DEVELOPMENT OF MODELS FOR THE SODIUM BOILING NATOF-2D by

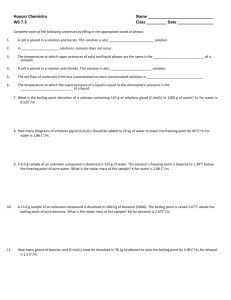

advertisement

DEVELOPMENT OF MODELS FOR THE

TWO-DIMENSIONAL, TWO-FLUID CODE FOR

SODIUM BOILING NATOF-2D

by

R. G. Zielinski and M. S. Kazimi

Energy Laboratory Report No. MIT-EL 81-030

September 1981

mmmuwIhn

Energy Laboratory

and

Department of Nuclear Engineering

Massachusetts Institute of Technology

Cambridge, Mass. 02139

DEVELOPMENT OF MODELS FOR THE

TWO-DIMENSIONAL, TWO-FLUID CODE FOR

SODIUM BOILING NATOF-2D

by

R. G. Zielinski and M. S. Kazimi

September 1981

Topical Report of the

MIT Sodium Boiling Project

sponsored by

U. S. Department of Energy,

General Electric Co. and

Hanford Engineering Development Laboratory

Energy Laboratory Report No. MIT-EL 80-030

go

N

-i-

REPORTS IN REACTOR THERMAL HYDRAULICS RELATED TO THE

MIT ENERGY LABORATORY ELECTRIC POWER PROGRAM

A.

Topical Reports (For availability check Energy Laboratory Headquarters,

Headquarters, Room E19-439, MIT, Cambridge,

Massachusetts 02139)

A.1

A.2

A.3

A.4

General Applications

PWR Applications

BWR Applications

LMFBR Applications

A.1

J.E. Kelly, J.

Assessment and

COBRA-IIIC/MIT

MIT-EL-78-026,

Loomis, L. Wolf, "LWR Core Thermal-Hydraulic Analysis-Comparison of the Range of Applicability of the Codes

and COBRA-IV-1," MIT Energy Laboratory Report No.

September 1978.

M. S. Kazimi and M. Massoud, "A Condensed Review of Nuclear Reactor

Thermal-Hydraulic Computer Codes for Two-Phase Flow Analysis," MIT

Energy Laboratory Report No. MIT-EL-79-018, February 1979.

J.E. Kelly and M.S. Kazimi, "Development and Testing of the Three

Dimensional, Two-Fluid Code THERMIT for LWR Core and Subchannel

Applications," MIT Energy Laboratory Report No. MIT-EL-79-046.

J.N. Loomis and W.D. Hinkle, "Reactor Core Thermal-Hydraulic Analysis-Improvement and Application of the Code COBRA-IIIC/MIT," MIT Energy

Laboratory Report No. MIT-EL-80-027, September 1980.

D.P. Griggs, A.F. Henry and M.S. Kazimi, "Development of a ThreeDimensional Two-Fluid Code with Transient Neutronic Feedback for LWR

Applications," MIT Energy Laboratory No. MIT-EL-81-013, April 1981.

J.E. Kelly, S.P. Kao and M.S. Kazimi, "THERMIT-2: A Two-Fluid Model

for Light Water Reactor Subchannel Transient Analysis," MIT Energy

Laboratory Report No. MIT-EL-81-014, April 1981.

H.C. No and M.S. Kazimi, "The Effect of Virtual Mass on the

Characteristics and the Numerical Stability in Two-Phase Flows,"

MIT Energy Laboratory Report No. MIT-EL-81-023, April 1981.

J.W. Jackson and N.E. Todreas, "COBRA IIIC/MIT-2: A Digital Computer

Program for Steady State and Transient Thermal-Hydraulic Analysis of

Rod Bundle Nuclear Fuel Elements," :IT-EL-81-018, June 1981.

J.E. Kelly, S.P. Kao, and M.S. Kazimi, "User's Guide for THERMIT-2:

A Version of THERMIT for both Core-Wide and Subchannel Analysis of

Light Water Reactors," 1MIT Energy Laboratory Report No. !'IT-EL 81-029,

August 1981.

-ii-

A.2

P. Moreno, C. Chiu, R. Bowring, E. Khan, J. Liu, and N. Todreas,

"Methods for Steady-State Thermal/Hydraulic Analysis of PWR Cores,"

MIT Energy Laboratory Report No. MIT-EL 76-006, Rev. 1, July 1977,

(Orig. 3/77).

J. Liu and N. Todreas, "Transient.Thermal Analysis of PWR's by a

Single Pass Procedure Using a Simplified Model'Layout," MIT Energy

Laboratory Report No. MIT-EL 77-008, Final, February 1979 (Draft,

June 1977).

J. Liu and N. Todreas, "The Comparison of Available Data on PWR

Assembly Thermal Behavior with Analytic Predictions," MIT Energy

Laboratory Report No. MIT-EL 77-009, Final February 1979, (Draft,

June 1977).

A.3

L. Guillebaud, A. Levin, W. Boyd, A. Faya, and L. Wolf, "WOSUB-A

Subchannel Code for Steady-State and Transient Thermal-Hydraulic

Analysis of Boiling Water Reactor Fuel Bundles," Vol. II, Users

Manual, MIT-EL 78-024, July 1977.

L. Wolf; A. Faya, A. Levin, W. Boyd, L. Guillebaud, "WOSUB-A Subchannel

Code for Steady State and Transient Thermal-Hydraulic Analysis of

Boiling Water Reactor Fuel Pin Bundles," Vol. III, Assessment and

Comparison, MIT-EL 78-025, October 1977.

L. Wolf, A. Faya, A. Levin, L. Guillebaud, "WOSUB-A Subchannel Code

for Steady-State Reactor Fuel Pin Bundles," Vol. I, Model Description,

MIT-EL 78-023, September 1978.

A. Faya L. Wolf and N. Todreas, "Development of a Method for BWR

Subchannel Analysis," MIT-EL 79-027, November 1979.

A. Faya, L. Wolf and N. Todreas, "CANAL User's Manual," MIT Energy

Laboratory No. MIT-EL 79-028, November 1979.

A.4

W.D. Hinkle, "Water Tests for Determining Post-Voiding Behavior in

the LMFBR," MIT Energy Laboratory Report MIT-EL-76-005, June 1976.

W.D. Hinkle, Ed., "LMFBR Safety and Sodium Boiling - A State of the

Art Report," Draft DOE Report, June 1978.

M.R. Granziera, P. Griffith, .W.D. Hinkle, M.S. Kazimi, A. Levin,

M. Manahan, A. Schor, N. Todreas, G. Wilson, "Development of

Computer Code for Multi-dimensional Analysis of Sodium Voiding in the

LMFBR," Preliminary Draft Report, July 1979.

M. Granziera, P. Griffith, W.D. Hinkle, M.S. Kazimi, A. Levin,

M. Manahan, A. Schor, N. Todreas, R. Vilim, G. Wilson,."Development

of Computer Code Models for Analysis of Subassembly Voiding in the

LIFBR," Interim Report of the MTI Sodium Boiling Project Covering

Work Through September. 30, 1979, MIT-EL-80-005.

~

lllllllW10

YIIII

IY

IIIi ^

~

61411111,i

A. Levin and P. Griffith, "Development of a Model to Predict Flow

Oscillations in Low-Flow Sodium Boiling, "MIT-EL-80-006, April 1980.

M. R. Granziera and M. S. Kazimi, "A Two-Dimensional, Two-Fluid

Model for Sodium Boiling in LMFBR Assemblies," MIT-EL-80-011, May 1980.

G. Wilson and M. Kazimi, "Development of Models 'for the Sodium Version

of the Two-Phase Three Dimensional Thermal Hydraulics Code THERMIT,"

MIT-EL-80-010, May 1980.

R.G. Zielinski and M.S. Kazimi, "Development of Models for the

Two-Dimensional, Two-Fluid Code for Sodium Boiling NATOF-2D,"

MIT Energy Laboratory Report No MIT-EL-81-030, September 1981.

