Preliminary Evaluation of Airlaid Nonwovens with Superabsorbent for Use in Protective

advertisement

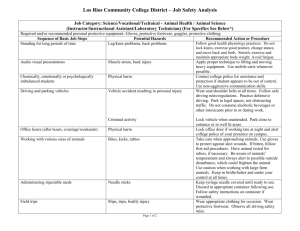

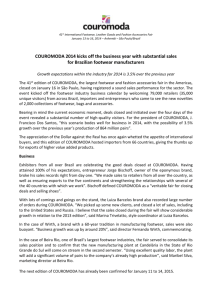

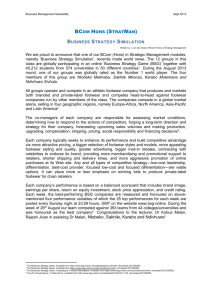

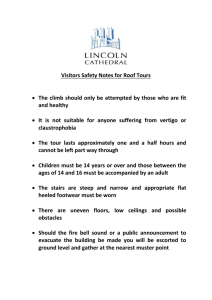

Emilia Irzmańska, *Jacek Dutkiewicz Preliminary Evaluation of Airlaid Nonwovens with Superabsorbent for Use in Protective Footwear: Tests Involving a Thermal Foot Model and Climatic Chamber DOI: 10.5604/12303666.1167432 Central Institute for Labour Protection – National Research Institute E-mail: emirz@ciop.lodz.pl *University of Bielsko-Biala, Poland Abstract The paper presents preliminary results of simulation studies evaluating moisture absorption from the air that indicate the possibility of applying a superabsorbent polymer (SAP) in the construction of protective footwear insoles. The performance of different types of nonwovens was tested in terms of moisture absorption from air of high relative humidity in a climatic chamber and on a thermal foot model. The tests simulated the temperature and humidity conditions that occur inside all-rubber protective footwear. It was found that insoles containing SAP dehumidified the air more effectively than either insoles not containing SAP or traditional wool felt insoles. The tests showed a new application potential of absorbent materials in protective footwear with a view to improving hygienic comfort during use. Key words: nonwovens, superabsorbent, protective footwear, insoles. excessive humidity in footwear lead to decomposition of the organic substances contained in sweat, thus enhancing the growth of pathogenic bacteria and fungi. These processes detract from the hygienic properties and comfort of use of the footwear [2]. nIntroduction In addition to exhibiting good protective properties, personal protective equipment (PPE) should meet certain hygienic, ergonomic, and health requirements [1]. This also applies to protective footwear, which is often made of impermeable materials and equipped with additional protective elements. While those materials and elements ensure protection of the feet against hazardous and noxious factors, at the same time they entail considerable energy expenditure of the human body and significantly deteriorate user comfort. The construction materials applied in PPE hinder the distribution of heat and sweat, which are profusely generated upon exertion. Commercially available protective footwear insoles are hygroscopic and retain large amounts of moisture in their structure, adversely affecting their hygienic properties. High temperature and 138 Footwear insoles absorb from 85% to 90% of the sweat secreted by the feet [3]. In particular, moisture tends to accumulate in the toe, plantar, and heel regions of the insoles (the density of sweat glands on the foot sole is generally very high). Insoles made of polymers or textile composites with moisture-buffering properties hinder effective transport of liquid moisture, and as a result sweat accumulates within the structure of these footwear textiles. However, desirable parameters of the microclimate inside impermeable protective footwear may be obtained by means of modeling the construction of insoles placed in it [4]. It has been found that the more moisture is removed from the immediate vicinity of the foot, the better the footwear microclimate becomes [5]. The hygienic properties and comfort of use of protective footwear may be improved by means of support textiles, such as liners, insoles, and socks [6]. The key factors influencing the distribution of heat and moisture inside protective footwear include the type of fibres and their spatial arrangement in the structure of support textiles [7]. In this context, a major role may be played by multifunctional liquid-absorbing nonwoven structures. Superabsorbents [8] are hydrophilic materials hydrofilowymi materiałami polimerowymi capable of binding a very large amount of water. The first water-binding polymers were synthesised in 1938 - acrylic acid (AA) and divinylbenzene synthesized by thermal polymerisation in water. The main absorbing materials are hydrogels, which are internally crosslinked polymers with hydrophilic properties. 