additional $5 million of ore was produced Introduction and history (Thompson, 1962).

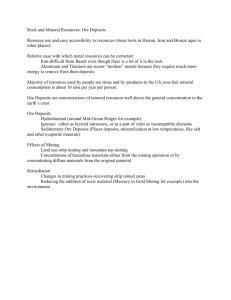

advertisement

anoldmine Newmethods ofworking NM Casehistory0l theEberleGroup,Mogollon, NM Socorro, Bureau of Mines& MineralResources, MiningEngineer, NewMexico W.Eveleth, byRobert presented atand subrished 8lJ[i.';: iliT w0rrd conference' cesscouldbe economicallyappliedto lowgradegold ore. Activatedcharcoalcould be used to extract the gold from unclarified cyanidesolutions(Zadra,l950). Unfortunately, the method was only suited to relatively silver-free ore becausethe causticsodium sulphidesolution usedto leach the gold from the loaded carbon also fixed the silver. In 1952the process was improved by using hot caustic cyanide solution to strip gold and silver from the loaded charcoal (Zadra and the processreothers,1952).Nevertheless mained unattractiveto the small operator becausestripping was time-consuming, requiring a minimum of 50 hours. Continuedresearchby the NevadaBureauhas developeda processwherebythe stripping time has been markedly reduced(Heinen This newmethod and others,1976,19'77). to processlowsmall operator the allows grade ores of the Mogollon district economically. additional$5 million of ore wasproduced Introductionand history "flx.,;::if,yfi:: The Cooney (Mogollon) mining district (Thompson,1962). The closingof the Fanny Mill on June is located in southwestCatron County, western New Mexico. Access to this 18, 1942forced a shutdownof the entire remotedistrict is via US-180and NM-78. districtbecausethe mill had beenprocessThe area, due to its isolation, has never ing ore for the local mines including the had rail servicealthoughplansweremade Last Chance,Pacific, Fanny,Eberle,and at various times to constructlines from others (Weatherly,1949).SeveralsubseSilver City, 80 mi south, or Magdalena, quent attemptswere made to revive min130mi northeast.During the earlydaysof ing in Mogollon district, but without a the raw ore was mill, ore had to be shippeddirectly to a the district (1880-1900), shippedto a smelterby freight wagonat a smelter.Gradeswere not then, nor are cost of $50 per ton (Thompson, 1962), they now, high enough to sustainsuch virtually precludingany large-scalepro- operations.With the exceptionof a brief duction until milling facilitieswere con- periodof activitybetween1943and1946, structed locally around 1900 (Allen, most such efforts failed and the district Eberlemine has remained virtually dormant. New 1909). Aker collected samples David 1967 reln would be the ideas modern technology and A German itinerant discovered district in 1870(Jones, 1904);however, quired for Mogollon to becomean eco- in the Eberlemine but found the ore was Iittle developmentoccurreduntil the area nomic mining district once again. The too low grade to warrant shippingto a was re-discoveredin 1875 by JamesC. technologywasto comein the 1970'sin a smelter.Nine yearslater, R' C. Manning Cooney,an army sergeanton a scouting processknown as cyanideheap leaching. visited several successful, small heapmission from Fort Bayard, New Mexico A group named ChallengeMining Com- leaching operations in Nevada and familiarized himself with the hydroTerritory. In 1876,after retirementfrom panywouldprovidethe newideas. metallurgicalwork of the U.S. Bureauof the military, Cooney, for whom the Recoveryof preciousmetals Minesat Reno,Nevada.Manningand his districtis named,organizeda prospecting by cyanidation partner at the time, GeneCook, submitparty to developthe wide, rich veins he Although the solubility of gold in ted a sampleof Eberle ore to the U'S. had discoveredearlier. But the area was the stronghold of a band of Apachesled cyanidehad beenknown for more than a Bureau of Mines for testing. Results by Victorio; constantharassmentby the hundredyears,the mining world did not showedthat the ore wasamenableto heap Indianswasto preventfull-scaledevelop- recognizethe processuntil J. H. Rae ob- leaching(Heinen,1977).Mr.Cook