-------- -----

I

_______________________________InIIIIIIIIIIEEIIIIEEIIYhIhIIIIIYI,,,IIL

-iv-

B.

Papers

B.1

B.2

B.3

B.4

General Applications

PWR Applications

BWR Applications

LMFBR Applications

B.1

J.E. Kelly and M.S. Kazimi, "Development of the Two-Fluid MultiDimensional Code THERMIT for LWR Analysis," Heat Transfer-Orlando

1980, AIChE Symposium Series 199, Vol. 76, August 1980.

J.E. Kelly and M.S. Kazimi, "THERMIT, A Three-Dimensional, Two-Fluid

Code for LWR Transient Analysis," Transactions of American Nuclear

Society, 34, p. 893, June 1980.

B.2

P. Moreno, J. Kiu, E. Khan, N. Todreas, "Steady State Thermal

Analysis of PWR's by a Single Pass Procedure Using a Simplified

Method," American Nuclear Society Transactions, Vol. 26.

P. Moreno, J. Liu, E. Khan, N. Todreas, "Steady-State Thermal Analysis

of PWR's by a Single Pass Procedure Using a Simplified Nodal Layout,"

Nuclear Engineering and Design, Vol. 47, 1978, pp. 35-48.

C. Chiu, P. Moreno, R. Bowring, N. Todreas, "Enthalpy Transfer between

PWR Fuel Assemblies in Analysis by the Lumped Subchannel Model,"

Nuclear Engineering and Design, Vol. 53, 1979, 165-186.

B.3

L. Wolf and A. Faya, "A BWR Subchannel Code with Drift Flux and Vapor

Diffusion Transport," American Nuclear Society Transactions, Vol. 28,

1978, p. 553.

S.P. Kao and M.S. Kazimi, "CHF Predictions In Rod Bundles," Trans. ANS,

35, 766 June 1981.

B.4

W.D. Hinkle, (MIT), P.M. Tschamper (GE), M.H. Fontana (ORNL), R.E.

Henry (ANL), and A. Padilla (HEDL), for U.S. Department of Energy,

"LMFBR Safety & Sodium Boiling," paper presented at the ENS/ANS

International Topical Meeting on Nuclear Reactor Safety, October 16-19,

1978, Brussels, Belgium.

M.I. Autruffe, G.J. Wilson, B. Stewart and M. Kazimi, "A Proposed

Momentum Exchange Coefficient for Two-Phase Modeling of Sodium

Boiling," Proc. Int. Meeting Fast Reactor Safety Technology, Vol. 4,

2512-2521, Seattle, Washington, August 1979.

M.R. Granziera and M.S. Kazimi, "NATOF-2D: A Two Dimensional Two-Fluid

Model for Sodium Flow Transient Analysis," Trans. ANIS, 33, 515,

November 1979.

I ii IliYI

"---

InmIhufI

I

411ll0

419u

lIM0II ill

DEVELOPMENT OF MODELS FOR THE

TWO-DIMENSIONAL, TWO-FLUID CODE FOR

SODIUM BOILING NATOF-2D

ABSTRACT

Several features were incorporated into NATOF-2D, a twodimensional, two fluid code developed at M.I.T. for the purpose

of analysis of sodium boiling transients under LMFBR conditions.

They include improved interfacial mass, momentum and energy

exchange rate models, and a cell-to-cell radial heat conduction

mechanism which was calibrated by simulation of Westinghouse

Blanket Heat Transfer Test Program Runs 544 and 545.

Finally,

a direct method of pressure field solution was implemented into

NATOF-2D, replacing the iterative technique previously available,

and resulted in substantially reduced computational costs.

The models incorporated into NATOF-2D were tested by

running the code to simulate the results of the THORS Bundle 6A

Experiments performed at Oak Ridge National Laboratory, and

four tests from the W-1 SLSF Experiment performed by the Hanford

Engineering Development Laboratory.

The results demonstrate

the increased accuracy provided by the inclusion of these

effects.

EIIIIImmII,,IIIIYIYLIIIIIYIIIIhA

111Wi

NOTICE

This report was prepared as an account of work

sponsored by the United States Government and

two of its subcontractors. Neither the United

States nor the United States Department of Energy,

nor any of their employees, nor any of their contractors, subcontractors, or their employees,

makes any warranty, express or implied, or assumes

any legal liability or responsibility for the

accuracy, completeness or usefulness of any

information, apparatus, product or process disclosed, or represents that its use would not

infringe privately owned rights.

,6

MIYM

ACKNOWLEDGEMENTS

Funding for this project was provided by the United

States Department of Energy.

This support was deeply

appreciated.

A very special thanks is due to Andrei L. Schor, whose

enthusiasm for Sodium Boiling provided a constant source of

information and inspiration.

The work described in this report was performed primarily

by the principal author, Robert G. Zielinski, who submitted

this work in partial fulfillment for the M.S. degree in

Nuclear Engineering at M.I.T.

-4-

Table of

Contents

Page

TITLE PAGE

ABSTRACT

.

.

..

.

.

.

..

. .

ACKNOWLEDGEMENTS .

.

TABLE OF CONTENTS

.

List of Figures

. .

List of Tables .

. .

Nomenclature .

. .

.

0

.

.

.

.

•

0

0

.

2

*

.

.

.

S

0

.

0

0

.

0.

3

.

6

"

6

4

.

.

.

.•

8

12

.

Chapter 1: INTRODUCTION

.

.

Sthe

.

.

.

S

0

.

.

.

6

0

0

17

SCod .

.

1.1

Description of

the Code

1.2

Scope of Work

-~CI1II

-

1.2.1

Chapter 2:

17

-l~~~-

21

~

Interfacial Mass, Energy,

and Momentum Exchange Models

.

.

.

1.2.3

Direct Solution of the Pressure

1.2.4

Comparison to Experiments on Boiling

.

.

.

.

.

.

.

.

.

.

22

iel

23

.

INTERFACIAL MASS, ENERGY AND MOMENTUM

EXCHANGE MODELS

.

.

.

. .

.

. .

.

.

. .

21

22

Fluid Conduction Model

.

.

. . .

1.2.2

Behavior

13

24

.

2.1

Introduction .

.. .

24

2.2

Conservation Equations Used in NATOF-2D

26

. .

. . . .

. . . .. .. ..

. . .

2.4 Energy Exchange Rate ........

. .

. . .

2.5 Interfacial Momentume Transfer . . . . .

. . .

.0 .

. .

2.6

Programming Information .0

. . .

Chapter 3: FLUID CONDUCTION MODEL . . . . .

. .

2.3

3.1

Interfacial Mass Exchange

Introduction .

. .

.

. . .

....

. .

.

.

. .

.

.

29

40

47

54

i55

-5-

Page

.

.

.

.

.

.

.

.

.

.

.

.

.

.

57

.

. .

.

.

.

.

.

.

.

.

.

.

.

61

.

.

.

.

.

.

.

.

.

65

3.5

Experimental Calibration .

.

. .

.

.

.

68

3.6

A Comparison with Effective Conduction

.

3.2

Formulation

3.3

Intercell Areas

3.4

Implementation Form

.

Mixing Lengths

3.7

Chapter 4:

.

.

.

.

.

Programming Information

.

.

.

.

.

.

.

.

.

.

.

.

.

.

DIRECT SOLUTION OF THE PRESSURE FIELD

.

.

.

.

..

.

.

.

.

4.1

Introduction

4.2

Direct Method Solution Techniques

4.3

A Comparison of Direct and Iterative

Methods

4.4

Chapter 5:

in

NATOF-2D

.

.

Programming Information

.

.

.

.

.

.

.

.

.

.

. .

.

.

.

.

5.3

On the Modelling of Sodium Reactors

5.4

The Mass Exchange Rate

........

5.5

Varying Mesh Spacing .

.

Chapter 6: VERIFICATION OF MODELS

.

.

.

.

