PHYSICAL AND NUMERICAL MODELING OF THE MECHANICS

advertisement

PHYSICAL AND NUMERICAL MODELING OF THE

EXTERNAL FLUID MECHANICS OF

OTEC PILOT PLANTS

by

Paul N. Singarella and E. Eric Adams

Energy Laboratory Report No. MIT-EL

March 1982

82-018

CO0-4683-10

PHYSICAL AND NUMERICAL MODELING OF THE

EXTERNAL FLUID MECHANICS OF

OTEC PILOT PLANTS

Paul N. Singarella

and

E. Eric Adams

Energy Laboratory

and

Ralph M. Parsons Laboratory for

Water Resources and Hydrodynamics

Department of Civil Engineering

Massachusetts Institute of Technology

Cambridge, Massachusetts 02139

Prepared under the Support of

Division of Central Solar Technology

U.S. Department of Energy

Under Contract No. DE-AC0278ET20483.A004

Energy Laboratory Report No. MIT-EL 82-018

March 1982

ABSTRACT

This study examined the near field external fluid mechanics of

symmetrical OTEC pilot plant designs (20-80 MWe) under realistic deep

water conditions. The objective was to assess the environmental impact

of different plant configurations and to determine if pilot plants can

be expected to operate without degrading the thermal resource available

for power production. Physical modeling studies were conducted to investigate the variation of near field plume dynamics and the sensitivity of

recirculation to different pilot plant designs. Experiments were conducted in a thermally stratified 12m x 18m x 0.6m basin, at an undistorted length scale ratio of 1:300, which allowed the upper 170m of the

ocean to be studied. Measurements included temperature, dye concentration

and visual observation from photographs. Both mixed and non-mixed discharge concepts were investigated. Discharge port design included two,

four or eight discrete circular ports, with significant variations in the

MWe/port ratio, issuing either horizontally or vertically. A range of

ambient uniform current speeds was investigated while an ambient density

profile, representative of potential sites off of Hawaii and Puerto Rico,

was chosen.

A previously calibrated integral jet model (Hirst, 1971a) was tested

against experimental observation to develop a valid, predictive tool that

would facilitate study of conditions that were not modeled with the present

experimental set-up. The model was modified to more accurately represent

the dynamics of the OTEC discharge in the near field. Major modifications

included adjustment of the equations that characterized the starting length

(length of ZOFE); introduction of jet deflection in the ZOFE; introduction

of a lateral spreading formulation that allowed the "squeezing" effects of

the ambient stratification to be simulated; and introduction of an aspect

factor, which accounted for interaction of a number of closely spaced vertical jets issuing from a circular array. Overall agreement between prediction

and observation was quite good. The potential environmental impact of the

discharge plume from an OTEC plant over a broad range of realistic conditions

was assessed through additional sensitivity simulations.

Results indicate that little recirculation occurs for the designs considered in this study. The recirculation that does occur appears to be the

result of plume upwash in the lee of the plant and, possibly, internal wake

-2-

effects on the plant bow. Environmental impact is argued to be proportional to the degree of perturbation caused by the OTEC discharge to

the upper mixed layer. For the conditions considered in the sensitivity

study the OTEC plume remained below the upper mixed layer except for the

largest layer depths considered (H~ 100m). These larger depths are near

the maximum values reported for either Hawaii or Puerto Rico and represent the only conditions where significant perturbations may be likely.

-3-

ACKNOWLEDGEMENT

This report is part of a research program concerned with the near field

external fluid mechanics of OTEC plants. Previous reports produced at MIT

under this program include:

Adams, E., D. Fry, D. Coxe and D. Harleman, "Research on the

External Fluid Mechanics of Ocean Thermal Energy Conversion

Plants: Report Covering Experiments in Stagnant Water," Report

No. MIT-EL 79-041 Energy Laboratory, MIT, June 1979

Coxe, D., D. Dry and E. Adams, "Research on the External Fluid

Mechanics of Ocean Thermal Energy Conversion Plants: Report

Covering Experiments in a Current," Report No. MIT-EL 81-049,

Energy Laboratory, MIT, September, 1981

Fry, D. and E. Adams, "Buoyant Jet Behavior in Confined Regions,"

Report No. MIT-EL 81-050, Energy Laboratory, September, 1982

Support for the research program has been provided by the Ocean Systems

Branch, Division of Central Solar Technology of the U.S. Dept. of Energy under

Contract No. DE-ACO2-78ET20483,A004. Technical program support has also been

provided by Argonne National Laboratory. Drs. John D. Ditmars and Robert A.

Paddock of ANL are gratefully acknowledged for their cooperation and editorial

comments and for having supplied the original computer code upon which the

numerical calculations were based.

The reserach was performed by Mr. Paul Singarella in partial fulfillment

of the degree of Master of Science in Civil Engineering at MIT. Supervision

was provided by Dr. Eric Adams of the MIT Energy Laboratory and the Department of Civil Engineering. Appreciation is expressed to Dr. David Fry and

Mr. David Coxe, former students, who put together most of the experimental

set-up in connection with past studies, and to Messrs. Richard Baker, David

Kubiak and Peng-Chong Sien, students who provided assistance during the

experiments.

-4-

TABLE OF CONTENTS

Page

Abstract

2

Acknowledgement

4

Table of Contents

5

List of Figures

9

11

List of Tables

Chapter 1:

INTRODUCTION

12

1.1 Principles of Power Plant Operation

12

1.2 External Flow Considerations

15

1.3 Research Objectives

18

Chapter II: PREVIOUS AND PRESENT MODELING EFFORTS

Chapter III:

19

2.1 Background

19

2.2 Description of Previous Studies

19

2.3 Description of Present Study

22

24

ThE PHYSICAL MODEL

3.1 Modeling Considerations and Scaling Laws

24

3.1.1

Jet Reynolds Number Objective

24

3.1.2

Mixed-Unmixed Discharge Constraint

25

3.1.3

Ocean Profile Consideration

25

3.1.4

Experimental Basin Bottom Influence

Constraint

25

3.1.5

Scaling Laws

26

27

3.2 Model Design

-5-

3.3 Characterization of the Ambient Ocean

36

Chapter IV: THE EXPERIMENTS

4.1 Experimental Layout

36

4.1.1

The Model Basin

36

4.1.2

The Towing Apparatus

36

4.1.3

Discharge and Intake Water Circuits

36

4.1.4

The Stratification System

42

4.1.5

The Temperature Measurement System

43

4.1.6

The Dye Measurement System

45

4.1.7

The Photographs

47

4.2 Experimental Procedures

49

4.2.1

Procedures before and During an Experiment

49

4.2.2

Workup of Flourescent Dye Samples

52

4.2.3

Manipulation of Slide Photographs

53

4.2.4

Accuracy of Temperature Data

53

4.2.5

Temperature Data Manipulations

53

4.3 Experimental Results

4.3.1 Data Summary

Chapter V:

30

61

62

4.4 Comment on Jet Reynolds Numbers

65

THE INTEGRAL ANALYSIS

66

5.1 Justification for Use of an Integral Jet Model

66

5.2 Previous Integral Model Studies of Buoyant

Jets in a Current

66

5.3 Description of the Hirst Model

68

5.3.1

The Governing Equations

68

5.3.2

The Entrainment Function

72

-6-

Page

5.3.3

75

The ZOFE

5.4 Hirst's Verification of His Model

76

5.5 Previous OTEC Related Use of the Hirst Model

77

5.6 Adaptation of Hirst

IModel

5.6.1

Jet Interaction

79

5.6.2

Deflection in the ZOFE

94

5.6.3

Starting Length

95

5.6.4

Lateral Spreading of Plume

99

5.7 Hirst Model Simulations of Experimental Conditions

Chapter VI:

78

104

5.7.1

Vertical Discharge Experiments

104

5.7.2

Qualification of Comparison for Vertical

Discharge Experiments

111

5.8 Horizontal Discharge Experiments

114

5.9 Additional Comments on the Model Equations

115

5.9.1

An Infinite Entrainment Rate?

