Investigation of the Mechanics and Performance of Woven Fabrics Using

advertisement

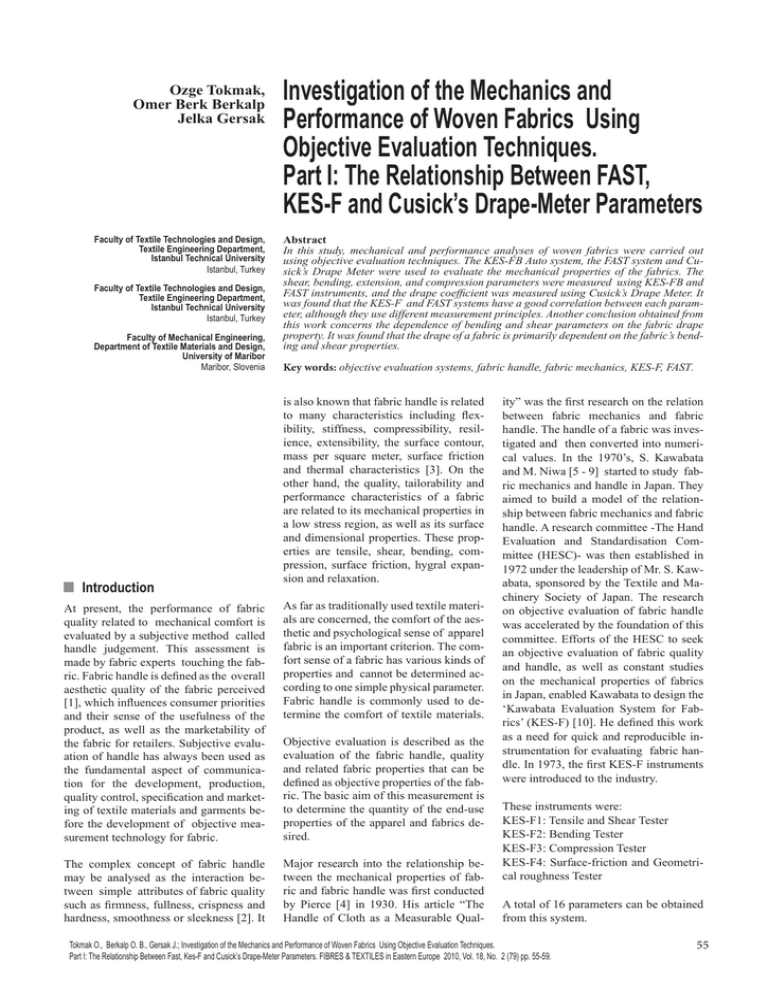

Ozge Tokmak, Omer Berk Berkalp Jelka Gersak Faculty of Textile Technologies and Design, Textile Engineering Department, Istanbul Technical University Istanbul, Turkey Faculty of Textile Technologies and Design, Textile Engineering Department, Istanbul Technical University Istanbul, Turkey Faculty of Mechanical Engineering, Department of Textile Materials and Design, University of Maribor Maribor, Slovenia n Introduction Investigation of the Mechanics and Performance of Woven Fabrics Using Objective Evaluation Techniques. Part I: The Relationship Between FAST, KES-F and Cusick’s Drape-Meter Parameters Abstract In this study, mechanical and performance analyses of woven fabrics were carried out using objective evaluation techniques. The KES-FB Auto system, the FAST system and Cusick’s Drape Meter were used to evaluate the mechanical properties of the fabrics. The shear, bending, extension, and compression parameters were measured using KES-FB and FAST instruments, and the drape coefficient was measured using Cusick’s Drape Meter. It was found that the KES-F and FAST systems have a good correlation between each parameter, although they use different measurement principles. Another conclusion obtained from this work concerns the dependence of bending and shear parameters on the fabric drape property. It was found that the drape of a fabric is primarily dependent on the fabric’s bending and shear properties. Key words: objective evaluation systems, fabric handle, fabric mechanics, KES-F, FAST. is also known that fabric handle is related to many characteristics including flexibility, stiffness, compressibility, resilience, extensibility, the surface contour, mass per square meter, surface friction and thermal characteristics [3]. On the other hand, the quality, tailorability and performance characteristics of a fabric are related to its mechanical properties in a low stress region, as well as its surface and dimensional properties. These properties are tensile, shear, bending, compression, surface friction, hygral expansion and relaxation. At present, the performance of fabric quality related to mechanical comfort is evaluated by a subjective method called handle judgement. This assessment is made by fabric experts touching the fabric. Fabric handle is defined as the overall aesthetic quality of the fabric perceived [1], which influences consumer priorities and their sense of the usefulness of the product, as well as the marketability of the fabric for retailers. Subjective evaluation of handle has always been used as the fundamental aspect of communication for the development, production, quality control, specification and marketing of textile materials and garments before the development of objective measurement technology for fabric. As far as traditionally used textile materials are concerned, the comfort of the aesthetic and psychological sense of apparel fabric is an important criterion. The comfort sense of a fabric has various kinds of properties and cannot be determined according to one simple physical parameter. Fabric handle is commonly used to determine the comfort of textile materials. The complex concept of fabric handle may be analysed as the interaction between simple attributes of fabric quality such as firmness, fullness, crispness and hardness, smoothness or sleekness [2]. It Major research into the relationship between the mechanical properties of fabric and fabric handle was first conducted by Pierce [4] in 1930. His article “The Handle of Cloth as a Measurable