c Journal of Applied Mathematics & Decision Sciences, 2(1), 23{50... Reprints Available directly from the Editor. Printed in New Zealand.

advertisement

c Journal of Applied Mathematics & Decision Sciences, 2(1), 23{50 (1998)

Reprints Available directly from the Editor. Printed in New Zealand.

A DECISION SUPPORT SYSTEM FOR

REGIONAL HAZARDOUS WASTE

MANAGEMENT ALTERNATIVES

MAHYAR A. AMOUZEGAR

m.amouzegar@massey.ac.nz

Institute of Technology & Engineering, SST 4.29, Massey University, New Zealand.

STEPHEN E. JACOBSEN

jacobsen@ee.ucla.edu

Department of Electrical Engineering, University of California, Los Angeles, CA 90024, USA.

Abstract. With the passage of the Resource Conservation and Recovery Act (RCRA), and the

subsequent amendments to RCRA, eorts to provide tighter controls on the transportation and

disposal of hazardous waste have been steadily gaining ground. This paper, intended as a decision

support tool for regional planning, incorporates information on the hazardous waste generation,

treatment capacity and the costs of waste treatment alternatives into an optimization problem

of nding the relationship between governing agency and the toxic waste producing rms. As an

example, we consider the problem of regional hazardous waste in the San Francisco Bay Area in

Northern California.

Keywords: Decision Support System, Hazardous Waste Management, Mathematical Programming, Bilevel Programming.

1. Introduction

Pollution has been an inevitable accompaniment to economic activities, and as such,

most societies have set goals to eliminate, or at least reduce, pollution. It has long

been recognized that industries or rms may not voluntarily reduce pollution levels

in the absence of any government compulsory intervention. Such intervention can

take either of two forms: a) the government can takeover and run some lines of

activity, or b) it can leave the activity to private initiative but regulate it.

Many states generate large amount of hazardous waste for which there is not, at

present, adequate treatment and disposal capacity within the state. Federal and

state legislation requires that management policies provide for adequate long-term

treatment and disposal capacity for such waste. California's policy, for example,

calls for meeting treatment requirements by reducing the generation of hazardous

waste, with expansion of treatment and disposal capacity only as a secondary solution. Within the state, hazardous waste management planning is also being done at

the regional level. Regional governments must project hazardous waste generation

and plan for adequate treatment and disposal capacity in their region. Estimates

of future waste generation are based on population and economic projections, and

then reduced by some percentage across-the-board to account for projected waste

reduction.

24

M. AMOUZEGAR AND S. JACOBSEN

At present, regional planners do not consider the relationship between treatment

capacity, treatment prices and hazardous waste generation. Large o-site treatment

facilities oer economies-of-scale provided that the are fully utilized however, if

the capacity is larger than anticipated demand then the facility could be forced to

increase the unit treatment price which could produce further decrease in demand

and price increases. As a result the facility many be be able to recover costs

or operate only at higher than projected unit prices. The addition of treatment

capacity could also produce other unintended outcomes: low treatment prices could

undermine waste minimization eorts or the facility may utilize excess capacity by

treating wastes from outside the region.

In order to fully understand the fundamental characteristic of hazardous waste

management, we must introduce two important agents in the economy: The central

authority and the rms. The central authority (CA) is dened as any agent in the

economy which has the authority to regulate the other agents' activity.

We dene a rm as any organization that, through its activity produces some

goods, not necessarily identical, in order to maximize its own prot. As a by

product of the rm's activity, hazardous waste is also generated which needs to be

managed.

In this paper, we present an optimization model for hazardous waste capacity

planning and treatment facility location. The behavior of private rms is modeled

to assess the eect of central planning decisions and price signals on hazardous

waste generation and demand for treatment and disposal. In short, we are mainly

concerned with the interaction between the two agents: the CA seeking to regulate

the rms in order to maximize the social welfare and the rms responding to these

regulations. Furthermore, we have focused our attention on a group of wastes

classied as incinerable hazardous wastes since it constitute the largest non-nuclear

waste group in the US.

The management of incinerable wastes are divided into four major categories:

1. Source reduction: The elimination or reduction of waste at the source.

2. Recycling: The recycling or reuse of waste material both on-site and o-site

(regional level). Recycling is not 100%, and some residuals need to be sent for

incineration and disposal.

3. Incineration: Thermal destruction of waste at o-site facilities.

4. Disposal: Releasing material into air, water and land. This option is assumed

to be a joint process with the incineration.

Among all the technique of waste management, source reduction is favored due

to its lower risk to the environment, and thus is the common sense solution to

the prevention of future hazardous waste problems. But due to lack of proper

environmental regulation and/or economic consideration, recycling and incineration

are part of today's waste management options. The latter processes bring with them

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

25

certain damage (or externalities) to the environment which we will call pollution

damage.

The model, intended as a decision support tool for a regional hazardous waste

management authority, is necessarily a simplication of the actual conditions and

subject to constraints and assumptions which are described below. Still, it provides

a framework for qualitatively comparing the eects of dierent planning options.

2. Scope of Hazardous Waste Problem

More than 60,000 chemicals (excluding pharmaceuticals or pesticides) enter into

many products and services that shape today's lifestyle. Taken together, these

chemicals, comprise a huge industry { in the United States alone, sales during 1995

were over $200 billion. The sheer variety, ubiquity and economic importance of

chemicals means that eective regulation to safeguard against undesirable health or

environmental side eects is quite challenging31]. In California, every year, about

26,000 rms generate and ship o-site over 2.2 million tons of hazardous waste{

more than 150 pounds per person in the state. This represents an increase of over

600,000 tons from the total reported just two years earlier. The rapid production

of hazardous waste combined with increase in disposal cost and decrease in the

available numbers of landll sites, changes in legislation, and more public awareness

have dramatically altered the way in which we can deal with hazardous waste. Prior

to the late 1980's, a detailed accounting of the generation and disposal patterns

for hazardous waste streams was unavailable however, with the data collection

provisions enacted under Superfund reauthorization and the Resource conservation

and Recovery Act (RCRA), the legal authority to collect such data was put in place.

Now there are several data bases which provide partial pictures of hazardous waste

generation and disposal. The Toxic Release Inventory (TRI)41], collected annually

under Superfund Amendment and Reauthorization Act (SARA), Title III, provides

data on the emission proles of more than 300 chemical species. While the TRI data

are useful for proling waste generation patterns, they provide little information on

disposal methods. In contrast, the biennial survey of generators and the biennial

survey of Treatment, Storage and Disposal facilities collected under RCRA, provide

data on disposal patterns but little data beyond waste category on the composition

of the waste streams.

In 1985, Environmental Protection Agency (EPA) conducted the National Screening Survey of Hazardous Waste Treatment, Storage, Disposal and Recycling (TSD)

facilities. The survey was designed to estimate the total quantity of hazardous waste

managed by TSD facilities and to identify hazardous waste management processes.

This survey identied 2,959 facilities, regulated under RCRA, which managed a

total of 247 million tons of waste 43]. An additional 322 million tons of hazardous

waste was handled by units exempt from RCRA reporting requirements.