115

5.9.2

Boundary Layer Assumption Inconsistency

116

ADDITIONAL SIMULATIONS WITH THE INTEGRAL JET MODEL

119

6.1 Introduction

119

6.2 Selection of Base Case Plant and Ocean

119

6.3 Sensitivity to Perturbation from Base Case Conditions 121

6.3.1

Presentation of Results

121

6.3.2

Discussion of Results

126

6.4 Modeling a Separate Condenser Jet

129

6.5 Modeling Experimental Conditions from a Previous

Physical Model Study

130

6.6 Future Use of Model for Environmental Assessment

133

-7-

Page

Chapter VII:

135

RECIRCULATION

7.1 Introduction

135

7.2 Direct Recirculation in Stagnant Water Tests

135

7.3 The Upwash Effect in Vertical Experiments in

a current

136

7.4 Recirculation in Tests in a Current

138

Chapter VIII: SUMMARY AND CONCLUSIONS

142

8.1 Summary

142

8.2 Physical Modeling

142

8.2.1

Conditions Modeled

142

8.2.2

Conclusions and Recommendations for

Future Work

143

8.3 Numerical Modeling

144

8.3.1 Methodology

144

8.3.2 Conclusions and Recommendations for

Future Work

145

147

References

Appendix I: SIMULATIONS OF THE OTEC NODEL DISCHARGE IN THE

VERTICAL, Y-Z PLANE, COMPARED TO EXPERIMENT

151

Appendix II:SIMULATIONS OF THE OTEC MODEL DISCHARGE IN THE

HORIZONTAL X-Y PLANE, COMPARED TO EXPERIMENT

170

Appendix III: FINAL COPY OF INTEGRAL JET MODEL CODE

207

-8-

LIST OF FIGURES

Figure No.

Page

Title

1.1

Examples of Vertical Temperature

Profiles for the Tropical Ocean

13

1.2

OTEC Power Cycle

14

2.1

Zones of a Submerged Discharge

20

3.1

Cutaway View of M.I.T. OTEC Model

28

3.2

Photograph of Model and Table of

Model Characterization

29

3,3

Coordinate System of Physical Model

3.4

Comparison of Proposed Model and

40 MWe Gibbs & Cox Design

33

3.5

Superimposed Experimental Profile

(Scale 1:300) for comparison to Ocean

Density Profiles

34

4.1

Schematic Diagram of the Experimental

Setup

37

4.2

Schematic of the Towing Apparatus

38

4.3

Blowup Schematic of the Towing Carriage

39

4.4

Photograph of Flow Apparatus and

Model Support Frame

41

4.5

Typical Variability Between Basin

Density Profiles of Experiments

44

4.6

Flow Chart for the Temperature

Data Acquisition System

46

4.7

Cross Sectional Schematic of the Sideview

Photographic Apparatus

48

4.8

Typical Side View Cross Sectional Photograph

50

4.9

Typical Overhead Photograph

50

5.1

Natural Coordinate System

71

5.2

Example Aspect Factor Illustration

81

-9-

Page

5.3

Aspect Factor Definition Sketch for

Two Jet Experiments

87

5.4

Aspect Factor Definition Sketch for

Four Jet Experiments

89

5.5

Aspect Factor Definition Sketch for

Eight Jet Experiments

91

5.6

Crossflow Ratio Versus Normalized

Starting Length

96

5.7

Vertical Pressure Distribution of Water

Column When the Plume is at Equilibrium

100

5.8

5.9

S250 (Observed) Versus S250 (Predicted)

Versus t250 (Predicted)

t250 (bserved)

105

106

250 (Observed) Versus W 2 5 0 (Predicted)

5.10

(Observed) Versus heq (Predicted)

107

108

5.11

h

6.1

Base Case Plant Configuration and AF Sketch

122

7.1

Side View Photograph of Run 4A Illustrating

Circular Motion of Upwashed Dye Billows

137

7.2

Annular Intake Structure Showing

Positions of Intake Thermistor Probes

139

-10-

LIST OF TABLES

Table No.

Title

Page

4.1

Experimental Parameter Schematization

54

4.2

Experimental Parameters (Prototype dimensions

except for Re)

56

4.3

Experimental Results

58

4.4

Time-Variant Experimental Results

of Non-Steady State Stagnant

Experiments

64

5.1.1

Description of Simulations for

AF Sensitivity Analysis

82

5.1.2

Statistical Results of AF Sensitivity

Simulations

83

5.2

Equivalent Source, No Interaction

Compared to Individual Source

85

5.3

Simulation Versus Observation for Vertical

Discharge Experiments in a Current

198

5.4

Statistics of Simulation Versus

Observation for Vertical Discharge

Experiments in a Current

104

5.5

Assessment of Model's Prediction of

Geometry in the Y-Z Plane

110

6.1

Base Case-Conditions

120

6.2.1

Description of Simulations (Perturbations

from Base Case Conditions)

121

6.2.2

Results of Simulations Described

in Table 6.2.1

123

6.3

Simulated Condenser Jets

130

6.4.1

Independent Parameters of Coxe's

Single Jet, Horizontal Discharge

131

6.4.2

Simulation Versus Observation for

Coxe's Initial Conditions

132

-11-

1. INTRODUCTION

1.1

Principles of Power Plant Operation

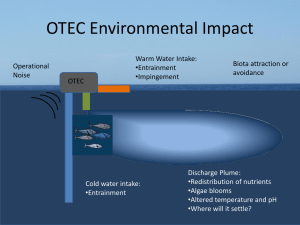

Ocean thermal energy conversion (OTEC) is a proposed energy conversion

process that uses the temperature differential between upper and lower ocean

strata set up by the sun.

Only in tropicalor subtropical waters is this temAnd

perature differential large enough for the technology to be considered.

even here, the preservation of the surface thermal resource will be critical to

profitable plant operation.

OTEC is a second order solar technology in that it does not directly utilize the sun's rays but taps the solar radiation captured by

the upper ocean. Fig.

1.1 depicts representative vertical temperature

profiles for tropical oceans, each exhibiting a characteristic mixed layer

of warm water near the surface above a stably stratified density structure.

water

Since

makes

around-the-clock

an

excellent

operation

of

heat

OTEC

and

reservoir,

minimizes

this

permits

annual

output

fluctuations.

Heat

Fig. 1.2 is a simple illustration of an OTEC closed power cycle.

from the warm upper water is used in an evaporator to vaporize a working

fluid such as ammonia or freon in a pressurized vessel.

expanded through a turbo-generator

The vapor is

to produce electric power and

is

subsequently condensed using the cold water sink.

The ideal thermodynamic efficiency,

E

T -T

c

Th

(1 -

K

-12-

1)

T(oC)

100

*

/

200

300

,

III

/

400 -

600

I

I

z (m)

---

Lockheed (Dugger, 1975)

Carribean (Fuglister, 1960)

---------w---

Figure 1.1:

Florida Straits (Pub. No. 700)

Hawaii (Bathen, 1975)

Examples of Vertical Temperature Profiles

for the Tropical Ocean (From Jirka, et al,

1977).