1 g of the hydrogel can absorb up to 1000 g of liquid [9]. For the synthesis of superabsorbents, the following are usually used: acrylamide, acrylic acid, methacrylic acid and its derivatives, divinyl monomers, ethylene glycol diacrylate, sodium divinylbenzosulfonate, tetrahydroxymetyloacetylenourea, allyl acrylate, poly (ethylene glycol, poly (aspartic acid), poly (vinyl alcohol), maleic anhydride copolymers, poly-N-vinylpyrrolidone [9, 10]. Multifunctional nonwoven structures with absorbent qualities were previously used mainly in personal care products, where they were designed to quickly absorb and store physiological liquids (urine or blood) [11]. The largest amount of absorbents produced worldwide is used in disposable diapers. For this reason, most of the research was focused on hygiene species which are normally used as powder in diapers. In the past two decades, absorption has increased to about 30 g/g, while Irzmańska E, Dutkiewicz J. Preliminary Evaluation of Airlaid Nonwovens with Superabsorbent for Use in Protective Footwear: Tests Involving a Thermal Foot Model and Climatic Chamber. FIBRES & TEXTILES in Eastern Europe 2015; 23, 6(114): 138-142. DOI: 10.5604/12303666.1167432 the free absorption capacity has decreased to about 50 g (salt)/g (polymer). Due to market demands for thinner diapers, diaper includes more absorbent than powder, which limits the maximum amount of absorbent in the diaper to about 10 g/piece, which is achievable for the absorbents have been improved. However, the aim is to achieve absorption at a level of 45 - 50 g/g to obtain much thinner diaper [12, 13]. Absorbent textiles must meet a range of requirements, depending on their designation. Their essential functions include liquid uptake, distribution, and prolonged storage. To ensure that these functions are fulfilled, designers must use appropriate raw materials and carefully design product structure in terms of area density, volumetric density, pore size, and porosity. Such materials can be manufactured by airlaid technology, where products may consist of several layers of different composition and structure, and hence they may exhibit two or more functions. Fast moisture absorption in the upper layer of the nonwoven can be obtained by using thicker and more rigid fibres, which create larger pores in regions that come into contact with the human skin secreting sweat. Synthetic fibres are often employed for such applications as they do not lose their rigidity after wetting. In turn, effective liquid distribution occurs in a layer consisting of thinner cellulose fibres, which form relatively smaller pores resulting in increased capillary pressure that allows moisture to be transported deeper and higher in the structure. Finally a layer rich in superabsorbent (SAP) granules ensures the absorption capacity required [14, 15]. The literature provides examples of the application of SAP fibres in underwear used with protective clothes exhibiting barrier properties [16, 17]. Bartkowiak [16] took on the development of materials containing superabsorbents characterised by a large sorption capacity which can be used in the construction of protective clothes for the absorption of sweat. On the basis of technological analysis of the different fibres, Oasis 102 fibres were selected, which are cross-linked acrylate copolymer fibres partially neutralised by sodium salt. They have very good sorption properties for salt water, which is very important for the absorption of sweat through protective clothing (full time sorption is 15 seconds). Another very important feature of FIBRES & TEXTILES in Eastern Europe 2015, Vol. 23, 6(114) Oasis fibre is satisfactory absorption of water vapor in the whole range of relative humidity. Wawro et al conducted a study on the microfibres of chitosan [18 - 20]. It was shown that fibres of this type are characterised by very high values of the secondary swelling index (1300%), which makes the fibres suitable for use in sanitary and medical products. Das et al [21] reported a method for producing an ultra-thin sanitary absorbent core with super-absorbent fibres (SAF), and blends of viscose in a different percentage composition sandwiched between two layers of nonwoven. Samples prepared were thinner than the control one (a mixture of cellulose and superabsorbent polymer SAP), and had significantly improved absorption rates for saline. It was demonstrated that there is a linear relationship with the mass absorption and percentage SAF, which will optimise the absorption capacity of the core depending on the absorption amount desired. Nowicka [22] in her work about the sustainability of particle bonding in the structure of absorbent non-woven describes the creation of an absorbing layer using the melt- blown technique. A composite nonwoven fabric made with this technique may include in its structure particles of sorbents such as activated carbon, aluminum oxide, or chitosan. It is assumed that the large size of sorbent particles allow for the creation