dropmentuntil the 1880's.Cooneyhimselfwas taineda patentin 1867for "an improved ped out of the partnershipand was rekilled during one encounter.The Indian methodfor treatingauriferousand argen- placedby Aker. ChallengeMining Comproblems were gradually resolved, en- tiferous ores." The processproved im- pany was subsequentlyformed and an at Mogollon. Extenabling productionto increaserapidly. By practical until l89l when a plant con- assaylab established that material determined used has testing sive Africa successfully produced in structed South of a total 1905,the district had in the area' dumps in the mine gold of process from some dissolved gold, which a in and copper million in silver, $5 (Lindgren,l9l0). cyanide was precipitated on zinc dust particularlythe Confidenceminedump, is The introduction of the cyanidation (Allen,19ll). Todayhowever,the costof also economicallyamenableto the heapprocessto the districtby ErnestineMining a conventionalcyanide mill, which in- leachingprocess.Testinghasalso yielded Companyin l9l0 (Allen, l9l l) alongwith cludes crushing and fine-grind circuits, additionaldata regardingpropergrinding efficient large-scale mills enabled agitation of the fine ore in vats with size,reagentconsumption,and optimum Mogollon'sminesto expandsteadilyuntil cyanide,de-aerationand clarification of leach-cycletime. A carbon desorptionl9l4 when annual production peakedat the leach solutions, and the ultimate electrowinningplant similar in designto $1.5 million (Ferguson, 1927). When precipitationof the preciousmetalon zinc the Reno plant built by the U.S. Bureau operationsceasedin 1926due to rising dust is prohibitive for a small operation of Mines has been constructed at Mogollon. A descriptionof the recovery low-gradeores. costsand decreasingprofits, the Cooney that processes processfollows. a concept Cyanide heap leaching, district had produced more than $15 with along 1967 recently as developed as gold, a and copper at million in silver, carbon'adsorption, Heap-leaching, time whenthe priceof silveraveragedless new techniquesfor recoveringgold and process at Challenge electrowinning than $1.00 per oz. Operationsresumed silver,however,providesan economically Mining ComPanY to again in 1931.Becauseof new orebodies attractivemeansfor the smalloperator The completeheap-leachingfacility and (althoughlower grade),efficientmanage- processsuch ores. In 1950, the United circuit is shownin fig. l. Ore is Nevada, crushing Reno, prices, Mines at Bureau of States in metal an increase and ment, these operations were successful for demonstrated that a cyanide-leach, crushedto minus % inchesand stackedup another l1 years,during which period an carbon-adsorption,electrowinningpro- to 12 ft high on the leachpads.Pad con- February l9?9 NewMexicoGeology 1 P lo s t i c k e y w o y 36'mil reinforced s o l o r -r e s i s t o npf I o s t i c D e t o i l so f s o l u t i o nl o n k Slimes 6 w o s h e ds o n d 2 2 - m i l p l o s l i c 6 " f i n e s o n d D eettooi il ss o ff p oo dd o nn dd p oo dd b oo ssee Frcurr 2-DerAILs oF cyANlDE soLUTtoN TANKSAND LEAcH pADs. Courtesy Challenge Mining Company. FtcunE 3-Flow DIAcRAM oF HEAp LEACHTNGcARBoNADsoRprroN-DEsoRprroN sysrEM.Adapted from Heap leach processing of sold ores by Heinen,Peterson,and Lindstrom,U.S. Bureauof Mines,Reno,NV, 1977. fourth. The nearly barren solution flowing from the fourth columnis recycledto the cyanide-solutionholding tank. A completeflow diagramis shownin fig. 3. In the electrowinningplant, the loaded Only 85 percentof the dissolvedsilveris carbon is placedin the strippingcolumn removedprior to carbonadsorption,thus (fie. a). A solution containingI percent assuring that excessNarS will not be NaOH (sodium hydroxide), 0.1 percent recycledback to the holding tank and the NaCN (sodium cyanide),and 20-volume FrcunE l-Lnyour oF TANKS,cRUsHER, LEACHpADs. heapwhereit would preventthe leaching percentethanol is heatedto 90o C, and AND cARBoN coLUMNs. Courtesy