-13-

Worm Water Seawater

Worm Water Seawater

Exhaust

Intake

22.8

Liquid

Pump

Electric

Power

Low Pressure

Ammonio Liquid

100C (50

0 F)

Cold Seowater Intake

50C (41 0 F)

Cold Seawater Exhaust

7.20C (45 0 F)

'

Figure 1.2: OTEC Power Cycle

-14-

of an OTEC plant

is 6 to 8% based on typical temperature differences

between the surface and a depth of 500 to 1500 meters of 18 to 240 C.

However, net mechanical efficiencies are estimated to be only about 2 to

3%, compared to 30 to 40% for conventional power plants.

In order to produce quantities of power comparable to conventional

power plants, an OTEC plant must utilize enormous amounts of water to

exploit the low grade energy

to produce

resource.

For example, for an OTEC plant

100 MWe at an efficiency of 3% with a realizable temperature

difference across the heat engine of 100 C, corresponding to a 200 C ocean

temperature difference (Allender et al, 1978), the warm and cold water

intake flows would each have to be 500 m3/sec (Fry, 1976).

1.2

External Flow Considerations

OTEC plants interact with the ocean environment by withdrawing water

through their intake ports and exhausting it through their discharge ports.

The

external

flow

field

this

process

generates

influences

plant

performance, as affected by any potential recirculation, and potential

environmental impacts, such as nutrient or pollutant transport and ocean

temperature modification.

Allender, et al (1978) have examined the sensitivity of OTEC power

output to a fractional loss in thermal resource.

AP

They found that:

A

n

P

n

1

E(l-a)

p

(1 - 2)

ep

where E, the fraction of the total thermal resource that exists across

the power cycle, is expected to be about 0.5 and a, the percentage of

-15-

A thermal resource,

parasitic power losses, anywhere from 0.16 to 0.40.

e , of 180 C represents the lower bound of practicality. If a 10C 66

p

P

0

occurred with an initial 6 of 20 C, the plant would experience a 13%

decrease in power output according to equation 1-2 with an a of 0.2.

Since the temperature of the deep cold water is expected to remain

will occur primarily through change in

approximately constant, change in 6

the warm water intake temperature.

Because of the enormous flows involved,

the warm water intake temperature is not only a function of ambient ocean

variability,

interactions

of potential

but

between

the

flow

fields

generated by the evaporator intake, the plant discharges and the mixed

layer depth (Ditmars

et al, 1979).

The extent of these interactions

depends upon a number of factors, including the location of the intake

and

discharge

ports

the

to

relative

mixed

layer

and

the

vertical

separation between them, the ambient ocean currents, the angle of the

discharge

with respect

the

to

horizontal

discharge flow relative to the ambient

discharges are always

and

density

thermal resource available

buoyancy of

structure.

colder than the warm water

such interactions can only serve to lower it.

recirculation.

the

the

Since the

intake temperature,

This degradation of the

to the plant is generally referred

to as

It may result from some fraction of the discharge volume

flux entering the warm water intake directly or from several indirect

causes such as recirculation of water entrained by the discharge jets,

turbulent

mixing

of

the

upper

stratified

layers

(induced

by

the

discharge jets) accompanied by a lowering of the mixed layer temperature

or selective withdrawal of the upper thermocline layers by the intake

port.

-16-

Operation of an OTEC plant may not only influence the utilization

of

the thermal

resource, but may

also have

ecological affects.

As

discussed briefly below, prevention and control of biofouling on the

heat

exchangers,

introduction

the

of

occurrence

deep,

of

working

nutrient-rich water

fluid

relatively

surface will all have environmental

impacts.

require

time-history

ccupling of

the OTEC plume

leaks,

and

close

to

the

the

Study of these phenomena

characteristics with

appropriate, biological and chemical, kinetic models.

Biofouling refers to the growth of organisms whether macroscopic,

such as barnacles and mussels, or microscopic, such as slime films, on

the heat exchanger surfaces.

Bell

(1977)

found that

thick slime layer precipitated a 15 to 25%

efficiency.

decrease in heat

formula

control

will

probably

transfer

be

a

infrequent and expensive mechanical scrubbing to remove

combination of

the growth

biofouling

The

a 50 micrometer

and

frequent

to its

and

cost

cheap

chemical

effectiveness,

to retard

it.

obvious choice

for

treatment

is the

Chlorine,

due

biocide.

The alternatives, chlorine dioxide and bromine are two to ten

times more expensive (Sands,

1980).

Chlorine however is toxic in trace

amounts.

Possible

isobutane.

working

Owens

fluids

include

ammonia,

freon,

propane

and

(1978) found that ammonia required the least amount

of surface area per kilowatt of net power produced of all these fluids.

Since

the

investment

heat

exchangers

(Sands, 1980),

working fluid.

represent

roughly

half

of

the

capital

ammonia appears to be the logical choice of

In the unlikely event of a massive rupture of the heat

-17-

exchangers, massive amounts of working fluid would be injected into the

Ammonia would cause the affected seawater to go strongly

environment.

basic

result

and

(Walsh, 1980).

in

massive

precipitation

of

hydroxides

metal

The depletion of these metals may be detrimental to the

local food chain.

The subsequent ammonium generated would act as a potent

inhibitor, uncoupling light

energy during photosynthesis

(Walsh, 1980)

Introduction of working fluid through continuous small leaks would cause

more subtle perturbations of the ambient water chemistry and ecosystem, if

any.

The OTEC plant will artificially upwell deep, nutrient-rich water.

However

the

discharge

plume will

generally

be

directed

into

the

thermocline in order to prevent recirculation and the upwelled nutrients

may remain essentially out of the area of primary productivity.

The

plume may entrain a portion of the surface zooplankton community and

relax the grazing stress of the species (Brookhaven, 1981).

1.3

Research Objectives

The objective of this study is to examine the external fluid mechanics

associated with modular, 10 to 100 MWe, OTEC pilot plant designs, under

realistic

ocean

conditions

to

facilitate

environmental impact and optimization.

assessment

of

pilot plant

This will be accomplished through a

series of physical model tests and subsequent verification of an integral

jet model with the test results.

-18-

II:

PREVIOUS AND PRESENT MODELING EFFORTS

2.1 Background

Claude built the first operational OTEC plant in

feasibility.

However

low

relatively

development.

As

cost

the

of

lack

fossil

technology has

of

sufficient

fuels

interest in OTEC has resurfaced.

technology

prevented

evolved and

1930 proving its

fuel

further

and

the

system

costs have

soared,

Consequently, numerical and physical

modeling studies have been undertaken to assess OTEC feasibility and to

evaluate how proposed power plant designs behave within the ocean

environment.

2.2

Description of Previous Studies

Most

studies pertain to specific zones of

A

the external flow.

submerged discharge can be divided into three such zones (Fig. 2.1), with

gradual transition between zones. In the near field zone, the jet dynamics

are governed by the buoyancy and momentum of the jet, the ambient current

and stratification, and any interaction with the OTEC plant structure, the

evaporator intake, the free surface or the ocean floor (in the case of a

shore-based or shelf-mounted plant).

In the intermediate zone, the jet has

arrived at an equilibrium elevation and exhibits lateral spreading due to

buoyant forces.

Jet momentum effects are relatively insignificant.

In the

far-field zone, only ambient turbulence is left to diffuse the plume.

The

following studies pertain to near field phenomena.

Several investigators

(Lockheed, 1975;

-19-

Fry,

1976;

Giannotti, 1977;

CI

Intermediate-field zone

Figure 2.1:

Zones of submerged discharge.

Ditmars et al, 1979) have used integral techniques to analyze the behavior

of individual buoyant jets representing evaporator and/or condenser flows

floating OTEC plant

from a

discharging

environment.

However proposed OTEC

into

a

stratified

site-specific

data

(Sands,

indicates that significant currents will be experienced.