6.2

THORS Bundle 6A Experiment, Test 71H,

Run 101

6.2.1

*

*

*

*

*

* a * a a a a * * * * * ,

.

.

.

88

. . .

97

101

103

* .

.

106

.

.

.

109

*

* .

113

*

* * .

*

.

115

* • 115

* *

*

116

*

*

116

Description of the THORS Bundle

6A Experiment .

6.2.2

*

87

* *

.......

Introduction .

.

...

.

.

6.1

.

..

102

Double versus Single Precision .

.

..

. *

5.2

.

..

102

Introduction .

.

..

.

5.1

.

..

92

.

.

79

.

.

.

.

88

.

.

.

.

.

EXPERIENCES WITH NATOF-2D

.

.

.

.

Simulation Results

.

.....

.

.

.

a

* 4 & 117

IIY

i

-6-

Page

6.3

6.4

The W-1 SLSF Experiinent

.

.

. . .

.

.

.

.

.

.

6.3.1

Test Objecti ve

6.3.2

Test Apparat Ius and Procedure

6.3.3

Tests Chosen for Simulation

.

W-1 SLSF Simulation Results

6.4.1

.

.

.

. .

.

.

6.4.3

BWT 2'

.

.

.

.

6.4.4

BWT 7B' .

.

. .

7.1

Conclusions

7.2

Recommendations

Apperidix A:

126

127

.

.

a

*

0

.

133

.

.

.

.S

0

0

6

0

.

. .

. . e*

133

*

*

a

.

0

.

.

.

138

*

.

145

*

*S

151

151

.

.

S

,

S

.

*

*

*

.0

a

S

0

*

0

6

0

*

0

0

153

0

**

.

.S

.

.

155

0

ow

SPECIFIED INLET VELOCITY AND MASS FL

157

157

Introduction .

A.2

Treatment of the Momentum Equations

A.3

Inlet Velocity Boun dary Condition

A.4

Specified Inlet Mas s Flow Rate Boundary

*

0

0

Condition . . . •

. o

S

Programming Informa tion

.

.

.

. .....

a

159

165

..

0

167

0

173

.

174

. .

.

Appendix B:

NATOF-2D INPUT DESCRIPTION

Appendix C:

INPUT FILES FOR NATOF-2D TEST CASES

C.1

.

127

A.1

A.5

.

..

CONCLUSIONS AND RECOMMENDATIONS

.

126

133

LOPI 4

Refer ences

.

LOPI 2A . .

6.4.2

Chapt:er 7:

.

.

179

Westinghouse Blanket Heat Transfer Test

Program Run 544

.

.

.

.

...

*.

.

0

C.2

Westinghouse Blanket Heat Transfer Test

..

. . . . . . . .

Program Run 545

C.3

THORS Bundle 6A Test 71H Run 101

. .

.

0

.

179

180

.

181

-7-

Page

W-1

SLSF LOPI 2A .

.

C.5

W-1

SLSF LOPI 4

..

186

C.6

W-1

SLSF BWT 2'

.......

188

C.7

W-1

SLSF BWT 7B'

.

.

.

C.4

.

.

.

.

.

.

.

.

.

.

Appendix D:

NATOF-2D HEXCAN MODEL .

.

.

.

Appendix E:

NATOF-2D SPACER PRESSURE DROP MODEL

Appendix F:

SAMPLE OUTPUT

Appendix G:

LISTING OF NEW NATOF-2D SUBROUTINES

.

.

.

191

.

.

.

.

.

*..

.

.

.

. .

.

.

.

.

.

.

.

.

.

.

.

.

.S

0

.

.

0

.

.

.

194

196

198

202

---

--

m'millinumiI

IIIflf

-8-

List of Figures

Number

Page

1.1

Typical Arrangement of Cells Used in NATOF-2D

19

2.1

Condensation Coefficient as a Function of

Pressure . . . . . . . . . . . . . . .

33

2.2

2.3

2.4

2.5

2.6

3.1

3.2

.

A Comparison of New and Old MasS Exchange

Rates for a Superheat of 2 C . . . . .

A Comparison of New and Old Mass Exchange

Rates for a Superheat of 20 C . . .

.

38

.

39

Variations between Vapor and Saturation

Temperatures for an Interfacial Heat

Transfer Nusselt Number of 0.006 ....

45

Vapor and Saturation Temperatures for an

Interfacial Heat Transfer Nusselt Number

of 6.0 . . . . . . . . . . . . . . . . .

46

Values of r and K as a Function of Void

Fraction for Typical Operating

Conditions . . . . . . . . . . . . .

.

51

Top View of Fluid Channels Showing the Radial

Heat Transfer Between Them . . . . . . .

58

Top View of Fluid Channels Showing Radial

Cell Boundary Numbering Scheme . . . . .

62

.

3.3

Unit Cell Used in NATOF-2D

. .

63

3.4

Radial Temperature Profile at the End of the

Heated Zone for Various Effective

Nusselt Numbers . . . . . . . . . . . .

71

A Comparison Between Westinghouse Run 544 and

NATOF-2D Radial Temperature Profiles at

the Heated Zone Midplane for Nul = 22 and

Nu 2 = 28 . . . . . . . . . . . . . . . .

72

A Comparison Between Westinghouse Run 544

NATOF-2D Radial Temperature Profiles

the End of the Heated Zone for Nu =

and Nu 2 = 28 . . . . . . . . . . . .

73

3.5

3.6

.

.

. . .

.

.

and

at

22

. .

-9-

List of Figures (continued)

Page

Number

3.7

A Comparison Between Westinghouse Run 544 and

NATOF-2D Radial Temperature Profiles 25

Inches Downstream of Heated Zone for

Nul = 22 and Nu 2 = 28

3.8

..........

3.11

*

.

.

.

.

3.13

.

.

.

.

.

74

e .

.

*

*

*

*

75

*

.

.

.

.

.

.

76

and

at

22

.

.

77

A Comparison Between Westinghouse Run 545 and

NATOF-2D Radial Temperature Profiles 25

Inches Downstream of the Heated Zone for

. . . . . . . . .

78

Possible Temperature Distributions Which Yield

the Same Cell Averaged Temperature

. .

.

81

19-Pin Cell Geometry Used for the Calculation

.

of Effective Mixing Lengths

4.1

.

A Comparison Between Westinghouse Run 545

NATOF-2D Radial Temperature Profiles

the End of the Heated Zone for Nul =

. .

..

and Nu 2 = 28 . . . .

Nul = 22 and Nu 2 = 28

3.12

.

A Comparison Between Westinghouse Run 545 and

NATOF-2D Radial Temperature Profiles at

the Heated Zone Midplane for Nul = 22

and Nu 2 = 28 .

3.10

.

Normalized Heat Input per Rod for Westinghouse

Blanket Heat Transfer Test Program

Run 545

3.9

.

. .

.

.

.

83

Arrangement of Cells for Pressure Field

Matrix Shown in Figure 4.2 .

.

.

.

.

.

.

.

89

.

. .

.

. .

.

.

. .

90

.

.

.

.

.

.

.

.

.

93

.

.

.

.

.

.

...

4.2

Pressure Field Matrix .

4.3

Upper Triangular

4.4

Lower Triangular Matrix .

4.5

A Comparison of Steady State CPU Usage

Between the Direct and Iterative

Techniques

(10 Axial Levels, 5 Radial Nodes)

.

.

98

A Comparison of Transient CPU Usage

Between the Direct and Iterative

Techniques

(10 Axial Levels, 5 Radial Nodes)

. . .

99

4.6

Matrix

.

93

.

-10-

List of Figures (continued)

Number

6.1

Page

Location of Cells Used in the NATOF-2D

Simulation of the THORS Bundle 6A

.

.

119

NATOF-2D Predicted Inlet Mass Flow Rate of

. .

THORS Bundle 6A Test 71H Run 101

.

121

Experiment

6.2

6.3

6.4

6.5

6.6

6.7

.

.

6.9

6.11

.

.

.

.

.

.

.

.