of a nonwoven fabric porous structure of sorbent particles well- „caught” by microfibres through these particular pores. Nonwovens produced in this way may contain from 10% to 90% (by weight) of the absorbent powder, without containing additional binders, which allows to maintain the unique characteristics of each of the particles of the absorbent [23]. Bartkowiak and Szucht [24] studied the sorption of sweat by materials to be worn under protective clothing. We analysed various double-layer systems consisting of woven fabrics of synthetic fibres and absorbent (polyester, polypropylene, cotton, rayon, wool). Studies have confirmed the high usefulness of the double-layer system with a diffusion layer directly adjacent to the wearer’s skin and an outer layer of sorption eliminating sweat. The optimal raw material for the diffusion layers are non hygroscopic fibres, especially polyester textured yarns. Experiments have shown that the viscose fibres are the most favorable of the traditional sorption materials. Both the velocity and efficiency of sorption of liquid sweat absorption are highest in comparison with other hygroscopic fibres. Superabsorbents absorb several times more sweat than most traditional absorbent cloth. The study of different morphological structures of knitted fabrics have shown that fabrics with a complex spatial structure, such as the stitch peak, have the best sorption parameters. Thus the hypothesis of high utility porous materials for both the diffusion and sorption of sweat was confirmed. In his work, Sadikoglu [25] examined the effect of moisture on the skin and clothing for comfort. The study aimed to determine the role of superabsorbent fibres in parallel stiffening nonwovens from the point of view of comfort. Five persons evaluated sample nonwoven fabrics comprising polyester, a mixture of polyester/copolyester, and superabsorbent fibres in different proportions. As used superabsorbent fibres are crosslinked acrylate copolymer, partially neutralised to the sodium salt, in fibre form. Studies have shown that the addition of 3.5% superabsorbent to the blend significantly improves the perception of wet feel, however, to employ a mixture of the clothes their properties after repeated washing should be checked. However, there are no reports in the literature regarding the use of SAP in protective footwear insoles. This paper presents preliminary results of a simulation study evaluating moisture absorption from the air and examining the possibilities to apply a superabsorbent polymer in protective footwear insoles. The study indicates a new application direction for absorbent materials in protective footwear with a view to improving user comfort. nMethods Materials The study involved 6 types of absorbent airlaid nonwovens made of short cellulose fibrils extracted from coniferous trees by the Kraft method (supplied by Buckeye Technologies Inc., now Georgia-Pacific, Steinfurt, Germany). Table 1 (see page 140) provides the basic technical parameters of those materials. Two of the variants studied (samples 4 and 5) exhibited increased absorbent capacity as they contained superabsorbent (SAP) granules. 139 Table 1. Technical parameters of airlaid nonwovens studied. Sample Area density, g/m2 Thickness, mm Tensile strength in dry state, N/5 cm Absorbent capacity, g/g SAP 1 80 0.87 19.0 10.0 - 2 80 1.05 24.5 8.5 - 3 60 0.95 16.0 12.0 - 4 150 1.35 27.0 30.0 Yes 5 175 3.00 20.0 40.0 Yes 6 300 5.00 55.0 12.0 - of the surface of the thermal foot model was 34°C. Changes in relative humidity levels inside the footwear were measured and recorded on-line for 8 h (which corresponds to one work shift). Relative humidity was determined in the space between the plantar region of the foot and nonwoven insole. Statistical analysis Assessment of moisture absorption by nonwovens on a thermal foot model Samples (insoles) were placed inside allrubber footwear. Moisture absorption in this system was evaluated using a thermal foot model (ATTElectro, Poland). A detailed description of the device and its operating principles was given in a previous publication [5]. Each variant Sample 11 Sample Sample 22 Sample was tested five times. During the tests the foot model was set to a constant sweat production rate of 15 g/h, which is typical of humans performing strenuous physical activity. The tests were conducted under static conditions (without foot movement or pressure on the walking surface) in order to ensure conditions identical to those in the climatic chamber. The temperature Sample 33 Sample Sample Sample44 Sample Sample55 Wool felt Wool felt Moisture sorption, g 0.4 0.3 n Results and discussion 0.2 Study results are presented in Figures 1 and 2. 