Mangarella

1980)

Van Dusen and

(1974) performed a similar analysis except relatively strong

currents were studied.

the

stagnant

Straits

Florida,

of

Massachusetts.

Their investigation was essentially only germane to

While

the

these

site

studied

investigations

by

used

the

University

of

established modeling

techniques none of the results were verified against experimental data

pertaining to an OTEC application.

None explored the possibility of a

multiple port discharge and subsequent jet interaction.

Several investigators (Sundaram et al, 1977; Jirka et al, 1977; Adams

et al, 1979; Coxe et al, 1980) have performed physical model studies that

examine possible interaction between the intake and discharge.

explored

a highly

schematic

plant

configuration

with a

Sundaram

two-layered

Jirka explored a similar ambient

stratification and realistic currents.

environment with a more realistic plant.

Adams and Coxe incorporated a

realistic range of stratification into their experiments as well as a

realistic plant and range of currents. However all these investigations

focussed on horizontal discharges.

The type of recirculation observed by

Adams and Coxe is significantly different from the type observed in this

study.

In addition, Adams and Coxe considered plants in the 100 to 600

MWe range; these plants are much larger than anticipated pilot plants.

Paddock

et

al

(1981)

recently

analyzed

field

measurements

associated with the mixed discharge plume of the one MWe, OTEC-1 facility

-21-

Dye measurements were compared with analytical model

off of Hawaii.

The model included an

prediction.

integral analysis in the near-field

and a dimensional analysis after Jirka et al (1980) to analyze lateral

spreading

in

field.

the intermediate

The analysis cannot be easily

extended to predict pilot plant plume behavior due to the limited data

which were

collected

and

uncontrolled environment.

the

uncertainty

of

an

in

measurement

In addition, the flow of the OTEC-1 facility is

an order of magnitude less than that of the smallest proposed pilot plant.

2.3

Description of Present Study

The optimal OTEC plant size in terms of cost effectiveness has been

estimated

exception

studies with the

aforementioned

plants of this order of magnitude.

100

MWe

(Gibbs and Cox,

to be in the range of 400 MWe

pilot

plants

commercialilzation.

will

of Paddock

1979).

(1981),

The

address

However the deployment of many 10 to

undoubtedly

precede

large-scale

Sands (1980) projects that a total of ten modular,

10 to 100 MWe pilot plants will be operational by 1995 off Hawaii and

Puerto Rico.

Possible plant

types

include

land-based,

shelf-mounted,

asymmetric ship and floating, deep water, spar buoy design.

At least

some of these plants will probably fall into the last category with one

or two discharge ports per module.

to be about 10 MWe.

The size of a module is anticipated

It is also likely

that some of the plants will

have vertically directed discharges (Scott, 1979).

The fluid dynamics of these pilot plants will differ from those

previously

orientation.

studied

due

to

different

plant

size

and

discharge

This eliminates the possibility of directly extrapolating

-22-

the results

plants.

In

from the studies

light

of

this,

of

we

the larger plants

have

examined

to

include pilot

experimentally

and

mathematically the near field external fluid mechanics of 10 to 100 MWe,

modular pilot plants discharging both horizontally and vertically into

deep water.

This work represents the first experimental study of OTEC

pilot plants.

-23-

THE PHYSICAL MODEL

III.

Modeling Considerations and Scaling Laws

3.1

To retain dynamic similitude between the prototype and the model,

undistorted densimetric Froude scaling was used, which preserves the ratio

of buoyancy and momentum forces.

Both the momemtum and the buoyancy of the

discharge determine the external flow field surrounding an OTEC plant and

is to be considered valid.

both must be represented if a model

The

selection of a model to prototype length scale, Lr ,must satisfy several

Reynold's numbers large enough to

Obtaining jet

competing objectives.

insure turbulent flow dictates a large scale ratio as does measurement

resolution.

Modeling large ocean depths dictates a small scale ratio.

In

addition, the experimental facilities impose certain physical constraints.

The following discussion addresses these length scale considerations.

3.1.1

Jet Reynolds Number Objective

2u b

0

R

e

The

v

u

= discharge velocity

b

= port radius

v

= kinematic viscosity

jet Reynolds number must

fully

where

turbulent

jet

exceed a minimum value

flow needed

for model-prototype

to maintain

the

similarity.

The

minimum value is generally accepted to be 1500 (Ungate, 1975).

However the

transition from turbulent to laminar flow is gradual and this value is

somewhat arbitrary.

For a given plant size, this objective is

-24-

increasingly difficult to meet for low discharge velocities.

Mixed-Unmixed Discharge Constraint

3.1.2

The flow system currently available to our experimental basin only

allows the discharge of a single temperature water thus preventing us from

modeling separate evaporator and condenser discharges.

Therefore we can

only model mixed discharges (combined warm and cold water flows) or warm

water discharge flow.

It is therefore assumed that the warm and cold water

discharge flow fields, when discharged separately, are independent of each

other.

Ocean Profile Consideration

3.1.3

The

reasonable ocean density profiles

ability to produce

in

the

experimental basin with fresh water at a length scale ratio of 1:300 has

been demonstrated by previous work (Adams et al, 1979; Coxe et al, 1980).

The 1:300 ocean density profile has been shown to be reasonably stable over

the duration of an experiment

(see section 4.1.4).

As L

r

decreases, the

relative perturbation to the temperature profile due to surface cooling

increases which would contribute to a general decrease of the stability

of

the

ocean density

profile

over

the

duration of

an

experiment.

Therefore to avoid further experimentation, it would be advantageous and

convenient to work with an L

r

3.1.4

of 1:300.

Experimental Basin Bottom Influence Constraint

At a scale ratio of 1:300, the experimental basin has a prototype

depth of 174 meters, much less than required for OTEC operation.

-25-

Therefore

the success of our simulations depends on the absence of significant

This consideration was most constraining to the

basin floor influences.

case of vertically directed discharges in stagnant water.

An investigation of available data (Fry,1980) suggested that bottom

basin interference could be avoided for vertical flows corresponding to

10 to

100 MWe

and

a length

scale

ratio

of

1:300 if

the

proper

combination of discharge depth, ambient current velocity, port size and

number of ports was maintained.

The investigation also indicated that a

length scale ratio of 1:400 severely limits examination of low velocity

discharges and low power

criteria.

(MWe) plants because of the Reynold's number

For example, at an L

r

of 1:300, R is approximately 2000 for

e

an evaporator discharge from a 10 MWe plant with a b

of

1:400, Re is approximately

o

of 3.1m. At an L

r

1400 for the same plant, if the same

similarity conditions are preserved.

In fact, under the same similarity

conditions, only about one third of our experiments would have had an Re

greater than

3.1.5

1500 for an L

r

of 1:400.

Scaling Laws

Due to the considerations described above, a length scale ratio of

1:300 was chosen.

This was a convenient choice since previous studies

(Adams et al, 1979; Coxe et al, 1980) had proven the viability of modeling

OTEC plants in the basin at this L .

r

The densimetric Froude number is

defined as:

IF = u(g A-- h)

where u,h , p

and Ap

density difference.

rp a characteristic velocity, length, density and

If the ratio of a characteristic quantity between the

-26-

model and protype is designated with subscript r, and if AO is assumed

r

equal to one,

then equality of densimetric Froude number

protype implies the following conditions for the ratios

in

model and

of velocity, time

and flow rate at an undistributed length scale of 1:300:

u

r

t

r

= L 1/2 = 0.058

r

= L 1/2 = 0.058

r

Qr = L

5/2

-7

/2 = 6.4 x 10

3.2 Model Design

The designs considered in

be modeled as

horizontally

intake

this study are limited to those which can

columns, discharging vertically

symmetrical vertical

from

round,

(see Fig. 3.1).

multiple

ports,

Designs with two,

with

an

annular

or eight

four

or

warm water

evenly

spaced

ports located at a single radius from the plant axis were investigated

It

Fig. 3.2 shows a photograph of the model.

model used by Coxe et al

are designed

(1980) in several ways.

differs

The discharge ports

instead

to discharge vertically downward,

from the

of horizontally.