Qual- Objective evaluation is described as the evaluation of the fabric handle, quality and related fabric properties that can be defined as objective properties of the fabric. The basic aim of this measurement is to determine the quantity of the end-use properties of the apparel and fabrics desired. ity” was the first research on the relation between fabric mechanics and fabric handle. The handle of a fabric was investigated and then converted into numerical values. In the 1970’s, S. Kawabata and M. Niwa [5 - 9] started to study fabric mechanics and handle in Japan. They aimed to build a model of the relationship between fabric mechanics and fabric handle. A research committee -The Hand Evaluation and Standardisation Committee (HESC)- was then established in 1972 under the leadership of Mr. S. Kawabata, sponsored by the Textile and Machinery Society of Japan. The research on objective evaluation of fabric handle was accelerated by the foundation of this committee. Efforts of the HESC to seek an objective evaluation of fabric quality and handle, as well as constant studies on the mechanical properties of fabrics in Japan, enabled Kawabata to design the ‘Kawabata Evaluation System for Fabrics’ (KES-F) [10]. He defined this work as a need for quick and reproducible instrumentation for evaluating fabric handle. In 1973, the first KES-F instruments were introduced to the industry. These instruments were: KES-F1: Tensile and Shear Tester KES-F2: Bending Tester KES-F3: Compression Tester KES-F4: Surface-friction and Geometrical roughness Tester A total of 16 parameters can be obtained from this system. Tokmak O., Berkalp O. B., Gersak J.; Investigation of the Mechanics and Performance of Woven Fabrics Using Objective Evaluation Techniques. Part I: The Relationship Between Fast, Kes-F and Cusick’s Drape-Meter Parameters. FIBRES & TEXTILES in Eastern Europe 2010, Vol. 18, No. 2 (79) pp. 55-59. 55 Table 1. Fabric properties. Fabric No. 1 2 3 4 5 Material 11 12 %100 wool %100 wool %100 wool %100 wool %100 wool %80 wool %8 polyamid %8 polyester %4 elastan %88 wool %8 polyamid %4 elastan %88 wool %8 polyamid %4 elastan %54 polyester %44 wool %2 elastan %54 polyester %44 wool %2 elastan %55 polyester %45 wool %55 polyester %45 wool 13 %50 polyester %50 wool 6 7 8 9 10 20 %40 wool %45 polyester %15 linen %40 wool %45 polyester %15 linen %80 wool %20 polyester %75 wool %25 mohair %55 polyester %45 wool %54 polyester %44 wool %2 elastan %50 polyester %50 wool 21 %50 polyester %50 wool 14 15 16 17 18 19 Yarn Count, Nm Twist t.p.m. - Linear Density, gr/m Warp Weft 77/2 - 811 - 0.026 78/2 - 812 - 0.026 72/2 - 678 - 0.028 38/1 - 706 - 0.026 78/2 - 815 - 0.026 78/2 - 833 - 0.026 80/2 - 813 - 0.025 80/2 - 821 - 0.025 70/2 - 710 - 0.029 37/1 - 760 - 0.027 Weave design Weight, g/cm2 2/1 twill 2/1 twill plain plain plain 165 165 145 140 160 72/2 - 718 - 0.028 72/2 - 741 - 0.028 plain 170 72/2 - 795 - 0.028 72/2 - 742 - 0.028 72/2 - 782 - 0.028 72/2 - 753 - 0.028 plain 2/2 basket and 180 66/4 - 520 - 0.030 66/4 - 474 - 0.030 2/2 filling rib 260 80/2 - 854 - 0.025 80/2 - 837 - 0.025 2/1 twill 210 100/2 - 934 - 0.020 100/2 - 917 - 0.02 2/1 twill 160 82/2 - 900 - 0.024 80/2 - 814 - 0.025 56/2 - 690 - 0.036 70/2 - 750 - 0.029 56/2 - 600 - 0.036 80/2 - 880 - 0.025 80/2 - 891 - 0.025 82/2 - 851 - 0.024 56/2 - 670 - 0.036 70/2 - 736 - 0.029 56/2 - 698 - 0.036 80/2 - 891 - 0.025 2/1 twill 3/1(+2 -1)twill 2-2/2-5(+3)twill plain 165 165 320 155 54/2 - 680 - 0.037 57/2 - 663 - 0.035 4/4 basket 200 16/1 - 541 - 0.063 76/2 - 837 - 0.026 80/2 - 912 - 0.025 16/1 - 534 - 0.063 38/1 - 765 - 0.026 80/2 - 850 - 0.025 2/1 twill plain 2/1 twill 250 