Lubricant-Derived Ash – In-Engine Sources and Opportunities for Reduction

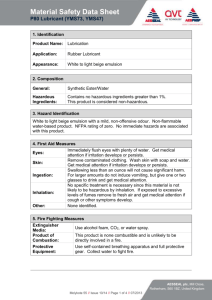

advertisement