.

122

123

A Comparison of NATOF-2D Predicted Liquid and

Vapor and Velocities

(THORS Bundle 6A, Test 71H, Run 101)

.

125

Location of Cells Used in the NATOF-2D

Simulation of the W-1 SLSF Experiments .

130

W-1

SLSF Test LOPI 2A Experiment Inlet Mass

5

/

.

.

134

A Comparison Between Experiment and NATOF-2D

Predicted Temperature Histories at the

End of the Heated Zone for the Central

Channel (W-I SLSF Test LOPI 2A)

. . . .

135

.

.

.

.

.

.

.

.

A Comparison of NATOF-2D Central and Edge

Channels Temperature Histories at the

End of the Heated Zone

W-1

.

SLSF Test LOPI 2A)

.

.

.

.

.

.

.

SLSF Test LOPI 4 Inlet Mass Flow Rate

/

5

/

.

•a .

a. • •

a• . . . •

136

137

A Comparison Between W-1 SLSF Test LOPI 4 and

NATOF-2D Temperature Histories at the

End of the Heated Zone for the Central

Channel

6.12

.

NATOF-2D Predicted Temperature Histories at

End of the Heated Zone for the Central

and Edge Channels

. .

(THORS Bundle 6A, Test 71H,Run 101)

(W-1

6.10

.

NATOF-2D Temperature Profiles of Central

Channel At Various Points in Time

(THORS Bundle 6A, Test 71H, Run 101)

Flow Rate /

6.8

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

139

A Comparison Between W-1 SLSF Test LOPI 4 and

NATOF-2D Temperature Histories at the

End of the Heated Zone for the Edge

Channel

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

140

-11-

List of Figures (continued)

Page

Number

6.13

NATOF-2D Void Maps for W-1 SLSF Test LOPI 4

for the Central and the Middle Channels

.

(Void Fraction = 0.1)

.

.

. .

.

.

. .

6.14

W-1 SLSF Test BWT 2' Inlet Mass Flow Rate . .

6.15

A Comparison Between W-1 SLSF Test BWT 2'

and NATOF-2D Temperature Histories at

the End of the Heated Zone for the

Central

6.16

.

.

.

. .

.

.

.

.

.

SLSF TEst 7B')

.

.

.

.

.

.

.

.

.

.

.

143

.

.

.

.

.

.

.

.

.

144

147

.

.

.

.

.

.

.

..

148

.

.

.

.

.

.

.

.

.

149

.

.

.

.

.

.

.

.

.

150

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

161

.

.

.

.

168

.

.

170

.

.

171

Example Cell Numbering Scheme for Flow

.

.

.

.

.

Cell Configuration for Matrix Shown in

Figure A.4

A.4

.

Positions Used for the Evaluation of

Boundary Calculation .

A.3

.

A Comparison Between NATOF-2D and W-1 SLSF

BWT 7B' Temperature Histories at the End

of the heated Zone for the Central

Variables

A.2

.

A Comparison of NATOF-2D Edge Channel Void

Maps for CF = 1.0 and CF = 0.01

Channel

A.1

.

A Comparison of NATOF-2D Central Channel Void

Maps for CF = 1.0 and CF = 0.01

(W-1

6.20

.

. . . . . . . . . . . . . . . . .

(W-1 SLSF Test 7B')

6.19

.

A Comparison Between W-1 SLSF Test BWT 7B'

and NATOF-2D Predicted Inlet Mass Flow

Rate

6.18

.

142

A Comparison Between W-1 SLSF Test BWT 2' and

NATOF-2D Temperature Histories at the

End of the Heated Zone for the Edge

Channel

6.17

.

Channel

141

.

.

.

.

.

.

.

.

.

.

.

.

Pressure Field Matrix With Flow Boundary

Calculation

.

.

.

.

.

.

.

.

.

.

.

.

-------

Ill

IIIYII IIYIIYYI

IIIIYI

iY

ii

-12-

List of Tables

Page

Number

2.1

Parameters Used in K versus r Comparison

.

.

52

3.1

Test Parameters for Westinghouse Blanket

Heat Transfer Test Program Bundle . .

.

.

69

3.2

Conduction Mixing Length Theory Results .

.

.

84

5.1

Convergence Criteria Versus Minimum Timestep

.

104

5.2

A Comparison of PWR and LMFBR Properietes . .

107

5.3

A Comparison of Water and Sodium Properties .

107

6.1

Description of THORS Bundle 6A

6.2

Geometric Parameters of W-1 SLSF Test

(Single

Bundle

6.3

.

Precision)

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.a

....

.

118

.

.

.

.

.

128

.

.

.

.

.

129

Power and Flow Rates of the W-I SLSF

Experiment

.

.

.

.

.

.

.

.

.

.

-13-

Nomenclature

Definition

Letter

Units(SI)

a

Fuel pellet radius

m

A

Area

m

A

Matrix of pressure coefficients

Ar

Volumetrically averaged

Radial area between cells

Ar*

Radial area constant

b

Fuel rod radius

CF

Condensation factor

d

Wire wrap diameter

D

Diameter

Dc

Conductive diameter

De

Equivalent diameter

f

friction factor

g

Gravity constant

m/s2

hfg

Enthalpy of vaporization

J/kg

h

Enthalpy

J/kg

H

Heat transfer coefficient

w/m 2-

J

Mass flux

kg/m2-s

K

Momentum exchange

coefficient

kg/m 3-s

L

2

oK

Lower triangular matrix

9ij

..

ij

Effective conduction mixing

length

Centroid-to-centroid distance

of adjacent cells

m

Momentum exchange rate

kg/m 2-s

-

IIIIIYIIIYIIIYIIIYIIiril

Nomenclature (continued)

Units (SI)

Letter

kg/mole

M

Molecular weight of particles

n

Row number

Nu

Nusselt Number

P

Pressure

N/m2

P

Fuel pitch

m

N/m 2

P

Perimeter

m

q

Heat flux

W/m 2

q'"

Power density

W/m3

q"

Heat flux

W/m2

Q

Heat generation rate

W/m

r

Radial spacial coordinate

m

R

Universal gas constant

J/mole- OK

S ij

Length of common cell boundary

m

SBT

Stable boiling timestep

s

t

Time

s

T

Temperature

OK

U

Velocity

m/s

U

Upper triangular matrix

V

Volume

w

Bandwidth of matrix

W

Total inlet mass flow rate

kg/s

z

Axial spacial coordinate

m

m

-15-

Nomenclature (continued)

Definition

Greek

a

Void fraction

a

Thermal diffusivity

6

Increment

A

Increment,

r

Mass exchange rate

Units(SI)

2

m2/s

spacing

kg/m 3-s

Interfacial velocity

weighting factor

3

p

Density

a

Mass exchange coefficient

Subscripts

r

Radial position

z

Axial position

v

Vapor

Liquid

i

Interface

e

Evaporation

c

Condensation

s

Saturation

T

Total

int

Interface

c

Conduction

w

Wall

kg/rn

kg/m 3

-16-

Nomenclature (continued)

Superscripts

n+1

New time step

n

Old time step

Ili,.

-17-

Chapter 1

INTRODUCTION

1.1

Description of the Code

computer

The

NATOF-2D

code

developed

was

Institute of Technology for the simulation of

Massachusetts

Liquid

both steady state and transient conditions in

Reactors

Breeder

Fast

the

at

I

/

/.

Metal

code uses the two

The

fluid model of conservation equations, and a two-dimensional

r-z geometry which takes advantage of the symmetry found

bundles.

LMFBR

two

The

effects

calculation allows the multidimensional

be

to

boiling

observed,

nature

dimensional

the

sodium

corresponding high

the

without

of

of

in

computational costs of a three dimensional code.

The

model

coupled

separately,

is

assumption

treats

made

the

and

liquid

about

two

the

the

relationship

phases,

generality.

The method thus requires the

and

between

allows

which

of

momentum

phases

by only the exchange coefficients.

properties

mass,

vapor

solution

No

the

greater

of

the

energy conservation equations for each

phase.

