Achieving Six Sigma Printed Circuit Board Yields

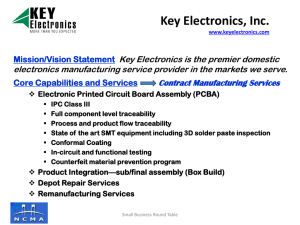

advertisement