M. AMOUZEGAR AND S. JACOBSEN

26

2.1. Evolution of State and Federal Regulation

Currently there are 11 major environmental laws for controlling dierent types of

waste generated throughout the country 42]. One of these laws which concerns

hazardous waste, is the Resource Conservation and Recovery Act of 1976 with its

\cradle-to-grave" provisions for controlling the storage, transportation, treatment

and disposal of hazardous waste. RCRA was signicantly amended in 1980 and

1984. The 1984 amendment of RCRA, called Hazardous and Solid Waste Act

(HSWA) is very important in establishing more stringent standards in waste management strategy. These amendments have restricted untreated hazardous waste

from land disposal (\Land Ban")40] and state laws such as Hazardous Waste Management Act of 1986 (SB1500), which augments the federal Land Ban to include

some California-only hazardous wastes. The Land Ban also species hazardous

waste treatment standards, which for many wastes require that specic treatment

technologies be applied. California law further requires that all hazardous waste

containing more than one percent volatile organic compounds or having a heating value of more than 3 000 BTU/lb must either be incinerated or treated by an

equally eective approved process 36].

Planning for hazardous waste treatment and disposal is being done at both the

state and county level. Federal law (CERCLA 104(c)(9)) requires that states, or a

cooperating association of states, prepare Capacity Assurance Plans (CAP) or lose

federal funding for Superfund cleanups in the state. Where there is a shortfall of

treatment and disposal capacity, the state(s) must show that measures are being

taken to meet the shortfall. In California, AB650 has required that the Department

of Toxic Substances Control prepare such a plan in 1989 and revise it every three

years.

Long before the state's rst Capacity Assurance Plan was prepared, the legislature

had recognized that additional facilities were needed, but that siting of such facilities

was meeting strong opposition at the local level. `Hazardous Waste: Management

Plans and Facility Siting Law'37], known as Tanner Act, provided guidelines and

funding for county and regional governments to assess hazardous waste generation

within their jurisdiction and to develop waste management plans to guide future

policy decisions, including the siting of new treatment facilities. The law also set

up a process for evaluating facility siting proposals through a Local Assessment

Committee and a state appeals board.

The legislation allows counties to participate in regional associations for hazardous

waste management planning. The two principle association are the Association of

Bay Area Governments (ABAG), comprised of Alameda, Contra Costa, Marin,

Napa, San Francisco, San Mateo, Santa Clara, Solano and Sonoma counties, and

the Southern California Hazardous Waste Management Authority (SCHWMA),

comprised of Imperial, Los Angeles, Orange, Riverside, San Bernardino, San Diego

and Santa Barbara counties. ABAG and SCHWMA account for approximately

25% and 50%, respectively, of all hazardous waste generation in the state.

x

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

27

3. A Survey of Pollution Control

A major tenet of this paper is that there are signicant gaps in our understanding of

pollution control and rms' behavior in other than highly abstract economies with

full information assumptions. It is important to recognize our limited knowledge

about the rms' response to regulatory action by the central authority and even

more signicantly, the lack of complete data on hazardous waste generation and

treatment.

In this section, we review past work that can contribute to a better understanding

of subsequent sections. Roughly speaking, the literature includes four broad, and

sometimes overlapping, topical areas: conceptual models, extensions to the earlier

models, eect of uncertainty and optimization methods.

3.1. Conceptual Models

Conceptual models and discussions focusing on eciency gains of market-base approaches compared with command and control has been discussed by many authors

such as Kneese22], Dale8], Baumol and Oats4], and Kneese and Schultz23]. Allen

Kneese22] had the early insights in terms of treating pollution management as an

economic allocation processes in his work on water pollution. His contribution was

to point out that pollution control is not just an engineering problem (which can be

solved by technology), or just a political problem, but it is also an economic allocation problem. His prescription was to utilize pigouvian fee (i.e., emission charge),

to achieve a socially desirable level of pollution.

Following Kneese's work on water pollution, Crocker7] examined air pollution

control as an economic allocation problem. Although his work treats the problem

on a very general level, he does introduce the notion of marketable property right for

the use of air resources. Dale8] expands considerably on the notion of a pollution

permit and property rights.

Although these early works introduced most of the ideas used by today's researchers, it is noticeably decient in the quantitative rigor needed to approach

pollution problems.

3.2. Extensions

Extensions of these models addressing complications such as space (i.e., multiple

regions) and uctuating pollutant disposal. Montgomery32] and Tietenberg39]

have developed general equilibrium model to examine optimal pollution control

focusing on these considerations. Montgomery32] examines marketable permits to

pollute within a spatial economy. His paper is important because it shows that an

equilibrium will exist for a marketable permit system such as proposed by Dale8].

Susan Rose-Ackerman34] pointed out a host of practical problems associated with

emission fees. Some of her criticism have previously surfaced in terms of general

28

M. AMOUZEGAR AND S. JACOBSEN

diculties with the marginalist allocation process. Other perceived problems with

emission fees are merely observation on the diculty of controlling pollution and

are not unique to economic instrument. Therefore, her criticism do not appear

to signicantly weaken the case for emission fees or marketable permits, a case

whose principal interest lies in its alignment of public and private incentives. RoseAckerman suggests two problems: One problems arises when non-constant return

to scale apply to either pollution damage or emissions. In such case, marginal

cost pricing can lead to nonzero prot for producer. A rm may be driven out of

business, or forced to leave the region, if it is forced to pay the emission fee. But

this can be true for any input and there is no indication that economic eciency is

reduced.

A second issue raised by her is the potential ineciencies associated with an

emission fee that is uniform in either space or time. These ineciencies (relative to

a uniform emission standard) associated with uniform fee depend on the curvature

of the cost and benet functions. But once again, it should be pointed out that

fees need not to be uniform.

Finally, Kruppick, et. al. 25] examined the marketable permit system for the

control of air pollution. In their paper, they allowed for free trade of emission

permits subject to the constraint of no violations of the predetermined air quality

standard at any receptor points.

3.3. Eects of Uncertainty Price vs. Quantity]

A number of authors have introduced uncertainty into their analysis and on this

basis have shown the optimality of particular control mechanism. Weitzman45]

has shown under what conditions price instrument are preferred to quantity instruments in centrally allocating production and consumption. He conrmed Lerner's

conjecture(29]) that under uncertainty, the choice between fee and permits will

depends on the slopes of the marginal damage and cost functions. Kolstad24]

explicitly included uncertainty in his empirical model. He examined and compare

three regulatory issues: price control vs. quantity control spatially dierentiated

vs. undierentiated control and command-and-control regulation vs. economic

instrument.

Beavis and Dobbs5] examined the rm behavior under regulatory control with

the assumption of stochastic euent generation. These authors assumed that waste

discharge depends on some input and a continuous random variable with a known

density function.

3.4. Optimization Approach

Many authors have attempted optimization techniques in the pollution abatement

problem (e.g., 30], 15], 17], 14]). Graves, et. al. 15] used a large scale nonlinear

programming in a pollution abatement model for West Fork White River in Indiana

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

29

in order to minimize the total cost of pollution abatement structure subject to water

quality in each section of the river. Haimes, et. al. 16] and Hass 19] approached

the abatement of water pollution through decomposition techniques of Dantzig

and Wolfe9]. Their goal was to simultaneously compute an optimal waste water

treatment conguration and to determine optimal pollution taxes to achieve this

conguration.

Models of Haime, et. al. 16] and Hass19] depend crucially upon the assumption that the system is i) centralized, and ii) the centralized system is capable of

decentralization. Jacobsen21] showed that once revenue sensitivities and appropriate benet measures are introduced, usually both of the above assumptions do

not hold. Hall and Jacobsen17] highlighted the importance of response functions

due to specic regulatory policies. They developed an optimization model based on

consumers' surplus, prot loss, and changes in tax revenues and concluded that,

when information costs are too high, it is most ecient to tax the solid wastes

directly rather than the tax the goods that produced such wastes.

