Document 11072541

advertisement

\

*\

ifT'Tvi

n ^1*5

1S88

•FB 5

L!'r>p

ALFRED

NEC:

P.

WORKING PAPER

SLOAN SCHOOL OF MANAGEMENT

Standardization Strategy for a Distributed

"Software Factory" Structure

Michael

November 1987

A.

Cusumano

WP //1954-87

MASSACHUSETTS

INSTITUTE OF TECHNOLOGY

50 MEMORIAL DRIVE

CAMBRIDGE, MASSACHUSETTS 02139

f^rr

\

^

NEC:

Standardization Strategy for a Distributed

"Software Factory" Structure

Michael A. Cusumano

November 1987

WP //1954-87

ir'EB

5 1988

RECEiVEO

Michael A. Cusumano

Sloan School of Management

8

November 1987

Software Project Paper #5

NEC: STANDARDIZATION STRATEGY FOR A DISTRIBUTED

"SOFTWARE FACTORY" STRUCTURE

INTRODUCTION

This paper

is

part of

a

larger study examining the question of whether or

not companies are choosing to

manage

large-scale software development with

organizational

as

as

well

a

complex engineering activity such as

a

range of strategic considerations and

approaches that corresponds

technological

spectrum usually associated with "hard" manufacturing,

i.e.

job shops,

organizations, and factories exhibiting various degrees of flexibility

mixes

The research

and technologies.

project

technology and policy criteria defining what

might look

like;

a

survey

the

includes

a factory

in

relation

in

the

batch

product

proposal

of

environment for software

of major software facilities in the U.S.

determine where firms stand

to

to these criteria;

and Japan to

and detailed case

studies examining the technology and policy implementation process followed at

firms identified as being close to the factory model.'

There are several interrelated conclusions:

"factory" approaches,

the U.S. and Japan.

is

(2)

(1)

This spectrum, including

clearly observable in the sample of software facilities

There appears

to

be nothing inherent

in

software as

in

a

technology that prevents some firms from creating strategies and organizational

structures to manage product and process development more effectively, even

with a relatively new and complex technology such as software.

technological

infrastructures

to

aid

software

process

(3)

The

basic

management are not

significantly different between Japanese and U.S. firms. (4) But, Japanese firms

-- led

by the NEC group and Toshiba, and followed by Hitachi and Fujitsu--

1

significantly

are

ahead of most

U.S.

competitors

implementing

in

"flexible

factory" type of strategies focused on reusing standardized components (modules

of code)

and then customizing end products.

This paper extends the survey approach to analyze what

--

most difficult aspect of the software factory

is

probably the

the implementation process and

the benefits or disadvantages this environment might offer

in

NEC

adopted

case

significant for the following reasons.

is

One,

it

operation.

The

software

a

factory strategy around 1976, but, unlike Hitachi or Toshiba, did not attempt to

construct

single major facility and use this as the main site for developing

a

Rather, top management at

factory tools and methods.

committee

and then

laboratory

organization

to

NEC used

the

direct

a

centralized

development

and

dissemination of factory-like software tools, standards, procedures, and control

methods among

all

the divisions and subsidiaries writing programs.

This approach appears to have reflected NEC's organization around product

divisions rather than factories, as

Toshiba.

It

has also led to a

in

the case of Hitachi and, to some extent,

remarkably high

level

of

standardization and

consensus regarding software development despite NEC's production

types of software,

of various

including telephone switching and transmissions systems,

computer operating systems, and business applications programs.

The organization

of

NEC and

detail

top

its

of this

is

as follows:

Part

I

presents an overview

development of the computer business, and then discusses

management's

organization

paper

factory

implementation

in

strategy

terms

of

for

software

divisional

development

structures,

in

and

committee

programs, R&D organization, corporate-wide programs, and subsidiaries

.

Part

II

focuses on the tools, methodologies, and management-control systems developed

to

support the factory

comparisons of

NEC

strategy.

to other

The conclusion makes some preliminary

Japanese and U.S. firms, as

well as offers several

suggestions about the general lessons regarding technology management that can

be drawn from this study.

I.

SOFTWARE-DEVELOPMENT STRATEGY AND ORGANIZATION

Corporate History

NEC was founded

1899 as

in

a

venture between two independent

joint

Japanese businessmen and AT&T's Western Electric subsidiary,

and import telephone equipment.

It

later

of electronic

and electric components and products.

multinational

corporation

organized

electronic

within

a

nine

systems

in

(including

1987

groups

(41%

of

1986

covering

sales),

As

a

consolidated

range of product divisions.

operating

manufacture

became an independent company

Sumitomo group and, over time, expanded

affiliated with Japan's

revenues came from

to

into a variety

$16.8 billion dollar

subsidiaries),

Each was

computers

communications

a

NEC

profit center

and

industrial

(switching

and

transmission systems as well as radio and microwave) products and services

(29%),

semiconductors and other electron devices (17%), and home electronics

(8%). 2

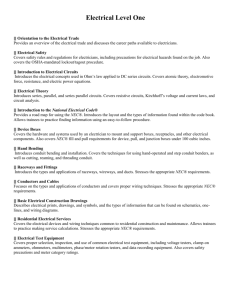

NEC OPERATING AND MARKETING GROUPS.

Operating Groups

Research and Development

Production Engineering Development

Switching

Transmission and Terminals

Radio

Information Processing

Marketing Groups

NT&T

Sales

Government Sales

Domestic Sales

International Operations

Advertising

Electron Devices

Home Electronics

Special Projects

Source:

NEC

Corporation, "This

is

1986

NEC, 1986,"

p.

9.

Toshiba, and Fujitsu,

Like Hitachi,

and software development,

earliest

producers

scientific-use model

of

computer technology, NEC entered

in

1962, through which

NEC

cooperate

1970s as

By

1986,

NEC

in

a

long history of computer

NEC was one

in

the world,

into a licensing

its

of

completing

sale

under the

hardware and software design technology.

relationship continued

1979 and the two companies

until

started supplying mainframe hardware to

manufacturers, ranking, among Japanese firms,

sales,

and second

its

in

the

American partner."^

largest computer and software

clearly one of the world's

and data communications

a

arrangement with Honeywell

marketing, the technology transfer situation reversed

NEC was

the

to the United States in commercial

manufactured Honeywell computers for

Japan and upgraded

label in

While this technical

still

it

computer

To catch up

1958.

in

has

dating back to the 1950s.

transistorized

a

NEC

first in software,

microcomputer,

mainframe sales, behind Fujitsu.

in

Early Learning and Technology Transfer

NEC's history

of

computer development

in-house efforts, beginning

in

is

a

combination of independent,

the mid-1950s, with hardware design and some

software technology acquired from Honeywell

in

The key figure

the 1960s.

in

software development from NEC's very earliest efforts has been Mizuno Yukio,

who entered the company

in

1953 after graduating from the

Tokyo

Technology, where he also received an engineering doctorate

Mizuno was

The

1956,

a

first

senior vice-president

programming efforts

in

in

charge

message and accounting data sorter for

to Mizuno,

built an analog

a

1960.