Challenge Minpumpedupward through the carbon,disof the silverminerals. ing Company. After eachday's operation,the loaded solvingthe gold and silver.The pregnant carbonfrom the first columnis sentto an solutionis cooledand storedin an agitastructiondetailis shownin fig. 2. Cyanide electrowinningplant. The carbon in col- tion tank. The silver is precipitated as solution(0.5lb per ton strength)sprinkled umn two is movedup to columnone, col- Ag,S (silver sulphide)by agitation with over the heap percolatesdown through umn three to column two; and column NarS. Calcium oxide (0.5 lb per ton of the crushedmaterial,dissolvingthe gold four receivesa fresh 150-lbchargeof car- solution) is usedas a flocculatingagent. and silver. Leach-cycletime rangesfrom bon. Precipitation of the silver is complete z$0to 60 days. Testsindicate 50 percent recoveryin 19 days; however,the company hopesto attain 70 percentminimum recoveryand will allow up to 60 daysto Recycle achieveit. Washing the spent ore with b or r en s -----> waterrequiresan additional20days-for a total maximum cycleof 80 days. Each rll' tiil of the two padswill hold 3,500tons-for t" l an annualcapacityof 34,000tons. Eleclrowinning cells The pH is maintainedbetween10 and C or b o n I I by the addition of lime. The pregnant column leach solution flows by gravity into the II l t R e s evr o ir pregnant-solutiontank. From there, the ilY solutionis pumpedfirst into a slimessetC o o l i n g Rec tling tank and then into an agitation tank bor whereenoughNa,S (sodium sulphide)is added to precipitate85 percent of the dissolvedsilver. The remainingsolution, containing15percentof the silverand all Precipiiote of the gold is slowing pumped through to filter press Corbon Aq ^S four columns(eachcontainingl50lbs of stripping o g i l o l i o nt o n k activatedcharcoal)to removethe remaining silverand gold. The overflowfrom the Frcunt 4-Flow DTAcRAMoF cARBoN DESoRprroNELEcrRowrNNrNc ILANT. Adapted from Gold desorption first column flows into the second,the sefrom activated carbon with alkaline alcohol solutions by Heinen, Peterson, and Lindstrom, U.S. Bureau cond into the third. and the third into the of Mines, Reno,NV, 1976. setlling tll I ,11: Februaryl9T9 NewMexicoGeology anotherconceptwith potentialbenefitto the smallmineoperator. Frounp S-TnucK BAcKEDup ro uNrr ANDwtNcH cABLEATTAcHEDTo HousrNc Courtesy Challenge Mining Company. after approximatelyone hour. The Ag:S 3) relativelyfreeof acid-formingagents whichconsume slurryis removedin a filter press;the gold lime in the filtrate is removedby electrowinnfines which will 4) free from excessive preventpercolationof cyanidesoluing on steel wool cathodes.The barren cyanidesolution is recyledto the cyanide tionsthroughthe heap. holdingtank. Ores that satisfy theseconditionsmay The advantagesof the heap-leaching be treated by heap-leachingtechniques, processthat make the method so attrac- but only extensivetestingcan determine tive to the smallmineoperatorfollow: the economics. l) Plant costsare about 20 percentof In addition to the economicsrealized from the use of cyanideheap leaching, conventionalcosts. 2) Operatingcostsareabout40 percent ChallengeMining Companyhasdesigned of conventionalcosts. and fabricated portable equipment3) High recoveriescan be obtained with low-gradeores. 4) Environmental damage is minimized. 5) Silver is selectivelyrecoveredprior to carbon adsorption, minimizing (the amountof carbonrequirements carbon required to absorb Ag is =30 times that requiredfor Au of equalvalue). 6) A batchofcarbon canbe strippedin 6-8hoursinsteadof = 50 hours. 