However horizontal discharge was achieved by fitting 900 elbows into the

ports.

The cold water pipe is

now included in

possible interaction between it

and

the model so as to study

a vertical

discharge.

The Coxe

model could discharge from a radial or annular port, as well as from

discrete ports, whereas the present model can only discharge from discrete

ports.

-27-

DISCHARGE

LINES

Figure 3.1:

Cutaway View of M.I.T. OTEC Model (shown for vertical

discharge; for horizontal discharge, 90 elbows were

attached to each discharge line and were directed

radially outward)

-28-

4 1

EXPERIMENTAL MODEL (1:300),

RANGE OF PARAMETER VARIATION

Qi (m3/s)

hi(m)

100-400

4.0

Qo (m3/s)

100-400

u (m/s)

0.8-3.9

b (m)

2.8-3.1

hd(m)

39-43

01(o)

0, +45 +90

02( 0)

0 and

J

90

2,4,8

r

(m)

23

4.1

r (m)

c

38-57

u.(m/sec)

-H (m)

Notes:

38-57

u

= discharge velocity

b

= port radius

o

r

o

r

u

o

c

= plant radius

= cold water pipe radius

co = ambient current velocity

Figure 3 .2: Photograph

of Model and Table of

Model Characterization

A

3.3

Characterization of the Ambient Ocean

Figure 3.5

(Miller, 1977) shows ocean density profiles for several

Underneath a well-mixed layer near the surface lies

tropical locations.

a thermocline, where temperature drops rapidly accounting for a strong

density gradient.

important

The stable density structure in the thermocline is an

inhibitor

to

momentum

vertical

and

heat

transfer,

and

therefore, is an important consideration in the study of OTEC external

fluid mechanics.

As shown in Fig.

3.5, this

study

considers realistic continuous

density profiles which are comparable to actual ocean density profiles.

Although each density profile produced in the laboratory is different in

detail, they are characterized by their values of H and Apa*

H is the mixed

layer depth, defined as the depth where the ambient temperature differs from

is the density difference between

the surface temperature by 1C. Apa

the surface and 165 meters, far enough above the basin bottom to avoid

any potential thermal boundary layer.

As reported by

Sands

the most

(1980),

frequently observed mixed

layer depths in Puerto Rico and Hawaii are 68 and 66m respectively.

As shown in Fig. 3.2,

monthly average is less than 40m.

examines a slightly conservative

(ie

shallow) range

No

this study

of mixed

layer

depths.

In addition

modeled.

to density

stratification, ocean currents were also

Monthly mean surface currents, u.,

range from 11 to 37 cm/sec.

in Hawaii and Puerto Rico

As shown in Fig. 3.2, this study examines a

realistic range of currents.

-30-

As previously mentioned, two discharge configurations are considered

in this study.

For a horizontal discharge, the vertical angle e2 between

the horizontal plane and the direction of discharge, equals 0O

3.3).

(see Fig.

The horizontal angle 61, measured from the axis normal to the

current toward the direction of the current (see Fig. 3.3), may vary from

-900 for a counterflowing jet to +900 for a co-flowing jet.

discharge, 62 = 900 while 61 is undefined.

For a vertical

The orientations of the vertical

port arrays for tests with 2.4 and 8 jets are shown in Figs. 5.3, 5.4 and

5.5.

The table in Fig. 3.2 lists the parameters used to characterize the

OTEC plant and the ranges corresponding to their variations in the model

tests.

The evaporator intake flow, Qi, which enters the model through a

radial configuration of circular port holes, is located at a depth hi below

the surface.

The condenser intake is not modeled.

The discharge flow, Qo'

is exhausted through a total of J ports, at a depth h d .

flow is mixed, Qo = 2Qi..

hen the discharge

When it is non-mixed (referred to from here on as

an evaporator discharge), Qo =

Q..

Fig. 3.4 shows the Gibbs and Cox (Scott, 1979) 40 MNe spar OTEC plant

against the outline of our experimental model.

discharge

are

shown at

experiments were run.

the

depths at

which

The model's intake and

the vertical

discharge

The horizontal experimental discharge was a few

meters deeper (see Table 4.2).

The separation between the intake and discharge in the model is less

than half of the separation in the Gibbs and Cox design.

To some degree, this

was necessary to avoid interaction with the basin bottom; however, it also

allowed us to explore conditions under which recirculation was most likely to

occur.

-31-

01

O

Y/

Figure 3.3:

Coordinate System of Physical Model

:rodel Intake

Prototyp

-

Intake

A

A

--

'rotot' pe

1)ischarge

Model

O

S....

Discharge

5

,

. .-

O

0a . - 115

•

Figure 3.4

;

_._....._ "

Mode!

30m.

rn.Prototype

Section A-A

Comparison of Proposed ,Model and 40 M1:e

Gibbs 6 Cox Design

-33-

1:crr.

6

5

241

3

0_

D

/

/

I

I

J

D

1

200-

IT/

200

I

*II

r

/

8/

I

/

i:

6:

DENSITY

3:

Figure 3.5:

I

I

S. Atlantic-Brazil

I2 If'S, 30002'W1

Rico

Puerto

iss.-la.

'WI

04'%, 64

1 0 ()'R

8 2 '\

[8

Superimposed Experimental Profile (Scale 1:3007',) for Comparisonh

to Ocean Density Profiles

-34-

[Miller, 1977].

The currents in our model are simulated by towing the model OTEC

plant

through

a

temperature-stratified

basin.

Thus,

prototype

conditions are modeled with a uniform ambient current and a horizontally

uniform, vertically stratified environment.

-35-

THE EXPERIMENTS

IV.

Experimental Layout

4.1

4.1.1

The Model Basin

The experiments were conducted in a 12.2 m x 18.3 m x 0.58 m basin

located on the first floor of the Ralph M. Parsons laboratory for Water

Resources and Hydrodynamics at M.I.T.

are insultated to minimize heat

The floor and sides of the basin

loss to the surroundings.

Figure 4.1

presents a general layout of the basin showing the experimental setup

for the tests performed in a current.

The Towing Apparatus

4.1.2

The towing apparatus is presented schematically in Figs. 4.2 and 4.3.

A continuous belt, driven by a reversible 3 horsepower varispeed motor,

pulls the towing carriage across the basin.

guides the belt,

carriage.

forming a closed

The model intake

An overhead support rail

loop with each side of the towing

and discharge

hoses,

attached to trolley

wheels in the overhead support rail, are pulled by the towing carriage

as it

crosses the basin.

Figure 4.3 shows the OTEC model located in

stage no. 1 of the towing carriage with data acquisition equipment

located on stages 2 and 3.

4.1.3

The Discharge and Intake Water Circuits

The intake and discharge water flow circuits

for the stratified

current tests are schematically illustrated in Fig. 4.1.

-36-

K

!-8

3m (60')

12 2m

(40')

To Drain

Window

U Filter

0

Roto Meter

H Head Tank

8

Control Valve

M Manifold

* Pulley

+ Profile Probe Stations

Figure 4.1:

Schematic Diagram of the Experimental Setup

Guide Pulley

,

To/From Pumps*Drive Pulley ---Motor

,

--

Guide Track

V Towing

Carriage

Figure 4.2:

OTEI

Schematic of the Towing Apparatus

Counterweight

Liftracks

Peristaltic

Sample Pump

/Mntnr

Solenoid Valves

Stage no 3

__

_

Apparatus

Support Frame

Sample Troy

IFrame

/ i

S/Supports

__

/Woz

-=

Z-

"-

.

