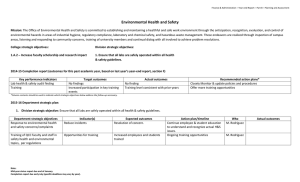

Environmental Health & Safety Core Activities and Performance

advertisement

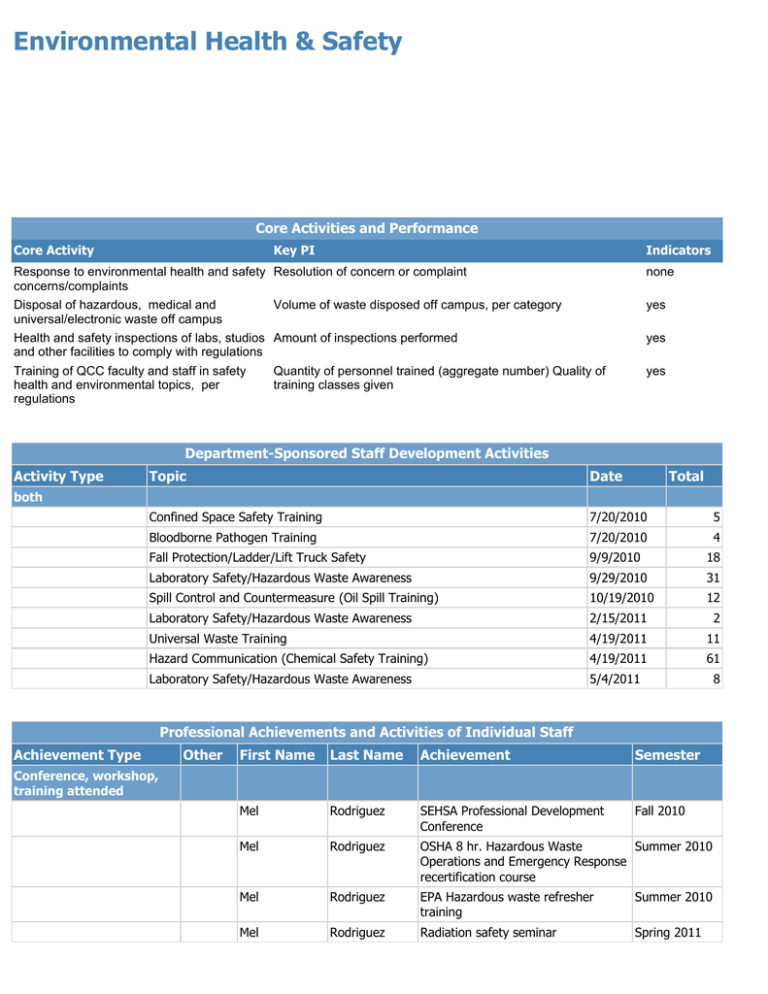

Environmental Health & Safety Core Activities and Performance Core Activity Key PI Indicators Response to environmental health and safety Resolution of concern or complaint concerns/complaints none Disposal of hazardous, medical and universal/electronic waste off campus yes Volume of waste disposed off campus, per category Health and safety inspections of labs, studios Amount of inspections performed and other facilities to comply with regulations yes Training of QCC faculty and staff in safety health and environmental topics, per regulations yes Quantity of personnel trained (aggregate number) Quality of training classes given Department-Sponsored Staff Development Activities Activity Type Topic Date Total Confined Space Safety Training 7/20/2010 5 Bloodborne Pathogen Training 7/20/2010 4 Fall Protection/Ladder/Lift Truck Safety 9/9/2010 18 Laboratory Safety/Hazardous Waste Awareness 9/29/2010 31 Spill Control and Countermeasure (Oil Spill Training) 10/19/2010 12 Laboratory Safety/Hazardous Waste Awareness 2/15/2011 2 Universal Waste Training 4/19/2011 11 Hazard Communication (Chemical Safety Training) 4/19/2011 61 Laboratory Safety/Hazardous Waste Awareness 5/4/2011 8 both Professional Achievements and Activities of Individual Staff Achievement Type Other First Name Last Name Achievement Semester Mel Rodriguez SEHSA Professional Development Conference Fall 2010 Mel Rodriguez OSHA 8 hr. Hazardous Waste Summer 2010 Operations and Emergency Response recertification course Mel Rodriguez EPA Hazardous waste refresher training Summer 2010 Mel Rodriguez Radiation safety seminar Spring 2011 Conference, workshop, training attended Professional Achievements and Activities of Individual Staff Achievement Type Other First Name Last Name Achievement Semester Mel Rodriguez UCLA Lab Incident seminar and discussion Spring 2011 Mel Rodriguez Hazardous Waste seminar, American Spring 2011 Chemical Society MARM Changes in Department within Last Year Change Type Change Reason Semester Purchase of TSI Aerotrak Particle Meter Needed ability to measure respirable dust for Indoor air quality evaluations Spring 2011 Installation of emergency phone by Main Accumulation Area of Hazardous Waste EPA regulations require a means of communication in areas where hazardous waste are accumulated Spring 2011 EHS Office moved from A Bldg to SER Bldg Reorganization within Finance and Spring 2011 Admin. Division ; closer interaction with B/G dept. Equipment Facilities/Space Assessment and Evaluation KPI Target Outcome Actual Outcome Action Plan Status Disposal of hazardous, medical and universal/electronic waste off campus Net increase in waste disposed, by category Increase 7% for hazardous waste amount disposed, increase 60% for medical waste disposed, decrease 55% for e waste disposed, as compared to previous FY (electronic waste disposal reliant on other department’s disposal schedule) Continue to encourage Continuing departments that use chemicals to dispose old/ unwanted chemicals that could be a liability in an EPA inspections; (*disposal of e waste and medical waste reliant on generating department’s operations Health and safety inspections of labs, studios and other facilities to comply with regulations N/A: Amount and frequency of lab inspections not previously quantified, all inspections done on ad hoc basis Lab inspections performed on Set and follow targeted Continuing systematic basis, over breaks (30 goals for amount and labs inspected each semester frequency of lab inspections , and set a score(ex., set goal of inspecting 30 labs/month, and attempt to complete this goal for a perfect score) Training of QCC faculty and staff in safety health and environmental topics, per regulations Perform training for personnel depending on need; goal of 100% staff attendance (per training topic) Est. 80% completed (some staff members unavailable Perform make up training Continuing for those unable to attend Assessment Plan Core Activity KPI Target Outcome Plan Continue to provide regular and as needed EHS training, to QCC faculty students and staff Aggregate number of staff trained, per topic 100% attendance for training , per training topic Identify areas where training is required; Reach out to applicable departments and stress the importance of training; explore alternative training techniques (self training, computerized training modules, etc); *NOTE* (CUNY just recently retained a contract with a vendor that can provide online EHS training,; will be implemented in FY11-12; Improve quality of training Positive response by training At least 80% satisfaction rate from provided by department attendees training attendees Feedback questionnaire and survey to be provided at end of each training class (already implemented Health and safety Perform inspections of all inspections of labs, studios QCC labs each month and other facilities to comply with regulations Allocate more time to lab inspections; explore use of technology to streamline task (ex., new computerized software with lab inspection applications) 100 % completion