Using Visual Analytics to Drive Lean ... Charalambos J. Antoniou By

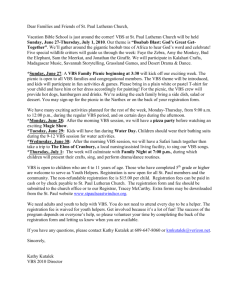

advertisement