section deflection history. show Figs. 7 and 8 the deflection results for the steel test section. These solutions are based on the impulses occuring within the first 50ms after the initial water column impact (t=0). The reference pressure (PR) used to integrate the pressure histories was 100 kPa for fig. 7 and 500 kPa for fig. 8. Table 4 lists the impulse data. In the figures, the solutions correspond to the superposition of up to the firstfour modes of vibration. The maximum amplitudes for PR = 500 kPa (fig. 8) are almost 50% less than those for PR = 100 kPa (fig. 7). Table 4 shows that the difference in the impulse magnitudes cannot account for the change in displacements. However, there is a large change in the application times for some of the impulses. Since the pressure forces at the elbows appose one another: F Y ~pAWn For small T1 (m (sin n (t-T1 ) - sin (wn(t-T 2 )) and T2 ~ F max F F T TA) pAL (B -- T where F is an impulse. (28) TB - TA is roughly equal to the wave transit time 2.5E-3 - 2.0 1L5 - 0 1.0 1.5 - S0.5 - z I- S-0.5 -1.0 H o -1.5 -2. 0 -2.5 -3.OE-3 -0.;2 0.0 0.2 0.4 0.6 0.8 i.0 -0.2 0.0 0.2 0.4 TIME CS) 06 0.9 .0 06 0=3 1.0 TIME CS) (a) I M de 2 Modes (b) 8E-3 -0.2 0.0 0.2 0. 0.6 0.9 1. -0.2 0.0 TIME (S) (c) Fig. 7 3 Modes Superposition of Natural Modes of Vibration (Steel Preference = 100 kPa. 0.4 0.2 TIME (S) (d) 4 M*oes Test Section, P = 310 kPa) 2.0E-3 1 5E-2 r 1.5 0.5 z U' -0.5 Li 0.0 -1.5 - 0.2 -1 00 0.2 0.4 0 . LO ILf -1.5E-3 -02 0.0 0.2 0.4 0& 0. 1.0 -1.0 -2.OE-3 -0.2 (b) TIME 2 0.0 0.4 0.2 -02 0.0 0.2 Mode 0.4 (c) 06 0.9 LO0 0.6 0.9 1.0 TIME CS) TIME CS) (o) I CS) (b) 0.6 0.9 1.0 -0.2 0.0 02 2 Nkxles 0.4 TIME CS) TIME (S) 3 Modes (d) 4 Modes Fig. 8 Superpositi on of Natural Modes of Vibration (Steel Test Section; Po = 310 kPa) PReference = 500 kPa. Table 4 Impulse Data for Steel Test Section (P0 = 310 kPa) Elk~ reference = 100 kPa Preference = 500 kPa El b w R A SA Impulse Time (ms) Magnitude (kPa.s) Duration (ms) 3.2 7.2 6.2 3.6 7.24 6.8 10.8 7.4 5.2 9.2 6.5 3.4 -1.6 - - - 12.6 0.9 2.8 - 16.8 20.6 43.2 0.7 0.1 0.3 3.4 0.6 0.4 16.6 20.0 43.8 0.7 0.2 0.3 -0.2 -0.6 0.6 45.2 3.0 3.0 45.8 3.0 2.8 0.6 0.4 3.0 48.4 0.2 0.4 47.8 0.2 0.4 -0.6 4.4 6.9 3.0 5.0 7.0 3.0 0.6 9.6 6.6 3.0 9.0 6.4 3.0 -0.6 12.6 0.5 0.8 13.2 0.5 0.8 0.6 15.6 0.2 0.2 16.0 0.4 0.6 0.4 20.8 0.1 0.2 20.2 0.1 0.2 -0.6 43.2 44.8 48.4 0.3 2.9 0.2 0.4 2.0 0.4 43.8 45.4 47.8 0.3 2.87 0.2 0.4 2.0 0.4 0.6 0.6 -0.6 B Time (ms) Impulse Magnitude (kPa-s) ________________________________ Duration (ms) TB - TA (ms) 0.4 0.6 ________________________________,__, ________________________________ _______________________________ between the two elbows. -34Eq. 28 shows that the maximum deflection is very sensitive to the application time assigned to each impulse. This can account for the differences seen in figs. 7 and 8 (see Table 4). to the experiments, fig. 8 shows much better agreement. section includes further discussion of this observation. Compared The results -35Bubble Collapse Model The preceding analysis was concerned with the system responses occuring after the initial steam bubble collapse. In this section, a bubble collapse model is introduced that can be used to describe the events leading to water column impact. Fig. 9 illustrates a representation of the water hammer generator at a time shortly after the opening of the reservoir valve. The initial length of the vapor cavity is k and the position of the moving water column is represented by x. The basic conservation equations can be applied to the control volume drawn in fig. 9. The continuity and momentum equations are: pdV + continuity: - pVdA = 0 (27) c.v. C.V. momentum: EF = - v. (pV) dV + p (V*dA) V (28) In terms of the quantities in fig. 9, eqs. 27 and 28 reduce to the following forms: V dx (29) dt P= pt (Vx) - 2 (30) dt where AP = P - Ps and P + pgh - (l1+K) ps = steam density p = water density AP = overall pressure drop pV2 Ps (31) -36- P0 h_..!.:.....:: ... ..... , .i ! i:. '".. :. T1 I Reservoir .. Moving Water Colu m n X=O I SI.:. :;..." I.. .". I." . Control Volume Cavity I I 'TP IIII~SIq I I -... Stationary Steam - Water Interface Statio' Water C lumn .. . Fig. 9: •... . * Control Volume for Steam Bubble Collapse Analysis. -37In eq. 31, ps and AP are functions of time. For the very fast transients involved, conduction heat transfer from the steam bubble is negligible. The enthalpy flux out of the steam bubble is almost entirely due to condensation. The energy equation