140 170 80/2 - 867 - 0.025 80/2 - 806 - 0.025 2/1 twill 185 46/2 - 602 - 0.043 46/2 - 612 - 0.043 2/2 twill 295 67/2 - 866 - 0.030 65/2 - 875 - 0.031 2/1 twill 205 Table 2. Results of tightness factors, the cover factor and weave factor. Tightness 56 FAST consists of three instruments and a test method to measure, in particular, the properties of wool and wool-blend fabrics related to their making-up properties, as well as the tailoring performance and appearance of tailored garments during wear. The instruments of the FAST system are; FAST-1: Compression Meter FAST-2: Bending Meter FAST-3: Extensibility meter FAST-4: It is a test method to measure dimensional stability: relaxation shrinkage and the hygral expansion of fabrics. Using the FAST system, 14 parameters can be measured and calculated. The aim of this study was to analyse the mechanical and performance characteristics of wool and wool-blended fabrics using both of the objective evaluation systems, and to search for a reliable relationship between the physical and mechanical properties of the fabrics. Weave factor Fabric No. Russell Galuszynski Seyam and El-Shiekh Cover factor Warp Weft 1 0.727 0.686 0.696 0.687 1.500 1.500 2 0.887 0.816 0.849 0.779 1.500 1.500 3 0.756 0.696 0.756 0.614 1.000 1.000 4 0.737 0.678 0.737 0.602 1.000 1.000 5 0.918 0.824 0.918 0.705 1.000 1.000 6 0.777 0.714 0.777 0.625 1.000 1.000 7 0.799 0.735 0.799 0.640 1.000 1.000 8 0.746 0.679 0.709 0.710 2.000 1.250 9 0.745 0.683 0.694 0.686 1.500 1.500 10 0.685 0.645 0.655 0.656 1.500 1.500 11 0.700 0.660 0.670 0.667 1.500 1.500 12 0.690 0.650 0.655 0.675 1.714 1.500 13 0.948 0.909 0.902 0.993 2.750 1.830 14 0.727 0.669 0.727 0.594 1.000 1.000 15 0.584 0.524 0.509 0.716 4.000 4.000 16 0.855 0.806 0.818 0.736 1.500 1.500 17 0.931 0.831 0.931 0.708 1.000 1.000 18 0.677 0.638 0.648 0.649 1.500 1.500 19 0.713 0.672 0.682 0.679 1.500 1.500 20 0.846 0.792 0.786 0.812 2.000 2.000 21 0.785 0.740 0.751 0.725 1.500 1.500 FAST (Fabric assurance by simple testing) was later developed by CSIRO (Australia’s Commonwealth Scientific and Industrial Research Organisation) as an alternative to the KES-F system to provide the industry with a simple, ro- finishing, the evaluation of new technologies (spinning system, finishing machinery), and in buying control for garment makers. bust, relatively inexpensive system for objective measurement of the mechanical properties of fabrics. It is mainly used by manufacturers, finishers and garment makers. The FAST system can be used in fabric development, the optimisation of n Materials and methods Twenty one wool (100%) and wool blended woven suiting fabrics, with a fineness which varied from 19.5 to 21.5 micron, were used in this study. The properties of the fabrics used in this study are shown in Table 1. The weave tightness, defined as the ratio of the cloth construction parameters to the corresponding parameters of the reference fabric, the cover factor, which is a number derived from the number of warp (or weft) threads per unit length and the linear density of the yarns, indicating the extent to which the area of a woven fabric is covered by warp (or weft) yarns, and the weave factor, which is defined as the ratio of the thread amount to the interlacing amount, were calculated. The tightness factors were calculated according to Galuszynski [15], Russell [16], Seyam and El-Shiekh [16, 17]. Results of the tightness factors, cover factors and weave factors are given in Table 2. The KES-FB Auto and FAST systems were used to evaluate mechanical properties of the fabrics: the extension, bending rigidity, and shear rigidity. The fabric drape (drape