In

1987

of software strategy.

NEC, according

when he and several other engineers

in

Institute of

were

in

1955-

computer and then

non-stored program machine

--

a

a

.

computer that was,

programs for storage

NEC completed

commercial sale

in

memory

NEAC

the

The NEAC

1959.

in

--

and the 2203,

1958,

in

an

2201,

a

required

transistorized computer

enlarged version

2201 and 2203 prompted

establish a programming section in 1959,

and

Their next project

"hard-wired."

essentially

introduced for

NEC managers

including Mizuno

with 26 engineers,

who had

leading Japanese computer experts at that time, Okazaki Bunji,

a

joined

NEC

after

Film.

One

of their first

to

building one of Japan's first electronic computers for Fuji

accomplishments was the completion of Japan's first

compiler."'

Honeywell machines supplanted the

Several

These gave way after 1965

repackaged versions

to

NEAC

the

of three small

NEAC

2200

models

in

which

series,

1962-1963.

contained

and medium-size mainframes Honeywell had

designed to compete with the IBM 1400, as well as several larger machines NEC

designed independently to compete more directly with the IBM 360 family.

ACOS

beginning

series

mainframes

NEC's basic product

remained as

2200 series

in

1974,

to

line

compete

NEC introduced

until

with

IBM's

a

decision

of

led

NEC

in

1965 to

dubbed the NEAC

build a large-scale computer for the Japanese market -- later

--

family

the

c

Despite the technical arrangement with Honeywell,

2200-500

370

The

not only to use integrated circuits (ICs), printed circuit

boards, and large-capacity core memory for the first time, but also to develop

independently an advanced operating system capable of on-line processing and

time

sharing

similar

to

Institute of Technology.'

technical

and

the

Multics

system developed

at

the Massachusetts

The hardware and software tasks presented major

organizational

challenges

to

NEC

engineers,

who had never

tackled such extensive projects, and did much to advance the technical skills of

company personnel

in

both areas.

°

^

The 2200-500 machine was based on

1964

in

NEC's

at

research

central

a

computer factory

Fuchu,

at

laboratories.

commercial model,

processing unit into

in

hardware design project completed

a

in

To develop the central

NEC management

1964

the outskirts of Tokyo, and

established

1965

in

a

computer

development group with about 30 engineers, including Mizuno as head

arguing that

its

models were adequate and that the software for

the proposed 500 would be too difficult to write.

Honeywell executives,

in

of the

Honeywell managers tried to dissuade NEC from taking on

programming section.

this project,

a

NEC completed

Much

the surprise of

to

the machine and operating system on time

1968 -- delivering the 2200-500 to Osaka University and receiving an award

from the Nikkan Kogyo Newspaper for having developed Japan's

system and entered into

machines.

NEC

Honeywell thereafter brought

computer.

a

formally into

its

first

IC-based

product planning

NEC

cooperative development program with

for future

Q

The operating system

for the 2200-500,

named MODE

NEC provided about

directly after the IBM 360.

NEC patterned

IV,

90% of the engineers working

on the system; Honeywell contributed some 10%, who came to Japan and worked

under Mizuno

how

Tokyo.

in

to plan for

Honeywell was quite helpful

and control such

a

in

teaching

NEC managers

large software project, although Mizuno was

disappointed to find that the Americans' level of technology regarding bug,

and productivity estimation was

cost,

forecasting led

models

during

control at

NEC

NEC managers

the

in

A major step

1970s,

low.

to collect their

which

1971

for

improvement

in

own data and devise new planning

became the basis for software production

the 1980s.

in

standardization of control methods as well as of tools and

development procedures was the creation of

in

The need

and then the decision

to build a

a

new computer development group

new operating system

for the

ACOS

This decision led to the separation of basic software (operating systems

series.

and related programs)

Fuchu

into an

From

plant.

1974,

independent division

Fuchu

the

plant,

hardware and operating systems, was referred

1974,

in

centered

at

the

produced mainframe

which

NEC

to within

"software

as a

factory," and became the center of software technology development until the

establishment of

a

separate laboratory for this purpose

At this point

1980.

in

the information processing group contained separate divisions for basic software

centered

at

Fuchu, and,

the Mita section of Tokyo, near

in

large-scale customized

for

software

NEC headquarters,

and user

(system engineering projects)

(business) applications software.

Unlike

Hitachi

and Fujitsu,

NEC's software development tasks did not

NEC thus continued

include trying to be compatible with IBM.

Mizuno

IBM compatible Honeywell operating system.

in

and Unidata

the U.S.

machines and then failed

NEC

to

still

customers.

a

limit to

Thus, even though he was head

of

IBM-compatible

of

its

machines to attract

product planning,

NEC headquarters

in

1974 Mizuno

Fuchu plant and spent

to the

three years directing the new operating system development effort.

IBM's 370 operating system did not have

was not well set up

to handle data bases,

add these functions

machine capability.

to

It

their

language, HPL,

was

still

a

the

new system,

difficult,

as

NEC managers decided

as

well

^"^

a

a

in

to try to

"task-level"

virtual

sophisticated operating

although they succeeded, using

PL/I subset, to write the system,

using assembler.

