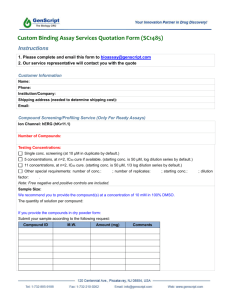

Application of Process Analysis and Optimization tools ... Lead Optimization phases of Drug Discovery at...

advertisement