for the steam bubble can be written as follows: a p edY 8t ; s s = - dV lch + Ps dts c (32) e = specific energy of steam where h = specific enthalpy of steam Vs = volume of the steam bubble and mc = mass condensation rate of the steam. Assuming an ideal gas and a uniform temperature profile in the steam bubble, eq. 32 becomes: (33) dX d S(c T1 sA (Y -x) + mcCpTl " Ps A = 0 (33) where c and cV are the constant specific heats. The condensation rate, mc, can be defined as: m= c (34) d (P A( x:) dt s o-x:)) The equation of state is: Ps = psRT 1 (35) where R is the universal gas constant. Eqs. 29, 30, 31, 33, 34 and 35 represent 6 equations in seven unknowns (x, V, AP, Ps' Ps, T1 and c ) all of which are functions of time. A seventh equation is obtained by specifying the condensation rate c. Appendix C presents the equations in dimensionless form and lists the appropriate variables. The equations are solved numerically -38using a Runge-Kutta integration technique. Gruel (1980) uses this method in an analysis of his experimental data. Creare (1977) presents solutions to a somewhat simpler set of equations, assuming an isothermal bubble collapse and various constant condensation rates. -38V Results Appendix A contains sample oscillograms taken for each set of conditions tested in the experiments. The tables in appendix B contain the numerical data complied from all of the recorded test runs. ponding theoretical calculations are included for some cases. CorresExperimen- tal reproducibility is discussed at the end of this section and in appendix D. Wave Propagation Experimental Results Fig. 10 compares the pressure histories (PA' t > 0) for the three test sections, with the back pressure (P ) equal to 170 kPa. compares the corresponding traces for P = 310 kPa. Fig. 11 The most apparent differences between corresponding oscillograms in figs. 10 and 11 are the magnitudes of the initial pressure spikes, which range from 3000 kPa for Po = 170 kPa to 5000 kPa for Po = 310 kPa. For a given back pressure, the early features of the pressure histories are remarkably similar for the different test sections. In the expanded time scales of figs. 12 and 13, it is clear that the initial pressure spike amplitudes and structures are nearly identical. The initial pressure spikes attain a maximum average peak pressure about which is. superposed other oscillating pressure variations. The average peak pressures range from 2200 kPa for PO = 170 kPa to 3000 kPa for P0 = 310 kPa, indpendent of the test section. The tables in appendix B contain the impulse magnitudes and time durations for several initial pressure spikes from which the average peak pressures can be determined. The similarity of the initial pressure spikes is expected since they are determined solely by the -39- 5000 Steel Pipe 4000 3000 PIA (kPo) (a) 2000 I000 170I .... 0 ' r n O 7"qT 1 40 80 120 160 200 160 200 t(ms) 5000 Copper Tubing 4000 - 3000- PIA (k Pa) (b) 20001000 170 0 40 80 120 t (ms) 5000 CPVC Pipe 4000 - 3000 PIA (c) (kPo) 2000 I000 170 0 Fig. 10 F 'I' 40 80 ! 120 t (ms) I'T 160 20 0 Experimental Pressure Histories for 3 Test Sections (P = 310 kPa). -40- 5000 Steel Pipe 4000 PIA (a) (kPo) 3000 2000 1000 170 0 40 80 120 t(ms) 0 40 80 160 200 160 200 160 200 200 5000Copper Tubing 4000- (b) PIA (k PO) 30002000 ILJUU - 170 120 t(ms) 5000 CPVC Pipe 4000PIA (c) (kPo) 300020001000 J, 170 0 Fig. 40 80 120 t (ms) Experimental Pressure Histories for 3 Test (P = 310 kPa). Sections -41- 5000 Steel Pipe 4000 3000 - PIA (a) (k Po) 2000 I000 170 0 10 20 30 t(ms) 40 50 10 20 30 t (ms) 40 50 5000 -1 Copper Tubing 4000- (b) PIA (kPo) 30002000I000170- CPVC Pipe 5000 4000 3000(c) PIA (kPo) 2000 1000 170 0 I 10 ' I 20 ' I ' 30 I 40 ' I 50 t (ms) Fig. 12 Experimental Pressure Histories for 3 Test Sections (expanded time scale, P0 = 170 kPa). -42- 5000 Steel Pipe 40003000- PlA (a) (kPa) 20001000170 -T 0 I0 20 30 t(ms) 40 50 10 20 30 t(ms) 40 50 1O 20 30 40 50 .,Mm.. 5000 Copper Tubing 4000- (b) PIA (k Pa) 300020001000170- CPVC Pipe 500040003000- (c) PIA (kPo) 2000I000170 - 0 Fig. 13 Experimental Pressure HistotreSor 3 Test Sections (expanded time scale, P = 310 kPa). -43characteristics of the water hammer generator and are not affected by the wave propagation dynamics through the test section. The reflected spikes from the closed end of the test section are recorded shortly after the initial pressure spikes (t = 10 ms for the steel and copper test sections, t : 17 ms for the CPVC test