Chapter 4 Process Costing

advertisement

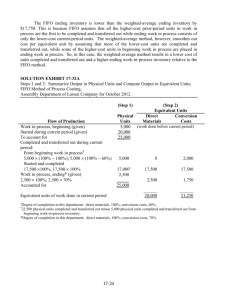

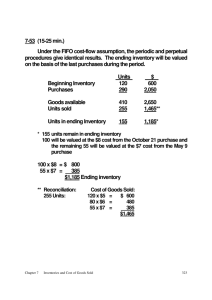

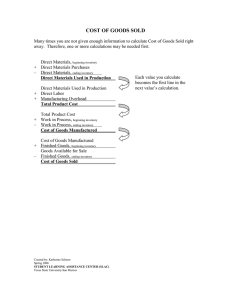

Chapter 4 Process Costing Similarities Between Job-Order and Process Costing • Both systems assign material, labor and overhead costs to products and they provide a mechanism for computing unit product costs. • Both systems use the same manufacturing accounts, including Manufacturing Overhead, Raw Materials, Work in Process, and Finished Goods. • The flow of costs through the manufacturing accounts is basically the same in both systems. Differences Between Job-Order and Process Costing • Process costing is used when a single product is produced on a continuing basis or for a long period of time. Job- order costing is used when many different jobs having different production requirements are worked on each period. • Process costing systems accumulate costs by department. Job-order costing systems accumulated costs by individual jobs. • Process costing systems compute unit costs by department. Job-order costing systems compute unit costs by job on the job cost sheet. Sequential Processing Departments T-Account Model of Process Costing Flows Process Costing and Direct Labor Dollar Amount Direct Materials Direct Labor Direct labor costs may be small Mfg. Ovhd. in comparison to other product costs in process cost systems. Type of Product Cost Process Costing and Direct Labor Dollar Amount Direct Materials Direct labor costs Conversion may be small in comparison to other product costs in process cost systems. Type of Product Cost Direct labor and manufacturing overhead may be combined into one product cost called conversion. Example A – January No Beginning/No Ending Inventory Work in process, January 1: Manufacturing Costs in Beginning Inventory: 0 units $0 Production started during January: Production completed during January: 1,000 units 1,000 units Costs added to production in January: $50,000 Work in process, January 31: Manufacturing Costs in Ending Inventory: 0 units $0 Manufacturing Costs transferred out in January: ? Example A – February No Beginning/Some Ending Inventory Work in process, February 1: Manufacturing Costs in Beginning Inventory: 0 units $0 Production started during February: Production completed during February: 1,000 units 800 units Costs added to production in February $45,000 Work in process, February 28 (50% complete): Manufacturing Costs in Ending Inventory: Manufacturing Costs transferred out in February: 200 units ? ? Equivalent Units of Production Equivalent units are the product of the number of partially completed units and the percentage completion of those units. Partially completed units are thus expressed in terms of a smaller number of fully completed units Equivalent Units of Production Two half completed products are equivalent to one completed product. + = 1 So, 10,000 units 70 percent complete are equivalent to 7,000 complete units. Quick Check For the current period, Jones started 15,000 units and completed 10,000 units, leaving 5,000 units in process 30 percent complete. How many equivalent units of production did Jones have for the period? a. 10,000 b. 11,500 c. 13,500 d. 15,000 Calculating and Using Equivalent Units of Production To calculate the cost per equivalent unit for the period: Cost per equivalent unit = Costs for the period Equivalent units of production for the period Quick Check Now assume that Jones incurred $27,600 in production costs for the 11,500 equivalent units of production. What was Jones’ cost per equivalent unit for the period? a. $1.84 b. $2.40 c. $2.76 d. $2.90 Example A – March Some Beginning/Some Ending Inventory Work in process, March 1 (50% complete): Manufacturing Costs in Beginning Inventory: 200 units $5,000 Production started during March: Production completed during March: 1,500 units 1,200 units Costs added to production in March $65,000 Work in process, March 31 (40% complete): Manufacturing Costs in Ending Inventory: 500 units ? Manufacturing Costs transferred out in March: ? Equivalent Units of Production Weighted-Average Method The weighted-average method . . . 1. Blends together costs from prior and current periods. 2. Determines equivalent units of production for a department by adding together the number of units transferred out plus the equivalent units in ending Work in Process Inventory. 3. Ignores percentage completion of the Beginning Inventory Weighted-Average Method • For each category of cost (material and conversion) in each processing department the following calculations are made: Costs to be Costs of Costs added accounted = beginning WIP + during the for inventory current period Equivalent Units Equivalent units units of = transferred + of ending WIP production out inventory Weighted-Average Method Cost per = Costs to be accounted for EU Equivalent units of production Costs of units = Units × Cost transferred out transferred out per EU Costs of units in = Equivalent units of × Cost ending WIP inventory ending WIP inventory per EU Production Report Example Double Diamond Skis uses process costing to determine unit costs in its Shaping and Milling Department. Double Diamond uses the weighted average cost procedure. Using the following information for the month of May, let’s prepare a production report for Shaping and Milling. Production Report Example Work in process, May 1: Materials: Conversion: 55% complete 30% complete 200 units $ 9,600 5,575 Production started during May: Production completed during May: 5,000 units 4,800 units Costs added to production in May: Materials cost Conversion cost $ 368,600 350,900 Work in process, May 31: Materials Conversion 400 units 40% complete 25% complete Manufacturing Costs in Ending Inventory: ? Manufacturing Costs transferred out in May: ? Production Report Example Section 1: Quantity Schedule with Equivalent Units Units to be accounted for: Work in process, May 1 Started into production Total units 200 5,000 5,200 Equivalent units Conversion Materials Units accounted for as follows: Completed and transferred Work in process, May 31 Materials 40% complete Conversion 25% complete 4,800 400 4,800 4,800 160 5,200 4,960 100 4,900 Production Report Example Section 2: Compute cost per equivalent unit Total Cost Cost to be accounted for: Work in process, May 1 Costs added in the Shipping and Milling Department Total cost Equivalent units $ 15,175 Materials Conversion $ $ 9,600 5,575 719,500 368,600 350,900 $ 734,675 $ 378,200 $ 356,475 4,960 4,900 Cost per equivalent unit $ 76.25 Total cost per equivalent unit = $76.25 + $72.75 = $149.00 $ 72.75 Production Report Example Section 3: Cost Reconciliation 4,800 units @ $149.00 Cost accounted for as follows: Transferred out during May Work in process, May 31: Materials Conversion Total work in process, May 31 Total cost accounted for Total Cost $ 715,200 Equivalent Units Materials Conversion 4,800 4,800 160 100 Production Report Example Section 3: Cost Reconciliation 160 units @ $76.25 Cost accounted for as follows: Transferred out during May Work in process, May 31: Materials Conversion Total work in process, May 31 Total cost accounted for Total Cost Equivalent Units Materials 100 units @Conversion $72.75 $ 715,200 4,800 12,200 7,275 160 19,475 All costs accounted for $ 734,675 4,800 100