Feature-Based Investment Cost Estimation Based on ... Pharmaceutical Manufacturing System

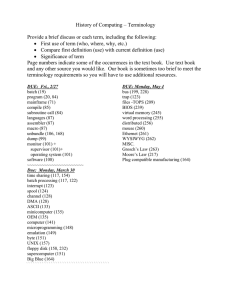

advertisement