For

calculational

purposes,

the

fuel

assembly

is

divided into a finite number of axial and radial mess cells.

There

is

no

constraint as to the positioning or number of

axial levels other than

at

each

level

the

mesh

spacing

-18-

remains

the

constant.

However, the boundaries between cells in

direction

radial

the

between

fall

must

pin

fuel

centerlines, and so the number of radial cells is limited to

the

of

number

Figure 1.1 shows a typical

pin rows.

fuel

arrangement of cells used by NATOF-2D.

The fluid properties of

of

average

volumetric

a

cell

treated

are

as

the

properties in that cell, which

the

necessitates the use of sufficiently small cells in order to

detailed

obtain

evaluated

at

velocities

fluid

each

cell

face.

calculation are P, a, Tv, TZ, Uvz

,

unknowns

The

Uvr

,

Utz

of

the

and Utr.

,

NATOF-2D uses a partially implicit method to solve

dynamics

fluid

The

equations.

velocity and interfacial exchange

However,

for

are

faces of the cell, and are assumed to be

the

across

uniform

The

information.

terms

are

involving

treated

the

sonic

implicitly.

the convective terms, only the velocities are

treated implicitly, while all other factors are evaluated at

the previous

timestep.

This

method

imposes

a

timestep

limitation such that

At -< Az

UZ

z

In most cases, this is not a detrimental

this

constraint,

since

timestep is usually the same order of magnitude as the

time at which information is

required.

The equations are

by

Iteration

solved

reduction

to

a

Newton

problem, in which the unknowns become linearized.

SIIIW IIIII

l

ll IYwl

JIJlil

-19-

Figure 1.1

Typical Arrangement of Cells

NATOF-2D

Used in

-20-

the

only

involving

equations

a

to

reduced

These equations are further

pressures

set

of

linear

a cell.

of

The

pressure field is then solved for by either an iterative

The

a direct technique, and all variables are then updated.

of

advantage

a Newton Iteration technique is that a

using

solution can always be attained

small

timestep.

or

The

by

taking

a

sufficiently

heat conduction equations are solved

implicitly and coupled to the fluid dydnamics equations.

The code has the capability to operate

velocity

or

flow

boundary

with

pressure,

conditions at the inlet, and a

pressure boundary condition at the outlet.

The velocity and

flow inlet boundary conditions are new features incorporated

into NATOF-2D, and are described in Appendix A.

NATOF-2D is able

boiling

conditions,

covered

in

this

to

handle

including

thesis

the

flow

addresses

most

severe

reversal.

some

of

The

the

sodium

work

major

difficulties encountered in past sodium boiling simulations.

------ -------

YYII

-21-

Scope of Work

1.2

Interfacial Mass, Energy and Momentum Exchange Models

1.2.1

The constituative equations used for the calculation of

the interfacial mass, energy

have

improved

been

to

of

ability

more

momentum

physically

the

two-fluid

model

boiling transients, since one of the

this

exchange

rates

for the

account

The terms have a pronounced

observed phenomena.

the

and

effect

on

simulate sodium

to

assumptions

major

of

is that for void fractions below 0.957 the vapor

work

phase does not come in contact with the

wall.

Thus

these

often represent the only source of mass, momentum and

terms

energy for the vapor phase.

The mass exchange rate, which has the strongest

of

any

constituative

effect

relation on the running of the code,

has been implemented in a more basic form than before, using

It

the kinetic theory of condensation.

fully

implicit

independent

so

manner

variables

are

that

all

accounted

is

treated

dependencies

for.

The

in

a

on the

momentum

been

modified to take into account the

effects of mass exchange.

Finally, the energy exchange rate

exchange

has been

rate

has

modelled

subcooled

transients.

vapor

to

or

prevent

superheated

the

appearance

liquid

of

highly

in two phase flow

-22-

Fluid Conduction Model

1.2.2

The high conductivity of liquid sodium coupled with the

the only mechanism available in NATOF-2D for

of

radial

small

the

temperature differences to exist

large

allowed

velocities

However,

transfer.

mass

to

solely

modelling

the

energy exchange between cells due

was

phenomenon

this

Previously,

gradients across the core.

temperature

radial

small

in

turbulence found in LMFBR bundles usually results

between internal channels and the edge channel.

incorporated

conduction

heat

Therefore, a radial

into NATOF-2D.

model

of

vapor

the

been

The model is applied only when

single phase liquid is present in adjacent cells

conductivity

has

phase is very low.

since

the

Presently,

only radial conduction has been employed in the code,

since

any

axial

effects

convection

axial

tend

to

dominate

conduction effects.

Calibration of the model is accomplished by

of

Westinghouse

two

experiments /

2

Blandket

/.

Heat

simulation

Transfer Test Program

The model developed is also compared

to analytic results based on conduction mixing length theory

/

3

1.2.3

1.

Direct Solution of the Pressure Field

The

computer

time

usage

of

NATOF-2D

is

strongly

dependent on the solution technique used for the calculation

of

the

pressure

field.

A more efficient method has been

--- -

YIIIIIIIIYIIIYIYIIYIIIYIIYYYIIIIIIIIIIII

uI

lI MY

M

-23-

solve

the

a

uses

implemented into NATOF-2D which

to

method

direct

pressure field matrix, rather than the iterative

The advantages of

technique previously employed.

substantially

reduced

are

this

time, and the capability of

running

using smaller axial mesh cell spacings.

1.2.4

Comparison to Experiments on Boiling Behavior

The

major

are

NATOF-2D

experiences

documented

in

Chapter

5

to

serve

foundation for future work, and also provide an

for

as

a

explanation

changes deemed necessary to the previously derived

any

models, especially the mass exchange rate.

the

running

while

encountered

difficulties

Also,

some

of

sodium boiling codes in general are

with

discussed.

Chapter 6

discusses

results

the

transients performed by NATOF-2D.

of

the

Thors

4

/,

One test was a simulation

while the other four are from

the SLSF W-1 experiments done

at

Development Laboratory /

/.

Finally Chapter

NATOF-2D.

five

Bundle 6A experiments conducted at Oak Ridge

National Laboratory /

thesis,

for

obtained

7

5

summarizes

the

the

Hanford

Engineering

findings

of

this

and makes recommendations for future development of

-24-

Chapter 2

INTERFACIAL MASS, ENERGY, AND MOMENTUM

EXCHANGE MODELS

2.1

Introduction

In the two fluid model NATOF-2D, each phase in the flow

energy,

field is described by a set of mass,

momentum

of these equations takes into account the

Each

equations.

and

occur

between

phases.

the

This

is

interactions

which

accomplished

by the use of empirical correlations or simple

physical models, that describe the mass, energy and momentum

exchange rates at the liquid/vapor interface.

One of the requirements of two phase flow modelling

mass, energy, or momentum be gained or lost at the

no

that

is

interface.

This is the so called "jump

This

interface.

requirement

equations of each phase can

be

is

met

summed

condition"

at

the

if the conservation

and

the

NATOF-2D

was

together,

interface exchange terms cancel each other.

For the sodium boiling transients

which

designed to simulate, these exchange rates take on a special

One of the basic assumptions of this work is

significance.

that only the liquid phase is in contact with the

values

of

void

fraction

up

to

0.957.

Thus,

applications, the vapor phase is entirely dependent

liquid

phase

as

a

mass,

energy

wall

for

for many

on

the

or momentum source, and

-25-

of

thereby dependent on the accuracy

the

exchange

models

incorporated into this code.

This

chapter

will

cover

the

models

developed

for

interfacial transport exchange, and compare the results with

those previously used in NATOF-2D /

1

/.

I

_

MINIIIIIIYIIIIiIUIIN

1 41

II I

-262.2

Conservation Equations Used in NATOF-2D

Since this chapter deals

interfacial

enegy

mass,

in this section.

the

modelling

used

form

by

are

NATOF-2D

Since NATOF-2D is a two-phase,

two-dimensional R-Z code, for each phase there will

mass

the

of

momentum exchange rates, the

and

conservation equations in the

summarized

with

one

be

and one energy conservation equation, and two momentum

equations (one for each

below

are

the

eight

at

direction)

conservation

each

node.

equations

Given

written

in

control volume form.