•

/7

"

I

.

j_

Stage no 2

Sampling Pr0ote

Support Frame

(Vorable Height'

Metal

Coaster - -

Wheels

Stage no I

Model

Support

Frame

\/

Figure 4.3:

Blow Up Schematic of the Towing Carriage

-39-

To

simulate

temperature

steady

of the

state

discharge

operation

of

an

flow must be kept

OTEC plant,

constant.

the

This

is

accomplished by mixing cold tap water with hot water that has passed

through a steam heat exchanger.

A mixing valve adjusts the relative flow

of hot and cold water to achieve the desired temperature.

The water flows

through the mixing valve to a constant head tank which provides a constant

pressure to the discharge flow and helps to damp out short term temperature

fluctuations.

The water is

filter, where it

pumped

from the head tank into a diatomaceous earth

is purified for photographic purposes.

Rhodamine B, a

flourescent dye, is introduced into the water with a peristaltic pump as

it leaves the filter.

Then the water passes through a rotameter and

control valve to the discharge hose.

The discharge hose carries the

water to a flow manifold located on stage no. 3 of the towing carriage.

The manifold

distributes

the water

through

eight

valves.

Hoses

connected to each valve lead to copper tubes in the upper portion of the

model.

The flow passes through these copper tubes and out to the

discharge ports.

The discharge temperature is monitored in the flow

lines near the model and before it enters the discharge hose.

Figure

4.4 is a photograph of the flow apparatus showing the constant head

tank, the filter, the rotameters, the intake and discharge hoses and the

towing carriage.

The intake circuit, driven by a pump, withdraws water from the

basin through the perforations in the annulus at the top of the model

(see figure 3.1).

The water flows through the intake hose, is measured

by a rotameter and controlled by a valve, before it is fed to a drain.

-40-

4-.

Figure 4.4:

Photograph of Flow Apparatus and Model Support Frame

It should be noted that for a mixed discharge flow configuration a net

flow was introduced into the basin.

No effort was made to adjust the

water level to account for this effect.

4.1.4

The Stratification System

The basin is filled with water of different temperatures, all of

which passes through the filter for photographic purposes.

Initially

the

takes

basin

is

filled

partway

approximately two hours.

with

Then,

cold

city

hot water

water,

which

from the mixing valve

is

bypassed through a hose network to a radial manifold located on a float

in the center of the basin, providing an even distribution of the hot

water over the cold water surface and minimizing mixing of the cold and

hot water.

The

period, diffusion

hot water

fill takes

takes place between

17

to

20 hours.

the warm and

resulting in a smooth temperature profile.

During this

the

cold water

Once the filling is over,

surface cooling mixes the upper layers thereby lowering the mixed layer

temperature.

water

The density difference between the entering hot and

is designed to be greater than the one desired, Apa.

cold

Thus a

cooling period of one to four hours follows the fill and precedes an

experiment.

Coxe et al, (1980) reported on the spatial and temporal variability of

typical temperature profiles obtained with this filling procedure.

found that

constant

temperature profiles throughout

at

any

given time.

(The average

They

the basin were essentially

standard

deviation

of

temperature was about 0.10 C with a maximum of 0.25*C occurring at the

thermocline.)

Temporally, for a typical experiment lasting 30 minutes,

-42-

the maximum change

surface and was

in temperature occurred near the

about 0.50 C.

These profiles

Figure 4.5 shows typical basin density profiles.

display the range of variability that can be expected with the filling

procedure.

The Temperature Measurement System

4.1.5

Temperature

thermilinear,

series 700,

0.05 0 C).

repeatability

made

measurements were

thermistor probes

to monitor the discharge

into

the

perforations

of

temperature.

the

temperature and fluctuation.

(time

constant =

Inc.,

1 sec,

the discharge

Four probes were lowered

to

intake

annular

Springs

stationed in

Two probes were

hose

Yellow

using

monitor

intake

Three probes were fixed on stage no. 1 at

an elevation that would immerse them in the mixed layer of the filled

basin.

These probes thus travelled with the model but were located in

areas that the discharge plume should

of

indication

ambient

temperature

among temperature

variance

not perturb.

(characterized by

variability

readings)

in

They provided an

the mixed

layer, which was

compared to the variance of recorded intake temperatures.

arrays of

ten

stationary probes,

designated as

located in the two far corners of the basin.

the ambient

temperature profile and

the

profile

Two vertical

probes, were

They were used to measure

its variability at various times

during the experiment.

The

(1980),

data

acquisition

system,

designed

consists of the following components:

-43-

originally

by McCaffrey

"104

10

'':/'m 3

20

30

I)

Run 16

60 -

Run 6

12()

I 1(m)

Ipt

Figure 4.5:

Typical Variability Between

Density Profiles of Experiment

-44-

Basin

A) General purpose computer; MITS, Altair, 8800B.

B) Disk storage units; MITS, Altair, 99DCDD.

C) Display terminal; Lear Siegler ADM-3A.

D) Data scanner; ADDS YModel 012130.

Fig. 4.6 shows a flow chart for these components as integrated into

a 300 channel per second thermal data acquisition system.

Temperature

information from the YSI 700 thermistor is scanned by the reed relay

which connects the temperature probe output to a YSI thermivolt signal

conditioner, which

is

scaled

to produce

signals which are directly convertible

linear DC analog millivolt

to temperature readings in °C.

After a prescribed number of scans, the digitized scaled analog voltages

for each individual probe are averaged and the average temperatures and

computed variances

are sent

to the display

screen.

During a typical

experiment approximately 600 temperature readings were made using this

system.

4.1.6 The Dye Measurement System

Flourescent dye

direct

recirculation

(Rhodamine B) measurements were used to determine

and

downstream

dilutions.

Sample

dye

concentrations were measured with a Turner Model IV fluorometer allowing

a threshold detection of 1 part per billion

(ppb).

Experiments could be

run with discharge concentrations of as much as 50,000 ppb and basin

background concentrations of less than 30 ppb.

A dye concentration of 10

ppb above background concentration was distinguishable and it was estimated

that measurement of direct recirculation down to 10 ppb/50,000 ppb = 0.0002

or 0.02% was possible (Coxe et al, 1980).

-45-

I

E

L-J

S

E

C

D

A

N

N

eF

I

I

Cormputer

Digital

9o ter

,R SConditioner

R

Figure 4.6:

Scan Interval

Digital

Real Time

Clock

Time Data

Flow Chart for the Temperature Data Acquisition System

Three types of dye samples were taken during an experiment using

the sampling apparatus shown schematically on stage no. 3 of the towing

carriage

in

Fig.

A

4.3.

peristaltic

pump

delivered

a

steady

Two sample

simultaneous flow from four sample points to a bottle rack.

probes attached to stage no. 2 of the towing carriage and located at the

same elevation were positioned

1.5m

(450m prototype)

and

O.8n

prototype) behind the OTEC model to measure field dilution.

(250m

Two more

samples were taken, one each from the intake and discharge flow lines,

and were used to measure direct recirculation.

The

field probes were

steered into

the center of

the plume by

adjusting the elevation of stage no. 2 from a switch panel located next

to the computer.

Stage no. 2 was supported by two motorized vertically

traversing lift racks.

The sample flow and bottle rack were also

controlled from the switch panel.

4.1.7

The Photographs

Injection of fluorescent dye into the discharge water also served to

tag

the

discharge

photographs of

plume

for

photographic purposes.

the power plant wake and

Both

overhead

side view photographs

of a

cross-sectional plane along the axis of the model were taken.

