RELATION OF MOISTURE CONTENT AND DRYING RATE OF WOO D

advertisement

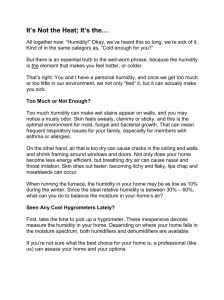

RELATION OF MOISTURE CONTENT AND DRYING RATE OF WOO D TO RELATIVE HUMIDITY OF ATMOSPHER E Revised, May 194 1 UNITED STATES DEPARTMENT OF AORI'Cl)Lff rRE )FOREST SERVIC E FORE-ST PRODUCTS LABORATOR Y Madison, Wisconsi n In Cooperation with the University of Wisconsin RELATION OF MOT 8TURE CONTENT AND 3RYI NG - T , -® F' WOO D TO RELATIVE HUMIDIFY OF ATMOSPHERE It is well known that wet wood gives off moisture under ordinar y atmospheric conditions, and that dry wood takes on moisture in damp weather . This causes a corresponding shrinkage and swelling, coeuai€nlQy known a ;s: "working ." As a result, doors, sash, and drawers frequently stick in damp weather and became -loose in dry weather . Wooden parts may check, warp, o r open up at the joints wYeh the relative hunU .dity of the air is low, o r expand excessively When it- is high . In fact, even properly seasoned wood under ordinary conditions dail y takes on or gives off moisture to accommodate itself to changing at-mo.spheri: c conditions, This property,' which is known as "hygroscopicity," is als o found in many other, materials, such as paper, clothing, hay, leather, and soil, The purpose of this article is to give informat on as to how th e relative humidity in the atmosphere outdoors, in the dry kiln, in the wood working shop, in_ the storage room, or elsewhere affects the moisture con tent of wood . A brief technical discussion of atmbbsphe .rie humidity an d how it may be accurately'determined is also included . Much of this information has been obtained though the researches of the U . S . Forest Products Laboratory . Fundamental Relation of - : foi :sture Content of Wood to Atmospheric Condition s The combination of water and wood may be oonside'red a solution o f water in wood, the wood being ._the solvent and the water t .lit solute . Them e is definite limrt to the amount of water that can be diss .olylOd In the'. Ve .ra, i and when this point is reached the wood is said_to be saturated . This i s commonly called , the "fiber-saturation point ." The vapor pressure at thi s time equals the saturate vapor pressure at the existing temperature, an d therefore the -wood is at equilibrium with 100percent relative humidity . As the amount of water in the wood-water solution decreases the vapor pressure decreases ; hence, the wood is at equilibrium with lowe x_ relative humidities . This relationship is shown by the curves in Figure 1 . These curves were constructed from data obtained on Sitka spruce, but areaija general applicable to all species . For example, wood expoterd to *relative humidity of 6 0 percent at 160° F . will finally attain . a-moistl-re •coat:ont of approximately S percent . It is interesting to note that changes in .relative, :4umidity , are more critical on moisture content than are changes to temperature . R509 Significance of Relative Humidity in Air Drying Woo d In air drying, lumber finally reaches a definite moisture conditio n below which it does not go, no matter how long it is kept on stickers , provided the atmospheric conditions remain fairly constant . Black walnut , after being stored in an unheated shed for 60 years at the Rock Island Arsenal, had a moisture content of 11 .6 percent, based on the oven dry weight , The moisture content of small blocks (1-1/2 by 1-1/2 by S inches ) air-dried under cover in an open sheda t , New Haven, Conn ., for over a year , is given in Table 1 : Table 1 .