Signature redacted SAMUEL LEMENT B.Sc.

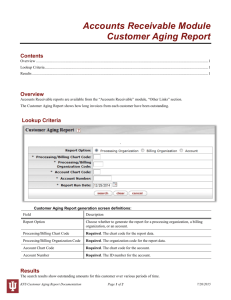

advertisement