Because

strong time-sharing capability and

a

turned out that developing such

system was extraordinarily

RCA

the compatible" approach.

had to offer competitive performance with

moved from the comforts

build

to

because

match IBM's subsequent 370 models, he and other

executives decided "there had to be

But NEC

recalls that

Europe had both tried

in

with the non-

a

high-level

contrast to IBM, which

For

future

product development,

One was the

significance.

programming methods and

two events

decision

to

to

and

tools

methodology for newly written application and system programs.

the

decision

to

create

NEC

beginning with

President

of

NEC's

Mizuno),

centered

Software

in

Parts

addition

in

to

Company

being

each division.^''

thus became the basis of

"software factory"

technology,

that

structured

in

based

on

this

Another was

"^

development,

software

in

long-term

Software, Ltd., and to recruit software houses to serve as

procurement departments

NEC Software

specialized

Subsidiaries and affiliated

subcontractors.

members

subsidiaries

had

programmers

train

standards

design

1975

in

scheme,

Mizuno and

Association

subject

to

(headed

controls

by Vice-

imposed

by

The Fuchu Software Factory and

geographically distributed, product-

a

based around structured programming

NEC manager,

another

promoting more aggressively from 1976.

software houses also became

1

c

"

Fujino

Kiichi,

began

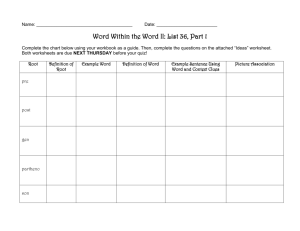

NEC SOFTWARE ORGANIZATION AND SUBSIDIARIES,

Information Processing

Basic Software

Group

Main Factories

Fuchu

System Engineering

Mita

Other Divisions

Transmission

Tamagawa

Switching

Abiko

Domestic Software Subsidiaries

NEC Software

NEC Information Service

Nippon Electronics Development

Nihon Computer Systems

NEC Communication Systems

NEC Engineering Information Systems

Kansai NEC Software

Chubu NEC Software

Kyushu NEC Software

Tohoku NEC Software

Hokuriku NEC Software

Chugoku NEC Software

Hokkaido NEC Software

Shikoku NEC Software

NEC Security Systems

Shizuoka NEC Software

Okinawa NEC Software

NEC Microcomputer Technology

NEC Engineering

NEC

NEC

NEC

NEC

NEC

IC-MicroComputer Systems

Telecom Systems

Koku-Uchu (Aerospace) Systems

Robot Engineering

Ocean Engineering

Note:

ca.

1986-87

Software Employees

2,000

2,500

1,500

1,500

2,100

900

1,000

800

800

150

500

300

200

100

na

na

na

na

na

na

na

na

na

na

na

na

na

na

employee figures are estimates by the author. An approximate

for the number of software engineers and programmers in

the NEC facilities and subsidiaries noted above is 16,000.

All

total

Sources:

NEC, Konpyuta sangyo no qeniyo to NEC (1985); Joho shori:

sofutouea kaisha roku (1985); Kiriu Hiroshi, Sofutouea sanqvo no

iitsuzo (1986); Nikkei konpyuta, 13 October 1986, p. 89; company

data; author estimates.

Software Factory Strategy

Mizuno began discussing

NEC's software strategy evolved gradually.

publicly his view of the software factory as early as an October 1975 article

in

Then the manager

of

a

leading Japanese journal on information processing.

NEC's

Software

Basic

had

industry

therefore,

he

evolved

felt

Development Division,

to

he

stressed

where cost and quality mattered

producers

had

move beyond

to

the

that

to

"individual

"

software

customers,

or

"craft"

approaches to production, and develop "modern" engineering and manufacturing

practices and tools:

As the use of computers has become more diverse and at higher levels,

software -- quantitatively and qualitatively -- has become increasingly

Thus, software is no longer the individualistic, craft-like

important.

once

was; there is evidence that it has become a modern

product it

Accordingly, we

product with a market value and market distribution.

have reached the point where the development process for software must

move beyond the individual or craft stage to a more rational, modern

Namely, we have reached the age where there is a

production system.

.

.

strong demand for high quality, maintainable software as

software cost reduction and productivity improvement...

well

as

for

consciousness of software as a highly modern and major

extremely low among both software producers and users.

The result is a tendency to pay too little attention to software inspection

or quality assurance, and not to invest enough time and resources in the

software development and production process...

In

general,

product

is

still

It seems we have reached the stage where current methods for software

production, which resemble a cottage industry, may be moving toward

'manufacture' (factory-method industry)... [But] the tools used at the

present for software development -- paper, pencils, machines, basic

language processors -- are extremely primitive.

To improve productivity in

software development, to produce software of higher quality, it is

necessary to go beyond cottage-industry type production methods. This

higher level of technology for the software production process can be

referred to by the term 'software engineering.' ''

.

This 1975 article, published only

Corporation

in

a

.

few months after System Development

the U.S. released information describing

its

"Software Factory"

project, elaborated on the concept of a physically distributed software factory

system using standardized procedures, tools, and components, with time-sharing

10

capabilities

link several

such as Fuchu, Tamachi/Mita, and Shinjuku

sites,

in

Mizuno estimated that, with factory-type standardized methods and

Tokyo.

productivity should rise from 2 to 5 times.

tools,

Several

basic

and

concepts,

tools,

systems,

necessary to support successful implementation of

First,

was the development

of

a

Mizuno's

in

view,

were

software factory system.

expandable, versatile high-level languages suitable

for system description using structured

programming methods.

Second, was the

use of structured programming techniques such as the top-down approach,

abstraction

reduction

of

techniques,

GO TO

standardization

standardization

statements

the

of

segmented

coding,

in

subroutine

of

of

introduction

listing

input/output

production

process,

industries, to improve productivity and quality:

process,

increases

through Taylor's methods,

in

productivity.

structures,

program modules,

Third,

been

achieved

in

or

was

other

"In the average production

standardization of tasks led to dramatic

the same way,

In

of

layers

interfaces.

had

as

and

standardization

in

the software

development process of the construction flow and documentation should make

possible to improve productivity.

development-process control.

claimed

checkpoints

table).

add

would

and

Fifth,

system for

some

reviews

Mizuno

quality

felt

Fourth, was

Mizuno offered

visibility

of

standardization should help reduce

In addition,

careless mistakes and increase reliability."

to

the

a

system for software

"phase-plan" system, which he

a

development

standardized documentation

In

addition,

he

process

each

for

the software factory should have

assurance.

it

a

identified

through

step

(see

comprehensive

nine

elements

fundamental to the technological infrastructure of an effective software factory

(see tables).

""S

11

MIZUNO'S INITIAL SOFTWARE FACTORY CONCEPT

METHODOLOGY AND MANAGEMENT

1.

High-level structured programming language for system description

2.

Disciplined structured programming and top-down modularization techniques

3.

Standardization of the development process

4.

System for process control

5.

System for quality assurance

TECHNOLOGY

1.

(High-Level) Language processing

2.

Program and data commonality

3.

On-line memory and control of program components and information units

4.

Simple system for integrating parts of programs being developed separately

5.

High-reliability

6.

High-level virtual

7.

Suitable development language and program control function

8.

"Boot-strap" function (capability of testing software developed in the

factory in the actual mode or o.i the actual machine it will run on, to

ease transfer)

9.

