Document 11012876

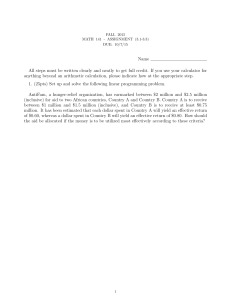

advertisement