0.1 The absorbent capacity of the materials studied is given in Table 1. Considering the fact that during walking insoles are subjected to pressure, some of the nonwovens selected contain a superabsorbent polymer in which water molecules are bound by solvation to carboxyl groups (samples 4 and 5). Such materials have a much greater absorbent capacity than airlaid nonwovens without SAP. In nonwovens containing SAP, polymer granules are located in the internal material layer. The external layers consist of fibres bonded together by means of two-component synthetic fibres and an adhesive deposited on their surface in the form of emulsion. In this way, SAP granules are trapped inside the material and are not readily lost from the nonwoven during use. This structure also leads to better liquid distribution between the fibres before water particles become firmly bound to SAP. An additional benefit of placing polymer granules in the internal layer of the material is that their swelling does not block channels in the external layers of the material, thanks to which the liquid can easily move along those channels. Insoles made of the airlaid nonwovens tested were applied in all-rubber protective footwear. 0.0 0 5 10 15 20 25 Time, h Figure 1. Moisture absorption curves for footwear insoles made of airlaid nonwovens with and without a superabsorbent polymer (SAP) in comparison to wool felt; tests conducted over water in a desiccator. Sample 1 Sample 2 Sample 3 Sample 4 Sample 5 Sample 6 Wool felt Relative humidity, % 100 95 90 85 80 0 2 4 6 8 Time, h Figure 2. Relative humidity inside protective footwear with insoles made of airlaid nonwovens; tests on a thermal foot model. 140 Statistical analysis was used to evaluate the significance of correlations between sorption and relative humidity levels for the airlaid nonwoven samples tested. A 95% confidence interval was determined for the mean values of the parameters studied. It was checked whether sorption and humidity readings exhibited a normal distribution. Correlations were evaluated using Pearson’s r. Due to the small number of measurements, a posteriori bootstrapping with 1000 replicates was used. Analysis was conducted using SPSS Statistics 21.0 software. FIBRES & TEXTILES in Eastern Europe 2015, Vol. 23, 6(114) Acting on the results above, the authors subsequently decided to apply an experimental method involving a thermal foot model. As can be seen from Figure 2, insoles containing SAP (samples 4 and 5) considerably dehumidified the air inside the all-rubber protective footwear. Relative humidity inside the footwear decreased from the initial value of 93% to 81%, which is close to the levels considered in the literature as comfortable for users (80%) [2]. In turn, insoles made of airlaid nonwovens without SAP did not significantly decrease the relative humidity. In the case of insoles made of wool felt, the relative humidity increased to almost 100%. These findings for the nonwovens studied are confirmed by the Pearson’s correlation coefficient between sorption levels (recorded in the climatic chamber) and relative humidity values (recorded inside protective footwear on a thermal foot model). As can be seen from Table 2, there is a statistically significant correlation between those parameters for the samples containing superabsorbent (samples 4 and 5). Analysis of the relationship between moisture sorption and relative humidity levels for insoles containing SAP gave results close to -1, which indicate a strong negative correlation (higher moisture sorption by insoles is accompanied by lower relative humidity inside protective footwear). Therefore there exists a clear interrelationship that may be interpreted from a physical point of view: the increasing ability of the material to absorb water in the chamber and the type of material studied decrease relative humidity inside footwear. Therefore the above-mentioned correlation of variables is determined by the affinity of a given material to moisture sorption (the physicochemical properties of the material). The test results showed that airlaid nonwovens with SAP are more efficient at moisture absorption than wool felt, FIBRES & TEXTILES in Eastern Europe 2015, Vol. 23, 6(114) which is now typically applied in protective footwear. This conclusion is of great interest because such nonwovens have not been used in protective footwear to date, and hence this paper presents a novel application possibility. Compared with literature in the field of shoe insoles [2, 4, 6, 7, 26], the