Tools for debugging,

continuous operation.

file

system

memory

dynamic

link

Source: Mizuno 1975, pp. 837-838.

12

functions,

project

control,

and

PHASE-PLAN SYSTEM

Phase

0:

PLANNING

Determination of product based on market

development costs, and technical capabilities

Definition:

Documentation

:

I:

BASIC DESIGN

Analysis of the objective of the planned project and

establishment of programming objectives

Definition:

Documentation

:

II:

Basic Design Specifications

Performance, Cost

Review:

Phase

Planning Specifications

Schedule, Cost

Review:

Phase

needs,

DETAILED DESIGN

Design of detailed functions and structure based on the

Definition:

programming objectives

Documentation

:

Cost,

Review:

Phase

III:

Functional Specifications (Language Specifications)

Logic Specifications

Manual Draft

Functions

IMPLEMENTATION

Coding and debugging

Definition:

of each

component based on the

detailed design

Documentation:

Programming Completion Document

User Manual

Review:

Schedule, Cost, Functions

Phase IV:

SYSTEM INTEGRATION

Test of debugged modules

Definition:

Documentation

combination

System Integration Test Document

Performance

Review:

Phase V:

:

in

INSPECTION

Definition:

Examination of whether the completed system meets the

planned specifications

13

:

Inspection Completion Document

Release Announcement

Documentation

MAINTENANCE

Phase VI:

Definition:

Support and Improvement

Documentation:

Program

Lists

Internal

Documents

of

completed system

Source: Mizuno 1975, p. 838.

As they made progress

changed emphasis

to quality

NEC managers

process standardization,

in

and reusability

control

improve overall productivity.

This shift

code as key ways to

of

thinking can be seen

in

where Mizuno discussed the two components

interview,

achieving continuous increases

in

productivity:

gradually

of

his

in

a

1986

strategy for

(1) a rigorous quality control

program

to

prevent errors, which become

program

is

released to the customer; and (2) "accumulation of knowledge" about

software

and

engineering

passing

this

difficult

on

to

and expensive

others

through

to fix after a

reusable

(a)

software modules, (b) reusable program patterns, and (c) bug or failure analysis

and the development of better test rules and check points.

known

as "Software Engineer's

Mizuno considered

programming

tool

a

"first

SEA/I (alternately

Arms" and "System Engineering Architecture")

step"

in

the

development

of

an

Mizuno

Thus,

using this "accumulation of knowledge" concept.

building upon process standardization and control as the foundation of

approach,

automatic

now explained the software factory

as

a

a

factory

"concept"

for

maximizing the "accumulation of experience" and capturing this experience

in

control systems, tools, and process inputs (reusable code or designs):

The term

'software factory' does not indicate a physical building.

method of producing software, or the tools used in

example a control system. The software factory refers

14

It

is

a

this method, for

to the integration

of these types of things.

It

must be understood as

concept.

a

Another point that should be emphasized is that it is important for a

software factory to be a place where systems are introduced that

incorporate the experience of people who have made software in the past

with new methods or particularly effective techniques.

It

is

an

Even if it doesn't go as far as a knowledge

accumulation of knowledge.

data base, it should be something where there is an accumulation of

knowledge.

For example, in coding inspection, a particular group keeps making

mistakes in register manipulation. Or they forget to close a table.

In a

software factory, it would be important to have a system for developmentprocess control that, reiving on a history of these mistakes, would prevent

them from reoccurring ^^

.

During the 1980s, the manager most responsible for implementing NEC's

software factory strategy has been Fujino Kiichi,

a vice

president under Mizuno

who headed the Software Product Engineering Laboratory

NEC

entered

1968

in

after

working

years

eleven

for

the

in

Fujino

1987.

in

Production

Engineering Laboratory of Waseda University, and had been one of Waseda's

first

graduates

degree

later

in

computer science, receiving

in

addition to a doctorate

in

a

B.S. degree

1973. ^'

In

in

1955 and

NEC

a

M.S.

he joined and

headed the Computer Science Research Laboratory, founded under the

R&D

central

Basic

1957,

in

labs to

Software

study software engineering, and subsequently managed the

Development

established

Division

in

1974.

^•^

He became

a

particularly avid proponent of the distributed, product-centered factory concept.

In

a

1984

article,

for

example,

Fujino

noted

that,

communications and computer businesses, NEC managers

in

in

programs were "fundamental"

needs of their customers:

software for

systems

application

software;

on-line

real-time

host

to serve the

computers;

control

distributed

software;

industry-

oriented application software; and built-in microcomputer software."'^

also concluded that,

"NEC must meet

different customer needs, so

15

its

the mid-1970s came

to the conclusion that five types of

"basic

reviewing

it

is

They

difficult

really desirable to standardize completely

and not

NEC managers

Fujino and other

"to

view

the

strategy

factory

The

production environments.""^

computers."

of

terms

in

At

the

same time,

factory-type rationalization was essential

felt

accommodate the expanding use

"-^^

.

This led to the decision to

and

"global

of

distributed

software

"modern software factory" system Fujino

attempted to implement consisted of five elements, with

a

centralized laboratory

directing tool and method development for closely linked operating divisions and

including subsidiaries. °

"satellite offices,"

SOFTWARE FACTORY CONCEPT

FUJINO'S

Central

Laboratory

for

Development

Standardized

of

Tools

and

Methodologies

Software Work Stations

Communications

Utilities

Appropriate Physical Environment

Management Engineering Techniques

Productivity Metrics

b) Quality Metrics

a)

c)

Cost Control System

d)

Management

Visibility

A key manager responsible

Motoei,

who

joined

NEC

engineering department

joining

Waseda University

software

as

an

Azuma

1963 and was manager of the software management

in

in

for developing tools and methods was

the Software Product Engineering Laboratory before

in

R&D-type

1987.

of

Azuma supported the view

only

activity

would

not

lead

to

substantial

NEC managers

improvements

in

have tried

develop "factory-like" systems, while recognizing that aspects of

software

to

productivity or quality.

development

which

are

Therefore, he and other

that treating

unique

16

make

it

inappropriate

to

transfer

manufacturing practices too directly from hardware plants.

Azuma's

environments

work focused on devising standards,

--

types of software

in

essence,

different factory structures

NEC produced.

relatively flexible environments.

closely resembled

be controlled more precisely.

--

tools,

and

for the different

For example, he believed that development of

large operating systems was more like

PBX software

methods,

R&D than manufacturing and

But smaller software products

required

like facsimile or

hardware design projects and, he thought, could

Business applications programs were often very

similar across different projects and, therefore, contained modules that could be

reused and offered possibilities for an automated production process.

