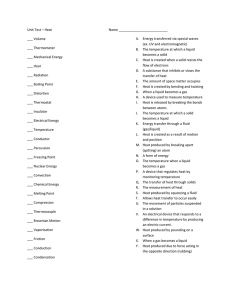

MECHANISM AND HEAT METALS Charles W. Deane, IV

advertisement