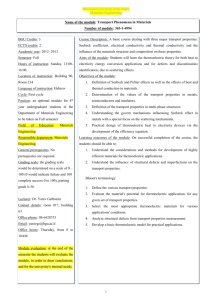

Device Testing and Characterization of Thermoelectric Nanocomposites

advertisement