Following

the standardization and structured methodology efforts of the 1970s, and the

quality control program of the early 1980s, process development at the Software

Product Engineering Laboratory during the mid-1980s thus pursued the dual

goals of automation

tools such as

and reusability,

leading to automated program-generator

SEA/I for applications software and

DECA

(Detailed Design and

Coding Assistant) for systems software.^'

Implementation of the Factory Strategy

Implementation of

factory strategy to meet diverse product needs began

a

with the founding of the Basic Software Development Division

centralization of operating systems development in the

efforts centered not on

any single

facility

Fuchu

in

Plant.

1974 and the

Subsequent

but were company- and even group-

wide, with the participation of corporate staff, operating-group line personnel,

and subsidiaries personnel.

system developed located

Tamagawa, and switching

lack of physical space

There was centralization, with most operating-

at Fi'chu, applications at Mita,

at

transmission systems at

the Abiko plant northwest of Tokyo.

and other factors, some groups as

17

But, due to

well as the

work

of

subsidiaries and software houses continued to be distributed

What was perhaps most important, however,

is

that,

in

in

different areas.

contrast to the System

Development Corporation's Software Factory, NEC created permanent centers

development managed by departments and not projects.

steadily through the

new

facilities,

of

Work, therefore, flowed

and provided managers with

a

rationale for

continued development of the factory's technological and management systems.

NEC implemented

the concept of standardized but distributed development

through the use of several sets

of

common techniques and

tools,

as well as

linking physically separated sites through communication networks,

under continual development.

File

in

process

transfers among different sites even made

no

reuse of the same code possible

a

by

more than one

facility.-^"

The

following

table presents an overview of key projects and dates in the factory-strategy

effort:

18

IMPLEMENTATION OF NEC'S SOFTWARE FACTORY STRATEGY

Year

Project/ Designation

Focus

1974

Basic Software Development

Division

Organizational separation of

software

from

hardware

development

1976-1979

Software Strategy Project

Standardization of data collection,

and

structured-programming

for basic and

applications software throughout

the NEC group, with the objectives

of raising productivity and quality

tool

methodology

1980

1981

Software Product

Engineering Laboratory

Centralization of process and

tool

R&D for dissemination

divisions and subsidiaries

Software Quality Control

Establishment of a group-wide

methodology, training program, and

control measures for improving

software quality, including quality

(SWQC)

to

circle activities

1982-1985

Software Problem Strategy

1)

Project

2)

3)

"Mapping" of software

development activities

Subcontracting management

Software

productivity

improvement

Source:

Interviews with Fujino Kiichi and

19

Azuma

Motoei, 7/28/86

SOFTWARE STRATEGY PROJECT,

The Software Strategy

1976-1979

Project was organized

in

1976 on

group-wide

a

basis (including in-house divisions and subsidiaries) rather than in the computer

group because NEC had large numbers

of

programmers

as switching systems, as well as In subsidiaries.

overseeing

applications

the

3-year project.

in

other divisions, such

Mizuno headed the committee

There were two sub-projects

software and one for systems

software,

the

latter

--

one for

by

directed

Fujino.

The

project resembled manufacturing initiatives taken at nearly

Japanese companies after the 1950s

"eliminating

waste."

In

in

practice,

the explicit focus on,

this

meant

all

phases of software production

--

tools,

large

Fujino's words,

and

collecting

performance data, and then developing standardized

methodologies for

in

all

analyzing

procedures, and

dealing with customers

(requirements analysis), as well as design, programming, documentation, testing,

installation,

maintenance, and user service and support.

The major thrust

of

the project turned out to be standardization and tool development to support

structured programming techniques. Among the systems developed,

opinion, most important

in

facilitating division of labor

large numbers of programmers has been

Engineering

for

follow in a

Fujino's

and cooperation among

STEPS (Standardized Technology and

Programming Support) for applications software. •^^

detailed discussion of

will

in

STEPS and other

tool

and methodology systems

(More

at

NEC

subsequent section.)

SOFTWARE PRODUCT ENGINEERING LABORATORY, EST.

1980

A problem that Azuma identified with the Software Strategy Project was

20

:

the lack of permanent manpower staff.

when they had

Mizuno

a

chance, but meetings were infrequent and progress was slow.

at the

felt

end

of the project that

productivity and

raise

reasons,

Members worked on the tasks assigned

quality

as

NEC managers decided

well

in

as

"we had to be more systematic" to

to

improve control. "^^

1980 to establish

the

For these

Software

Product

Engineering Laboratory to head the software development effort, organizing this

as part of NEC's central research laboratories.

Mizuno launched the new laboratory then delegated the post of director

Fujino

in

1981.

researchers

and

to

This made Fujino responsible for managing about 30 full-time

another 30

By

members.

affiliated

1986,

the

number

of

researchers had grown to about 170 full-time members (out of about 900 total

assigned to the central research labs),

including those

laboratory for microcomputer software development.

Fujino

interpretation,

management techniques.

was

to

link

software

To accomplish

this

in

newly-separated

The mission

production

they

a

of the lab,

technology

organized

it

into

in

with

three

departments covering software technology, management methods, and interface

architectures

NEC SOFTWARE PRODUCT ENGINEERING LABORATORY

Departments

Areas of Research

Software Engineering

methodologies and tools for

production, and maintenance

Software Management

Engineering

methodologies and tools for software production

and products management

Interface Architecture

network architecture, information portability

Source:

Fujino and

Azuma interview, 7/28/87.

21

software

design,

Funding

R&D funds

projects,

of tool

well

as

and method development

as

was often

as

NEC

from internal

the

in

rather than from specific

users,

software

case for

the lab came from corporate

tool

Management policy considered research on

companies.

development

tools that could

with computer hardware as part of product development,

funds assigned

to the lab

covered their expenses.

U.S.

in

be sold

and corporate R&D

Tools that would not be sold

outside the company as products but had specific in-house applications

funded partially by R&D expenses and partially by costs charged

NEC

to in-house

divisions that eventually used the tools. "^^

Transferring technology developed

One was

ways.

engineers from

to

plan

and develop

line divisions.

in

tools

and methods

Another was for

and then teach division employees how

lectures

at the lab to divisions

to use them.*^-^

in

two

conjunction with

lab researchers to

large groups and through quality circles.