In most of these models, the solution is derived from a microeconomic approach,

in the sense that it is found by locating the point where the marginal treatment

cost equals to the marginal damage cost from the perspective of a particular individual polluter (some noted exceptions are Jacobsen21], Hall and Jacobsen17],

and Kolstad24]). However, a serious shortcoming of these models is that complete

information on the production and damage cost functions of each and every rm

is assumed to be known. Although, each rm may know its own production cost

functions, there is no reason to believe that this information will be readily available

to the central authority.

Some researcher have conceptualized the problem in terms of a multilevel frame

work 1], 19], 16], 24]. Although Hass19] seemed to realize the existence of two

levels, he did not formulate his model as such. Instead, he modeled the problem as

a single level and solved it by using Dantzig-Wolfe nonlinear decomposition.

Haimes, et. al. 16] also recognized the need to consider the problem from a multilevel modeling viewpoint. They proposed a formulation consisting of three level:

a central authority, a regional treatment plant, and the individual polluter. Their

solution method decomposed the optimization problem into a set of hierarchically

ordered subproblems. The solutions of these subproblems were then coordinated

to obtain an optimal solution to the original problem. More specically, once the

central authority determines the tax schedule, it send this information down to the

lower levels. The lower levels then process the tax structure and pass results back

up to the central authority as optimal treatment levels. Using these treatment levels, the central authority checks the quality constraints to determine if the previous

taxing structure is too high (no binding constraints), too low (some constraint violated), or optimal(no constraints violated, some binding constraint). If the previous

tax structure is not optimal, a new tax structure is developed. The iterative nature

of this solution technique is necessary since there is no mechanism, inherent in the

model, which assumes that central authority has any knowledge of the lower level

optimization problems. The obvious diculty with such iterative tax setting is that

30

M. AMOUZEGAR AND S. JACOBSEN

Table 1. Hazardous Waste Generation in California

1988

1989

In-state generation, HWIS 1,498,258 1,954,829

Exports, based on HWIS

159,834

254,964

Exports, from OSMA

52,009

74,880

Total in-state generation

1,550,267 2,029,709

Total exports

211,843

329,844

1990

2,169,715

292,326

71,841

2,241,556

36,4167

1991

2,145,283

259,521

90,115

2,235,398

349,636

the lower level (rms) assumes the initial taxes are substantially correct, and they

plan their pollution control program which may take several years to complete, and

it is largely irreversible once in place.

Kolstad24] formulated his Four Corner case study in terms of a stochastic bilevel

problem, but his interest was to derive some empirical properties for various air

pollution regulations.

4. Management of Hazardous Waste in California

In the 1989 Capacity Assurance Plan, the state established a goal of managing

California's waste within the state and limiting exports to 1987 levels. While emphasizing waste minimization and source reduction as the preferred way of managing hazardous waste, the plan saw a need for additional treatment capacity for

incineration of liquids, sludges and solids, and projected that several new incineration facilities would be built. However, all proposals for incineration facilities

listed in the 1989 and 1992 CAPs as pending have since been withdrawn. Waste

exports have increased signicantly1 (see Table 1), due in part to the lack of in

state capacity for treating incinerable waste and a hazardous waste fee structure

that encourages out-of-state disposal. The state's 1992 Capacity Assurance Plan

emphasizes California's participation in the Western States Regional Agreement

on Capacity Assurance, a tacit admission of California's continuing dependence on

waste exports.

The state has continued to pursue waste minimization and source reduction as

a way of balancing waste generation and treatment capacity. Funding is provided

for local governments to develop waste minimization programs and to assist small

businesses through loans for implementing waste minimization 35]. Hazardous

waste generators are required to prepare waste management plans that identify

hazardous waste streams and potential source reduction alternatives, formulate a

plan for source reduction, and periodically review it 38]. In 1991, the Department

of Toxic Substance Control initiated a review of these plans from four industry

groups thought to oer the greatest potential for reducing incinerable wastes.

The DTSC promotes waste minimization and source reduction through a series

of industry-specic waste minimization `audit-studies', a waste recycler's catalog,

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

31

the California Waste Exchange, and a variety of research and outreach eorts.

Many studies, including the department's `Incinerable Hazardous Waste Minimization Project', indicates that large reductions in hazardous waste generation can

be achieved by implementing available pollution prevention and waste reduction

measures.

5. Development of a Decision Support Model

This paper is concerned with developing a model to aid in regional hazardous waste

management planning. The model cannot incorporate all the factors that need to be

considered in regional waste management planning, such fairness or desirability of

waste treatment versus waste reduction. Hence, the model is intended as a support

tool to assess the impact of various policy alternatives rather than as a source of

nal answers.

In section 3.4, we highlighted the fundamental diculties with assuming a complete cooperation between the rms and the Central Authority (CA). It is clear

that the major diculty the CA faces, is dening an objective that would increase

the social benet while satisfying the desire of the rms to maximize their prot.

We attempt to take a step toward a more realistic model of an economy where the

central authority has control over a subset of decision variables (e.g., prices) and

the rms control the other variables (e.g., production).

It is reasonable to assume that the CA has no direct control over such decision

variables as source reduction, or amount of on-site recycling. Rather, it can only

set certain charges, issue permits, or designate a certain capacity for an o-site

facility. This observation split the problem into two: rms and the CA with a

hierarchical structure in which a decision maker (CA) at one level of a hierarchy

may have an objective function and the decision spaces are determined, in part, by

other level (rms). This leads to a model for the operation of a rm as it relates to

waste generation. Given a particular set of prices for osite treatment (including

transportation cost, fees and taxes), what is the rm's demand for osite waste

treatment?

5.1. Risk Assessment

One the most dicult aspect of this decision support model is the assessment of risk

and more specically quantication of risk. In general, emission is caused both by

production activities and treatment methods. These emissions are converted by the

environment into pollution concentration which vary continuously over space and

time. Evaluating the damage these pollution concentrations have had on human

and environment is of particular concern when forming a robust environmental

policy. Risk assessment measures both risk acceptance, or appropriate level of

safety and risk aversion, or methods of avoiding risk that can be used as alternatives

to involuntary exposure. Identifying the risk associated with certain product may

M. AMOUZEGAR AND S. JACOBSEN

32

help in forming policies curbing the production or use of such materials. The risk

assessment should not stop at measuring only the health and life, such as those

resulting in morbidity and premature death, but it should also identify short and

long term environmental and economical impact.

The process of risk evaluation for hazardous waste disposal and treatment greatly

depends on the technology used and the exposure pathway. In particular, in absence

of an alternate technology (e.g., replacing solvent by water-based cleaner) there are

many possible point of hazards. We must evaluate the hazard level during and

after treatment as well as the possible long run risk to the environment from the

disposal of residuals. The treatments and potential hazards points are illustrated

in Figure 1.

Air Pollution

Potential

Hazard

Production

Incineration

Waste Stream Treatment

Little or

No Risk

Technology

Possible

Risk

Recycling

Potential

Hazard

No Risk

Alternative

Technology

Potential Hazard

Disposal

Water/Ground

Pollution

Figure 1. Risk Evaluation for Hazardous Waste Management

Toxicology and epidemiology can provide quantitative data on the relation between the dose(concentration) and response. Several formal and informal methods

are available in estimating a quantitative relationship 28]. In developing a quantitative model we must focus on the quantication of risk in terms of human health.