section). The time intervals between the initial impact spikes and the reflected spikes are determined by the acoustic wave propagation times through twice the length of the test section (At = 5 ms for steel and copper, At = 10 ms for CPVC). Immediately after the reflected pressure spikes, the oscillograms show periods of very low pressure that correspond to water column spearation in the region of the initial water column impact. For the higher back pressure cases (P = 310 kPa) shown in figs. 11 and 13, the periods of cavitation and column spearation are shorter than those for the lower back pressure cases (P = 170 kPa) shown in figs. 10 and 12 (Atcavitation cavitation = 310 kPa, Atcavitation 15 ms for P0oaitto 40 ms for As expected, these cavitation periods appear to be Po = 170 kPa). unaffected by the test section wave propagation dynamics. tion is terminated by a recollapse the cavitation. Column separa- of the vapor bubble generated by A second water column impact occurs, analogous to the one following the original steam bubble collapse. For example, the second impact time is at t = 60 ms for the steel test section (fig. 10a) and at t - 35 ms for the CPVC test section ,(fig. 13c). As before, the impact pressure amplitudes increase with increasing back pressures. The pressure history after thesecond water column impact consists of cyclic cavitations and bubble collapses qualitatively similar to the initial transients. The transients finally die out and the pressures in the test section end at the reservoir back pressure. -44The experimental reproducibility of the pressure transients was generally excellent. Appendix D includes some typical oscillograms recorded for successive runs under identical conditions. The initial impact peak pressures generally varied less than 10% for a given set of experimental conditions. same repeatability. The average peak pressures had about the The time periods between initial and reflected spikes were also consistent within about 10%. The time-durations of the cavitations following the reflected pressure spikes varied less than 20%. Wave Propagation Theoretical Results Theoretical results were obtained for the steel and CPVC test sections. The necessary inputs to the computer model are described in the section on theoretical analysis. A sample of the input is shown in table 5 for the CPVC test section (P0 = 310 kPa). The first two sections of the CPVC nodal representation are identical to those for the steel test section (see fig. 3). cases. The initial conditions ara similar for both The only empirical inputs are the final water column impact velocity and the specification of the regions in which column separation is allowed to occur. Eq. 15, with the experimental data in appendix B, is used to calculate the impact velocity. This equation appears to lead to a good agreement between the calculated peak pressures and the experimental average peak pressure for the initial impact pressure spikes. Figs. 14 and 15 illustrate the numerical results obtained for the steel and CPVC test sections (Po = 310 kPa) with the corresponding experimental tests. Gruel (1980) outlines a calculation of the impact velocity using the bubble collapse model summarized in appendix C. There is still, -- ~~IIIYIYYIII r , ~IIIII~ ' ~YYIIYII 0I il ll I -45TABLE 5: Sample Input for Wave Propgation Model (CPVC Test Section; P = 3i 10 kPa; Ps (initial) = 170 kPa) 0N Nodal Representation Section 5 Material Steel Lexan Steel CPVC CPVC Length (L) (m) Adjusted Wave #Division (Ni) Diameter (D.) speeds(CJ) (m/s) (m) .88 .27 .0467 .0381 1366 457 .69 .0309 3.30 .0188 1374 689 3.30 .0188 689 Total # odes = 62 (two nodes per junction) Initial Condi ions - (Refer to fig. Pressures Po = 310 kPa (Reservoir Pressure) 0 Pl =P2 = P3 = P4 = P5 = P6 = P7 = 310 kPa (neglecting kinetic Energy Losses) All other Pn = 170 kPa (steam pressure) Velocities (from eq. 15, appendix B) I = 20.3 kPa - s Initial Impulse: Time interval: Vimpact = T = .005 s 2 (20.3 x 103) (I x 103)(1391)(.005) = 5.84 m/s V1 =V 2 = V3 = V4 = V5 =V 6 = V7 =5.84 m/s Vu = Vu2 = Vu3 = Vu4 =Vu 5 = Vu6 = Vu7 = 5.84 m/s All other Vn and Vun = 0 Cavitation Data 1) Initially there is no cavitation anywhere in the network. 