Mass Conservation

liquid phase:

j

- f(l-a)p dV +

- (l-a)p

Az+ Az_

v

=

Ar+

-

(1-a)p

Ar-

dV

U

rdA

(2.1)

ap vUv

-vz dA

vU

apv dV

v

+

V

vapor phase:

at

UzdA

AZ+

Az_

=

Ar+

F dV

f ap Uvr dA

Ar-

(2.2)

-27-

Energy Conservation

liquid phase:

+

(eZ + U2 /2)dV

(1-a)p

Az+

Ar+

- Ar( l-a)pzUkr(ek

v

P TF dV

Ar+

V

j

-

qZidA

(2.3)

Ai

+

+ U2/2)dV

V

+ U /2)dA

aPv Uvr(e

AZ-

v

- fa PVUz(eV

Az+

S-

k

+ U /2)dA = fQdV- f(l-a) p gU zdV

k

P•n-U dA +

i U" f*zdA

A

P,

w

vapor phase

ap v(e

+ U /2)dA

(1-a) pU(e

=

v

+ U 2/2)dA

V

Az-

f

Q dV -

p gU vdV

V

Ar-

fP

-

-f dA + jP'n*U dA

at

dV

+

I qVi dA

(2.4)

Ai

Momentum Conservation--Axial

Direction

liquid phase

t

(l-)pUtzdV+

I

-

(-)

Az+ - Az-

IAr+-

I(1-a)Pk UzU

rdA -

(1-a)p g

P-k*-

AR

Ar-

dV - fM

zdV

2)dA

p U£zdA

dA =

fkzdA

-

Aw

(2.5)

_~_~~I _

I __EIEIIIHIIwI

,IuIIIl

WNNNO

-28-

vapor phase

-4apvUvzdV

2c

PdA

ap U

A

Az+

V

f

J

+

Pek*n

-

Aw

-

vUvz U vr dA -

A

Ar+

AzAz

_

dA = -fvzdA

A

+

f

A r-

+

pvgdV

f MvzdV

v

V

(2.6)

Momentum Conservation--Radial Direction

liquid phase

-

_lt-(l-a)p ZUrdV +

v

Az+

-

Ar+

z-

-

f(l-a)p Ur dA

(1l-a)ptUrUtzdA +

A

SPr*n

dA

=

Ar_

-f f rdA + f MrdV

(2.7)

v

Aw

vapor phase

a

PvUvrdV +

V

-

P.r-n dA

Av

v

-

-

fvUvz vrdA +

Az+

A z_

=

fvr dA

Aw

w

Ar+

-

i

ap vU2 dA

Ar-

MvrdV

v

(2.8)

-29-

Interfacial Mass Exchange

2.3

2.1 and 2.2) r represents the mass

(equations

phase

vapor

exchange

rate

positive

for

and

liquid

In the mass conservation equations for the

phases,

between

At the

1 has units of kg/m3-s.

evaporation.

rate

present time, the accepted model for the mass exchange

is

This model

based on the kinetic theory of condensation.

particles departing from the interface.

are

particles

The

be arriving from the vapor phase, and departing

to

assumed

When the arrival

from the liquid phase.

condensation is

occurring.

the

exceeds

rate

In

the reverse

departure

rate,

situation,

evaporation takes place and when the net flux

an

zero,

the

/

mass

6

condition exists.

equilibrium

rate

exchange

is

essentially

is

The derivation of

due

to

Schrage

/.

Using a Maxwell-Boltzmann distribution, it is

to

a

particles arriving at the interface, and a flux of

of

flux

between

difference

the

views the interaction simply as

as

defined

be

will

and

show

that

in

a

possible

stationary container the mass flux of

particles passing in either direction through the

interface

is given by:

M= 2 p

i

2rR

T

(2.9)

where

ji

= mass flux of phase i (kg/m

2 -s)

M = molecular weight of particles

____

^_

_

~ I_

I I11

-30-

R = universal gas constant

P = pressure exerted by the particles

T = temperature of the particles

If there exists a progress velocity on the

=

towards the interface such that Jv

M

2 P

side

vapor

PvVp then

T

(2.10)

where

S= e-2

+

(2.11)

+ erf#)

or(1

V

P

2R/

(2.12)

(.

p v(2RT/M)

(2RT/M) T

Vp = progress velocity

not

At the liquid-vapor interface

striking

the

striking

defined as the fraction of molecules

which

actually

do

represents the ratio

condense.

of

the

In

flux

a

of

c

Therefore,

condense.

will

surface

molecules

the

all

similar

surface

the

manner,

molecules

is

oe

actually

leaving the interface to the flux given by equation 2.9.

At the condensing surface, molecules are arriving at

progress

flow

rate

pvVp,

surface at a rate equivalent

a

and molecules are departing the

to

that

of

molecules

in

a

-31-

Thus the net flux towards the surface

stationary container.

is given by:

P

i

.

M

2JR

2

P

(2.13)

v

TTeT

T

C

If it is assume that P << 1, or in other words that the

be

can

Y

condensation rate is low,

approximated

by

the

following expression:

T

+ 1

/

Pv( 2RT /M) T

(2.14)

Substituting this into equation 2.13 yields

eT

a 2fRT 2

v

2

c

e

(2.15)

When the two phases are in equilibrium, the net flux, j,

to

equal

zero,

and

ac

=

Since

e*.

the values of the

individual coefficients in non-equilibrium systems have

been determined, it is justified to set a

is

= ae

=

not

a,. Using

this approximation the net flux becomes:

J=

2a

M 21

1J

v

2

(2.16)

and the mass exchange rate is thus

F

.2a

= -jA = A T_

M

2Mv

FP

-

v -1

w(2.17)

where

A = the interfacial

area per unit volume

-32-

The literature shows a wide variation in the value of a

for sodium, ranging

a = 0.001

/,

7

of

presence

the

pressures

figure

however, attributes

this

variation

non-condensible

gases

which

tend

to

to

additional

These gases add an

on

conducted

Tests

to

2.1).

(See

condensation.

to

low

at

pressures

congregate at the interface.

resistance

1.0

a =

atmospheric

at

Rohsenow /

from

nearly

gas-free systems where the flow was high show that any gases

present are swept away from the interface, and

a = 1.0

for

all pressures.

In the models developed for

that

only

NATOF-2D,

it

assumed

is

the liquid phase is in contact with the wall for

values of void fraction up to adryout .

Below

this

value,

all heat gains to the vapor phase are solely from the liquid

the

liquid

phase

is

evaporating,

phase.

When

phase is

entering the system at the saturation

Similarly,

condenses

a < adryout,

temperature.

condensation occurs when the liquid phases loses

The

heat to the wall, and becomes subcooled.

again

the vapor

at

vapor

the saturation temperature.

phase

Thus, for

it is justified to set T v to T s and Pv to Ps in

equation 2.17.

For values of a > adryout' the liquid becomes entrained

in

the

vapor

experiences

T

phase,

and

then

it

the heat losses and gains.

= Ts, and PP = P s in equation 2.17.

is

the

vapor

which

Thus for this case,

In order

to

obtain

-33-

1.0

0.1

0.01

0.001

I

I

L

0.01

0.1

1.0

Pressure (bar)

Figure 2.1

Condensation Coefficient as a Function of

Pressure

- ---

I

YIIIIYIYIYIYIYYIIYYU

rl~

-34-

the

correct

behavior

of this relation, it is necessary to

a

reverse the sign of equation 2.17 so that in

vapor

superheated

environment, the entrained liquid evaporates, instead

of condensing.

section

Equation 2.30 of the next

confirms

this behavior.

sodium

For the range of temperatures in which

and

condensation

occurs,

f

Ts

Ts .

and T2

approximation, the final form of the mass exchange

boiling

With this

rate

is

arrived at.