The precise question is how pollution aect illness and death rates, including partial

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

33

disability, missed work and expenditures on health. One of the major problems in

attempting to answer these questions is the lack of theoretical model specifying the

way pollution aects health. For example, in terms of air pollution, the predominant eect is more subtle and relates to chronic diseases. Although the principal

eect of air pollution is respiratory diseases, the human body is complex enough so

that other chronic diseases, such as heart disease, are aggravated.

An additional diculty is the methodology used in risk assessment. In particular,

it has been argued (for example, see 27]) that investigating morbidity is more reasonable than examining mortality since death is the end of a complicated sequence

that starts with an initial disease and may evolve in many ways. Unfortunately,

data on morbidity rates, absence rates and health expenditure are not extensively

available. There are, of course, other factors such as Urban living, life style, and

errors in data collection that contribute to computing a damage function.

Adding to an already dicult problem is the fact that with a few notable exceptions, as in the case of asbestos, the determination of human health hazards must

be assessed primarily on the basis of animal studies which are both costly and time

consuming. Some specic sample costs and testing methodologies are presented in

a report for the Oce of Pesticides and Toxic Substances 12].

In our development of a decision support system, we will rely on developing a conceptual damage function that can be set by policy makers according to availability

of data. Accordingly let ( ) denote pollution concentration from production, recycling and incineration. Because our only use of pollution concentration information

is as an argument in pollution damage function, the specic nature of is governed by the damage function, (). Therefore, if pollution damage is a function

of annual average or annual maximum concentration in a region, the can be one

dimensional. If, however, is a nonlinear function of concentration at all points

in a region or regions over all points in time during a year, the will be a nite

approximation to those concentrations.

5.2. Hierarchical Decision Making

The central authority, in order to encourage source reduction, may adopt a policy

of rewarding rms for each unit of source reduction beyond some lower limit set

by the CA. At the same time, the CA desires to punish rms who fail to meet the

minimum source reduction standard and for shipping hazardous waste to osite

incinerators. The rms, of course, incur other cost other than the penalty (tax) set

by the CA. The rms, in planning their waste management policy, need to consider

such costs as the onsite recycling cost (including the setup and operating costs) and

osite recycling and incineration costs. Notationally, let x denote the quantity

of waste type w, w = 1 : : : W , rm i, i = 1 : : : I , sends for onsite recycling, and

similarly let u and v denote the quantity of osite recycling and incineration of

waste type w produced by rm i and shipped to region r, r = 1 : : : R, respectively.

Recycling processes leave certain quantity of residual which need to be incinerated.

Therefore, let , i = 1 : : : I , w = 1 : : : W , denote the fraction of residual from

iw

iwr

iw

iwr

M. AMOUZEGAR AND S. JACOBSEN

34

onsite recycling, and let denote the fraction of residual from osite recycling.

The per unit costs of onsite recycling, osite recycling and osite incineration are

denoted by c , RC and IC , respectively. The total cost to each rm is therefore

denoted by

wr

iw

TC =

rw

X

i

rw

c x + RC u

iw

iw

rw

iwr

+ IC ( x + u

rw

iw

iw

wr

iwr

+ v )]

iwr

r w

P

Let s = x + r ( u + v ) denote the total waste w earmarked for

incineration by rm i and let L denotes the lower bound set by the CA for the

waste type w for each rm i. The CA may attempt to encourage the reduction of

s by setting up a tax/reward system. For example, it may tax each rm for any

value of s > 0, or may reward each rm for source reduction by paying an amount

for each unit of L

s . Notationally, let denote the per unit price CA is

paying each rm for reduction of waste type w, and let denote the per unit tax

the CA levies against rms who generate beyond the lower limit set by law. It may

be that this tax/reward strategy could only be applied to a certain waste type. Let

# be a set of wastes eligible for tax/reward scheme. Benet to each rm is then

iw

iw

iw

wr

iwr

iwr

iw

iw

iw

;

iw

w

w

B (s w ) = ((LL

iw

i

;

w

iw

w

;

iw

s ) if L

s ) if L

;

iw

iw

iw

;

iw

s

0

s >0

iw

iw

Therefore the lower level objective function is expressed as follows

min

X

i

TCi

;

X

w2

Biw (siw )

!

Firms are constrained by the capacity of each of the facilities available to them,

any environmental laws on source reduction, and other physical constraints. In a

decision support model, we can assume a xed quantity of waste generated at the

initial iteration and then revised this quantity to play dierent scenarios of waste

reduction goals. If we denote the initial quantity of waste w generated by each rm

as q then each rm has the following constraint

iw

X

r

u

iwr

+v ]+x

iwr

iw

q

iw

A exible model should not mandate the existence of on- and osite facilities,

rather the solution to the optimization should indicate the need for such facilities.

Let cap denote the possible capacity of an onsite recycling, and let Cap and CAPr

denote the osite recycling and incineration capacities in region r respectively. Then

the three capacity constraints are as follows

i

r

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

X

iw

cap y

u

iwr

Cap z

+v ]

CAP t

w

X

iw

X

iw

x + u

iw

iw

wr

iwr

x

iwr

i

for all i

i

r

for all r

r

r

35

r

for all r

where y , z and t are the binary decision variables.

The upper level (the central authority) has its own objective to optimize. It is

conceivable that the central authority may wish to minimize the total waste treatment costs and pollution damage cost incurred to the region through the necessity

of meeting some predetermined source reduction standard. These costs include

both the local(on-site) treatment cost function f( ), regional recycling and treatment cost functions ( ) and ( ), respectively and the premium cost p. Thus, the

upper level objective function can be expressed as follows

i

r

r

H

min

p

L

X

X

X

f (x ) +

( u )

wr

iw

i

X

X

x + u + v ]) + ()

wr (

iw

Hwr

iw

L

wr

iw

i

iw

iwr

wr

iwr

iwr

where () denote the pollution damage cost.

5.3. Social Welfare Model

Our second model is to maximize the social welfare of the region and is based partly

on Kolstad's (24]) air pollution control model. One way of dealing with social

welfare is by the idea of economic surplus for the region. Let's dene the economic

surplus ES, in the absence of environmental regulation as the integral under all

inverse demand functions from zero up to consumption level less producers' cost.

ES (g q) =

n Z g

X

P^i ()d Ci (gi qi )

i

i=1

0

;

(1)

where P^i () is the inverse demand function and Ci (gi qi ) is the i-th producer's cost

with gi and qi = (qi1 : : : qiW ) denoting the output level and the vector of waste

quantity respectively.

The role of the CA is to choose a regulation so that when rms respond to the

regulation, social welfare is maximized. One such welfare is dened as economic

surplus (1) less pollution damage. Therefore the CA's objective is to choose a

regulation that maximizes welfare.

M. AMOUZEGAR AND S. JACOBSEN

36

W = ES (g q) ():

(2)

In promulgating a regulation, r, output levels, g(r) and q(r) will be determined

by the market in response to the regulation r. Let the prot function PF for each

rm be dened as revenue minus cost where cost may include regulatory charges.

;

max PF

q u v satisfy r

X

u + v ] + x

q

r

X

(L2)

x

cap y for all i

w

X

u

Cap z for all r

iw

X

x + u + v ] CAP t

iw

iwr

iwr

iwr

iw

iwr

i

iw

iw

i

iwr

r

iw

iw

wr

iw

r

iwr

iwr

r

r

for all r

and the CA optimization model is to seek a regulation r, within a set of feasible

regulations R, which maximizes welfare, given the manner in which the economy

response to such regulations (L2). Then the CA's problem is to

max

W (r)

r 2R

where the value of W is dened by r indirectly through the optimization problem

of the rms (i.e., (L2)).