--Moisture content of small blocks throughl y air seasoned at New Haven, Conn . Moisture conten t Percent 13 . 3 Longleaf pine Loblolly pine Red spruce Eastern white pine California red fir White ash Hard maple Red ash Sweetgum Chestnut 14 . 7 15 . 0 13 . 4 14 . 1 14. 4 14 . 9 14 . 9 14 . 9 13 In a drier climate these specimens would have dried down to a lowe r moisture content, and in a damp climate they would not have become so dry . Wood thoroughly air dried in the humid parts of France and England is sai d finally to reach from 15 to 17 percent moisture . Table 2 shows how the relative humidity varies with the seasons i n different parts of the United States . In general, the outdoor relativ e humidity is highest in winter and lowest in spring, although exception s occur in some parts of the country . By means of the curves in Figure 1 , the ultimate dryness of small pieces of wood during the different season s and in various parts of the United States may be estimated . For example , at Seattle, Wash ., the ultimate dryness of pieces of wood unprotected fro m the weather, except from snow and rain, will be reached in the winter an d will be at about 19 percent moisture, whereas in western Texas, it will b e reached in the spring and will be about 6 percent moisture . This seasonal and geographic variation in relative humidity i s important in connection with the rate at which drying proceeds . Lumbe r exposed to the spring and summer atmosphere will dry most quickly, principally because of the comparatively low relative humidity at that time o f the year, but also because of the warmer temperature . For example, R509 -2 - A railroad ties, of ponderosa pine, cut in May and June arfecos, NI~Iex ;, we i practically seasoned in 1 month, while those cut in Nove+er and becembe r required about 6 months for seasoning . On the other hand, winter-cut lumbe r suffers less from checking and other defects during air seasoning . Dryin g is slow at first and when spring comes the lumber is already partly dry, s o that deterioration is not great . Furthermore, in any climate with a high relative humidity and warm temperature, lumber is more subject to infectio n with stain and decay-producing organisms than it is in drier climates . Table 2 .--Average relative humidities over a period of at least 15 year s at different seasons in various parts of the United States * Mean relative New York Cleveland, Madison, Bismarck, Havre, Spokane , humidity, percent Mont . Wash . City N. D . Ohio Wis . Winter Spring Summer Fall Annual mean 73 70 74 75 73 :. 82 70 71 75 74 77 72 70 74 73 r82 61 47 67 64 79 66 56 6s 67 73 6s 65 71 69 Seattle, Portland, Salt Lake City, Denver, Kansas City, Memphis, Washington , D .C . ., ,-gash Tenn . Ore, Utah Colt, . Mo . 74 72 g4 g3 75 7 6 9 52 51 73 72 69 7 75 )49 7 65 67 36 70 869 51 46 71 79 72 71 73 76 75 53 50 Chattanooga, Wilmington, Jacksonville , Tenn . N. C. Fla . 75 70 78 77 75 Phoenix, Ariz . San Diego, Calif . 45 47 74 78 81 78 78 4 , 40 *46 38 Galveston , Tex . 84 82 79 78 79 75 78 77 77 77 79 75 78 El Paso, Tex . ,41 27 tt. 74 80 83 79 32 32 New Orleans , La . so so 78 78 83 81 80 Pensacola , Fla . San Francisco, Calif . sl Sacramento , - Calif . 80 71 61 66 69 79 79 84 80 80 Weather Bureau Bull . Q, "Climatology of the United States . " ry The effect of differences in locality on the drying rate is als o marked., even iip 'he same latitude . For example, while the ponderos a pine ties at Pecos, $ . MAT, . seasoned in 1 month, shortleaf and lobloll y :; R509 -3 1 L. f■ i .". mu 5 ' 1 1 1 tiY . r I err,'F-, - pine ties cut at the same .time of year in eas,txn Texas required from 3 to 4 months for 'seasoning . This was dui• princi iI Ly Rt;e4iffer-q es in th e relative hum fttei _Pecos being in . a comp +ative"ly . 