7) Carbon can be reused, thereby eliminatingsmeltingto recoverpreciousmetals. Unfortunately, not all ores are amenable to the heap-leachingprocess;only those ores that meet the following basic requirements canbe first considered.Ores mustbe: l) relatively free from carbonaceous materialsthat precipitategold and silver 2) freefrom cyanide-consuming agents Ftoune 6-UNtr ts DRAwN up oN BED JUsr BEyoND such as sulfidesof copper,arsenic, CENTERoF GRAvrry Courtesy Challenge Mining Company. and antimony Portableequipmentat Challenge MiningCompany R. C. Manningoriginallyconceivedthe idea of portablemilling equipmentwhen he was in the trucking businesshauling grain in seasonand buying, selling,and haulingmilling machineryduring the offseason.He subsequentlyrebuilt a 1970 Mack truck and a 1974Fruehauf trailer and equipped them with hydraulically operatedbedsfitted with rollersand a 35ton winch. Steel containers,8 x A ft weredesignedand built with underframes and rollers to match the truck and trailer beds.The containersare open at the top, have double doors at the rear (which operatesimilarto thoseof a semitrailer), and have optional steelbows that can be fitted to the top of the unit and covered with a heavycanvastarpaulin.Thesecontainers are suitable for hauling many materialsincluding grain, ore for small mining operations,and machinery. An emptycontaineris left on locationand the full containeris hauledto a mill. In the caseof a smallmining operation,this service eliminatesthe need of a permanent ore storage facility. The operator is chargedonly the freight and a nominal rentalfeefor the container. While buying and selling machinery mills, Manning recogand disassembling nized that once an operationfolded, the mill, being too costly to tear down and move, becameessentiallyworthlessscrap Frcune 7-Bpp rs LowERED,UNIT RoLLEDFoRwARD ANDLocKEDINTopLAcE.Courtesy Challenge Mining Company. February1979 New MexicoGeology 9 iron. On the other hand, if the machinery wasportable,it would retain somevalue. He then designedwaysto mount various piecesof milling machineryin the containershe had usedin his grain-andorehauling operations. A set of flotation cells, for example,could be mounted in one container;and a ball mill in another. Larger pieces of equipment could be designedto roll directly onto the bed of the truck or trailer. Puttinga mill together with equipmentof this sort is just a matter of mechanicalingenuity.Theseideasand designshave been refined to the point where all the equipment in use at the Eberleventuretoday, with the exception of the leach pads and holding tanks, is portable. The equipment includes rolls and classifer, crusher, ore bin, bucket elevator,and power plants. The carbondesorption and electrowinningplant is built into a semitrailer. The largestsinglepieceof machineryis the rolls and classifierunit, weighingapproximately40,000lbs. The Mack truck handlesthis load with relativeease.First, the truck is backedup to the unit (fig. 5). The rollers on the truck bed and the classifierhousingallow the heavyunit to roll easilyonto the bed. A winch cableis connectedto the classifierhousing, and the unit is drawnup on the raisedbed to a point just beyond the unit's center of gravity (fig. 6). The bed is then lowered and the unit rolled forward into traveling position and locked into place (fig. 7). Unloading is the reverse of this procedure.The truck or trailer can be loaded in this mannerin lessthan two minutes. The use of portable equipment has manyadvantages: l) Concrete foundations are not needed. 2) Mill setup and disassemblytime is heldto a minimum. 3) Permanent structures are not abandonedwhenoperationscease. 4) When a property ceases to be economical,the machineryis loaded up and movedto anotherlocationthe operator is no longer out of business whenthe ore is depleted. Challenge Mining Company is conductingmining and milling operationson landswithin the Gila NationalForest.The U.S. Forest Service has approved the company'splansmainly becausethe portableequipmenthaslittle impactupon the environment. Economics Discussingprofitability of a company not yet in productionis premature.Many things can go wrong. The ore, however, l0 February 1979 NewMexicoGeology has been tested by the U.S. Bureau of Mines and repeatedlytestedby Challenge Mining Company.Testresultshaveyielded reagent,fuel, and electricitycostsfrom