2) Column separation is only allowed in nodes 5, 6, 7 and 8. (b) Theory (a) Experiment 5000 5000 PIA (kPa) Pressure at entrance to test section 4000 4000 3000 )- 3000 2000 2000 100C 1000 )-a 17C 40 0 80 10 160 204 0 t(ms) (kPo) Pressure at entrance to test section (expanded time scale) 120 160 200 40 50 500 400 4000 3000 3000 2000- 2000 W 1000 170- 80 1 (mS) 5000 PIA 40 TT 0 I0 Fig. 14: 20 30 t (ms) 1000 40 0 10 20 30 t (ms) Theoretical Pressure Results Compared to Experiment for the Steel Test Section (P = 310 kPa). (0) (b) Experiment Theory 50004000PIA (kPa) 3000 Pressure at entrance to test section 2000 1000 1700 0 I'so 80 '1 120 t (ms) 40 200 t (ms) 5000- 5000 4000- 4000 IA (k Pa) Pressure at entrance to test section (expanded time scale) 1 3000- 3000 2000 2000 F' 1O00- I000 170 1 0 C --S i 10 1 1 I 1 20 t(ms) Fig. 15: 30 I 1 40 ioo 1A S1 i 1 10 20 IL1 4*Ai. AI 30 40 t (ms) I I 50 Theoretical Pressure Results Compared to Experiment for CPVC Text Section (P = 310 kPa). -48however an empirical input to that model which involves the estimation of the heat transfer rate from the steam bubble to the water column. The numerical results in figs. 14 and 15 show good agreement with experiment during the early phases of the transients. The agreement is better for the steel test section, perhaps because the nodal representation used for the steel test section more closely approximated the actual system. After the first two cavitations, the agreement between theory and experiment is poor. This decay phase of the pressure transients is of less interest and has little effect on the induced test section deflections. -49Displacement Experimental Results Figs. 16-19 show experimental results for the displacement histories of the 3 test sections. These traces include the responses at locations D1 (figs. 16, 17) and D2 (figs. 18, 19) (see fig. 2) for back pressures of P = 170 kPa and 310 kPa. The displacement magnitudes for the respective test sections increased with increasing back pressure. The ringout frequencies were fairly constant although the observed amplitudes of higher mode vibrations varied at different points (see for example D2 (x = L/2) for P0 = 310 kPa). For a given back pressure, the displace- ment frequencies and amplitudes varied considerably with the different test section materials. Figs. 20 and 21 plot the first mode displacement frequencies and amplitudes against theoretically motivated parameters characterizing the test section properties. For all of the experimental runs, the initial displacements were in the negative direction (towards elbow B, fig. 2). Free constant amplitude vibrations corresponding to the ring out of the test section were observed for times greater than about 20 ms. This supports the assumption that the important part of the pressure transients occur within a time period that is much smaller than that for the test section vibrations. Displacement Theoretical Results Numerically calculated displacement histories have been derived using the wave propagation calculations and the deflection model outlined in the previous section. The wave propagation model provides the impulse data, similar to that shown in table 4, for the two elbows. pressure of 500 kPa was used in the integrations. A reference The test section parameters defined for eq. 17 are listed in table 6. Fig. 22 shows the -50theoretical results for the steel and CPVC test sections using a single mode analysis at the position x = L (D1 ). The agreement with experiment is shown in figs. 20 and 21, where the calculated maximum amplitudes and first mode frequencies are plotted with the experimental results. Other calculations are included in appendix B. The predicted frequencies appear to agree very well with experiment. The computed maximum dis- placements show good agreement for the steel test section but overpredict the CPVC test section displacements by over 100%. -51- 2.0Steel Pipe 1.0DI (a) 0- (mm) -1 .0 -2.0 0.4 0.2 7.5 1.0 0.8 0.6 t(s) Copper Tubing 5.0 2.50I (b) 0- (rMM) -2.5 -5.0 - -7.5 0 I 0.2 ' I 0.4 15.0CPVC ' I 0.6 t (s) ' I 0.8 ' I 1.0 Pipe 10.0 5.0 DI (rMM) (c) 0 -5.0 -I0.01 -15.0 Fig. 16 0- 0.4 0.8 1.2 t(s) 1.6 2.0 Experimental Deflection Histories for 3 Test Sections (x = L, P0 = 170 kPa). -52- 2.0Steel Pipe (a) 1.0- DI (rMM) -1.0 -2.0 0 0.4 0.2 0.6 1.0 0.8 t(s) 7.5Copper Tubing 5.0 2.5- D0 (b) (rMM) 0- -5.0 -7.5 I 0 I 0.4 0.2 15.0CPVC Pipe 0.6 t (s) 0.8 1.0 10.0 5.O- (c) 0 DI (mm) -5.0 -10.0 -15.0 T I 0.4 0 Fig. 17 Experimental (x = L, Po = - I 0.8 I , 1.2 t (s) 1.6 1 1 2.0 Deflection Histories for 3 Test Sections 310 kPa). -53.0 - Steel Pipe 0.5D2 (a) O- (mm) -0.5 I I 0.2 I I I I I 1 1 1.0 0.8 0.6 0.4 t (s) I 0.2 I 3.0Copper Tubing 2.0I.O D2 (b): (m m) -1.0 -20. -3.00 