coefficient) was measured using Cusick’s Drape meter (Table 3). FIBRES & TEXTILES in Eastern Europe 2010, Vol. 18, No. 2 (79) Table 3. Results of mechanical properties evaluated by FAST, KES-FB and the drape coefficient (evaluated by Cusick’s Drape meter). Fabric type KES-FB test results FAST test results Bending rigidity B, cN.cm²/cm 01 2,74 0,059 0,090 0,94 2,60 5,45 0,090 46 0,394 02 2,89 0,068 0,098 0,91 2,55 6,45 0,108 44 0,391 03 2,98 0,046 0,033 1,10 3,05 3,95 0,042 55 0,385 04 3,50 0,046 0,044 1,16 3,50 4,05 0,040 57 0,339 05 6,00 0,057 0,060 0,81 6,20 4,80 0,056 37 0,365 06 8,48 0,044 0,054 0,74 8,70 4,30 0,070 30 0,339 07 9,09 0,050 0,042 1,11 9,30 3,95 0,047 43 0,341 08 9,23 0,086 0,056 1,74 8,50 6,70 0,066 60 0,400 09 12,80 0,057 0,118 0,98 13,85 5,70 0,090 36 0,404 10 7,08 0,036 0,109 0,91 7,55 4,10 0,092 44 0,409 11 1,99 0,051 0,073 0,91 2,05 3,85 0,068 39 0,383 12 2,13 0,048 0,059 1,01 2,10 4,55 0,064 43 0,360 13 1,54 0,244 0,126 1,65 1, 00 15,70 0,095 79 0,529 14 2,22 0,064 0,114 1,04 2,45 6,45 0,104 50 0,511 15 1,87 0,088 0,176 0,50 1,90 7,55 0,152 19 0,478 16 4,27 0,162 0,231 1,51 3,60 11,15 0,203 66 0,509 17 3,24 0,052 0,043 0,97 3,35 4,25 0,045 46 0,427 18 2,97 0,045 0,078 0,67 3,45 3,80 0,057 29 0,342 19 8,16 0,056 0,185 0,98 8,45 5,30 0,162 35 0,449 20 2,29 0,246 0,279 3,14 1,75 36,05 0,218 738 0,748 21 2,08 0,097 0,113 1,73 1,85 9,70 0,110 82 0,497 n Results and discussion Comparison of FAST and KES-FB parameters The first step of this study was to compare the two objective evaluation systems. As shown in Figure 1, the correlation between FAST and KES-FB values was as high as expected. The correlation coefficients between the two systems were found to be 0.93 for the shear parameter, 0.98 for the compression parameter, 0.99 for the extension parameter and 0.88 for the bending parameter. These values show that FAST and KES-F instruments measure similar values, although they use different measurement principles. As also shown in literature [11, 12], the values show a similarity between previous studies and the present one. Consequently, both the FAST and KES-FB instruments can be used effectively to measure the mechanical properties of fabrics. Shear rigidity G, cN/cm.deg Drape test results Extension EM, % Compression energy WC, cN.cm/cm² Extension E100, % Bending Rigidity B, μN.m Compression surface thickness ST, mm Shear G, N/m and shear properties that are the most important, which are known as the primary dependent properties for fabric drape. In view of this it was decided to correlate the drape coefficient with the bending and shear properties from both systems (FAST and KES-F) to validate the correlation of these parameters. The correlation between the drape coefficient, FAST bending and shear properties was high, as can be seen in Figure 2. Drape coefficient According to Figure 2 (see page 58), the correlation coefficients are 0.91 between the drape ratio and FAST bending parameter, and 0.80 between the drape ratio and FAST shear parameter. The correlation between the drape ratio and bending is higher than the shear, which is a sign that the bending property is more related to the drape property than the shear. The correlation between the drape ratio, KES-F bending and shear properties is Comparison of the drape coefficient, bending and shear properties Drape is the term used to describe the way a fabric hangs under its own weight. It has an important role in how good a garment looks in use. The draping behaviour required from a fabric will differ widely depending on its end-use. Drape is a very complex attribute of a fabric and is dependent on most of the physical and mechanical properties of a fabric; however, of all of them, it is the bending FIBRES & TEXTILES in Eastern Europe 2010, Vol. 18, No. 2 (79) Figure 1. Comparison of KES-FB and FAST parameters. 