'y'r: ion, .Wh reas the. , '°' •' F climate in eastern Texas is mere humid ; =~: = in Connection with Kiln" Drying; and Conditioning of Lumber • Relat. ve H ni.djty r- • " ' A1thde gh the relative humidity has an importa ti : effect on the dryin g rate of a pile of lumber being air seasoned, this effect is less whe n lumber is kiln dried . The rate of aar circiilation within a pile of lumbe r being air seasoned is low, conseq-dently air entering-at a high -relativ e humidity rapidly'approaches saturation and greatly deereases its capacit y for drying l The circulatioa of air within a pile of lumber in a dr y is usually l ; much greater than that in an air-seasoning . pile, an_d"therefor` e air entering at a high relative humidity does not appreach . so' near saturation before it leaves the pile . The chief functions of relative humidit y i4. .the kiln drying of lumber . are the regulation of the surface drynes s the TaguJation of the ultimate moisture content to which the'lnmbe r Wi l l dry ., . r . During the early stages• of drying in a kiln, a comparatively highs: .. relative humidity is used, especially . if the lumber is green, so as to_ pm event . the surface from reaching too low a moisture contentt with 0e0g;tant n. checking and casehardening . This must be aecomPanied by good c'i're-ul otherwise the atmosphere 'id-thin the pile will rapidly approach satui Mfr 'r r @ual4-tbie end of the drying, when there is ' less'danger of ' injury, a compara-r kFre- r . 1qw relative ,humidity may be used in order to dry the lumber to th e desir,e, .final moisture content . If it is desirable to condition lumber for the relief of casehardening stresses during the kiln drying process, the relative humidity can b e so manipulated that the ,sufaces absorb moisture while the center is stil l . drying; The seasoning of lumber which is not to be dried to a low averag e moist..re,;content may be hastened by drying the surface layers down to a low,e' moistllr-e content than is ultimately desired . The kiln drying operatiom;may !be stopped before-the center has reached the desi =red m'o'istur e •ce te3rltbecause the moisture will continue to move from the wetter ce1nte r %tom the-drier -surface, layers until the, desired ultimate average moi's'tur e content-'has been reaches'. Relative Humidity in Storage Sheds, Shops, and Buildings in Genera l 3,1 Fro m what has already been said it will be seen that by properly con From trolling the temperature and the relative humidity of the surrounding air , *,. seasoned lumber may be kept at any desired moisture content . For eY R509 -44- flooring stored in a shed may be kept at about percent moistur e indefinitely if the relative humidity is held at about 42 percent when th e temperature is around 70° and slightly higher at higher temperatures an d lower at lower temperatures . (See Fig . 1,) In factories making furnitur e and other wooden products requiring a low moisture content, particular car e should be taken to keep the doors and windows closed in damp weather . O n the other hand, in winter when the air is heated, it may be advantageou s to raise the humidity artificially to at least 30 percent . The same principle applies also to storerooms in which the finished articles are kept . One source of trouble in plants manufacturing wooden products whic h must meet exacting demands lies in not keeping the relative humidity fairl y constant throughout the plant . For