whichper-toncostshavebeencalculated. Easily mined surfaceore on the south end of the Eberle vein and a srnall quantity of high grade ore underground amounts to approximately28,000 tons averaging.08oz gold per ton and 4.5 oz silver per ton. Confidence dump ore amounts to approximately30,000 tons assaying.045 oz gold per ton and 2.5 oz silverper ton. Other smallerdumpsunder lease contain a few thousand tons of similargradematerial. The company'stwo-year plan calls for processing34,000tons of vein and dump materialper year. Gold recoveryis 82.5 percent; silver 69 percent. Profits and costsareoutlinedbelow: ANNuar pnooucrroN:34.000ToNs Eberleore 14,000tonsperyr. Gold perton .08oz Totalgold ll20oz Productionat82.5v/o recovery 924o2 Silverperton 4.5 oz Total silver 63,000o2 Productionat 6990recovery 43,472oz Dump ore 20,000tons per year Cold perton .045oz Total gold 9A0oz Productionat 82.590recoverv 743oz Sifverperton 2.5 oz Total silver 50.000oz Productionat 6990recovery 34,500oz Total annualproductiongold: 1,667oz 77,972oz silver: The economicsof the Eberlegroupventure wereoriginallybasedupon $150-peroz gold and $4.50-per-ozsilver. These priceswill be usedherefor the purposeof cost/profit projection,for as the price of preciousmetalsincreases, operatingcosts will increaseaccordingly. OpgnenNccosts Dollars Per Ton Mining: Supervision, insurance, labor, fuel, explosives, maintenance, expendables 2.225 Milling: Supervision .705 Labor (mill operation,ore hauling) .95 Power(fuel,electricity) .70 Reagents(lime, cyanide,sodium hydroxide) .'15 Water .10 Maintenance .44 Royalties(leases) .97 Ore handling(transportation, Ioading) .40 Carbonadsorption(carbon,lime, sodiumsulphide) .24 Gold recovery(alcohol,sodium sulphide,steelwool) .24 Supportfacilities(assays) .12 Fixedpaymentson machinery 2.57 Total $10.41 Pnorrr Total gold value,1,667oz at $150 peroz Total silver value,77,9'12oz at $4.50per oz Grossvalue Operatingcosts,34,000tons at perton $10.41 Annual profit $250,050.00 350,874.U $600,924.00 $353,940.00 $246,984.00 ChallengeMining Companyis a partnershipownedby threepersons.Two are operating partners who enteredthe venture with approximately$300,000worth of machinery, supplies,and cash. The third memberis a financial partner who matched the operating partners' investment by putting up $300,000for expenses incurred during constructionand startup. The total investment therefore is A projectedannualprofit of $600,000.00. $247,000.00should amortize the investmentin lessthan threeyears. Futureof ChallengeMining Company Phaseone of ChallengeMining Company's plan of operationsprovides for processing34,0N tonsofsurfaceveinand dump material per year. Surfacematerial will be depletedin two years.The operation, if it is to survivebeyondthat point, will haveto beginfull-scaleunderground mining. The future for processingunderground ores is bright. Production at the time of shutdownin 1942wasminedfrom a winze sunk from the third level of the mine. Recordsof ore shippedto the Fanny Mill at this time (138tons)show0.17 oz gold per ton and'l .28 oz silverper ton (Weatherby,1949).The ore left untouched, however,averages4 oz silverper ton and .08 oz gold per ton. Material of this gradewasuneconomicalto mine and processby conventionalmethodsand, therefore, was left. Today, a minimum of 300,000tons of this low-gradematerialis availablefor mining. Summary Production from the Cooney mining district has been minimal for more than 30 years.Known ore bodiesin the areaare of insufficientgrade and tonnageto attract the interestof a large mining company. Challenge Mining Company, a small operator, is taking advantageof new,low-costtechnologyand a few novel ideasof its own to treat theselow-grade ores, AcrxowLnocvpnrs-The author wishesto thank David P. Aker and Richard C. Manning of ChallengeMining Companywithout whosecooperation this paperwould havebeenimpossible. References cited Allen, R. S., ed., 1909, The Mogollon Mines: Mogollon,NewMexico,v. l, Novembert*n -_