Figure 4.7 illustrates the apparatus used to take the

side view

pictures.

A spotlight emits a horizontal slit of light above the water

surface.

A long, narrow mirror attached to the towing carriage deflects

the light slit downward to illuminate a vertical plane, approximately 50cm

wide x 60cm high, along the axis of the model, parallel to the direction of

current.

A water tight box uses mirrors to reflect the field of vision of

-47-

Adjustable

Mirror

Spotlight

Su pport

00

35 mm

Camera

1000

Towing

Carriage

Mirror

Water Tight

Photo Sub

Watt

Light

Beam\

Light Shutter

Spotlight

_

Plane of Light

Optic Light

So urce

Figure 4.7:

Fiber

Pole

T""lJBasin

ondow

Floor

Weld

Adjustable Mirror

Vision

Cross Sectional Schematic of the Side View Photographic Apparatus

a 35 mmcamera through a front

submerged model.

glass window at

the elevation of the

As the towing carriage moves past the photo station,

pictures are taken of the 50cm x 60cm plane illuminated by the spotlight.

On the average, 5 such pictures were needed to capture the flow field

perturbations extending to 1.5m (450m prototype) downstream of the model.

Figure 4.8 shows a cross section photographed as the model moved by the

field of vision.

The water used to fill the basin was filtered to provide adequate

clarity.

In order to measure quantitatively the position and thickness

of the spreading layer, marker poles containing fiber optic strands were

mounted along the mirror attached to the towing carriage, providing a

reference grid.

Overhead pictures were taken from a balcony

basin.

located next

to the

A grid of black crosses painted on the basin floor provided a

reference grid.

Figure 4.9 is an overhead photograph taken during an

experiment.

4.2

4.2.1

Experimental Procedures

Procedures Before and During an Experiment

Once the basin had been filled, DEMO, a computer program written in

BASIC (all the programs mentioned below are also in BASIC), was used to

scan and print out the thermistor probe readings on the display terminal,

which permitted continuous monitoring of changes in the temperature profile

and the density difference between the upper and lower layers.

Twenty minutes before the start of an experiment, the water for the

-49-

Figure 4.8:

Typical Side View Cross-sectional Photograph

.

Figure 4.9:

Typical Overhead Photograph

-5^.-

discharge

flow was turned on, injected with

fluorescent dye and run

This allowed for

through a bypass loop and rotameter at 45 gal/min.

fine adjustment and stabilization of the discharge temperature and dye

concentration and purged the main sections of the discharge and intake

lines of air.

The intake and profile probes were placed in the upper 3cm of the

water column for calibration.

They and the 3 surface probes attached to

stage no. 1 were calibrated by the program CAL against the temperature

0

of the mixed layer as ascertained by a mercury thermometer to +0.05 C.

After

calibration, the profile probe

the

intake

probes

arrays were positioned

were

placed

inside

the

the

for

intake

experiment

and

structure.

At the end of an experiment, the program DISCAL calibrated

the

discharge

thermistors

the

against

temperature

discharge

as

ascertained by a mercury thermometer.

When the proper density difference,

experiment began.

Ap_,

had been reached, the

The dyed discharge flow was routed through the model,

the intake circuit was activated

and the varispeed

turned on and adjusted to the proper tow speed.

when the wake was judged

to be in steady

towing motor was

Temperature scans began

state.

The program OTEC

collected a prescribed number of scans, designated as n, calibrated the

readings by calling CAL and displayed the average and the variance of

the readings of the n scans for each thermistor probe on the display

terminal.

A photograph was taken of this result.

Typically n= 15.

Since one tow of the model across the basin significantly disrupted

the stratification, an experiment could only last one complete end to

end tow.

This was enough time to investigate two different tow speeds.

-51-

Each tow speed was given a run letter.

Thus experiment 5 consisted of

runs 5a and 5b.

Three to five sets of four dye samples were taken during each run.

As the model passed the photo-station, the photographer told the switch

panel operator in which direction to move stage no. 2 in order to place

the sampling probe in the center of the plume.

Overhead pictures of the wake and side view pictures of

discharge

jets

and flow field were

taken

during each run.

photo-stations were used when an experiment was run in a current.

the

Two

In the

stagnant experiments, the model was positioned in the center of the

basin at the start of an experiment so that the length of time before

wall effects became important could be maximized.

One photo-station was

directed at the model while the other was directed at the mirror 1.5m

(450m prototype) from the model.

4.2.2

Workup of Flourescent Dye Samples

Fluorescent dye samples taken from the intake line, discharge line

and

flow

field were

flourometer.

diluted

as

necessary

for

analysis with a

Concentrations were determined from a calibration curve.

These measurements were used to determine direct recirculation defined

as intake concentration/discharge concentration and centerline dilutions

at 250m and 450m (prototype) directly behind the power plant; dilution was

defined as the discharge concentration/maximum concentration of the

field samples.

-52-

4.2.3

Manipulation of Slide Photographs

A photo-enlarger was used to trace the visible dye boundaries, as

The side view slides were

seen in the slide photographs, onto paper.

pieced together so that

into

one

tracing.

the complete set of

Appendix

I shows

slides

the complete

could be combined

set

of

side view

tracings and compares them with computer simulation (see Section 5.7).

For the overhead pictures, parallax error was corrected by tracing the

wake and the reference grid of black crosses and then reconstructing an

undistorted representation of

the picture.

Appendix II indicates

the

width of the wake at 250m prototype as ascertained by this procedure and

compares it with computer sinulation (see Section 5.7).

4.2.4

Accuracy of Temperature Data

The horizontal uniformity of the upper layer of the water column is

about ±0.15°C.

Since the probes were located at three distant locations

in the basin, the three sets (i.e. the two profile arrays and the intake

calibrated

probes) were

against

three

Thus the overall accuracy of the probes,

locally measured temperatures.

reflecting the accuracy of the

mercury theremometer and the repeatability of the individual probes, was

about 0.1

0

C.

4.2.5 Temperature Data Manipulations

Tables

4.2 and 4.3

temperatures,

list

the

characteristic discharge and intake

the mean intake temperature

-53-

depression and

the average

Table 4.1:

RUN #

Net

Power

(MWe)

Experimental Parameter Schematization

TYPE OF DISCHARGE

DICAG

M/E

61

0

CURRENT

SPEED um

S/I/H

1

1A

40

M

8

90

I

lB

40

M

8

90

H

2A

80

E

8

I

2B

80

E

8

90

90

3A

40

E

8

90

I

3B

40

E

8

90

H

4A

20

M

8

I

4B

20

M

8

90

90

5A

20

M

4

90

I

5B

20

M

4

H

6A

40

M

4

90

90

6B

40

M

4

90

H

7A

80

E

4

90

I

7B

80

E

4

90

H

8A

40

E

4

90

I

8B

40

E

4

90

H

9

40

E

4

90

S

10

40

M

4

90

S

11A

20

M

2

90

I

11B

20

M

2

H

12A

40

E

2

12B

40

E

2

13A

80

E

8

0±45±90

90

90

90

0

13B

80

E

8

0±45±90

0

H

14A

40

M

8

0±45±90

0

I

14B

40

M

8

0±45±90

H

15A

40

E

8

0±45±90

0

0

15B

40

E

8

0±45±90

H

16A

20

M

8

0±45±90

0

0

16B

20

M

8

0±45±90

0

I

-54-

H

H

I

I

H

I

I

H

Table 4.1

RUN #

17

(Continued)

TYPE OF DISCHARGE

CURRENT

Net

Power

(MWe)

M/E

40

E

8

0±45±90

0

0±90

0

0

J

,

J

SPEED u 0

S/I/H

1

02

18

40

E

4

19A

80

E

4

0±90

19B

80

E

4

0 ±90

20A

40

E

4

0±90

0

0

20B

40

E

4

0-+90

21A

40

M

4

0±90

0

0

21B

40

M

4

0±90

22

40

M

4

0±90

23A

40

E

4

+450

23B

40

E

4

+450

0

0

0

Notes)

Type of discharge:

Current speed:

M = mixed; E = evaporator; J = number of jets.