example, the dry lumber may be stored i n a room where the temperature is 60° F . and the relative-humidity 60 percent . Under such conditions the moisture content of the lumber will tend to go up to 11 percent . This lumber may then be taken into the shop and worked up a t 70° and a relative humidity of 49 percent . As a result, the moisture con tent of the lumber will fall more rapidly, especially if it is in smalle r pieces, to about 9 percent . Later, the completed article may be put int o the finishing room where the temperature is 80° . This rise in temperatur e alone will lower the relative humidity of the shop air to 34 percent and the lumber will dry out to about 6 percent moisture . The finished produc t may then be stored in a room where the temperature is again 60° and the .relative humidity 60 percent with the result that the wooden parts wil l take on moisture and swell, When the article later appears in the store , office, or home, it may again dry out, checks may form, and glue joint s . .may open up . In general, changes in moisture with small change in relativ e humidity take place slowly, especially if the wood is coated on all side s with varnish, shellac, paint, or other protective coatings . Although suc h coatings do not prevent the absorption of moisture, they do retard it . The moisture content which wood has at the time of manufactur e should correspond approximately to the average it will eventually attai n in use, or slightly less, The relative humidity of the air surrounding the article in use should, therefore, govern the extent to which lumber i s dried, This is of particular importance to manufacturers of furniture , cabinets, and other wooden products in which shrinking and swelling must b e reduced to a minimum . Wooden articles sent to the coastal regions of th e south Atlantic, Gulf,-and Pacific States where the outdoor relative humidit y is comparatively high the greater part of the year (Table 2) and wher e buildings are heated during a small portion of the year only, should hav e a higher moisture content than similar wooden articles sent to the Rock y Mountain region or to the inland valleys of the Southwest, where th e relative humidity is comparatively low . Explanation of Humidit y i • gee? Although it is generally understood that by humidity is meant th e moisture in the air, it is believed that a more detailed explanatio n will be of value . -5- II ' Absolute humidity means the actual amount of moisture present in th e air in the form of vapor . This may be expressed in grains per cubic foot , or grams per cubic meter, or in any other suitable units . The maximum amount of moisture air can hold in the form of vapo r varies with the temperature, as follows : Temperature ° F . Number of grains of moisture pe r cubic footwhensaturated 4o 6o SO 100 120 14o 16o 1SO 2.00 220 2 .9 5 .8 00 11 .0 0 20 .00 34 .00 57 .0 0 91 .0 0 140 .0 0 208 .0 0 *302 .00 *At 17 .2 pounds absolute pressure . In kiln drying, it is more convenient to express the amount of moisture in the air as a percentage of the moisture saturation at the temperature of the air . This is known as the relative humidity . For example, a t 100° F . the air can hold 20 grains of moisture per cubic foot when full y saturated, but if only 5 grains are present, the air is one-fourth saturated , or has a relative humidity of 25 percent . On the other hand, a relativ e humidity of 25 percent at 160° means that 22 .7 grains of moisture per cubi c foot are present . When the air is fully saturated, the relative humidit y is said to be 100 percent . Since the amount of moisture that air can hold varies with the temperature, it follows that heating air containing any fixed quantity o f vapor lowers its relative humidity, and, conversely, cooling air raises it s relative humidity . When air has been cooled sufficiently to become full y saturated, it is said to be at the dew point . If its temperature is lowere d still more, the air cannot hold all the moisture and condensation takes place . The Relation of Relative Humidity to Evaporatio n The average rate at which evaporation takes place from wet surface s depends considerably on the relative humidity of the air . At 100 percent relative humidity evaporation ceases entirely . However, the average rate o f evaporation is not altogether proportional to the relative humidity . Fo r example, at a relative humidity of 60 percent and a temperature of 110°, th e evaporation will take place at a certain rate, while at 60 percent relativ e humidity and 130° the rate will be much greater . The reason is that at th e 8509 -6 - S higher temperature the difference between the vapor pressure of the wate r in the wood and of the water vapor in the air is greater . In drying lumber, however, we do not have very wet surfaces, o r only for a very limited time, and therefore the average rate of drying in a kiln is only partially governed by its relative humidity . Another facto r enters in ; namely, the average rate at which the moisture comes to the surface of the wood . This average rate depends on the kind and thickness o f lumber, whether plain-sawed or quarter-sawed, sapwood or heartwood, as wel l as on the atmospheric conditions . Heat hastens the transfusion of the mois ture from the interior outward ; therefore, the temperature should be kept a s high as the lumber will stand, and the relative humidity should be regulate d accordingly . a- . -•. How to Determine Relative Humidit y Relative humidity in the dry kiln or in the atmosphere may be deter mined with a wet and dry-bulb hygrometer . A hygrometer is made by attachin g two similar thermometers to a convenient stand, the bulb of one being kep t moist by means of a wick which dips into a vessel of water . These instruments depend for their action on the fact that the drier the air, the mor e rapid will be the evaporation from a wet body exposed to the air . Sinc e evaporation requires heat, it follows that the extent to which a wet bod y is cooled by evaporation will depend upon the ability of the surroundin g air to absorb moisture . If the air is saturated, no evaporation takes plac e and the wet and dry-bulb thermometers read alike . If the air is no t saturated, evaporation will take place and the cooling effect of evaporatio n will cause the wet bulb to indicate a lower temperature than the dry bulb . The dry bulb gives the actual temperature, regardless of the relative humidit y To determine relative humidity by means of a hygrometer requires a fair circulation of air . At ordinary temperatures a circulation of at leas t 15 feet per second is required, but at higher temperatures the rate may b e lower . If the circulation is feeble it is necessary to fan the instrumen t before an accurate reading can be made . Read the temperatures and subtrac t the reading of the wet-bulb thermometer from that of the dry bulb thermometer . In the relative humidity table on the following page find the temperature o f across the table to th e the dry bulb in the left-hand column and follow column under "Difference Between Wet and Dry-Bulb Temperatures," as give n at the top of the table . The figure given