Consider two types of emission regulations: emission fees and marketable emission

permits. We assume both regulations are set before the rms have made their

production decisions.

1. Emission Fee:

We may either impose an emission fee on all the hazardous wastes generated or

just on those wastes that are send for incineration. (L2) is modied to account

for the imposition of a fee on all hazardous waste at the source or a fee for

lack of source reduction.

2

3

X

Maximize 4PF t

q 5

;

or,

iw

(3)

iw

2

3

X

Maximize 4PF +

B (s )5

iw2

iw

iw

(4)

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

37

Equation (3) refers to charging all hazardous wastes generated, and equation

(4) refers to previously dened partial charges and incentive.

2. Marketable emission permits:

We may simulate the action of a marketable permit system through a constraint

on (L2). Let Mw be the issuance of emission permits then we may append the

following to the constraint set of (L2)

n

X

i=1

q

iw

Mw w W

(5)

2

Permit trading may be assumed to occur over the entire economy as in equation

(5) or trading may occur only within zones (regions).

5.4. A Brief Note on Centralized Planning

The task of developing a full decision support model requires that we consider the

instances where cooperations between the central authority and the rms may be

possible. Consequently, we present brief descriptions of microeconomic model as

well as a system optimization model that may be useful at certain instances of

policy making.

Our st model considers the problem from the point-of-view of the rms where

as before in a given geographical region many rms operate and produce certain

amount of goods which are not necessarily identical. As a by product these rms'

activities a certain quantity of hazardous waste is generated which need to be

managed.

Let g, denote the output level of a rm which uses factors of production z1 : : : zJ .

Let pj , j = 1 : : : J , denote the per unit price of factor j and let (z ) denote the

rm's production function, where z = (z1 : : : zJ ). Let P (g) denote the rm's

inverse demand function for its product (i.e., P (g) is the per unit price consumers

will pay for a total of g units). Let q(z ) = (q1 (z ) : : : qw (z )) where w W denote

the vector of resulting hazardous wastes. In this model rms may manage their

waste using on-site and o-site facilities, as well as having waste minimization as

an additional option. The usual concept of `waste minimization', at its initial state,

is that the rm may have a few alternatives with respect to the nature of the very

technology that the rm may use to produce its output. We proceed, formally, to

model this important aspect as follows. Let there be T technologies, indexed by

t = 1 : : : T , available to the rm and let t , t = 1 : : : T , denote the corresponding

production functions. Let t = 1 denote the technology the rm is currently using

to produce its output. Assume also that only one technology may be used by the

rm. Denote

technology t is used, and

yt = 10 IfOtherwise

2

M. AMOUZEGAR AND S. JACOBSEN

38

and let T1t denote the cost of switching from the current technology to another

technology denoted by t, t = 2 : : : T . Let qt (z ), t = 1 : : : T denote the rm's

waste vector when using technology t.

In this conceptual framework, the objective of all rms is to maximize the revenue

minus the productions cost, change of technology cost, pollution damage cost and

the operating cost (TC).

max

X

i2I

Pi (gi ) gi

;

XX

i2I j 2J

pij zij

;

XX

i2I t2T

T1it yit ()

;

;

X

i2I

TCi

The constraint set is same as the model of section 5.2 with an addition of the

production constraint

T

X

t=1

it (z i ) yit gi 0:

;

The second model is a simple system optimization model where the problem is

approached from the point-of-view of the central authority. In this area of waste

management where there is a total cooperation between rms and the central authority, the CA is in the control of all the location and allocation decisions.

P This

approach will try to minimize the total cost to the system (i.e., minimize i2I TCi )

given the capacity constraints for all the on- and o-site facilities. In this model,

the optimal solution, if exists, will dictate the behavior of each rm, even though

such optimal solution may not be optimal for a particular rm. Therefore, two very

important questions come to mind, who owns these facilities? And how does the

CA distribute the costs eciently?

We don't allow the sale of excess capacity between the rms, so each on-site facility

is owned and paid for by the corresponding rm. It is in the o-site facilities where

the ownership question arises. One scenario is cooperative ownership by all the

users (rms), another is the ownership by the CA. The third option is a private

ownership. In the rst two scenarios, the cost functions are the set-up cost plus the

operating cost distributed `eciently' between the rms. In the latter scenario a

closer attention, is needed.

If the o-site facilities are owned privately but are fully controlled by the CA, it

would be the same as the CA operating these facilities. Therefore, we must assume

that after the CA has decided on the size, number and the location of the facilities,

it will allow `outside' operation and ownership of these potential facilities through

some sort of allocation system such as marketable permit system. These permits

may incorporate two types of operating systems, private (i.e., allow some type of

prot maximization) or public (i.e., zero prot scheme).

Now, whether we employ the marginal revenue equal marginal cost rule (prot

maximization), price equal average cost rule under economies-of-scale or price equal

marginal cost rule under diseconomies-of-scale (public utility), we are faced with

the diculties of computing accurate demands for these o-site facilities, since the

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

39

o-site cost functions are no longer the set-up cost plus operating cost. The new

o-site cost functions are just the per unit prices charged by these facilities. It is

immediate that rms' demand for the o-site facilities depends on the o-site prices

which in turn depends on the demands by the rms. It is unrealistic and inadvisable

for the CA to set arbitrary prices (hence the reason for the bilevel programming

model) and then adjust these prices as the o-site facilities respond. The building

and planning of such facilities, alone, take years and the rms' production decisions

may not be so easily changed.

To remedy this cyclical problem, we must assume a full capacity use of each

potential facility. We must further assume that each facility is chosen from a discrete

set of facility sizes (an assumption that is more true to reality). We may then

compute the per unit prices which maximizes the potential owner's prot for each

facility size.

In the case of public utility, we set the price equal the average cost under economiesof-scale or price equal the marginal cost under diseconomies-of-scale with a full

capacity operation. In the case of a prot maximizing industry, the CA must have

some knowledge of these industries revenue functions. Currently, operating facilities may give some indication of desired prot margins, or the permit issuing CA

may set a ceiling on the prot margin (e.g., 10% above cost).

If all the cost functions are convex, the problem becomes `trivial' in the sense

of Generalized Bender's Decomposition 13] where the decision variables of the

constraint set are partitioned into a discrete variable space and the continuous

variable space.

The diculty, beyond the large size of the problem, is where there is an economiesof-scale in play. It is reasonable to assume that in some of these facilities the

marginal cost may decrease as more quantity of waste is sent to them which yield

a nonconvex optimization problem. The diculty with this type of problem is that

current solution techniques may not be able to nd the global (optimal) solution

to the problem. The nonconvexity combined with integer variables, which create

a discontinuous feasible region, will make the problem even more dicult to solve.

Yet, it is exactly this economies-of-scale in the o-site facilities that makes the

model more realistic, and in certain cases it is to each rm's benet to pool their

undesirable products together in order to get a `cheaper' per unit cost.

As we have mentioned earlier this model is appropriate when the decisions are

centralized. In this model the o-site facilities play the role of the suppliers and

the rms have some xed demand. The prices for the o-site facilities depend on

the dierent types of ownership scenarios and the benet function derived from

these scenarios. A benet measure would be the revenue in a private industry,

but in a public facility the is measured by adding to the revenue the additional

benet accruing to consumers from receiving a price lower than the maximum they

would be willing to pay. In another word the gross benet to the society is just the

`willingness-to-pay'.

