18th Annual Beef Cattle Day Report May 14, 1977 Oregon State University, Corvallis

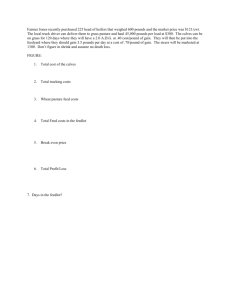

advertisement