in the table at the intersectio n is the relative humidity, expressed in percentage . As an example, the following may be taken : Dry-bulb temperature, 140° F . ; wet-bulb tempera Find the dry-bulb temperature in th e ture, 132' F . ; difference, 5° F . across the table to the proper colum n left-hand column, and follow under "Difference Between Wet and Dry-Bulb Temperature ." A 8° F . difference , we find the figure 79, which is the relative humidity expressed in per centage . R509 - 7- ■ ■ ■■ UM . ■■•■ ■ill■■■■■■■■ IMIMI . ■ II■■Ia■► ■■■: ■ ■ an ■■■■: jl Elll - ' -4; ■■ .. .M P g ~■ AMMON■■k . MfMl _ ■■l= =~1 1~1■■ ■ ■■■■■■ ■N!■l~ K1, 1 r ■■■ IM , lM .■ ■■■■■■ ■MM11 ;1 t~~■ EiEffnalEbia ___ : : , r -u~ - 1 I . ~r ► nwrodi ► i■iq fN St ... a N 4 'd (1N10 d1d) 1N?1NO .2 3dn1S/O W n 0 t N 4` MN"** MMM ,1,1 ,1.40 AA40 Am os.O-00 .N•1M* .141 .4. .4,4 .4 .-I NM100A 0404. 4 . 4 .0. M* .41.10w.4 x,I,11OO, M N 1^100,04 010M01M ,1,10404 11000 .4 .1-4 , 4 44 ..1 NN LIN00 .OAmO.O MN14M0 1 c,os00 .1 NNnM1 * 'aau\Ltoo 10,,,0 4 oN1^ NN N NNNNN NNNNN NNNNN MM M .INNN N 5 NNNN N 0N^^0 NNNN N NM •110 ,tl D\ .-4,4,-44 . 0 .444 .-I .4 . .-INMN N NNNN N MM* 0,4001 .4 .1 . .01441 .4 0 .4 .,10 NNNNN NNNN N MM*10 ,101MNNN04 .7 NNNN 0MM0 P .1 .1 K010 ♦ . 0 1-400,00 M .INN NNNNN N 40 1 M M10010P 04010041 14+0,04 mM,1NNN 010 MM NM4*41 100„mN MM,1 M,1M,1,1 NNNNM NNNN N041Atl 01M01 M* 4041-4001 .IN, ,^*414. 40 400 Am4001 00 NNNN NNNN NNNNN NNNNN NNNN N NNNN131, NNNNN 11040410 NNNNN NNNNN NNNNN 10,1-4 0m NNNNN NNNNM MMM NNN 01,0.1 04^0 5 050,00 0 NN,,, MA, , . NNNNN NNNNN 0405040.404 . NNNNN NNN101M1 M,,MM Pm0O+OS .1 NNMMI^ NNNNN 00 M 04,.04 0 MMMMM NNN, n :040404040 4 MM * 1 . . .I MMMMM ~y NMM 1n.n0Ml4 Np1 OO MMMM 1 M,M~1,,, M MY1ne.M ,,,~•, ,MMM, 1.10 4 0404,004404 041'0 040404 e0104104 1.1040 4 LAI-05 MM M 100401 MMM N 4041-040 .,. M0N NNNNN M* NNNN *10010 , 0 MNM*01 MM,1,1M ~ ,40 N NNN 010.1 MV y 41,04 .°4 .. .NyM'14 N0M*A M*10, 00010,1 0 44O Ato m N N 0 MM 4 .NN NNNNN NNNNN . ,0 41 ,0400N d1 1R0,tl 010,1N N M*41404 ,1-000101 1004 01° 4 01-1,000 000 ,504 000 .41-1,1,1 NNNNN NNNNN NNNN N A 4OMN4 M4N-WO. NNNNN 00NM* 41001-140010100 ..1 N MM NNN NNNNN NNNMM MM MM 1"1 M M,•M n,,, , ,, M,,,,•11.M1 Y1*' tl O M 1~, 1010,0401 OM M I= NNNNN N MO MM M 04050404 040',°05,04 0504mn,mn 04e01̀0000 000 Y 222= NNNNN MMO N .~1 N N .QIN NN NNNNN NNNNN RA= 0504040404 0504051-5 ,,,, 00010 1 . 0 154'1.010, 0-04400105 MN 4001005MMM 0(004 4 050050405 0504040505 01004 ,^7.4 .4 .4.4 NNNMM 01 1, M ,1010Atl .4-.1504 MONK," NNNNN 04101-40 NNNNN NMMMM 11113 Mo4 • 1 • ,1,11-1,1 . 4 • 0104 100,010 NM*01 NNNNN 10,,m01 .004 IIM M*10100 ^ ..NM MM M N NNNNN MMMM M 1^I+r~lAnl^N, 0,1,0,00 0000 0131 0 1 1-0 00 . O NN NNNNN NN N, . M ",,M ,,,,,,,,., ~nM1Mm1M.1MO1 11000 000.x.0 000X0 0010 010 '0 00N" 1410,01 01000N .04MM0~,MM 1010,1 p 1p 0101 pp MMNNM MM*11n 4/410/050 WO . ,041501 NNNN NNNNN NMMMM 04,"nM ,044^041041 11111 00004 .511 .40 11044\ 0M 004,141 .AWM01 OMNMM 0MM43, Amm0.01' OM,1 N M .. NNNNN NNNNN MMMMM """,, MMMMM .?1?1 00021 00 4111400 0000 u4Nn - • • ▪ • .a~rI .10i MMN NNNNN NNNMM ,,,^,+104041 0, .1M01MMM 4452 d 100 Am N0 00N^ 00M4 , M., 04,0 05005 040404040/ M N 140401041-4 N,m .10 ,1 .N 0 .1M01 ,1 -.t.,g N N N N . M MM 404 AMMAmM . .01̀0100 ,^011 • 2 I'N NN,O^MM Mf11M'g1ON. mN SM,.,1VNnM M*M PA,.A4mn 044110 ,,,,M M MPm MMMAY N -4"gN -';.; ,,,MM O ~ 01 ,,040 ?1M n m01 -0014\ NNM M ., M111 M 1* 01MNMM •a N4 1-, p:M1 Mg10Y01 2,1;1 M 0N,M .0000 0 00 00 • 2 pp11pp • 0 A M 0 A 1 0 q 0 • • • • MnMM Y . 