Let

M. AMOUZEGAR AND S. JACOBSEN

40

P (u v) be the joint inverse demand function for recycling and incineration respectively.

We can mathematically state the benet to a private and public industries as

follows:

1. Private:

For a private enterprise the gross benets are from the revenues, thus the private

benet is

B (u v) = R(u v) = P (u v) (u + v):

(6)

2. Social benet:

For a social enterprise, we dene total benet as the consumers' `willingness to

pay' plus the producers revenue. Suppose for the incremental unit added to a

demand of 1 < u and 2 < v, the `willingness-to-pay' is the price P (

1 2 ) and

therefore the consumers' surplus is

S (u v) =

=

Zu Zv

Zu Zv

0

0

0

0

P (

1 2 ) P (u v)] d

1 d

2

;

P (

1 2 )d

1 d

2 R(u v)

;

and the total social benet is just consumers' surplus plus revenue,

B (u v) = S (u v) + R(u v) =

Zu Zv

0

0

P (

1 2 )d

1 d

2 :

(7)

Now we can introduce a model that considers the benet to all rms and at the

same time regards the pollution damage and the benets to the region. It is easy

to see that the goal of the CA is to maximize the net benet, but the diculty is

whose benet should the CA consider?

It is clear that under any pricing scenario the monetary benet to the o-site

facility is a cost to the rms, and thus the o-site benets and the rms' benets

are not additive. Therefore, our attempt should be to try to maximize the rms'

revenue (benet) minus the on-site, o-site and the pollution damage cost. Of

course, the o-site costs are just the per unit prices set by the o-site facilities

under dierent ownership scenarios of equations (6) and (7).

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

41

Table 2. Hazardous Waste Generation and Capacity for ABAG Coun-

ties(Tons)

Hazardous Waste Generation

County

1988

Alameda

97,502

Contra Costa 65,306

Marin

1,993

Napa

1,200

San Francisco 44,167

San Mateo

69,645

Santa Clara

92,449

Solano

14,668

Sonoma

7,603

Total

394,533

1989

89,599

95,172

3.253

1,801

64,679

90,919

83,804

25,108

8,743

462,808

1990

86,400

135,287

2,983

1,323

50,787

113,828

95,308

38,587

36,108

560,611

1991

88,282

63,733

3,463

1,663

39,551

114,983

111,041

32,049

8,648

463,413

Treatment

Capacity

80,520

0

2,430

0

76,000

78,900

68,773

0

0

306,643

Waste generation computed from summary tapes of Hazardous

Waste Manifest Data from Department of Toxic Substances Control 26].

Source:

6. Application to the San Francisco Bay Area

Our models have been implemented, for a limited set of waste streams (see Appendix A.1), using San Francisco Bay area as a case study. The nine counties of

this region, which form the Association of Bay Area Governments (ABAG), account

for over 25% of the waste generated in California. Table 2 shows the total osite

disposal of hazardous wastes and current treatment capacity in each county.

The current implementation focuses on incinerable wastes, due to the acute shortage of treatment capacity for them and the limited number of treatment and disposal options. The model includes:

20 dierent waste types, based on California waste codes.

Options for waste management are on- and o-site recycling and incineration,

plus two disposal options for the residuals.

Osite facilities in three discrete sizes.

Capital and operating costs are given for each type and size of facility, based

on an EPA studies 10], 11]

Transportation costs are based on mileage, using the distance between the centers of the counties as average distances, and a cost of $0:23/ton-mile.

Waste generation data for each waste type in each ABAG county, computed

from the `Tanner tapes' of DTSC's Hazardous Waste Information System.

Waste generation in each county is divided among small, medium and large

rms, with the assumption that they account for 20, 30 and 50%, respectively,

of the total generation of each waste type.

42

M. AMOUZEGAR AND S. JACOBSEN

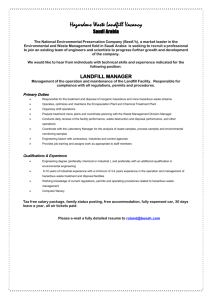

Conceptually, the decision support model will consider the regional hazardous

waste problem and depending on the desire of the policy makers and/or the availability of the information partition the problem into centralized or decentralized

planning (see Figure 2). Many solution techniques and commercial softwares are

available for the linear or the convex optimization formulations of the centralized

planning. Appendix A.2 illustrates an example of a system model using GAMS 6]

modeling language. One of the basic results of this model has been the dominance

of the transportation costs. Further studies is war ranted and is underway. In

case of nonconvex optimization problems (i.e., presence of economies-of-scale in

the objective), there are less choices and specialized programs must be developed.

For more detailed description of these technique see a monograph by Horst and

Tuy 20].

If it is desired to develop optimal taxing or pricing scheme, we must formulate

the problem as a hierarchical model. In the case of the linear upper (i.e., CA)

objective and the linear lower (i.e., rms) objective, there are half a dozen algorithms with varying degrees of success (e.g., see Bard and Moore 3], Hansen et.

al. 18], Amouzegar and Moshirvaziri 2]). To the best of our knowledge, they can

handle about 100 leader variables and 100 follower variables and 50 constraints.

When discrete variables are added, the manageable problem size shrinks by nearly

an order of magnitude. In case of nonlinear objectives, only a few algorithms exist

(e.g., see Vicente and Calamai 44]) but they can only handle small size problems.

Naturally, any nal analysis depends on the political and physical considerations.

7. Summary and Remarks

We have developed a decision support model in order to aid policy makers in developing a sound managerial decision regarding an important issue facing many

industrialized nations. This paper gives a brief history of methods developed in the

area of environmental economics including recent attempts in using optimization

techniques. In this paper, we have recognized the interaction between the central

player and the others by developing a hierarchical model that deals with setting optimal taxing schemes. Issues such as social welfare, risk assessment and cooperation

with rms are also addressed.

A single level model (i.e., where the CA controls all decision variables) is implemented in GAMS, a modeling and optimization package which enables a concise

algebraic description of complex mathematical programming models. The current

implementation contains more than 150 000 continuous variables and 300 binary

variables. Due to the size of the problem, a smaller Hierarchical model is implemented using the algorithm developed by Amouzegar and Moshirvaziri 2]. This

algorithm has been coded on Matlab using the subroutines developed in 33]. Unlike linear or even integer programming problems where we are able to solve very

large scale problems, bilevel models need to be scaled down due to their inherent

complexities. Hence the development of a decision support system where we are

more concerned with a model that can interact with a decision maker.

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

43

Hazardous Waste

Management Problem

Centralized

Decentralized

Planning

Planning

Production

No

No

Functions

Known?

Yes

Linear

Objectives?

System

Model

Yes

Firms

Model

Linear

Approximation?

Yes

Penalty Method

Branch & Bound

NO

Traditional

Linear/Nonlinear

Heuristics

Branch & Bound

Techniques

Political and Physical Considerations and Feedback

Figure 2. Decision Support Flow Chart

Notes

1. Sources: `Tanner Tapes' of the California Hazardous Waste Information System (HWIS) plus

data from the Out-of-State Manifest System (OSMA), obtained from the Department of Toxic

Substances Control.

References

1. M.A. Amouzegar and S.E. Jacobsen. Analysis of mathematical modeling methods for regional

hazardous waste management. Technical Report ENG-95-147, Optimization and Communi-

44

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

M. AMOUZEGAR AND S. JACOBSEN

cations Systems Laboratory, Department of Electrical Engineering, University of California,

Los Angeles, 1994.