57 Drape = Kb×0.866 + Ks×0.602×10-1 + (1) + 0.288 (r = 0.862) Drape = Kb×1.059 + Ks×0.604×10-1 + - Tg×0.251 + 0.452 (r = 0.883) (2) Drape = Kb×0.940 + Ks×0.625 + - Ts×0.170 + 0.407 (r = 0.879) (3) Drape = Fb×0.948×10-2 + (4) Fs×0.812×10-4 + 0.357 (r = 0.824) Figure 2. Comparison between the drape coefficient and FAST bending and shear values. Drape = Fb×1.145×10-3 + - Fs×0.324×10-4 + Tg×0.181 + + 0.223 (r = 0.838) (5) Drape = Fb×1.039×10-3 + + Fs×0.345×10-4 + Ts×0.066×10-1 + (6) + 0.306 (r = 0.827) where; Kb - KES-F bending value Ks - KES-F shear value Fb - FAST bending value Fs - FAST shear value Tg - Tightness of Galuszynski Ts - Tightness of Seyam Figure 3. Comparison between the drape ratio, KES-F bending and shear values. n Conclusions In this research, the mechanical properties of wool and wool blended fabric were measured using objective evaluation systems. The relationship between the KESFB and FAST systems and that between the drape ratio and the bending and shear properties measured by the FAST and KES-FB systems were investigated. The following conclusions can be drawn from the findings of these investigations: It was found that the KES-FB and FAST systems have a good correlation between each parameter, although they use different measurement principles. Figure 4. Relationship between the bending and shear Properties measured and the FAST, KES-FB and drape coefficients. also high, as shown in Figure 3. According to Figure 3, the correlation coefficients are 0.83 between the drape ratio and KES-F bending parameter, and 0.79 between the drape ratio and KES-F shear parameter. The correlation coefficients are very similar for both comparisons of the drape with FAST and KES-F bending and shear parameters. It is once again shown that the fabric drape property is mostly related to fabric shear and bending properties. On the other hand, drape is a very complex attribute and is not only dependent on bending and shear parameters but also on other properties of fabrics; however, 58 their effects are not as high as the bending and shear, which is why the correlation coefficients are nowhere near 100%. Chen [13] also studied drape in which the drape coefficient was correlated with mechanical properties, and a correlation was found within the range of 60 to 95 percent for ten fabric samples. In the present study, the correlations found are in the same range as the literature. In the study, the drape ratio is also expressed by bending and shear properties, with both the FAST and KES-FB results and the tightness factor of Seyam and Galuszynski. The multi regression formulas derived are shown below: A high correlation was obtained between drape-shear and drape-bending parameters. It is once again seen that these are the primary parameters that effect drape. According to the statistical analyses, a high correlation was also obtained between multi regression models of drapeshear-bending and the additional tightness factor. The coefficients in the models were also found to be significant. Since the textile industry is still searching for a reliable method to end discussions between fabric manufactures and consumers over quality, it seems that objective evaluation systems like KES-FB and FAST will continue to be used and will have an important role in the future as today. FIBRES & TEXTILES in Eastern Europe 2010, Vol. 18, No. 2 (79) References 1. Kim J. O., Lewis Slaten, B.; Objective Evaluation of Fabric Hand: Part 1. Relationship of Fabric Hand by the Extraction Method and Related Physical and Surface Properties, Text. Res. J., 69, No. 1, (1999) pp. 59-57 2. Postle R.; Fabric Objective Measurement Technology, Int. J. of Cloth. Sci. and Tech., 2, 3/4 (1991). 