Searching for Deep Understanding: Implementing a... Engineering Design Process in K9-K12 Physics...

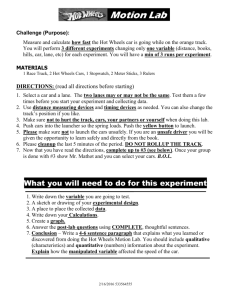

advertisement