Multi-Project Management: Strategy and

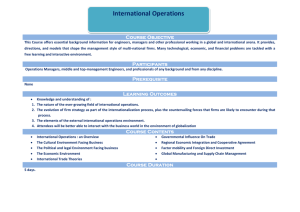

advertisement