Education Department assisted the lab

in

was done

develop tools

This was done through

A

staff-level Software

education planning and implementation,

in

•JO

especially

In

areas such as quality control. "^"^

in

addition to tools and methods,

identifying

optimal

studies done

in

laboratory researchers also worked on

"software factory environments."

hardware factories, but took

This effort

resembled

into account the greater "mental

effort" required in software development:

The work environment has been considered

to be an important factor for

productivity and quality improvement in hardware production. This field of

research is called Industrial Engineering or Plant Engineering... The same

approach is expected to increase software productivity. However, the

mental work utilization rate in software work is greater than in hardware

work because of the difficulty of machine utilization in software work.

Therefore, not only is the same approach taken, but the effects on

programmer mentality must be taken into account."^

Particularly

important

were motion factors,

22

such

as

the

layout

of

equipment (desks, chairs,

movements;

physical

contributed

motivation,

filing cabinets, terminals),

and

fatigue;

to

such

noise

as

furniture

including

factors,

mental

in

worked on separate parts

might desire partitioned spaces.

software

common

factories,"

in

NEC

concentration

color

coordination

a

although

of a

program independently, and therefore

Both were considered "work environments for

team-oriented

the

approach

NEC's

of

SWQC program

much QC training

in

date

back

software and Japanese firms,

study of software QC, and enlisted as

Professor Moriguchi

from Tokyo University,

knowledgeable about software.

Fujino the sub-leader,

to

in

an

a

related

staff.

a

at this

Azuma's estimation,

of this

study group,

The group remained

As with the original

full-time activity for the committee

Meetings lasted

although they managed to cover

problems,

NEC

expert on quality who was

and Azuma the chief secretary.

Software Strategy Project, this was not

month,

when

consultant the help of

active for 3 years, and included hardware people as well.

a

1978,

There was not

Mizuno was the leader

members and there was no regular

1981

NEC Chairman Kobayashi proposed they

were considerably behind the U.S.

twice

proved most

has

facilities. "^^

origins

initiate a formal

surroundings.

"individual oriented work style," where

established a software quality control (QC) study group.

time

of

and

"team oriented work style,"

SOFTWARE QUALITY CONTROL (SWQC) PROGRAM, EST.

The

which

lighting,

team are constrained to develop software through

a

close mutual communication," and an

individuals

or

affecting

Researchers designed work environments both for

where "programmers

layout

factors

or

levels

which required unnecessary

a

a

few hours once or

wide variety of quality-

and began drawing up better guidelines for procedures

,

23

required

in

software development, for example, on how to write documentation

properly.

Several conclusions came out of this study.

that there appeared to be a

close connection

One, according to Fujino, was

between software quality and

software productivity, and that any "revolution"

require equally revolutionary improvements

While similar observations had come

productivity,

this

software productivity would

software quality control practices.

other studies of software quality and

in

type of thinking

in

in

had

pervaded

NEC's

QC

activities

hardware, which dated back to 1945 (under U.S. Army guidance).

strategy as

Fujino

productivity

will

Second,

hardware

in

interpreted

was

it

to

"pursue quality

in

The best

and

software,

follow."

group concluded that software was

the

that

it

quite

different

required more intellectual activity and "desk work."

led to a decision not to rely on

hardware QC experts but

quality evaluation and design review.

Third, they

felt

it

from

This

work with several

to

U.S. software quality experts such as Gerald Weinberg to develop

to "inspect out

in

a

system for

was impossible simply

bugs," and that quality had to be "built

in

development," with department-level managers fully involved

at

in

each phase of

any

QC

effort,

as well as lower-level employees."^'

was the observation that "human factors"

Fourth,

important

in

achieving Innovations

in

software development, determined through

surveys of in-house software projects (see table).

to develop automation

techniques,

it

before

automation,"

clearly was

they

decided

the

development groups should develop automation

program focused on motivation,

While they believed

NEC had

not possible to automate

all

Therefore, since human "motivation [should

phases of software development.

come]

seemed to be most

laboratory

tools,

tool-

while a quality control

teamwork methodologies,

24

and other

and other "human

philosophy was clearly

factors."^"

This

published

Computer

in

reflected

in

a

1983

article

Mizuno

:

Software projects tend to overemphasize technical aspects.

After all,

For projects to proceed

people organized into teams do the work.

smoothly, the human factor must receive adequate consideration.

The

capability of those involved in software work varies remarkably.

Many

claim that the relative abilities of programmers can vary by as much as 30

become ever more vital to structure projects so that

It will

to one.

software quality and productivity do not directly reflect these differences.

Training can develop skills, and we can produce tools that yield quality

and productivity within given ranges regardless of the worker. We can

also assemble teams and assign work in ways that compensate for

.

.

individual differences.

We need

to develop better techniques for software production, but we must

carefully study our organizational frameworks for software

development and maintenance. We must devise control methods that match

the frameworks.

also

People are at the heart of software work; obviously, human error cannot

be allowed to lead to major bugs or malfunctions. Here, teamwork will be

the key. Team members working together are, in their collective wisdom,

far more effective than individuals working alone. "^^

PRODUCTIVITY FACTORS (NEC APPLICATIONS SOFTWARE)

Key: Scale of

to 2,

with 2 indicating highest impact

SCALE

Human Factor [Programmer

1.80

1.48

1.42

1.28

1.23

1.22

1.13

Quality

Generality

Hardware

Contract [with Customer]

l.n

Specification Volatility

0.98

Development Methods

Source:

Mizuno 1983,

Fifth, since

how

Capability]

User [Program] Complexity

Development Tools

it

p.

69.

seemed that getting

to solve quality problems

all

workers

was the best way

25

to think together in

to try to

groups

make progress

in

software quality control, they decided to adopt the manufacturing practice of

quality circles. ^

In

a

6-month

trial

applying other techniques used

control and studies of

Finally,

needed

a

in

during 1980, NEC also experimented with

hardware QC, including

1981

quality

worker behavior. ^^

the study group determined that to continue their efforts they

formal,

company-wide program covering

all

production, management, services, sales, and training.

in

statistical

as the

"SWQC" (Software

aspects

of

The program took form

SWQC Group

Fujino the Administration Committee.

the educational

programs.

This was

Quality Control) organization.^^

incorporated into NEC's zero-defect (ZD) structure, as indicated

below, with Mizuno heading the

software

in

the table

Activity Steering Committee and

The SWQC Information Center directed

Quality circles,

meeting once per week for two

hours, were the chief vehicles used to carry out

QC

training and functions. ^^

(More detailed discussion of the quality control system

at

NEC

follow

will

in

a

subsequent section.)