3. Tyler D. J.; 1991. Materials Management in Clothing Production, BSP Professional Books, pp. 35-40. 4. Pierce F. T.; ‘The Handle’ of Cloth as a Measurable Quality, J. Text. Inst., 21, T377 (1930). 5. Kawabata S., Niwa M.; Objective Measurement of Fabric Mechanical Property and Quality: Its Application to Textile and Clothing Manufacture, Int. J. of Cloth. Sci. and Tech., 3, (1991) pp. 7-18. 6. Kawabata S., Niwa M.; Fabric Performance in Clothing and Clothing Manufacture, J.Text. Inst., 80, No. 1 (1989). 7. Kawabata S., Niwa M.; High Quality Fabrics for Garments, Int. J. of Sci. and Tech., 6, (1994) pp. 20-25. 8. Kawabata S., Ito K., Niwa M.; Tailoring Process Control, J. Text. Inst., 83, No.3 (1992). 9. Matsudaira M., Kawabata S., Niwa M.; The Effect of Fibre Crimp on Fabric Quality, J. Text. Inst., 75, No.4, (1984) pp. 273-277. 10. Bishop D. P.; Fabrics: Sensory and Mechanical Properties, Textile Progress, Vol. 26, No. 3 (1996). 11. Barndt H., Fortess F., Wiener M., Furniss J. C.; The Use of KES and FAST Instruments: In Predicting Processability of Fabrics in Sewing, Int. J. of Cloth. Sci. and Tech., 2, 3/4, (1990) pp. 34-39. 12. Ly N.G., Tester D. H., Buckenham P., Roczniok A. F., Adriaansen A. l., Scaysbrook F., De-Jong S.; Simple Instruments for Quality Control by Finishers and Tailors, Text. Res. J., 61, No. 7, (1991) pp. 402-406. 13. Chen B., Govindoraj M.; A Parametric Study of Fabric Drape, Text. Res. J., 66, No. 1, (1996) pp. 17-24. 14. Geršak J.; Study of relationship between fabric elastic potential and garment appearance quality, Int. J. of Cloth. Sci. and Tech., 16, No. 1/2, (2004) pp. 238-251. 15. Galuszynski S.; Fabric Tightness: A Coefficient to Indicate Fabric Structure, J.Text.Inst., 72, (1981) pp. 44-49. 16. Seyam A. M.; Structural Design of Woven Fabrics, The Textile Institute, 66, No.3 (2002). 17. Seyam A., Aly El-Shiekh; Mechanics of Woven Fabrics Part III: Critical Review of Weavability Limit Studies; Text.Res.J., 63, (1993) pp. 371-378. Received 09.06.2008 , Instytut Biopolimerów i Włókien Chemicznych Institute of Biopolymers and Chemical Fibres Multifilament Chitosan Yarn The Institute of Bioploymers and Chemical Fibres is in possession of the know- how and equipment to start the production of continuous chitosan fibres on an extended lab scale. The Institute is highly experienced in the wet – spinning of polysaccharides, especially chitosan. The Fibres from Natural Polymers department, run by Dr Dariusz Wawro, has elaborated a proprietary environmently-friendly method of producing continuous chitosan fibres with bobbins wound on in a form suitable for textile processing and medical application. Multifilament chitosan yarn We are ready, in cooperation with our customers, to conduct investigations aimed at the preparation of staple and continuous chitosan fibres tailored to specific needs in preparing non-woven and knit fabrics. We presently offer a number of chitosan yarns with a variety of mechanical properties, and with single filaments in the range of 3.0 to 6.0 dtex. The fibres offer new potential uses in medical products like dressing, implants and cell growth media. Instytut Biopolimerów i Włókien Chemicznych ul. Skłodowskiej-Curie 19/27; 90-570 Łódź, Poland; Phone: (48-42) 638-03-02, Fax: (48-42) 637-65-01 E-mail: ibwch@ibwch.lodz.pl http://www.ibwch.lodz.pl Reviewed 07.09.2009 FIBRES & TEXTILES in Eastern Europe 2010, Vol. 18, No. 2 (79) 59