Designing a RIO Mezzanine Card for Beer Brewing Automation with...

advertisement

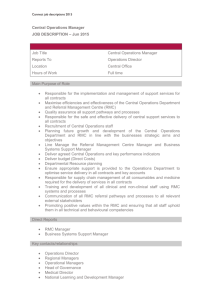

Designing a RIO Mezzanine Card for Beer Brewing Automation with NI Multisim and NI Ultiboard Publish Date: Dec 28, 2015 Overview This reference design demonstrates how NI Multisim and NI Ultiboard can be used to design a custom RIO Mezzanine Card fo home brewing system powered by NI Single-Board RIO and LabVIEW. Table of Contents 1. 2. 3. 4. 5. 6. Introduction Multifunction I/O NI Single-Board RIO Custom RIO Mezzanine Card RIO Mezzanine Card Design with Multisim RIO Mezzanine Card Design with Ultiboard Additional Resources 1. Introduction One of the most popular demos at NIWeek 2012 was the Automated Brewing System, which uses NI Single-Board RIO (sbRIO and a custom RIO Mezzanine Card (RMC) designed with Multisim (http://www.ni.com/multisim) and Ultiboard ( http://www.ni.com/ultiboard) to control the brewing process. The sbRIO device hosts a LabVIEW Real-Time application that monitors temperature and controls various elements (for instance: pumps), and the RMC contains custom circuitry to connect signals and sensors. Click here (https://decibel.ni.com/content/projects/the-wobbly-boot-pico-brewery?view=blog) to get more technical details on the brewing system. 2. Multifunction I/O NI Single-Board RIO NI Single-Board RIO (http://ni.com/sbrio) products are designed for high-volume embedded control and data acquisition applications. These devices feature and onboard real-time processor and FPGA chip that can be programmed with LabVIEW Real-Time and LabVIEW FPGA. The brewing system is powered by the sbRIO-9626, which features a 400 MHz processor, reconfigurable Xilinx Spartan-6 LX45 FPGA, communication ports (Ethernet, Serial, USB, CAN, SDHC), a 50-pin IDC connecto (which provides connections to 16 analog inputs, 4 analog outputs and 4 3.3 V DIO lines), and a RIO Mezzanine Card (RMC) connector that provides direct access to 96 3.3 V DIO FPGA lines. Figures 1 and 2 show a view of the sbRIO-9626 device with the IDC connector and RMC connector highlighted in yellow. Figure 1. Primary side of the sbRIO-9626 featuring the 50-pin IDC connector. Figure 2. Secondary side of the sbRIO-9626 featuring the RMC connector. 3. Custom RIO Mezzanine Card 1/8 www.ni.com 3. Custom RIO Mezzanine Card The 50-pin IDC connector and the RMC connector provide an open architecture for expansion and customization and enable users to design custom daughter cards (or RIO Mezzanine Cards). For the brewing system we needed analog inputs for potentiometers and sensors, digital inputs/outputs for relays and switches. In this reference design we used NI Multisim (http://ni.com/multisim) and NI Ultiboard (http://ni.com/ultiboard), the circuit design and prototyping tools from National Instruments, to design the custom daughter card. 4. RIO Mezzanine Card Design with Multisim Multisim features a vast collection of schematic symbols and simulation models organized in a Master Database. Furthermore, database includes connector symbols and footprints that designers can use to develop custom boards for NI hardware systems including: data acquisition devices (R Series, S Series, X Series), CompactRIO, Single-Board RIO, GPIB and SCXI. The RMC connector used in the sbRIO-9626 (and other sbRIO devices) is a high-density 240-pin Searay connector, the recommended mating connector is the SEAM-40-03.0-S-06-2-A-K-TR which can be found in the Multisim Master Database. Th symbol is divided in three sections: DIO, MISC (Power, Ground, USB) and RES (reserved pins), as shown in Figure 3. Figure 3. RMC connector symbol The RMC design features four main modules: Power, Analog I/O, Digital I/O, Relays and Temperature Sensors. In order to hav modularized architecture the schematic in Multisim is organized into various multi-page schematics, as shown in Figure 4. Figure 4. Multi-page design in Multisim Power Module The power module consists of six blocks organized in one page (Figure 5). For a description of each block refer to Table 1. Figure 5. RMC power module Table 1: Power Module Description 2/8 www.ni.com Table 1: Power Module Description Description Block RMC Connector Power Power connections from the RMC Connector which are being used in the design. Fuse 3.3 V Contains the necessary circuitry to fuse the 3.3 V power pin from the RMC Connector. Fuse 5 V Contains the necessary circuitry to fuse the 5 V power pin from the RMC Connect Indicator LEDs Power status indicator LEDs. Screw Terminal with Power Pins 10-pin screw terminal connector 15 V Connector Connector for an external 15 V power supply. Analog I/O Module As previously mentioned the sbRIO-9626 features 16 analog inputs and 4 analog outputs that can be accessed via the 50-pin I connector (see Figure 1). All these channels are connected to the custom board through a ribbon cable and, to provide an easy way to connect signals to the board, we have two screw terminals. (a) (b) Figure 6. RMC AIO module Digital I/O Module The RMC connector features 96 FPGA I/Os; 12 DIOs are used to control the relay channels, 8 DIOs read data from temperatur sensors and 32 DIOs are used for other tasks. 