Sugar Processing Sugar Concentration Duracon* RO-1 4040C-50P Fact Sheet

advertisement

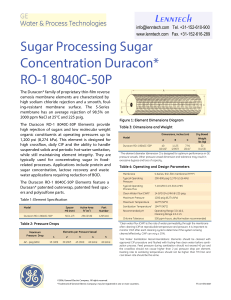

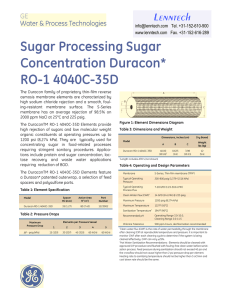

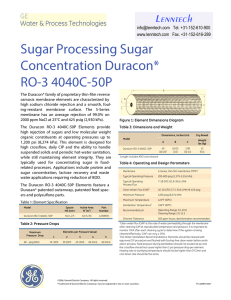

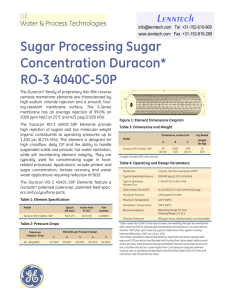

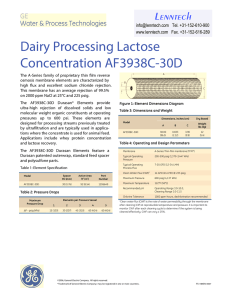

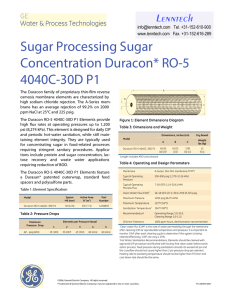

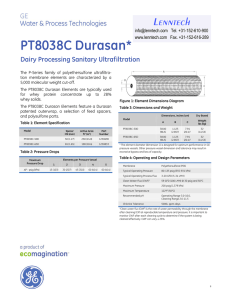

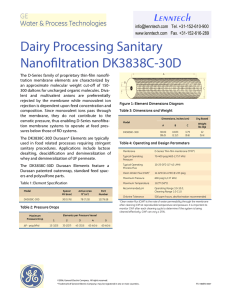

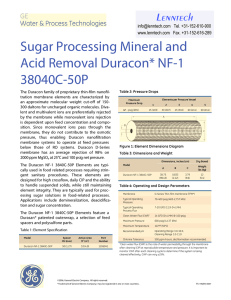

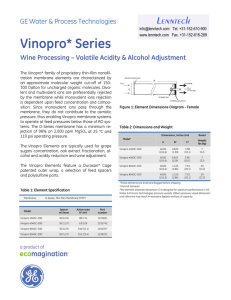

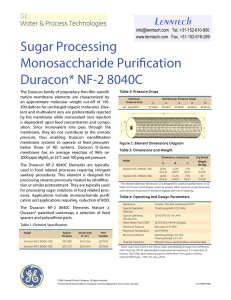

Lenntech Fact Sheet info@lenntech.com Tel. +31-152-610-900 www.lenntech.com Fax. +31-152-616-289 Sugar Processing Sugar Concentration Duracon* RO-1 4040C-50P The Duracon* family of proprietary thin-film reverse osmosis membrane elements are characterized by high sodium chloride rejection and a smooth, fouling-resistant membrane surface. The S-Series membrane has an average rejection of 98.5% on 2000 ppm NaCl at 25°C and 225 psig. The Duracon RO-1 4040C-50P Elements provide high rejection of sugars and low molecular weight organic constituents at operating pressures up to 600 psi (4,137 kPa). This element is designed for high crossflow, daily CIP and the ability to handle suspended solids and periodic hot-water sanitation, while still maintaining element integrity. They are typically used for concentrating sugar in foodrelated processes. Applications include protein and sugar concentration, lactose recovery and waste water applications requiring reduction of BOD. Figure 1: Element Dimensions Diagram Table 3: Dimensions and Weight Dimensions, inches (cm) Duracon RO-1 4040C-50P Duracon RO-1 4040C-50P Part Number 50 (1.27) 67 (6.22) 1226498 ∆P - psig (kPa) Weight lbs (kg) 40 (101.6) 1 0.625 (1.6) 3.98 (10.11) 12 (5.4) Membrane S-Series, thin-film membrane (TFM*) Typical Operating Pressure 200-500 psig (1,379-3,448 kPa) Typical Operating Process Flux 7-18 GFD (11.9-30.6 LMH) Clean Water Flux (CWF)2 14 GFD (24 LMH) @ 225 psig Maximum Pressure 600 psig (4,137 kPa) Sanitization Temperature 122°F (50°C) 3 194°F (90°C) Recommended pH Operating Range 3.0-10.0, Cleaning Range 2.0-11.5 Chlorine Tolerance 500 ppm-hours, dechlorination recommended 2 Table 2: Pressure Drops Maximum Pressure Drop C Table 4: Operating and Design Parameters Maximum Temperature Active Area ft2 (m2) B Length includes ATD’s (not shown) Table 1: Element Specification Spacer Mil (mm) A 1 The Duracon RO-1 4040C-50P Elements feature a Durasan* patented outerwrap, a selection of feed spacers and polysulfone parts. Model Dry Boxed Model Elements per Pressure Vessel 1 2 3 4 5 15 (103) 30 (207) 45 (310) 60 (414) 60 (414) Clean water flux (CWF) is the rate of water permeability through the membrane after cleaning (CIP) at reproducible temperature and pressure. It is important to monitor CWF after each cleaning cycle to determine if the system is being cleaned effectively. CWF can vary ± 25%. 3 Hot Water Sanitization Recommendations: Elements should be cleaned with approved CIP procedure and flushed with fouling-free clean water before sanitization process. Feed pressure during sanitization should not exceed 40 psi and the crossflow should not cause higher than 2 psi pressure drop per element. Heating rate to sanitizing temperature should not be higher than 5°C/min and cool down rate should be the same. ©2006, General Electric Company. All rights reserved. *Tr a dema r k of Genera l Elec tr ic Compa ny ; ma y be r egis ter ed in one or more c ountr ies . FS1208EN 0607