M.A. Amouzegar and K. Moshirvaziri. A penalty method for linear bilevel programming

problems. In A. Migdalas, M. Pardalos, and P. Varbrand, editors, Multilevel Optimization:

Algorithms, Complexity and Applications, chapter 11. Kluwer Academic Publishers, 1997.

J. Bard and J. Moore. A branch and bound algorithm for the bilevel programming problem.

SIAM Journal on Scientic and Statistical Computing, 11:281{292, 1990.

William Baumol and Wallace Oates. The Theory of Environmental Policy. Cambridge,

M.A., Cambridge University Press, 2nd edition, 1988.

B. Beavis and I. Dobbs. Firm behaviour under regulatory control of stochastic environmental

wastes by probabilistic constraints. Journal of Environmental Economics and Management,

14:112{127, 1987.

A. Brooke, D. Kendrick, and A. Meerhaus. GAMS: A User's Guide. Boyd & Frazer.

Thomas D. Crocker. The structuring of atmospheric pollution control system. In Harold

Wolozing, editor, The Economic of Air Pollution. W. Norton, New York, 1966.

J. H. Dale. Pollution, Property, and Prices: An Essay in Policy-Making. Toronto: University

of Toronto Press, 1968.

G.B. Dantzig and P. Wolfe. Decomposition principle for linear programs. Operations Research, 8:101{111, 1960.

DPRA Incorporated, St. Paul, MN. Baseline and Alternative Waste Management Cost

Estimation for First Third Land Disposal Restriction, 1989. prepared for US EPA.

DPRA Incorporated, St. Paul, MN. Baseline and Alternative Waste Management Cost

Estimation for Third Third Land Disposal Restriction, 1989. prepared for US EPA.

R. Evans, J. Bakst, and M. Dreyfus. Analysis of TSCA reauthorization proposals. Technical

report, Oce of Pesticides and Toxic Substances, U.S. EPA, Washington D.C, 1985.

A.M. Georion. Generalized Bender's decomposition. Journal of Optimization Theory and

Applications, 10:237{260, 1972.

G.W. Graves, G.B. Hateld, and A. Whinston. Water pollution control using by-pass piping.

Water Resource Research, 5(1):13{47, 1969.

G.W. Graves, D.E. Pingry, and A. Whinston. Application of a large scale nonlinear programming problem to pollution control. In AFIPS, 1971.

J. Y. Haimes, M. A. Kaplan, and M. A. Husar Jr. A multilevel approach to determining

optimal taxation for the abatement of water pollution. Water Resource Research, 8(4):851{

860, 1972.

J. Hall and S.E. Jacobsen. Development of an economic analytical frame work for solid waste

policy analysis. Technical report, Oce of Research and Monitoring, U.S. EPA, Washington

D.C., 1975.

P. Hansen, B. Jaumard, and G. Savard. New branch and bound rules for linear bilevel

programming. SIAM Journal on Scientic and Statistical Computing, 13(5):1194{1217,

1992.

J. E. Hass. Optimal taxing for the abatement of water pollution. Water Resource Research,

6(2):353{365, 1970.

R. Horst and H. Tuy. Global Optimization. Springer-Verlag, 1993.

S.E. Jacobsen. Mathematical Programming and the Computation of Optimal Taxes for Environmental Pollution Control, volume 41 of Lecture Notes in Computer Science, pages

337{352. Springer-Verlag, 1975.

Allen Kneese. Water Pollution: Economic Aspect and Research Needs. Resources for the

Future, Washington D.C., 1962.

Allen Kneese and Charles Schultz. Pollution, Price, and Public Policy. The Brooking

Institution, Washington D.C., 1975.

C. D. Kolstad. Empirical properties of economic incentives and command-and-control regulation for air pollution control. Land Economics, 62(3):250{268, 1986.

Alan J. Krupnick. On marketable air-pollution permits: The case for a system of pollution

osets. Journal of Environmental Economics and Management, 10:233{247, 1983.

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

45

26. R.S. Larson. Sta report. Technical report, San Francisco Bay Area Hazardous Waste

Management Facility Allocation Committee, 1991.

27. L.B. Lave. Air pollution damage. In A. Kneese and B. Bower, editors, Environmental Quality

Analysis, pages 213{244. The John Hopkins Press, 1973.

28. L.B. Lave. Methods of risk assessment. In L.B. Lave, editor, Quantitative Risk Assessment

in Regulation, pages 23{54. The Brooking Institution, 1982.

29. Abba P. Lerner. The 1971 report of the president's council of economic advisers: Priorities

and eciency. American Economics Review, 61:527{530, 1971.

30. J. C. Liebman and W. R. Lynn. The optimal allocation of stream dissolved oxygen. Water

Resource Research, 2(3):581{591, 1966.

31. M. K. Macauly, M. D. Bowes, and K. L. Palmer. Using Economic Incentives to Regulate

Toxic Substances. Resources for the Future, Washington D.C., 1992.

32. W. David Montgomery. Markets in licenses and ecient pollution control programs. Journal

of Economics Theory, 5:395{418, 1972.

33. K. Moshirvaziri and M.A. Amouzegar. A Matlab linear programming tool for use in global

optimization algorithms. Technical Report ENG-95-146, Optimization and Communications

Systems Laboratory, Department of Electrical Engineering, University of California, Los

Angeles, 1995.

34. Susan Rose-Ackerman. Euent charges: A critique. Canadian Journal of Economics,

6(4):512{528, 1973.

35. State of California. Assembly Bill AB4294, and Senate Bill SB788. The Hazardous Waste

Technology, Research, Development, and Demonstration Program (AB4294) and the Hazardous Waste Reduction Loan Program (SB788).

36. State of California. Health and Safety Code x25155 5.

37. State of California. Assembly Bill AB2948, 1986. This bill formed Articles 3.5 and 8.7 of

the Health and Safety Code.

38. State of California. Senate Bill SB14, 1989. The Hazardous Waste Source Reduction and

Management Review Act (SB14).

39. T.H. Tietenberg. Derived decision rules for pollution control in a general equilibrium space

economy. Journal of Environmental Economics and Management, 1:3{16, 1974.

40. United States Environmental Protection Agency, Center for Environmental Research Information, Oce of Research and Development. Permit Writer's Guide to Test Burn Data,

Hazardous Waste Incineration, epa/625/6-86/012 edition, 1986.

41. United States Environmental Protection Agency, Oce of Solid Waste and Emergency Response. The Waste System, 6/9-248/00766 edition, 1989. U.S. Government Printing Oce.

42. United States Environmental Protection Agency, Pesticides and Toxic Substances (TS-779).

The Toxic-Release Inventory, Executive Summary, epa/560/4-89-006 edition, June 1989.

43. United States Environmental Protection Agency, Washington D.C. Hazardous Waste Treatment, Storage, and Disposal Facility Report, 1985.

44. L. N. Vicente and P. H. Calamai. Bilevel and multilevel programming: A bibliography review.

Journal of Global Optimization, 5(3), 1994.

45. Martin L. Weitzman. Prices vs. quantities. Review of Economic Studies, 41(4):477{491,

1974.

:

M. AMOUZEGAR AND S. JACOBSEN

46

Appendix

A.1. Waste Streams

This appendix presents the 20 types of waste streams used in this paper. The

numbers are the California Waste Category identication numbers.