3/8 www.ni.com Figure 7. FGPA I/Os used in the design For future development and expansion, two connectors were added to provide access to unused DIO lines Figure 8. Connectors for unused DIO lines Relay Module There are 12 relay channels available in the custom board. Signals can be connected using screw terminals. Each relay chann features a relay driver circuit that requires an external 15 V power supply (the power supply connector can be found in the Pow module). The relay driver circuit was simulated in Multisim to ensure current and voltage levels were adequate. Figure 9. Relay driver circuit Temperature Sensors Module For temperature measurements we used the DS18B20, a digital sensor. This device requires a power supply and pull-up resist to work. In total we have 8 sensors that can be connected through a screw terminal. The use of a digital sensor simplified the circuitry in the custom board, however the challenge was to implement a 1-Wire protocol in the sbRIO device. If interested you find an example here (https://decibel.ni.com/content/docs/DOC-24136). 5. RIO Mezzanine Card Design with Ultiboard 4/8 www.ni.com 5. RIO Mezzanine Card Design with Ultiboard NI Ultiboard is a flexible environment for PCB layout and routing and provides the tools engineers need for quick prototyping. Furthermore, Ultiboard is fully integrated with Multisim, so you can quickly translate a circuit to PCB prototype. In Multisim you can simply select Transfer»Transfer to Ultiboard»Transfer to Ultiboard 12.0 to transfer the netlist to Ultiboar Ultiboard creates a default board outline and places all the parts outside of the board (see Figure 10). Figure 10. Transferring the schematic from Multisim to Ultiboard The yellow lines (ratsnest) represent the netlist. The dimensions for this board are exactly the same as the sbRIO-9626 board. The dimensional indicators for the board are pla on the mechanical layer so that they do not get printed on the board during fabrication. It is a good idea to use the mechanical layers if you have to add additional information about the design. We designed a four layer board with power planes in the inner layers. The Copper Inner 1 layer contains power planes for all th different voltage levels available on the board and the Copper Inner 2 layer contains the power planes for the analog and digita grounds. Figure 11. RMC Design in Ultiboard Traces on this board are between 6-8 mils. The relays drive a lot of current so the trace width for all the relay inputs is 45 mils. Most of the traces on the board were routed using the Bus Autorouting feature in Ultiboard. This enables you to route traces together and have better signal integrity. Also, some of the traces were routed using the Autorouter. 5/8 www.ni.com Figure 12. Routing in Ultiboard One of the challenges was routing the signals from the RMC connector. This process could require hours of manual work. To make things easier, we used the Fanout feature in Ultiboard and the work was done in seconds. Figure 13. Fanout in Ultiboard Before exporting the fabrication files (Gerber, NC Drill, etc) you can display a 3D view of your design in Ultiboard, as shown in Figure 15. You can use your mouse to rotate the board 360 degrees in all directions. Figure 14. RMC card top view (3D) Finally, here are some pictures of the electronic box that controls the brewing process. The RIO mezzanine board is attached behind the sbRIO-9626. 6/8 www.ni.com (a) (b) Figure 15. Electronics box with sbRIO-9626 and custom RMC 6. Additional Resources Learn more about NI Multisim (http://www.ni.com/multisim) Learn more about NI Single-Board RIO (http://www.ni.com/singleboard/whatis/) PRODUCT SUPPORT COMPANY Order status and history (http://www.ni.com/status/) Submit a service request ( https://sine.ni.com/srm/app/myServiceRequests) Order by part number ( http://sine.ni.com/apps/utf8/nios.store?action=purchase_form Manuals (http://www.ni.com/manuals/) ) Drivers (http://www.ni.com/downloads/drivers/) Activate a product ( http://sine.ni.com/myproducts/app/main.xhtml?lang=en Alliance Partners (http://www.ni.com/alliance/) ) About National Instruments ( http://www.ni.com/company/) Events (http://www.ni.com/events/) Careers (http://www.ni.com/careers/) Order and payment information ( http://www.ni.com/how-to-buy/) MISSION 7/8 www.ni.com NI equips engineers and scientists with systems that accelerate productivity, innovation, and discovery. (http://twitter.com/niglobal) ( http://www.facebook.com/NationalInstruments) ( http://www.linkedin.com/company/3433?trk=tyah) (http://www.ni.com/rss/) ( http://www.youtube.com/nationalinstruments) Contact Us (http://www.ni.com/contact-us/) (http://privacy.truste.com/privacy-seal/National-Instruments-Corporation/validation?rid=bc6daa8f-7051-4eea-b7b5-fb24dcd96d95) Legal (http://www.ni.com/legal/) | © National Instruments. All rights reserved. | Site map ( http://www.ni.com/help/map.htm) 8/8 www.ni.com