S = stagnant;

I = intermediate; H = high.

-55-

Experimental Parameters (Prototype dimensions except for]Ree )

Table 4.2:

OCEAN

PLANT

I

Qi

(m/se3

(a /sec)

-

4

41

Qo

-

(m/sec)

-----

~b

1

hi

(m /sec)

(m/sec)

(m)

(m)

I

hd

(m)

-I

T'o

4

II

o

del)

(Model)

(oc)

Apx10

H

4

.'

U,

T'a(z hi)

Ta (z =hd

(g/cm

(m)

(m/sec)

(0C)

(oC)

3)

1A

200

400

1.67

3.1

4

17.8

7.4+

1531

24.3

54

0.28

25.2

25.1

1B

200

400

1.67

3.1

4

16.5

7.4+

1443

23.7

2A

400

400

1.67

3.1

4

22.2

12.44+

1993

24.3

57

45

0.51

0.28

25.2

25.2

25.1

24.8

2B

400

400

1.67

3.1

4

22.8

14.6+

2052

23.8

51

0.51

25.2

25.0

3A

200

200

0.83

3.1

4

22.8

1027

24.0

0.28

25.0

24.7

3B

200

200

0.83

3.1

4

22.8

7.5+

1026

23.8

50

56

0.51

25.0

24.8

S4A

100

200

0.83

3.1

4

17.2

3.8+

778

24.2

49

0.28

25.3

25.1

S4B

100

200

1.67

3.1

4

17.2

3.8+

780

24.1

50

0.51

25.3

25.'

5A

100

200

1.67

3.1

4

17.2

6.3+

1629

24.0

48

0.28

25.3

25.1

5B

100

200

3.35

3.1

4

17.2

6.34

1634

23.9

51

0.51

25.3

25.2

6A

200

400

3.35

3.1

4

17.2

12.6+

2893

24.7

50

0.28

25.7

6B

200

400

3.35

3.1

4

17.2

12.6+

3256

24.8

49

0.51

25.8

25.9

7A

400

400

3.35

3.1

4

23.6

31.2+

4180

24.3

39

0.28

25.3

24.4

7B

400

400

1.67

3.1

4

23.6

30.84+

4180

25.2

50

0.51

25.4

25.2

8A

200

200

1.67

3.1

4

22.S

10.8+

2056

24.6

50

0.28

25.4

25.4

8B

200

200

1.67

3.1

4

23.3

12.0+

2067

24.2

54

0.51

25.3

25.3

9

200*

200

1.67

3.1

4

22.5*

8.7+

2513*

22.9*

38*

0.00

24.6*

24.1

10

200

200

3.35

3.1

4

17.2f

9.7+

3537*

21.4*

53*

0.00

24.1*

24.1

11A

100

200

3.35

3.1

4

17.0

10.6+

3521

23.78

48

0.28

25.3

25.3

11B

100

200

3.35

3.1

4

17.1

10.8+

3546

23.51

48

0.51

25.3

25.3

12A

200

200

3.35

3.1

4

23.6

21.9+

4461

24.87

48

0.28

25.5

,,,

25.7

-----

25.4i

i

Experimental Parameters (Prototype dimensions except for P)

Table 4.2:

OCEAN

PLANT

I

U

Qo

Qi

u

o

b

hi

hd

(m)

o0

Ao x104

H

(Model)

(g/cm 3)

(m)

1R

e

IF

o

u

(m/sec)

I

I

I

RI

I

I1

bT

T'a (z-h

i )

T'(z =hD)

(oc)

(m3/sec)

(m3/sec)

(m/sec)

(m)

(m)

12B

200

200

3.35

3.1

4

23.6

21.9+

4466

24.87

48

0.51

25.5

25.4

13A

400

400

1.96

2.9

4

19.8

7.4+

2259

23.13

48

0.28

25.5

25.3

13B

400

400

1.96

2.9

4

21.1

7.7+

2278

23.85

48

0.51

25.5

24.7

14A

200

400

1.96

1.9

4

18.3

6.0+

2175

23.45

54

0.28

24.5

24.4

14B

200

400

1.96

2.9

4

18.3

6.0+

2175

23.45

54

0.51

24.5

24.4

n 15A

200

200

0.98

2.9

4

16.0+

1345

44

0.28

15B

200

200

0.98

2.9

4

17.0

16.0+

1345

23.68

43

0.51

25.3

24.2

16A

100

200

0.98

2.9

4

19.4

3.7+

1223

20.22

54

0.51

23.6

23.5

16B

100

200

0.98

2.9

4

29.4

3.9+

1227

20.07

55

0.28

23.6

23.5

17

200

200

0.98

2.9

4

23.2*

7.2+

1330*

22.9*

54*

0.00

24.6*

24.5*

18

200

200

1.93

2.9

4

23.3*

16.0+

2837*

22.5*

44*

0.00

24.9*

23.6*

19A

400

400

3.88

2.9

5

22.3

21.3+

5400

23.14

54

0.28

24.4

24.1

19B

400

400

3.88

2.9

5

23.3

20.84

5468

23.06

52

0.51

24.4

24.1

20A

200

200

1.93

2.9

5

22.5

13.84,

2757

20.9

54

0.28

24.2

24.0

20B

200

200

1.93

2.9

5

22.5

13.8+

2757

20.8

54

0.51

24.2

23.7

21A

200

400

3.88

3.9

5

18.3

12.8-

5143

22.3

48

0.28

24.4

23.9

21B

200

400

3.88

2.9

5

28.5

13.24

5205

22.3

45

0.51

24.4

23.5

22

200

400

3.88

2.9

5

17.2*

10.7+

5343*

24.5*

48*

0.00

25.4*

25.4

23A

200

200

1.93

2.9

5

22.8

12.6+

3040

23.6

52

0.28

25.3

25.0

23B

200

200

1.93

2.9

5

22.9

14.8+

3040

23.3

52

0.51

25.3

25.0

I

_______________

(OC)

I ____________________________________________

I-___________

1

4

__________-I

________________

" 4 " under IF indicates directioL of plume buoyancy

Note:

"*" connotes time averaged value.

"--" signifies that the data does not exist

(o0C)

OT '0

1600

0'0

0'o

C0'0

flzoa0

Z0O0

TO'0

T0'0

TO'0

69'T

OL 'T

89'T

00

TO '0

0

69' T

*Z9*T

TO 0

TWOr

TO '0

0 0

TO'0

170*0

90

00

fl

ncO*O

9010

n

0'0

90'0-

9L 'T

L'1 L '6T-

-

L'O

L '0

9 T

T,.I

Lk

4

-

69T

ZL'T

9'T

V'N

'V'N

I

-

I

OO

T6

I

8 ZT UZTC

8 " ZT

69

£6

9L

TOZT

T'ZT

ZL

L*O

'0

1*0

y*O

ZOO

COOO

6'T

'V'N

'V'N

'V'N

SOZ

900

0*T

TOO

'V'N

'V'N

IV

6N

'V'N

*V'N

L'0

ci~' .~z0

dV

I

S

9AO

8 'OT

T8

00£

VZT

UTT

VS

L '8

T9

08

16

T 'OT

98

09£

V/OT

OL

VL

V9

V91

69

Z17

0&T

OOC

0'S

LL

005

C 6