0 0.4 7.5 CPVC I 0.6 ' 0.8 1.0 t (s) Pipe 5.0) 2.5(c) D2 (mm) 0- -2.5 -5.0 -7.5 I 0 Fig. 18 0.4 I I I 1 0.8 1.2 t (s) 1 1.6 2.0 Experimental Deflection Histories for 3 Test Sections (x = L/2 Po = 170 kPa). -541.0- Steel Pipe 0.502 (a) 0- (mm) -0. -1.01 I 0.2 0 I II I I 0.4 0.6 0.8 1.0 0.8 1.0 '1 t(s) 3.0 Copper Tubing 2.0 .0 (b) D2 (mm) 0- -I.0 -2.0-3.0- 0.2 0.4 0.4 0.8 0.2 1 0.4 7.5 CPVC 0.6 0.6 t(s) 0.8 1.0 Pipe 5.0 2.5 02 (c) 0 ,. ' (mm) -2.5 -5.0 -7.5 0 Fig. 19 1.2 t (s) 1.6 2.0 Experi mental Deflection Histories for 3 Test Sections (x = L /2 P0 = 310 kPa). pA W VS. 20EeorSteel Experiment 20 I Wl W (S1) '5 Copper 15 , CPVC 50 -- S , Fig. 20: 3.73 I (71 I 1, 1 5 10 , I5 I5 A (S) First Mode Vibration Frequencies for Test Sections. 16.99 I I 20 25 20 Ymox (MX1-3 (mxO ) 15 I0 5 .04 .02 Fig. 21: .06 .08 .10 .12 .14 pALW, Test Sections for Similar Experimental Conditions of Maximum Displacements (P = 310 kPa, x = L). -56Table 6 2) (N/m (m4 ) Test Section Parameters for Deflection Model. Steel Test Section 207.0 x 10 CPVC Test Section 2.9 x 109 1.576 x 10-8 -8 1.881 x 10 (kg/m) 2.058 .7152 (m2/s) 39.81 8.733 (m) 2.87 2.87 (m- 1) .6533 .6533 1 .636 1 .636 2.737 2.737 3.831 3.831 16.991 3.728 106.5 23.36 298.2 65.42 M4) (m- ) (mn1) -l ) (m(m- l ) (s-1 (s - ) (s- ) (s-1) 584.4 128.2 (a) (b) Experimen Theory -A - 1.01 Steel Pipe DI (rMM) 1.0 -O 0- -I.0- I.O - -2.0 -T 0 0.2 0.4 I 15.0 0.6 t(s) I 1 0.8 ~-- J -0.2 -0.2 L- I I 1.0 | I 0.2 0.4 0.6 0.8 t (s) 1.0 , CPVC Pipe 10.0 - 20.0 5.0DI (MMr) 1i0.0 O- 0 -5.0 - -10.0 -10.0-15.0- -20.0 I 0.4 I 0.8 I 1.2 t (s) Fig. 22: 1.6 ' I 2.0 -0.5 0 0.5 1.0 1.5 2.0 t (s) Theoretical Displacement Results Compared to Experiment (Po = 310 kPa, o x = L). -58- VI Conclusions The purpose of this study was to investigate various features of water hammer transients generated by steam bubble collapse. The experimental work provided a body of data on water hammer pressure transients and piping system responses under carefully controlled repeatable conditions. The simple experimental system was designed to test all of the phenomena believed to be important in real piping networks: the collapse of an isolated steam bubble in subcooled water, the propagation and reflection of acoustic pressure waves, the cyclic cavitation and reimpact of the water column, and the development of unbalanced loads inside the pipes leading to pipe deflections. The theoretical analyses illustrate the types of computations necessary to explain the phenomena observed at the different stages of the experimental transients. Anticipating and predicting the extent of water hammer damage to piping networks is the ultimate goal of this type of research. A better understanding of the initiating mechanisms that lead to steam bubble entrapment and the condensation processes that govern steam bubble collapse is still required. Creare (1977) provides some limited discussion of a possible initiating mechanism. Gruel (1980) has investigated the dynamics of steam bubble collapse in the water hammer generator. More work is required, however, before these studies can be confidently applied to full scale systems. The wave propagation model developed in part IV has shown that -59pressure wave propagation and cavitation can be predicted quite adequately, although accurate modeling of the cavitation dynamics presents some difficulties. The manner in which the pressure transients induce unbalanced forces is qualitatively well understood. The simple deflection analysis presented here produced adequate and generally conservative agreement with experiment. More sophisticated codes exist, however (for example NUPIPE and PIPERUP) that could be used in this stage of the analysis. In this study, the uncoupling of the wave propagation analysis from the piping network structural response calculations was an acceptable approximation of the experimental system. This is an important simplification since it allows the use of well established acoustic wave propagation models to determine the pressure transient "forcing functions." A similar approach for full scale conditions is probably possible, but requires a more formal justification based on conditions corresponding to the full scale wave propagation speeds and piping network natural frequencies. -60References A-Moneim, M.T. and Chang, Y.W. 1979 "Comparison of ICEPEL Predictions with Single-Elbow Flexible Piping System Experiment" Transactions of the ASME,Vol. 101 (May). Creare, Inc. 1977 "An Evaulation