Summary 8– Minimization of waste generation, source reduction, reagent substitution, green chemistry, microscale

advertisement

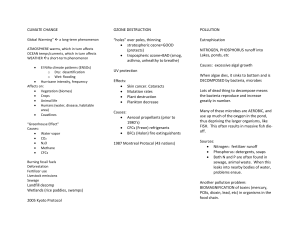

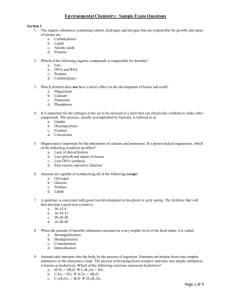

Summary 8– Minimization of waste generation, source reduction, reagent substitution, green chemistry, micro­scale Read Prudent Practices in the Laboratory –CH 4 p.64­7 Read “Origins, Current Status and Future Challenges of Green Chemistry,” by Anastas and Kirchhoff Read “Green Chemistrt: A powerful approach to pollution prevention, waste minimization and hazard reduction.” By Hutchison Goals of Source Reduction To minimize: quantities of chemicals to be used disposal of hazardous materials risks that expose laboratory workers and storeroom and receiving personnel to hazardous materials. Importance of Minimizing Chemical Orders The cost of a chemical includes the purchase price as well as the storage and disposal costs. Free materials can end up costing a lot. The advantages of small orders include: · · · · · · Small package are less likely to break. Smaller containers pose less of a risk of accident and exposure to the hazardous material. Small containers require less storeroom space. Smaller containers are emptied faster, resulting in less chance for decomposition of reactive compounds. Equipment, such as smaller transfer containers, funnels, pumps, and labels may be needed if the large "economy size" is ordered. Additional labor to subdivide the larger quantities into smaller containers, as well as additional personal protective equipment for the hazards involved, may also be needed. Any unused hazardous material must be disposed Strategies to Minimize Hazardous Waste Generation When designing experiments all potential sources of hazardous waste expected from the proposed experiment should be evaluated and strategies to minimize those sources should be developed. Some strategies include: 1. smaller scale – minimize the amount of material used in each step of an experiment and make just the needed amount of product. 2. improve yields. 3. use less solvent to clean equipment. 4. use more sensitive analytical equipment so less material is needed. 5. substitute nonhazardous, or less hazardous, chemicals where possible by considering alternate synthetic routes and alternate 6. recycle and reuse materials where possible 7. develop steps for deactivating hazardous materials or reducing toxicity. Microscale Work In microscale chemistry the amounts of materials used are reduced to 25 to 100 milligrams (mg) for solids and 100 to 200 microliters (µL) for liquids, compared to the usual 10 to 50 g for solids or 100 to 500 milliliters (mL) for liquids. Substitution of Materials Examples A Beer's law experiment formerly used a considerable volume of a copper­ammonia complex. Copper should not be released directly into a sewage treatment system. The experiment was modified to use an iron­salicylic acid complex, which can be disposed of down the drain. Chromic acid cleaning solutions for glassware can be replaced by proprietary detergents Fluorine and fluorinating reagents such as perchloryl fluoride are among the most demanding reagents to handle because of their high reactivity and toxicity. F­TEDA­ BF4, or 1­chloromethyl­4fluoro­1,4­diazonia [2.2.2] bicycloctane bis(tetrafluoroborate) can be substituted in many fluorination procedures. Green Chemistry – the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances. The Twelve Principles of Green Chemistry 1. Prevention It is better to prevent waste than to treat or clean up waste after it has been created. 2. Atom Economy Synthetic methods should be designed to maximize the incorporation of all materials used in the process into the final product. 3. Less Hazardous Chemical Syntheses Wherever practical, synthetic methods should be designed to use and generate substances that possess little or no toxicity to human health and the environment. 4. Designing Safer Chemicals Chemical products should be designed to preserve their desired function while minimizing their toxicity. 5. Safer Solvents and Auxiliaries The use of auxiliary substances (e.g., solvents, separation agents, etc.) should be made unnecessary wherever possible and innocuous when used. 6. Design for Energy Efficiency Energy requirements of chemical processes should be recognized for their environmental and economic impacts and should be minimized. If possible, synthetic methods should be conducted at ambient temperature and pressure. 7. Use of Renewable Feedstocks A raw material or feedstock should be renewable rather than depleting whenever technically and economically practicable (agriculture waste converted into ethanol, crab shells converted to chitin, which is used to make polymers, the genes of microorganisms can be modified to produce desired chemicals). 8. Reduce Derivatives Unnecessary derivatization (use of blocking groups, protection/ deprotection, temporary modification of physical/chemical processes) should be minimized or avoided if possible, because such steps require additional reagents and can generate waste. 9. Catalysis Catalytic reagents can enhance the selectivity or extent of reaction, which increases the yield and reduces waste and/or lower the temperature, which reduces energy requirements. 10. Design for Degradation Chemical products should be designed so that at the end of their function they break down into innocuous degradation products and do not persist in the environment (DDT caused so much damage to the environment because it did not degrade). 11. Real­time analysis for Pollution Prevention Analytical techniques need to be further developed to allow for real­time, in­process monitoring and control prior to the formation of hazardous substances. Monitoring the progress of a reaction reduces energy requirements and prevents undesirable side reactions. 