use of superabsorbents (SAP) in airlaid nonwovens allows to obtain better microclimate parameters, which indicate footwear comfort when using inserts containing SAP. nConclusions The study presented in the first step towards the application of materials containing a superabsorbent in protective footwear insoles. The results of laboratory experiments have confirmed the hypothesis that nonwovens with SAP are much more efficient at absorbing moisture from the air than nonwovens without SAP or traditional wool felt materials. Finally the practical benefits predicted from those experiments were verified by means of a thermal foot model simulating the use of protective footwear. The resulting parameters of the microclimate in footwear indicate that the use of airlaid nonwovens and SAP allows for greater comfort footwear. Preliminary data estimated using bootstrap statistical analysis allow us to conclude that the data obtained warrant further research with a view to developing a new technology for all-rubber protective footwear containing insoles made of nonwovens with a superabsorbent polymer. Aknowledments nThe publication draws on results obtained as part of a research task implemented under statutory activity of CIOP-PIB (2010–2012) and research grant No. N N404 068240 (contract number 0682/B/ P01/2011/40) financed by the National Science Centre in the years 2011–2013 at the CIOP-PIB. nThe publication was based on the results of Phase II of the National Programme “Safety and working conditions improvement”, funded in the years 2011-2013 in the area of research and development works by the Ministry of Science and Higher Education/The National Centre for Research and Development. The Programme coordinator: Central Institute for Labour Protection – National Research Institute Table 2. Pearson’s correlation coefficients between sorption levels in g and relative humidity in % for the airlaid nonwovens studied: * p ≤ 0.05; ** p ≤ 0.10 (statistical tendency). Moisture sorption, g The nonwovens were tested with samples placed over water in a desiccator (at 37 °C and relative air humidity of 93%). As expected, the absorption curves (Figure 1) showed the nonwovens containing SAP to be more efficient at absorbing moisture from the air than the other nonwovens. The results of experiments conducted in the climatic chamber and desiccator with water also indicate that airlaid nonwovens perform better than the wool felt typically used in protective footwear. Relative humidity, % Sample 4 (with SAP) -0.987** Sample 5 (with SAP) -0.975 Sample 4 (no SAP) -0.846 Sample 5 (no SAP) -0.893** Sample 1 (no SAP) -0.848* Sample 2 (no SAP) -0.864 Sample 3 (no SAP) -0.884* References 1. Akbar-Khanzadeh F, Bisesi MS, Rivas RD. Comfort of personal protective equipment. Appl. Ergon. 1995; 26(3): 195-198. 2. Irzmańska E. Footwear use at workplace and recommendations for the improvement of its functionality and hygiene. AUTEX 2014; 14(2): 89–94. 3. Hole LG. Sweat health disposal from footwear and hygiene of foot skin. J. Soc. Cosmet. Chem. 1973; 24; 43-63. 4. Irzmańska E, Brochocka A, Majchrzycka K. Textile Composite Materials with Bioactive Melt-Blown Nonwovens for Protective Footwear. Fibres & Textiles in Eastern Europe 2012; 20, 6A(95): 119-125. 5. Irzmańska E. Case study of the impact of toecap type on the microclimate in protective footwear. Int. J. Ind. Ergonom. 2014; 44(5): 706–714. 6. Irzmańska E. The impact of different types of textile liners used in protective footwear on the subjective sensations of firefighters. Appl. Ergon. 2015; 47: 34 – 42. 7. Irzmańska E and Brochocka A. Influence of the Physical and Chemical Properties of Composite Insoles on the Microclimate in Protective Footwear. Fibres & Textiles in Eastern Europe 2014; 22, 5(107): 89-95. 8.Kabiri K, Omidian H, Zohuriaan – Mehr MJ, Doroudiani S. Superabsorbent hydrogel composites and nanocomposites: a review. Polym Composite 2011; 32(2): 277-289. 9. Glados S, Maciejewski M. Hydrogels. Syntheses and application. Wiadomości chemiczne 1998; 52: 101-123. 10. Bereś J, Kołędkowska M. Superabsorbents. Chemik 1992; 3: 59-61. 11. Bartkowiak G, Frydrych I. Superabsorbennts and their medical applications, p. 505-547. In: Bartels VT. Handbook of medical textiles. Ed. WP, The Textile Institute, 2011. 12.Zohuriaan-Mehr MJ, Kabiri K. Superabsorbent polymer materials: a review. Iran Polym Mat 2008; 17(6): 451-477. 13.Kokabi M, Sirousazar M, Muhammad Hassan Z. PVA-clay hydrogels for 141 wound dressing. Eur. Polym. J. 2007; 43: 773. 14. Dutkiewicz JK, Goerg-Wood KA, Guay DF, Kalmon MF, Kressner BE, Li Y, Qin J, Szymonski KA, Tanzer RW, Wallajapet PRR. Absorbent structure and method. Patent Pat. 6,329,565 B1, USA, 2001. 