Waste Group

Recyclable:

Halogenated Solvents

Non-Halogenated

Solvents

California Waste Category

211 Halogenated Solvents

741 Liquids with Halogen

(Org. Comp. > 1000 mg/l)

212 Oxygenated Solvents

213 Hydrogen Solvents

214 Unspecied Solvent Mixtures

Oily Sludges

222 Oil/Water Separation Sludge

Waste oil

221 Waste Oil and Mixed Oil

223 Unspecied Oil Containing Waste

Non-recyclable

Organic Liquid

133 Aqueous with Total Organics > 10%

134 Aqueous with Total Organics < 10%

341 Organic (Non-solvents) Liquids

with Halogens

342 Organic Liquids with Metal

343 Unspecied Organic Liquids Mixture

Halogenated Organic

Sludges and Solids

251 Still Bottoms with Halogenated Organics

351 organic Solids with Halogens

451 Degreasing Sludge

Non-Halogenated Organic 241 Tank Bottom Waste

Sludges and Solids

252 Other Still Bottom Waste

Dye and Paint Sludges

and Resins

Miscellaneous Wastes

271 Organic Monomer Waste

331 O-Spec, Aged or Surplus Organics

A.2. Data Structure

This appendix describes the data used in the system formulation of the problem.

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

47

sets

I

The nine ABAG regions /region1*region9/

F

Different size firms /fs,fm,fl/

R

Different size recycler /rs,rm,rl/

D

Different size incinerator /incin1*incin3/

*

To simplify we will only consider landfill as an option

*

with three different size to build.

*

Also due to geographical limitation and political considerations

*

only region 1 and 5 can have a landfill.

DS Disposal sites location /DS1, DS5/

DT Different size of disposal sites /DT1*DT3/

*

*

DT1

Landfill

*

DT2

Land Treatment

*

DT3

Waste Pile

*

DT4

Disposal Surface Impoundments

*

DT5

Storage Surface Impoundments

WS

20 waste streams /ws1*ws20/

*

Waste generated by each region ton/year

TABLE A(ws,i) table of waste produced by each region

1

2

ws1

726.5

95.5

ws2

33.4

8.0

ws3

809.5

89.6

ws4

2184.0

96.2

ws5

2627.9 725.0

ws6 19494.7 5889.7

ws7

2602.4 4615.3

125.2

59.2

ws8

ws9

538.4 675.6

ws10

1.1

1.9

ws11

7.9

.6

ws12

250.6 847.8

ws13

429.5 2778.9

ws14

54.9 640.2

ws15

7.7

12.3

ws16

4.5

7.0

ws17 1617.9 934.4

ws18

15.3

0.0

ws19

48.0

7.4

ws20

118.2

70.5

3

4

7.5 0.7

0.0 0.0

8.0 8.2

14.0 0.5

44.7 13.9

85.9 49.6

14.6 3.4

0.0 1.5

7.1 65.9

0.0 0.0

0.0 0.0

1.2 0.2

32.5 0.0

49.8 0.0

0.0 0.0

0.0 0.0

33.7 2.4

0.0 0.0

0.0 0.0

1.0 0.0

5

6

7

8

9

17.0

171.6 1950.0

45.7 258.9

1.3

1.0

13.7

76.2

0.0

33.3

214.6 3326.6

21.2

37.2

87.8

32.5 1642.0

8.2 1659.1

467.3 10123.6 6423.0 175.7

68.6

1045.8 47243.1 12672.0 1982.9 675.7

922.5

119.4 1259.7 1159.7 141.6

21.2

58.9

204.1

0.0

4.8

1376.7

602.9

577.5

38.9

52.7

0.0

.2

50.1

0.0

0.0

1.2

0.0

29.8

0.0

0.9

58.4

244.4

487.4

27.2

52.9

236.5

70.1

329.3 1129.8

8.8

0.0

0.5

4.4

0.0

0.0

0.8

0.0

33.9

0.0

0.0

0.2

1.1

7.2

0.0

0.0

887.1 1686.5

568.9 161.2 125.6

1.3

1.5

2.6

0.0

0.0

1.3

0.1

56.3

2.7

0.0

26.0

15.5

59.9

35.8

0.4

M. AMOUZEGAR AND S. JACOBSEN

48

* Recycling capacities for small, medium and large

*

TABLE Rcap(f,r) table of capacity of recyclers at firm f

rs

rm

rl

fs

1000

0

0

fm

1000

3000

0

fl

1000

3000

8000

* distance between the regions, computed from the center

* of one region to another.

TABLE M(i,j) distance between the counties

1

2

3

4

5

6

7

8

1

0

20

50

50

30

30

30

50

2

20

0

50

50

30

50

50

30

3

50

50

0

30

20

50

80

50

0

50

80

100

30

4

50

50

30

5

30

30

20

50

0

30

50

60

6

30

50

50

80

30

0

30

70

7

30

50

80

100

50

30

0

80

8

50

30

50

30

60

80

80

0

9

100

80

30

30

60

80

140

60

9

100

80

30

30

60

80

140

60

0

*

incineration prices, average cost prices from the third-third

*

report.

*

Parameter cost(d)

/

incin1

incin2

incin3

1.944

1.234

1.033

/

* convert the cost function form $/gallon to $/ton

* 238.09524 gallon = 1 ton.

*

parameter Icost(d) cost for incineration option dollar per ton

Icost(d) = cost(d) * 238.09524

* Disposal cost from the third-third report

Parameter cost2(dt) cost for disposal sites dollar per gallon

/

dt1 2.5

dt2 2.1

DSS FOR REGIONAL HAZARDOUS WASTE MANAGEMENT ALTERNATIVES

dt3

49

1.9/

* convert the cost function form $/gallon to $/ton

parameter Dcost(dt) cost for disposal option dollar per ton

Dcost(dt) = cost2(dt) * 238.09524

* we have assumed three types of firms with certain percentage

* contribution to the waste generation.

parameter Firm(ws,i,f) amount of waste w at firm size f at region i

Firm(ws,i,'fs')= .2*waste(w,i)

Firm(ws,i,'fm')= .3*waste(w,i)

Firm(ws,i,'fl')= .5*waste(w,i)

parameter FR(r) cost of building recycler size r

FR('rs')= 5000

FR('rm')= 9000

FR('rl')= 35000

parameter FI(d) cost of building incineration type d

FI('incin1')= 37000000

FI('incin2')= 49300000

FI('incin3')= 108000000

parameter FD(dt) cost of building disposal site of size dt

FD('dt1')= 100000

FD('dt2')= 150000

FD('dt3')= 250000

Parameter

Ocap(r) capacity of off-site recycler

Ocap('rl')=10000

Parameter Setup(r) setup cost of off-site recycler

Setup('rl')=50000

Parameter Charge(r) per unit charge for off-site recycler

Charge('rl')=270

parameter

Icap(d) capacity

Icap('incin1') =

Icap('incin2') =

Icap('incin3') =

of incinerator at k type t size d

120000

170000

400000

parameter Dcap(dt) capacity of disposal site at k type dt

Dcap('dt1')= 25000

M. AMOUZEGAR AND S. JACOBSEN

50

Dcap('dt2')= 35000

Dcap('dt3')= 50000

parameter Rcost(w,r) cost of recovery of wastes using size r

Rcost(w,'rs')$(ord(w) le 5)= 450

Rcost(w,'rm')$(ord(w) le 5)= 400

Rcost(w,'rl')$(ord(w) le 5)= 260

parameter TC(i,j)

transportation cost

TC(i,j) = M(i,j)*.23

parameter TR(i,ds) transportation cost for residual

TR(i,'ds1')= M(i,'1')* .28

TR(i,'ds5')= M(i,'5')* .28