12. Inherently Safer Chemistry for Accident Prevention Substances and the form of a substance used in a chemical process should be chosen to minimize the potential for chemical accidents, including releases, explosions, and fires. Examples – chlorofluorcarbons (1) One historian remarked that Thomas Midgley "had more impact on the atmosphere than any other single organism in earth history." Thomas Midgley, Jr. (2) was born May 18, 1889 and died November 2, 1944. He was a mechanical engineer turned chemist. He developed tetra­ethyl lead additive to gasoline and chloro­fluorocarbons (CFCs). While praised at the time for his discoveries, today his legacy is seen as far more mixed. While working for General Motors, he discovered that leaded gasoline kept internal combustion engines from "knocking". The subsequent addition of lead to billions of gallons of gasoline eventually released huge amounts of lead into the atmosphere, causing health problems around the world. Workers producing the additive were most affected. In 1924, Midgley took a prolonged vacation to cure himself of lead poisoning — a fact he deliberately kept secret, holding a press conference to demonstrate the "safety" of contact with the substance. In this demonstration, he poured tetra­ethyl lead over his hands, then placed a bottle of the chemical over his nose and breathed it in for sixty seconds, declaring all the while that he could do this every day without succumbing to any problems whatsoever. Eventually, he repented of lead. Lead is no longer added to gasoline and lead levels in the air and soil have been reduced. Next he invented the chlorofluorocarbon CFC ­12, CCl2F2 , after hearing about people suffocating from gas leaks from refrigerators. CFCs replaced the poisonous and explosive upon heating ammonia in refrigeration. CFCs were also used as propellants in aerosol spray cans, metered dose asthma inhalers, cleaning solvents for circuit boards, and as blowing agents for making expanded plastics. CFCs were good refrigerants because they have a low boiling point are nontoxic and nonreactive under normal conditions. In a demonstration for the American Chemical Association, Midgley demonstrated all these properties by inhaling a breath of the gas and using it to blow out a candle. The Refrigeration Cycle (4) 1. The compressor compresses the gas. The compressed gas heats up as it is pressurized (B). 2. The coils on the back of the refrigerator let the hot gas dissipate its heat. The ammonia gas condenses into liquid (A) at high pressure. 3. The high­pressure liquid flows through the expansion valve, a small hole. 4. The liquid immediately boils and vaporizes (C), its temperature dropping to ­27 F. This makes the inside of the refrigerator cold. 5. The cold gas is sucked up by the compressor, and the cycle repeats. There has been a movement since the late 1970s to ban CFCs because of their destructive effect on the ozone layer ­ one of CFCs' most attractive features—their unreactivity—has been instrumental in making them one of the most significant pollutants. CFCs' lack of reactivity gives them a lifespan which can exceed 100 years in some cases. This gives them time to diffuse into the stratosphere. Here, the sun's ultraviolet radiation is strong enough to break off the chlorine atom, which on its own is a highly reactive free radical. This catalyzes the break up of ozone into oxygen: Cl + O3 → ClO + O2 ClO + O → Cl + O2 Note the chlorine is regenerated at the end of these reactions, making it able to repeat this reaction millions of times producing an ozone hole observed over the poles and upper latitudes of the Earth. Decreases in stratospheric ozone have been linked to increases in skin cancer. The Montreal Protocol called for a complete elimination of CFCs in 2000 in developed countries. By the year 2010 CFCs should be completely eliminated from developing countries as well. Replacing CFCs Work on CFC alternatives began in the late 1970s. By adding hydrogen to the chemical formulation, chemists made CFCs less stable in the lower atmosphere enabling them to break down before reaching the ozone layer. Still, HCFCs do release chlorine and have contributed to more chlorine buildup in the upper atmospheric than originally predicted. Development of non­chlorine based chemical compounds as a substitute for CFCs and HCFCs continues. Lead in Paint (5) Lead carbonate (white lead) ­ white pigment most commonly used in house paint. . Titanium dioxide, a white pigment with hiding power superior to lead oxide has larger replaced it since 1978. Microwave Induced Reactions In some types of reactions using microwave induced heating reduces energy requirements as well as catalyst and solvent needs. Replacement of Organic Solvents with Supercritical Fluids Supercritical Fluids (SCFs) are above the critical temperature and pressure. 1. The density of SCFs can be adjusted by changing the temperature and pressure. SCFs have a gas­like compressibility. Generally, the greater the density, the greater the solubility of a solute. 2. Solutes diffuse most easily in gases then SCFs then liquids – generally the greater the diffusivity the more easily solutes dissolve 3. The viscosity of SCFs is less than liquids but more than gases CO2 Tcritical = 31.1C, Pcritical =70 atm – not extreme conditions. It is nonflammable, nontoxic and generally nonhazardous. Many nonpolar organics will dissolve in supercritical CO2. Supercritical CO2 is used to decaffeinate coffee and tea. Previously hexane was used. The coffee beans or tea leaves are placed in a CO2 environment. The temperature and pressure are raised above the critical point. The caffeine dissolves in the supercritical CO2. The temperature or pressure is lowered and the caffeine crystallizes separately. This process has been patented to replace dry cleaning fluid. Kerr­McGee uses this process to extract smaller hydrocarbons from asphalt. It is also used for: 1.Extracting essential oils from leaves (example wintergreen oil). Research is ongoing to remove cholesterol from eggs and oil from potato chips 2. Regenerating activated carbon. Granular activated carbon will adsorb organic compounds such as pesticides, contaminating water (it is used in Brita water filters). There is a maximum amount of organic compounds that can be adsorbed on the surface of the activated carbon. In industrial settings supercritical CO2 can be used to regenerate activated carbon. Clean SC CO2 Water containing organic pollution Granular Activated Carbon Granular Activated Carbon SC CO2 plus dissolved organics Clean Water Water cleaning step Granular activated carbon regeneration step (1) http://www.absoluteastronomy.com/encyclopedia/c/cf/cfc2.htm (2) http://www.absoluteastronomy.com/encyclopedia/t/th/thomas_midgley,_jr.htm (3) http://www.absoluteastronomy.com/encyclopedia/c/cf/cfc2.htm (4) http://home.howstuffworks.com/refrigerator4.htm (5) http://www.asbestos.org/lead/lead_history.html