S< adryout

n+l

S>

2a

2 - a

L

3HL

n+1

s

_

M

yTT

i

(2.18)

s

dryout

n+l

n+1 2- a

M

(2.19)

P

s

where

PV = pressure corresponding to a saturation

temperature of T

Pk = pressure corresponding to a saturation

temperature of TZ

Ps = system pressure

T s = saturation temperature

A

= interfacial area calculated implicitly

The formulations previously used for the mass

rate in NATOF-2D were:

exchange

-35For evaporation

{P

A

I'=

2

h

ngfT

Tn+i

S

(2.20)

For condensation

(p v h fg n, T v - T s n+1

n+

R

n+ (l_)n

S=

relations

These

AT/T s << 1,

were

where

AT = T, - T s .

discussed

be

will

in

that

assumption

Simulations by NATOF-2D,

detail

furthler

results

These

large.

quite

however, show that AT can be

S

the

on

based

(2.21)

T2

s-

in Chapter 5.

The

interfacial areas in equations 2.20 and 2.21 were calculated

explicitly, and the term a(1 to zero for single

treats

all

terms

eliminated the a(1 /

8

phase

a) was added to force F to go

The

flc)w.

present

implicitlyr, including the areas, and has

a) term.

The

areas

and depend on the flow regime.

/,

formulation

are

from

Wilson

The following is

a summary of the equations us(

a < cm

A

3a

1 rm

m

23

mM

/D3 (P/D)2-

r m = 6. x lO1

7/2

(2.22)

- -

----

--

IYIIIIIYIIUIII

-36-

(a

m

<

a < 0.55

A2

2

D

-

2/3 (P/D)

(2.23)

0.55 < a < 0.65

a + b.a

A3

3

2

+ c

+ d-t

3

where

-

- 0.55

a

S-0.65 -

a = A2

0.55

b =

3A2

3a

aA2

c = 3(A 4 - A3 ) - a3A 4

aA 2

-+

-a-- + 2(A

d

So

ol

22

-

2*A

-

A4

(2.24)

)

0.65 < a < 0.957

4

D

4

2/3r(P/D)2

(2/3(P/D)

ITra

-

2

2/3(P/D)

-

T

(2.25)

0.957 < a < 1.0

A5

SA

4

"

1 -

0.957

(2.26)

-37-

A transition regime area, A3 ,

between A2 and A4,

and

their

is

which

has been added in order to keep the areas

derivatives

with

to a

respect

comparison was made between the previous

exchange

rate

formulations.

2.2

and

respectively.

predicts

a

term,

the

expected.

present

results

are

shown

that

the

new

mass

in

formulation

rapid vapor production especially in high

Even discounting the effects of the

a(1 - a)

present mass exchange rate still is 2 to 4 times

greater than the

vigorous

and

A

for liquid superheats of 20C and 200C

The results show

more

void regions.

2.3

continuous.

The system pressure used for

this comparison was 2 bars, and the

figure

fit

polynomial

a

and

one

previously

sustained

implemented.

Thus

more

boiling for the same superheats is

Ell

I

--

-38-

U

W

103

J

4W3

I

0)

C

'U

X

U,

L&

U)

U)

'U

102

0.1

0.2

0.3

0.4

Void

Figure 2.2

0.5

0.6

0.7

0.8

0.9

1.0

Fraction

A Comparison of New and Old Mass Exchange

Rates for a Superheat of 20 C

-39-

u

C-,

C,

!

E

o,

w

4.)

,

C.)

a

u-J

C,

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Void Fraction

Figure 2.3

A Comparison of New and Old Mass Exchange

Rates for a Superheat of 200 C

_

I~~

II

I

11111U111

-40-

Energy Exchange Rate

2.4

Reliable constituative relations

for

transfer are not available at the present time.

in

heat

interphase

This is due

part to the insufficient attention which this phenomenon

has recieved until only recently, and also

to

the

extreme

difficulty in gathering useful data on the subject.

Starting. with

equations,

two

the

phase

2.3 and 2.4, one can define an energy

equations

exchange due to the difference in

and

phase

conservation

energy

temperature

between

the interface, and an energy exchange associated

With

with the heat transferred by virtue of mass exchange.

the

premise,

this

the

energy

exchange

from the liquid/vapor

interface to the vapor become

qiv = r.hvs + AiHiv(Ti -

energy

Similarly, the

exchange

TV)

from

(2.27)

the

liquid

to

the

liquid/vapor interface is:

.i

=

r*hts + AiH£I(Tz - Ti)

where

r

= mass exhange rate

hvs = enthalpy of the vapor at the saturation

temperature

hts = enthalpy of the liquid at the

saturation temperature

A.

= interfacial area

(2.28)

-41-

H.

= interface to vapor phase heat transfer

coefficient

HPi = liquid phase to interface heat transfer

coefficient

the

Since the "jump condition" at

interface

requires

that

qiv

£i

we have

-*h

+ A.H i(T

-

+ AiH i(T

Tv) = r'hs

for

Equation 2.29 can be used to solve

the

-

Ts)

mass

(2.29)

exchange

rate to yield

H.

ivAi(T

-

Ti

)

+ H i.A(T

- Ti )

hfg

(2.30)

The above relationship shows that if Hiv and H£i were known,

and if Ti was defined,

determined.

exchange

mass

the

Unfortunately,

2.28 and the

interfacial

would

be

there is a lack of data on the

interface heat transfer coefficients at

Therefore,

rate

the

time.

present

an alternative is to use either equation 2.27 or

given

formulation

energy

in

exchange rate.

section

2.3

for

the

One cannot use equation

2.27 for the vapor energy equation and equation 2.28 for the

liquid energy equation simultaneously since there

would

be

no guarantee that the jump condition was being satisfied.

Attempts to define

an

interface

temperature

with

a

-42-

value

somewhere

in

temperatures

have

temperature

based

the range between the liquid and vapor

proven

For

fruitless.

an

interface

on two infinite bodies in contact, Ti is

given by the relation

T

- Ti

T

-

(kpc )

_

T

(kpc

)

(2.31)

Since the conductivity and density of the liquid phase is so

much greater than that

vapor

TR.

Ti

yields

2.31

equation

the

of

phase,

This

solution

of

would

be

result

acceptable is T, stayed near the saturation temperature when

but

both phases are present,

attaining

a

sodium

high

difficulties

experienced

condensation

vapor

rate

resulted in vapor coexisting with liquid which is

in

have

subcooled

by as much as 100 0 C.

Therefore, the decision was made to set the interfacial

temperature to the saturation temperature.

temperature

chosen

was

it

since

temperature for a two-phase mixture,

for

is

The

the

saturation

equilibrium

As previously

stated,

values of a < adryout' the vapor gains heat solely from

the liquid.

state

In an evaporating

the

assumption

that

Ti = Ts implies that all the liquid superheat is utilized as

latent

where

heat

Tk < Ts,

temperature,

virtue

for

of

and

mass

evaporation.

And

is

kept

the

all

vapor

losses

heat

transfer

to

the

in a condensing state

at

from

liquid

the

saturation

the vapor are by

phase.

For

-43-

With

the roles of each phase will be reversed.

a >adryout

this understanding, the final form of the interfacial energy

exchange rate becomes:

C <

dryout

S=Svs

n+h

(n+1

+ An+1

s

iv

i

(2.32)

+1)

-

C > adryout

n+1 hs

qi=

+ An+lHH

(2.33)

(Tn+1 - Tn+1)

where

H.

Nu

iv

De

k

= Nu

H

V

e

previous

The

formulation

of

the

heat

interfacial

exchange rate was

i

(T

AiHI(T

+ AiH

+ r h

= F h

ehvs + chs

+

- TV)

-

(2.34)

Tv)

This formulation effectively kept T V equal to T,, and led to

situations of the vapor phase being subcooled by as much

100 0 C.

as is

as

The present formulation has eliminated this problem

shown in

figure 2.5.