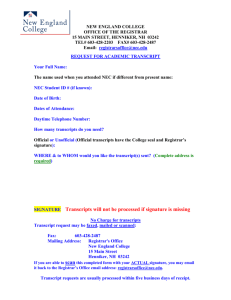

NEC'S SWQC ORGANIZATIONAL STRUCTURE. 1986

Focus

General

Structure

Zero-Defect Steering Committee

Quality

Hardware and Software

Policy Formation,

Corporate-Director Level

Software QC Policy Formation,

Division-Manager Level

Company-Wide SWQC Group Activity

Steering Committee

Administration Committee

Planning for Training and Education

SWQC

Training and Education

Information Center

Study Group

SWQC Group

Activity

Research and Recommendations

Management

Policy and Implementation,

Department- Level and Suppliers

Committee

SWQC Groups

Quality Circle

Employees

26

Activities,

All

Source: Mizuno 1983, p. 71;

Fujino interview, 7/28/86.

SOFTWARE PROBLEM STRATEGY PROJECT,

Unlike the

NEC,

within

SWQC program, which

but

similar

to

the

1982-1985

has remained a permanent organization

1976-1979

Software

Software Problem Strategy Project (SPSP) launched

The

effort.

on

heavily

programming techniques,

structured

standardization.

The follow-up attempted

on

involved

divisions

all

quality

formally

control,

and

designate

product divisions.

to impose

productivity-improvement

NEC

and

1982 was

a

of

software

began

enforce

relying

process

of

to

standardization,

and

measures,

factories

three-year

tools,

the

the

more top-down organization

software development,

in

series

a

Project,

had developed new methods and

project

earlier

in

Strategy

serve

establish

or

NEC's different

President Sekimoto was the formal head of the project,

with Mizuno as the sub-leader.^''

The 1982-1985

NEC

called

organizational

project focused on three major activities.

"software

layout of

production

mapping."

information

processing

This

involved

activities

First,

a

was what

logical

and

by product (basic

software, system engineering programs, user applications, transmission, switching

systems, microcomputers) to determine which software houses divisions were

using, or which subsidiaries

to assist divisions in

NEC should

create to serve as "software factories"

program development.

to systematize procedures for

Second, was

a

more formal attempt

managing software subcontractors.

Third, was

another effort to improve and link software productivity and quality assurance

measures.

The

last

element

included

the

establishment

of

a

Software

Productivity Committee, which worked on documentation control, quality control,

27

software productivity and quality measurements,

and software production environments.

project management, tools,

the results from these efforts

The project

that Mizuno,

be discussed

education,

(Some

^

two specific trends

development and

--

of.

subsequent sections.)

in

software development

in

Azuma, and other NEC managers believed they had

"decentralization"

confront:

will

also dealt with

Fujino,

cost estimation,

support of

programs

to

by

geographically distributed groups; and "asynchronism" -- development of parts of

programs

at different times.

"

For example, due to the cost of physical space,

the shortage of programmers living or willing to live

to service

became

customers from

increasingly

all

spread

the city, and the need

NEC's software operations

parts of the country,

around Japan

in

after

rather

1980,

than

being

centralized.

NEC

did

implementation

Software

not

emphasize the

(detailed

Factory),

Software Factory).

Hitachi

and coding)

(Omori

Nonetheless,

divide up work between

houses. ^°

design

NEC

separation

it

was

design

formally

as

Software

of

Factory),

a

still

program

from

as

Fujitsu

(Kamata

or

Toshiba

(Fuchu

common practice

in

NEC

to

divisions and subsidiaries or affiliated software

Implementation of this type of factory concept whereby design was

performed

one location and programming

in

programs were developed

at different times

another,

in

and

in

or where parts of

different places, depending

on manpower availability and expertise, clearly required methods of ensuring

that groups

tools.

in

different places followed the same procedures and used the same

Tools used throughout the

NEC group, such

as

STEPS, SEA/I, and SPD

(Structured Program Diagram) for applications software, and

Engineering

for

Advanced

Reliability

Engineering)

and

HEART

(Hopeful

SDMS (Software

Development and Maintenance System) for systems software, were designed

support

a

distributed but standardized approach to development.

28

to

II.

TOOLS. METHODS. AND MANAGEMENT SYSTEMS

Product Technology and Process Choice

Characteristic of

all

the software factory approaches

development of specific process techniques and tools

factories

--

established

initially

for different types of software.

software factory

a

done

the

in

same

in

case,

although

facility,

it

separate

tools,

product

technology they

Two

a single set

types

felt

which

and

methods,

relatively easy to divide the factory

one for systems software and another for applications.

standardize around

specific

effect,

in

the case of Hitachi,

managers did not centralize software development

different

Japan was the

1969, systems and applications programs were

standards evolved gradually and made

into two,

In

--

in

in

a

In

single

NEC's

site

or

or tools or procedures, but tended to emphasize

and the constraints or opportunities

in

process

these different products (and markets) offered.

main kinds of programs are general purpose systems software, and

user software.

Azuma and Mizuno adopted the

systems software,

compact, use

Therefore,

little

it

like control

programs for operating systems, usually had

memory, and offer

seemed

to

position that general purpose

a

to be

variety of functions for different users.

them that programmers writing

tliis

type of software

"are required to have a high degree of skill," and that reuse of standardized

modules or patterns was not an appropriate process choice, although they

emphasized

factory-type

techniques

assurance, and project control.

processors

and applications

for

process

standardization,

On the other hand, they noted

software

contained

more

still

quality

that language

similarities

and

less

functional constraints, and thus offered more opportunities for using software

29

engineering methods such as modularization and structured programming, and

even manufacturing-type techniques such as assembly of standardized program

i

49^

components.

Azuma and Mizuno provided several examples

how process R&D

in

NEC

has taken into account the characteristics of different types of programs.

For

of

example, one application area they called "Large-Scale and/or Complex Software

Used Repeatedly," including train seat reservation systems, process control

programs

for

steel

These had

banking programs.

operate

a

systems,

control

common primary requirement,

NEC

But

accurately."

production

factory

mills,

did

on

focus

not

tools

and on-line

i.e.

that "they

verify

to

logical

correctness or to reuse code, but concentrated on "techniques, documentation,

nomenclature,

[which

etc.

are]

important

for

harmonizing

work

by many

programmers."

complex applications software such as for scientific and

Medium-scale,

engineering calculations required accuracy and

implemented by the code were complex,

area of

a

NEC

felt

Used Only Once,"

engineering

application

of

such

calculations.

as

Unlike

is

not

a

significant factor."

program was "Small-Scale,

management

complex

was the main

that "Programs of this type have

character close to the arts, and standardization

A third type

Since the algorithms

verification technology

Azuma and Mizuno

research.

reliability.

reports

from

applications,

Simple Software

databases

or

simple

Azuma and Mizuno

considered these easy and inexpensive to write and, therefore, not

in

need of

factory-type tools or standards.