of PWR Steam Generator Water Hammer" U.S. Nuclear Regulatory Commission. Cybernet Services, " PRTHRUST/PIPERUP Pipe Force and Whip Analysis" and "NUPIPE II/THREAT Piping Analysis Programs" Control Data. Graff, Karl F. 1975 "Wave Motion in Elastic Solids". University Press. Ohio State Gruel 1980 Master's Thesis, Massachusetts Institute of Technology, "Steam Bubble Collapse and Water Hammer in Piping Systems: Experiment and Analysis" Wylie, E. Benjamin and Streeter, Victor L. 1978 Fluid Transients. McGraw-Hill International. Timoshenko, S., Young, D.H., Weaver, Jr.W.,1974 Vibration Problems in Engineering. John Wiley and Sons. -61Appendix A: Sample Oscillograms for each Set of Experimental Conditions. The following figures include some sample oscillograms for each of the experimentally run test conditions. Throughout the text of the report, other oscillograms are illustrated to present a larger cross section of the test data. -625000 4000 - PIA (kPa) 3000 - Pressure at entrance 2000to test section (expanded time scale) 1000 170-: 0 I I I 30 20 10 I t 50 40 t (ms) 5000- 1 4000- PIA (kPa) 3000- Pressure at entrance to test sect ion 2000 0001 -120 (kPa) Depressurization -80 -40 U 170 "- I T I Fig. Al: I170 0 40 150 80 1 t (ms) 100 / 0 160 200 Steel Test Sec tion ). (P0 = 170 kPa) 50 50u 12000P3 (kPa) Pressure at closed end 8000-4000170 !1 0 40 80 120 t (ms) 160 600 800 DI (mm) Pipe Displacement at X= L (compressed time scale) 200400 t (ms) 200 -635000 4000PIA 3000(k Pa) Pressure at entrance 2000 to test section (expanded time scale) 1000 170 b t'ws 3!0 4b 5000" 4000 PIA (k Po) 3000 Pressure at entrance to test section 2000 I000 -80 -40C I)IM0 0 170 P2 150 (kPa) Depressurization 100 0 A 80 l0 1160 200 t (ms) Fig. A2: Steel Test Section (P0 = 240 kPa). 50 0 -1 12000 P3 (kPa) Pressure at closed end 8000 4000 I170 0 Dj 40 80 160 120 t (ms) 200 1.0- (mm) Pipe Displacement of X=L (compressed time scale) -1.0I 0 1 I 200 I I I 400 600 t (ms) f I 800 I -6450004000PIA 3000(kPa) Pressure at entrance 2000to test section (expanded time scale) 1000 170- r- r 0 I 10 I I I 20 30 -- F--T---T 40 50 t (ms) 5000 4000 PIA (k Pa) Pressure at entrance to test section 3000 2000 1000 )-T -80 P2 -4C 170 10 40 0 170150 160 2 t (ms) Fig. A3: (kPa) Depressurization t00 Steel Test Section (P0 = 310 kPa). 500- 12000 P3 (kPa) Pressure at closed end 80001 4000- 1700 40 80 120 t (ms) 6IO 200 660 400 t (ms) 800 DI (mm) 0-0 Pipe Displacement at X= L (compressed time scale) 200 -655000 40004 PIA (kPa) Pressure at entrance to test section (expanded time scale) 300020001000 1700 20 10 t (m.s) Ms 30 40 50 t 50004 000 PIA (k Pa) Pressure at entrance to test section 0002000 I000 -120 -'-i -80 -40 170 4' 0 " 40 80 170 P2 (kPa) S150 Fig. A4: -100 Depressurization 10 t (ms) 160 200 Copper Test Section (Po = 170 kPa). 12000 P3 (kPa) Pressure at closed end 8000 4000170-' 0 I- 40 I I I 80 i 120 t (ms) 160 400 660 t (ms) 800 200 DI (mm) Pipe Displacement at X L (compressed time scale) -1.0- 200 1000 -565000 4000IA (k Pa) Pressure ofatentrance to test section (expanded time scale) 30002000 - 1000170- II 0 I I 10 I 50 40 30 20 t (ms) 5000-4000PIA (kPa) (kPO) Pressure at entrance to test section 300020001000- -80 P2 -40 170 0 17 0 L 40 1501 120 80 160 200 t (ms) 0, Fig. A5: (kPa) 100 Depressurization 00 Copper Test Section (P = 240 kPa). 0 12000 P3 (kPo) 8000 Pressure at closed end 4000- 170J 0 I 40 ' I 80 I t 120 t (ms) '1 21 ' 0 160 200 DI (mm) Pipe Displacement at X L (compressed time scale) 0 200 600 400 t (ms) 800 1000 -6750004000PIA 3000 (kPa) Pressure at entrance 2000 to test section (expanded time scole) 1000 170 0 10 20 .t 30 (ms) 40 50 50004000 PIA (kPa) Pressure at entrance to test section 3000 2000 1000 -80 -40 170 S40 10I t (ms) 8 170- P2 150- Fig. A6: (kPa) Depressurization 100 160 200 Copper Test Section = S(P 310 kPa). 