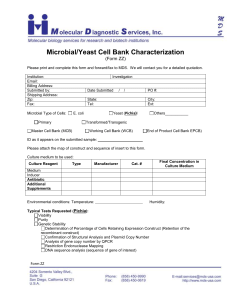

Pichia Pastoris Vasiliki Panagiotou

advertisement