The nusselt number

transfer

temperature

coefficients

of

the

chosen

has

phases.

a

for

the

pronounced

To

interfacial

effect

illustrate

this,

on

heat

the

three

-44of a sodium boiling transient were run in which

simulations

only the interfacial nusselt number was

varied.

these

In

cases there was no switch in correlations at a=adryout.

temperatures

correspond to those found at the top of

given

As can

the heated section of the fuel bundle.

figure

been

(Nu

2.4,

plotted

= 0.006)

temperature

time,

versus

to

leads

to

a

small

saturation

seconds

in

number

nusselt

At

temperature.

boiling inception, at a

after

to

void fraction corresponding

began

seen

quite a variation between the vapor

the

0.55

be

vapor and liquid temperatures have

the

where

and

approximately

The

the

adryout

phase

vapor

The liquid temperature

superheat to high levels.

stayed very close to the saturation temperature.

When

Nu

indicates.

=

6,

This

Tv

Ts

and

T

as

figure

2.5

test case also showed that the saturation

temperature was more stable with time,

wild

= Ts

fluctuations.

For

and

less

prone

to

Nu = 6000, the results were about

the same.

Based on these simulations, a

recommended.

A

value

of

2.33.

term

=

10

is

value in this range will keep the vapor at

the saturation temperature, but not make the

contribution

Nu

sensible

heat

the dominating one in equations 2.32 and

-45-

1120

-

Saturation Temperature

1100

-

A

r

1060

1040

/

I

I

1

!

I

r

1020

I

cIII

'

1,

000 -

I

I I

I II

980 a

I

II

II

S960

940

920

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Time (sec)

Figure 2.4

Variations Between Vapor and Saturation

Temperatures for an Interfacial Heat

Transfer Nusselt Number of 0.006

-46-

1120

1100

1080

1060

1040

0

03

5-

1020

4L

543

1000

E

03

980

960

940

920

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

Time (sec)

Figure 2.5

Vapor and Saturation Temperatures for

an Interfacial Heat Transfer Nusselt

Number of 6.0

-47-

Interfacial Momentum Transfer

2.5

the

The interfacial momentum exchange rate, similar to

energy exchange rate, is composed of two terms.

interfacial

The first term takes into account the momentum gain

exchange

mass

interface,

the

across

due

to

and the second term

accounts for the effect of shear stresses at the

interface.

section will show how these terms can be combined into

This

a single term which contains both of these effects.

phase

The momentum conservation equation for the vapor

in the z-direction written in differential form is

t

+

U

Vv

(p

a

=

3Z

z

(ap U 2

vz

f

- ap v.35)

g - Mi

-fwz

(ap UvrUvz)

vz v r

r

+

+

- Ui r

(2.35)

where

Miz = shear stress contribution

U.i

= contribution due to mass exchange which is

traveling at an interfacial velocity

i

= rlnu

+

factor (0 I

(1 -

r)Uv, where n is a weighting

n < 1)

In order to facilitate the implimentation of the finite

difference scheme utilized by NATOF-2D, it is

cast

equation

2.35

into

non-conservative

necessary

form.

to

This is

accomplished by applying the product rule of differentiation

to the following terms:

-48-

Uv

-a-(apv Uvz )_ = a+ vat

at

a (ap U2 ) = ap

z

v vz

v vz

3r-(ap v Uvz Uvr

(2.36)

U-(ap

a

vapv

vzat

U aVzp

z

(2.38)

+

a (apU vr

+r Uvz 3r

ap v Uvr au

2.35,

equation

into

Substituting these values

(2.37)

v vz

z

the

vapor

momentum equation becomes:

vz

apvz

vvr

-f wz

(ap v ) + ap vUz

vz -t

at

+U vz

a pv T-

-

ap

a (aPUv)

U

vz Dr

vr

+

g

-

Miz

+U vz az (apU vz ) +

aP

a-p

3z

+

-

(2.39)

Uizr

+

The vapor mass conservation equation is given by:

v(() + -(ap

v UV

r

(ap Uv

+

(2.40)

and this can be substituted into equation 2.39 to yield

non-conservative

auvz

+

pV

v at

-f

Next Mz

vz

-

the

form

auvz

acp vUvz 7t

ap g

-

M

+

+

ap U

-a vz

v vr ar

-

Uiz

Uv

+

ap

a aaz

(2.41)

is defined such that

M'

vt

=

-Miz

Vziz

+

U iz

i.

-

Uvz

v2)

(2.42)

-49-

where

(2.43)

- j, z )

vz

V

izZ :

K = interfacial momentum exchange coefficient

be rearranged by the following procedure:

M'

VZ can

Mz

vz

(1-n)U~vz - Uvz]F

= -K(Uz - U z) + [ nUz

= -K(U

Uvz

Ezz)

-

+

[ n(U

-

Ezvz

+ U v-

U v)

vz

Uv

vz

= -(K + Jr)*(Uvz - Uz)

(2.44)

One can follow the

same

the

for

procedure

liquid

phase

momentum equation to obtain the non-conservative form, which

is:

(l-)pt

(l-c)fr

t+

3tz

3t

S

+ (l-a)P Uz

Z az

R

-f wz -

(l-)p

(l-)j

+ (1U-a)p

r

-z z

+ Mizz)- Uizr

+ URz

iz

(2.45)

Defining

where

Mz = Miz Miz

Uizr + Uzr

= K*(Uvz - UZ)

one can simplify MIz to obtain

Mz = (K PIZ

(l-n)F)*(U vz -

U Ezz)

(2.46)

In order to better interpret these results, consider

a

-50-

situation

where

n = 0.5

terms

MIz

and

evaporating

an

where UV> Uk. For

both

MIz

U

that

so

= (Uz

condition

+

Uv)/2, and

(F > 0),

The vapor phase bulk

decrease.

(Ui < UV )

momentum decreases by picking up slower particles

and

the

liquid

momentum

bulk

phase

the

decreases by losing

particles traveling at Ui > UY.

In a condensing condition, both MI

vapor

The

and

M

increase.

phase bulk momentum increases by losing its slow

particles and the liquid phase gains momentum

by

receiving

fast particles.

A comparison of K and nr verses void fraction was

in

order

to

access the importance of this phenomenon.

can be seen in figure 2.6, for values of

term is the dominating one.

a > 0.88,

made

As

the

This is a desired result, since

as the liquid becomes entrained in the vapor phase, the slip

ratio

should

decrease as the liquid particles become borne

in the vapor phase.

Parameters used for this comparison are

given in Table 2.1.

To determine what effect this modification actually has

on NATOF-2D simulations, a sodium boiling transient was

with the new correlation (with n = 0.5),

same

transient

insignificant

without

difference

The

it.

for

the

run

and compared to the

results

full

range

showed

of

an

void

fractions.

Simulations were also run in which n was varied in the

range from 0.0 to 1.0.

The only noticeable

difference

was

-51-

1

v,

t

C

v

4

SL

C

rCI

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Void Fraction

Figure 2.6

Values of r and K as a Function of Void

Fraction for Typical LMFBR Transient

C,onditions

1.0

-52-

Table 2.1

Parameters Used in K versus nr Comparison

Pressure (N/m2

)

Saturation Temperature (OK)

2.

x 105

1235.59

Fuel Pin Diameter (m)

5.842 x 10

Hydraulic Diameter (m)

4.223 x 10-3

Pitch/Diameter

1.25

Vapor Density (kg/m 2 )

0.53

Vapor Velocity (m/s)

Liquid Velocity (m/s)

T

- Tsat (OK)

25.0

5.9

2.0

-53-

that

for

n = 0.0

the

vapor

was lower than for

velocity

n = 1.0, and for n = 0.0 the liquid velocity was higher than

for n = 1.0.

condensation

Since these results are

is

occurring

Refering to equation 2.44, the

when

n = 1.

(r < 0),

this

term

(K + qr)

region

was

is

Refering to equation 2.46,

where

expected.