12000 P3 (kPo) Pressure at closed end 80004000170- + 0 I 40 I I 80 I I 120 t (ms) I 160 i 200 DI (mm) Pipe Displacement atof X= L (compressed time scale) 0- -I0 200 S 400 600 t(ms) 800 1000 -6850004000PIA (k Pa) 3000- Pressure at entrance 2000to test section (expanded time scale) 1000170 i Il0 lR 20 " 30 t (ms) 40 5000 4000 PIA (k Pa) Pressure at entrance to test section 3000 2000 1000 -120 Lq -80 -40 170o 40 80 -170 -150 P2 (kPa) Depressurization l0 t (ms) Fig. A7: 160 200 CPVC Test Section (P 0 = 170 kPa). -100 12000 - P3 (kPa) 8000- Pressure at closed end 4000170-F 0 40 80 120 t (ms) 160 200 10.0 DI (mm) Pipe Displacement at X L (compressed time scale) 5.0 0 - 5.01 10.r1 0 11 4 1 1I .8 t I 1.2 (s) 1.6 2.0 -6950004000PIA 3000 (k Pa) Pressure at entrance 2000 to test section (expanded time scale) 100030 40 50 t (ms) 5000 4000 Pt A (kPa) 3000 Pressure at entrance to test section 2000 1000 -80 -4 0 -- I 7A Icy jt 170- pu 60 150 410 '4'o 18 10 'ab' Fig. A8: (kPa) Depressurization I00- -- -1 ---- 't60' O '1 i.o' (ms) 200 CPVC Test Section = 240 kPa). (P 12000 P3 (kPoa) Pressure at closed end 8000 4000 l70- 0 40 80 120 t (ms) 160 200 10.0-t DI (mm) Pipe Displacement at XL (compressed time scale) -5.C - lo.oF 0 1 4 1I 6 .8 1 1 1.2 (S) 1 1 1.6 - 2.0 -7050004000PIA (k Pa) Pressure at entrance to test section (expanded time scale) 20001000- 60 17 io'30 40 50 t (ms) 5000 4000- PIA (kPa) 3000- Pressure at entrance to test section 20001000- -80 I I -40 I 170-P 0 I 40 1 0 80 160 200 t ( ms) 170 P2 150 (kPa) Depressurization 100 CPVC Test Section (P = 310 kPa) . Fig. A9: 50 0 12000P3 (kPa) Pressure at closed end 80001 4000 10 DI (mm) Pipe Displacement at X=L (compressed time scale) 0 40 80 4 .8 m120 t (ms) 160 200 1.6 2.0 5.0 0 -5.00 t 1.2 (5) -71Appendix B Experimental Test Data Table Bl : Table B2: Table B3: -72Table BI: P = 170 kPa 0 x=L Initial Depress. Material (kpa-s)(s Initial Impulse (kpa-s)(s) Steel 1) 7.51 .126 2) 12.5 11.6 .005 Copperl)8.16 .112 10.7 2) 7.70 .110 4.8 .005 Theory 3) 4) .994 18.81 16.99 .327 18.62 16.99 3.48 1.945 12.32 1.636 13.23 .004 1.964 12.69 1.964 13.37 2.055 12.57 1.945 13.51 2.409 12.82 3.227 12.82 2.727 12.82 5) 6) 7.93 .111 10.7 .005 Theory CPVC 1) 7.83 .113 12.5 2) 7.31 .116 12.2 3) Average Theory .336 18.48 .318 18.76 .836 19.04 7.51 .126 12.1 Average Impact Velocity Y max max m (m/s) (ms) (mm) (s- 1) (mm) (s-1) .005 1.109 18.21 .005 1.036 19.19 3) Average x=L/ 2.388 12.67 1.848 13.37 10.00 10.00 .006 4.727 5.67 2.727 5.67 .006 7.000 3.455 5.45 3.773 5.39 5.64 5.061 5.50 3.250 3.73 5.65 3.73 .006 7.57 .115 12.4 7.70 .116 11.94 .005 3.08 3.56 Overall Average - - - - 3.43 -73Table B2: = 240 kPa i Material Initial Depress. (kpa-s)(s) Steel 1) 5.81 .076 2) Initial Impulse (kpa-s)(s) y max (mm) (s-1) x=L/2I Y Impact max Velocity (mm) (s-'I (m/s) 15.6 .006 1.164 18.08 .473 18.35 15.7 .005 1.000 18.76 .427 18.48 .450 18.42 x=L 3) Average Theory 18.62 5.81 .076 15.6 .006 1.082 16.99 Copperl) 6.99 .006 1.818 12.32 1.745 12.44 2) 6.14 .084 14.1 .008 2.600 12.57 1.636 12.57 3) 6.40 4) .083 15.7 .007 2.691 2.255 13.09 12.57 1.527 2.364 13.09 13.51 5) 3.091 12.32 6) 3.045 12.69 7) 3.270 12.44 2.681 12.57 1.818 12.90 6.51 .084 15.1 .007 Theory 10.00 .084 15.7 .007 7.727 5.35 4.454 5.61 2) 6.53 3) .084 17.2 .006 8.364 6.818 5.35 5.41 4.682 5.32 .084 16.5 .007 7.636 5.37 4.568 5.47 6.37 Theory Overall Average 3.73 6.35 .083 15.6 .006 4.34 10.00 1) 6.20 Average 4.49 16.99 .085 15.4 Average CPVC 18.49 4.73 3.73 4.48 -74Table B3: = 310 kPa x=L Material Initial Depress. (kpa-s)(s) Initial Impulse (kpa-s)(s) x=L/2 y max (mm) (s-1) max (mm) (s-1 1.127 18.76 .591 l Impact elocity ) (m/s) Steel 1) 4.57 .064 16.0 2) 3) 18.8 .008 1.182 18.76 18.21 .509 18.21 4.57 .064 17.4 .008 1.155 1.1 18.58 16.99 .550 18.42 .65 16.99 .007 2.945 13.09 1.818 11.86 2) 6.40 .084 15.7 .009 2.182 12.32 2.309 12.08 3) 5.88 .072 18.8 .007 1.582 12.96 2.436 12.20 16.6 .008 1.164 12.69 2.200 11.86 5) 6) 3.227 12.96 2.400 13.44 3.818 12.57 7) 4.364 12.44 3.307 12.72 2.233 12.29 Average Theory Copper 1) 5.22 .079 19.0 4) Average 5.83 .078 17.52 .008 .008 10.00 Theory CPVC 1) 2) .007 10.182 .009 8.545 5.27 5.27 10.090 5.24 5.52 .080 20.3 .008 9.606 25.0 5.26 3.73 5.52 .077 .008 4.90 .080 19.6 6.14 .080 20.9 3) Average Theory Overall Average 18.18 18.62 5.01 5.04 10.00 4.682 4.363 5.417 4.523 8.5 5.499 3.73 5.580 5.84 5.23 -75Appendix C Development of Bubble Collapse Model The governing equations for steam bubble collapse, developed in Section IV, can be summarized as follows (see fig. 9) p2 AP dx2 P= P x dt 2 Momentum: d__x cdt v -x)) + m c T = PA dx s dt c p 1 S Condensation rate: AP Pressure Drop: (C4) RT 1 S d dt = - c = (C3) o s P =p Eq. of state: (C2) T p A( (c d Energy: (Cl) V dx dt Continuity: (C5) P=+P gh - (1+K)- p V2 _P(C6) P Pe (pA 5 ( o-x)) These equations can be nondimensionalized by defining the following dimensionless variables (Creare 1977): x x* - = t* o P* Vat Ps T*= AP AP AP* P0S P0 P psoRT o 1 p o (C7) C* = Vg Va V* = Va V P s so 12 where Va = ( ) Pk m and Vg = Ap (C8) Ap s Here C* is a dimensionless condensation rate which is determined by the variables