15. Dutkiewicz J, Erspamer J, Boehmer B, Wahal S, Hood R. Structure a hautes performances. Patent WO2000041882 A1, France, 2000. 16. Bartkowiak G. Liquid Sorption by Nonwovens Containing Superabsorbent Fibres. Fibres & Textiles in Eastern Europe 2006; 14, 1(55): 57-61. 17. Bartkowiak G. Influence of Undergarment Structure on the Parameters of the Microclimate under Hermetic Protective Clothing. Fibres & Textiles in Eastern Europe 2010; 18, 4(81): 82-86. 18. Wawro D, Ciechańska D, Stęplewski W, Bodek A. Chitosan Microfibrids: Preparation, Selected Properties and Application. Fibres & Textiles in Eastern Europe 2006; 14(57): 97-101. 19. Stęplewski W, Wawro D, Niekraszewicz A, Ciechańska D. Research into the Process of Manufacturing Alginate-Chitosan Fibres. Fibres & Textiles in Eastern Europe 2006; 14(58): 25-31. 20. Wawro D, Struszczyk H, Ciechańska D, Bodek A. Investigation of the Process for Obtaining Microfibrids from Natural Polymers. Fibres & Textiles in Eastern Europe 2002; 10: 23-26. 21. Das A, Kothari VK, Makhija S, Avyaya K. Development of High-Absorbent LightWeight Sanitary Napkin. J. Appl. Pol. Sci. 2008; 107: 1466–1470. 22. Nowicka C. Composite Nonwovens: The Bonding Durability of Sorbent Particles. Fibres & Textiles in Eastern Europe 2003; 11(42): 46-49. 24. Nowicka C. Porównawcze badania zdolności adsorpcji węgli aktywnych i włóknin kompozytowych PP meltblown/węgiel aktywny. Prace Instytutu Włókiennictwa, Łódź, Rocznik XLVI, 1994-1995; 59-67. 25. Bartkowiak G, Szucht E. Liquid Sorption in Two-Layer Packets of Structurally Differentiate Knitted Materials. Fibres & Textiles in Eastern Europe 2002; 1(55): 57-61. 26. Sadikoglu TG. Effect on Comfort Properties of Using Superabsorbent Fibres in Nonwoven Interlinings. Fibres & Textiles in Eastern Europe 2005; 13(51): 54-57. 27. Irzmańska E, Dutkiewicz J, Irzmański R. New approach to assessing comfort of use of protective footwear with a textile liner and its impact on foot physiology. Text. Res. J. 2014; 84(7): 728–738. Received 07.07.2014 142 FILTECH 2016, Cologne THE FILTRATION EVENT 2016 Conference, exhibition and short courses October 11 - 13, 2016, Cologne, Germany FILTECH 2016 Conference will feature once again the latest advances and techniques in liquid/solid and gas/particle separation (dust, gas & air filtration) in 3 days of in depth exposure. Technology and know-how transfer is a main target. The topics are fundamentals, equipment and strategies to “Solid-LiquidSeparation” by filration and sedimentation, as well as “Air and Gas Cleaning’” by filtration, setting, electrostatic precipitation, scrubbing, and “Membrane Separation Technology”. Plenary Lecture n Prof. Gerhard Kasper, Karlsruhe Institute of Technology, Germany Gas Cleaning with Pulse-Jet Filters: Emission Sources and Dust Abatement Strategies Keynote Lectures n Dr. Christof Asbach, IUTA, Germany Long-term Stability and Energy Efficiency of Filtration Solutions n Prof. Anti Häkkinen, Lappeenranta University, Finland Role of Solid/Liquid Separation Technology in Circular Economy n Prof. Eiji Iritani, Nagoya University, Japan Approach to Membrane Filtration from the Perspective of Cake and Blocking Filtration Laws nProf. Hans Theliander, Chalmers University, Sweden On local Cake Properties in Liquid Filtration n Prof. Peter Walzel, Dr.-Ing. Damian Pieloth, Technical University Dortmund, Germany Dust Removal in Scrubbers - State oft the Art and Challenges n Dr. Wolfgang Witt, Sympatec GmbH, Germany Particle Size and Shape Analysis for Laboratory and Process Environment Enginneers, managers, researchers and scientilists are invited to submit an Abstract for the FILTECH 2016 Conference. FILTECH exhibition has an established track record in bringing together the technical and commercial sectors to develop global business relationships. This Exhibition is a must for all those concerned with designing, improving, selling or researching filtration and separation equipment and services. FILTECH is the international platform and solution provider for all industries covering every market segment. One day prior to FILTECH 2016 two 1-day short courses will be held: nSolid/Liquid Separation - Dr.-Ing. Harald Anlauf - Academic Director at the Karlsruhe Institute of Technology (KIT). nFine Dust Separation - Prof. Dr.-Ing. habil. Eberhard Schmidt - Full Professor for Safety Engineering/Environmental Protection at Wuppertal University. For further details see: www.filtech.de →Conference Reviewed 23.02.2015 FIBRES & TEXTILES in Eastern Europe 2015, Vol. 23, 6(114)