0 .00100 00000 000 .0.0 3000.0 10 .04..04 11111 13004 aaaa 1 110a 1aaNN , , NMMM M 11 13111 11 3 004 10f1 10(4I1~c11[I MM M~1,m.1,m04 yy~1 1 00011 10100 1On 10 n401MM I[1N1[1tf11Nl M Mt N 11, .~~~y1 ▪ Am .411 0 0 000 101051MM 1~51(1 1N5MM 4141411/11 5 US414141 ~4( ~ ~. p p mmep ep p MMM*4 1 4110(4(1.0 r01O 00000 00131 011 .01 1 21/10[1 V..= = 1 N n 4/445414/ 414/4/1441 4141 .0 NM*14\ 11110 41010 M1r 11 OOM,1M 111451541 , lfK+ mOM 00000 41 u141 NMMMM 414\414141 1514414/4/ 101010, 414/414141 0010 000 .x0 MO 101u1L 1(110404041MM 1 1c1M11i11Mn1Mn M`1OilMMM 1nuP1m1i1 1mi1i~i 505010 040404445 =MM. 1(10004 1 450 0, 4M1 4M11400 G, 1 111_01 30,10044 A 44141414141 X00 1 IV = .44101 0 0(11004 :Av.= 1(04 100411 4 u n' ram: 1?.YY .Y.O 11100 1f11n111f141 414 41t1n 'RAA41= n1An LMT. ■T: gs S } -- 10(11h1[1 1N[11Nf11[ 4\1311 4~1411l~111~11~11 - D.- nn 010.010 ,100 0 4\41410 1010101010 -411 .0 M1nM10 WMMO NN,, 3140410 OMM,1N 1010101010 NMMMM MN,00 0111 . 1!141MMM 4141MMM 10,,MM 41MMM MMM M O 1010101010 .4NN 14141 0P1-m204010100 01MMN NMMM1 10140101 0,O NM41 34/41414/ 4/4/1515 411044\ 154141.010 0,0101010 101010101 0 11000/0/00 40 4 222 1010 " 41141 50„0 N ~1010~ 10 ~~t04 o t 15110100 m 01 4010101010 1005050 40001000/0 10 .010010 1D ,M .4 AM154/1041515 NM 015 0,1-04 01010 00 ip00000N 10N 10M10M10M S 001001014 100100 1001010 010101010 10401010O 0 ~tit M50 ,10404 N 0501104 1[5414110441 1044/400/ 4 i MMNN MM_Y1 /104411/ 0 1010,AM mm1p 4001 N M* 0101000 00M,1M 0 4 4 4041 1 (1 411504". 010101010 1010101010 1010101010 1010101010 1010101010 1010,MM Arr„ A, N M 1111 11(540 04400 1010101010 15MM0 0 1010'ii1010 10 M1„m 1010101010 50ti,AM AtiA tip,M M A 04 541 4 1151 lnryi,AH[MO 1001D 1MD1N01N0 101010100 p 1 01044040 400545010 N MMMMM 4400 1 „ 0505, NNN , MM ,A , ~4#11 „5 M , M.e4p1yf1IP6-1 10 1001M0V 1N0 1010 1001010 1010101010 1010101010 0,000A 00040404 , A "nN,A 0 N M, N .4• 01 A ,p^,l1 M b1MV= 4)~i01~05D10 00000 104140000 o^-4,-a N` Y 015010 '050000050 0005050050 00̀. 0 .44̀ . 440.1` 0405 00MM5* MMM01 0 Pr„ *44 .45504 P P 00 0 .0.01, ,,,,,0, 05050410 m M0,4'OP PAA,1 MMNNM 010000 4110010 PP,,, MMM010 1•-IAA F10AAA ,AA, ,40m40 A,AA A tl 404101-1- AMAti 1104.1-1 001-, , 0-, 40 MMI 0410 .INW 1 •0100000 1 - 1-(1-,0 IW N0 m N . 004040440 400440404 0 0 10047WW mmmm m 1- -00o10Y140 M 041040 m 40 0010010010,001 04000 0 ,nLMM 0113 3 N 010MNM 01010101 tl 01010,0, 0101010101 M 1014 .01010 10 PM1M1A 01010101 0101010101 0001P010101 „ FO~A2 2=2 NMMMM 1010101010 0000M 50500 050 M,,,, M 0-00 0 ,,,, 10-0000 A04m tiAA MM ,M,,,~- °°.AAA ,,~-,,, NN-m 0M,,, W W . WW MM, MMO O O O M(y0 ,,PAPAW ,,,,, AAr,A mmm 40 041 00000 NNNNN 00000 4000404040 04000 4 MMMMM NNNNN NMMMM """0 0 145104 tiNrNti ,MM, W W W W W 4040404004 0404040404 4040000404 mmmmm mm m MMMM M ggtl N 0y40 040440 0 0 040404040 0 M M 004044040M M N N 0404(4040 4 4 mmmmm 0 4 00 4040404040 404 W a0W000 700004NN NN .O . 0b 40ge~0 04004040 ~WWWW cWWWm 0404040 15100 04Ommmmm 101010 PA ,M,,1 mmm NNW .. mmmmm KM . 004WWW 4400001001 005 g eg mmm 0505 440144 010100 0 0 0 0 0101010101 00 .00 0101010101 MMMMM 0101010101 .NNNN NA N1 mmmmm mmmmm mro01 04 0 0501010101 04010 MMMMM N N N01 MMMM M 0404040405 0405*13 010101010 1111 01 0101010101 NNNN 010101 0 10N1 NN 0 1010101 0101010101 01010101•0 0101010101 ***1 31111M 4/1005154/ 4140,050, 01004050 , 4/404/010 1010101010 0 01010101 0,01010101 0,05010101 010101010, 0505010101 0,010+0105 010,04010 1 33 2 010101 1010150 05010 5 APr ,AA,01010,0101 AA,t l tlm40044 0 „„mm 0404mm40 mm5m 00001 10101 0101010101 01 4 0101 01 . 4004404040 01401401 0101MMM W1 il4 0, 1N 0410 M, .1M1M1 4 .41411... MMMMM aR0 0010M MMMMM 0000 .04 .404M1.MM i t ,1M .Na .N4 N .N4 M MMMM M WA M MM,1044 HM 2110O 80 0 NN N