defined in eq. C8. pso is the initial density -76of the steam in the steam bubble. Substitution into the governing equations yields: dx* Continuity: = V* V (9 (C9) dt AP* = x* d2 x*2 dt* Momentum: Energy'. d (CI0) (p* (1-x*) T*) + yC* T* = (y-1) b Enrg.dt* P* dx* (C) dt* c where y = p C v (C12) Eq. of State: P* = p* T* Condensation rate: Pressure Drop: C* (C13) d (p* (l-x*)) (l+K) V*2 - p* AP* = 1 - (C14) 2 Equations C9 - C14 represent 6 equations in 7 unknowns. They can be solved numerically be specifying C* as a function of time. The Runge-Kutta numerical integration method can be applied if the derivitives of each of the unknowns are specified. The following equations represent the necessary relationships: dx*= V* Position: Posiion-dt* Velocity: Delcity: Density: = AP x* Vdt* - C* do* = 0*V*l-x* dt* (Cl5) (C16) (C17) -77Temperature: dT* dt* p* T* V* - T* (l-x*) dP* dt* -y C* T* + (y-l) P* V* (c18). p* ( -x*) Pressure: Pressure Drop: dP* dAP* dt* Condensation rate: d (p* T*) - V* dV* dt* (C19) dP* dt* (C20) C* to be specified Some numerical solutions to these equations can be found in Gruel (1980). -78Appendix D Experimental Repeatability. Generally, the run to run experimental repeatability was about the same for the different experimental conditions, Typical results are presented here for the copper test section. Figs. Dl and D2 show several pressure traces for the copper test section recorded on two different time scales. The traces shown in (a) and (b) of the two figures demonstrate the typical run to run repeatablility. The "largest" run to run discrepencies, for nominally identical conditions, are shown in traces (c) of figs. Dl and D2. Several factors may have played a role in explaining the occasional run discrepancies evidenced by the differences between traces (a) and (c) of figs. Dl and D2. Residual air bubbles in the test section could have significantly reduced the acoustic wave speeds. Air in the steam bubble could have had a similar effect on the impact pressure magnitudes. The boundary condition at the downstream end of the test section may have occasionally deviated from an ideal "closed end." Any leakage or compliance in the downstream valve (fig. 2) could have reduced the magnitude of the reflected pressure spikes (at t = 10 to 15 ms). The greater time differences between the initial and reflected spikes in figs. Dl and D2 (c), as compared to the corresponding intervals in figs. Dl, D2 (a) and (b), could be explained by slower wave speeds caused by air in the system. I -79The displacement data exhibited about the same level of repeatability as the corresponding pressure histories. Fig. 03 show a representative set of traces for a fixed set of experimental conditions. Traces (a) and (b) illustrate the typical run to run repeatability for the displacements at the end of the test section (x = L). In most cases, primarily the first modes of vibration were excited. Occasionally, the second mode of vibration was superposed on the 03 (c). 1 st mode excitations, as illustrated in fig. Fig. 03 (d) shows a case where the displacements were dominated by only the second mode. The trace in fig. D3 (d) generally occured when the pressure histories were of the type shown in figs. Dl (c) and D2 (c). The amount of second mode ring out in the test section could have been affected by the degree of damping arising from pipe connections or from friction in the displacement transducer. The overall displacement amplitudes appear to have been dependent on the magnitude of the pressure spikes. -80- 5000 4000 () pA (kPo) 3000 2000 1000 170 -- 120 t(ms) 160 200 120 t(ms) 160 200 120 160 200 40 80 0 40 80 0 40 80 0 5000 4000 (b) PIA 3000 (kPO) 2000 1000 I000-I 170 -- 5000' 4000 (c) PIA 3000 (kPo) 2000 I000 170 t (ms) Fig. DI: Reproducibility of Pressure Data (Copper Test Section, PO- = 310 kPa). -815000 4000 (l) PIA (k Po) 300020001000170- i0 ' I 20 5000- PiA (kPo) I 30 t(ms) 40 40 50 50 1 7 4000- (b) ' 30002000- .A 1000170 30 5000. 4000- 3000 (c) PIA (kPo) 2000 1000 170 Fig. D2: t (ms) Reproducibility of Pressure Data (expanded time scale; Copper Test Section, P = 310 0 (0) 0! (mm) (b) 7.5 7.5- 5.0 5.0 - 2.5 2.5- 0 0-2.5 -2.5 -5.0 -5.0w -7.5 -7.5 0 0.4 0.2 0.6 t(s) 0.8 0 1.0 0.2 0.4 0.6 0.8 1.0 0.8 1.0 t(s) 3.0- D, (rMM) 5.0- 2.0 2.5- I1.0 0 0 - -2.5 - -1.0 -5.0- -2.0 -7.5- -3.0 I 0.2 Fig. D3: ' I 0.4 I 0.6 t(s) 0.8 1.0 0 0.2 0.4 0.6 t (s) (d) (c) Reproduci bility of Displacement Data (Copper Test Section, Po x = L). = 310 kP