A fourth type

Used Repeatedly"

applied

STEPS

--

of

applications software --

"Small-Scale,

Simple Software

was the focus of the STEPS system, although NEC also

to other applications

programs.

Small-scale software of this

fourth type included batch processing programs such as for inventory updates

30

and common business applications generally averaging about 500

steps

COBOL, ranging

in

to as high as 3000.

"When these program are

classified

lines of

code or

Azuma and Mizuno noted

according to process

patterns

that,

such

as

updating and inquiries, about 90% of them belong to any one of about 20 types

of patterns.

Programs involving entirely new patterns are few."

was so much

similarity,

the

NEC managers found

it

Since there

relatively easy to develop

standardized techniques, nomenclature, and documents, as well as standardized

components

For

.

types of software, since 1980 or so

all

NEC

has followed a relatively

consistent strategy for process development, according to Fujino, by focusing on

computer-aided design and manufacturing techniques

existing software to build

(CAD/CAM);

reuse of

new programs; cross-product planning, and better

requirement definition techniques, to reduce duplication and wasted effort; as

well as standardization, quality assurance,

and education programs directed

at

raising both quality and productivity:

THE NEC APPROACH TO SOFTWARE PRODUCTIVITY AND QUALITY

METHOD

GOAL

improvement

Reuse

in

development

of existing software

CAD/CAM,

Standardization

Reuse technology

Waste prevention

Cross-product planning

Elimination of excess

Methodology and tools for

requirement definition

functions

Product quality improvement

Software

quality

metrics,

tools

for

new and

old

quality assurance

Personnel quality improvement

Source:

Education programs for

employees and managers

Fujino 1984, p. 58.

31

Applications Software Standardization and Reuse

Most important for standardizing work procedures and documentation

in

order to promote division of labor for general applications software written

in

COBOL

Azuma and Mizuno,

Support).

stemmed from

to develop this

can

STEPS (Standard Technology and Engineering

has been

in a 1981

Programming

paper, described how their motivation

desire to standardize practices so that people

a

work together effectively

incompatible

for

teams,

in

software-engineering tools

communication among engineers:

with

or

methods,

as

due

problems

minimal

well

as

to

restricted

"Regardless of how excellent these [software

engineering] technologies are, the desired objective cannot be accomplished

each member of

his

own

will.

a

team or an organization developing software adopts them

at

This problem occurs because some technologies conflict with each

communication

other and

if

between

engineers

is

Hence there

restricted.

is

necessity for standardization of software."'''

After development began

for in-house use

in

1972.

in

1971,

NEC

released an

Azuma and Mizuno

recall,

version of

initial

STEPS

however, that "The

version was intended to be comprehensive, fool proof and was compiled

form of

led

to

a

manual 30 cm thick.

Therefore

another effort to produce

completed

in

1974.

Revision

was never used."

system easier to use,

a

of

it

the

sites using

STEPS by

STEPS was due

component

of

to

1984.

their

standardized

^'^

NEC engineers

tools,

procedures,

program" modules accessible through

a

32

the

which

NEC

tools

staff

has

NEC and NEC-customer

claim that the recent success of

approach:

two-fold

in

This experience

STEPS methodologies and

continued every year since, with approximately 1200

first

offering

and

of

a

technological

"prefabricated

standard

program library; and emphasis on

a

.

philosophy outlining how programs should be developed through each stage of

the software

cycle.

life

The philosophy underlying STEPS, according

on the historical experience of companies

in

to

Azuma and Mizuno, drew

"hardware" manufacturing industries

which had found ways to improve productivity through standardization and

division of labor,

materials,"

as

well

as process

"intermediate products,"

"product utilization."

counterparts

in

All of

through analysis of "raw

rationalization

final

"products,"

"work methods," and

these process inputs, they insisted, had conceptual

software:

The productivity

Revolution. The

of industry has greatly increased after the Industrial

basic concept of the Industrial Revolution was to achieve

.drastically reducing the

high volume production of standardized products

manufacturing cost ... by thoroughly incorporating standardization not only

of the final products but also their parts...

.

.

In spite of essential differences between software and hardware, a

of similarities can be found where standardization is concerned.

(1)

Program language, macros, subroutines,

in producing software...

etc.

number

which correspond to raw

materials

(2) Documents and specification documents corresponding

Their standardization facilitates division

products.

to intermediate

of labor and

automation.

Mass production of

(3) Programs and documents correspond to products.

standard products are [sic] similar to general purpose applications of

computer manufacturers and software houses. The needs and circumstances

of users are identical to other examples were production of orders are

tailored to the customer.

Products should perfectly be made with parts in

units which are as large as possible, that is, by combining standard

modules

(4) Tools correspond to the software used for software production.

Compilers, test data generators, etc. are examples of these.

(5) Work methods represent standardization of methods such as application

system designs, software designs, and coding.

(6) The product utilization method concerns which data is processed by the

software.

To efficiently design individual items of software and to

eliminate contradictions among them, standardization of data will be

important. In other words, this concerns standards of languages, modules,

program structures, tools, methods, documentation, and data, and

standardization must be conducted systematically under a consistent

33

philosophy.^"'

The STEPS procedures required program development

five distinct "phases," with subsets of "activities" and then

activity,

to be divided into

"work sets" for each

consisting of specific procedures and "basic work elements,"

which managers monitor as part of scheduling and progress control.

standardization

came from

standardizing

each

work

set

and

documents, using form sheets or simple headings for "work of

type."

NEC managers considered

degree essential for communication

maintenance

separation

in

of

particular

design

of

Process

accompanying

more creative

standardization and documentation of this

in

general and division of labor and program

(see table)."*''

from

a

all

production

Division of labor also included the

to

the

extent

that

NEC

divisions

sometimes "handed off" high-level design documents to subsidiaries, which then

did detailed design,

coding, and testing. ^^

34

P^ojer^ file

.-cr-3

shec:

Wcrxset

.-ora

sheet

>crR

Wcrhse;

/

sheet

/

Worxse:

doc-jmer.l

Dc-^t-.tjt^=" vrrx

STEPS PROGRAMMING STANDARDS

Programming Standards

Work

Outputs

Standard Patterns

General System

Design

Processing Flow

Standard Specifications

(Structured Program

Diagrams)

Detailed System

Program

Design