Hydrodehalogenation of Aromatic Halogens Using Sodium Borohydride and Palladium under Ambient Conditions

advertisement

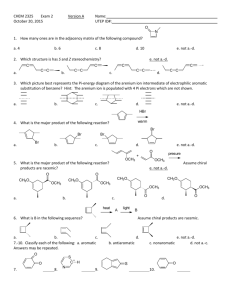

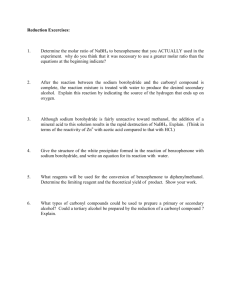

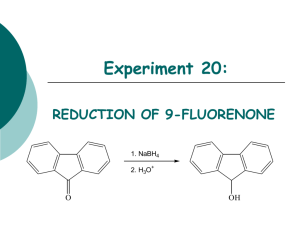

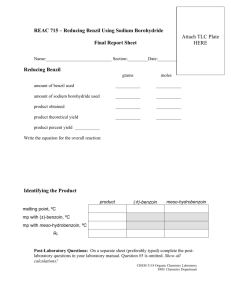

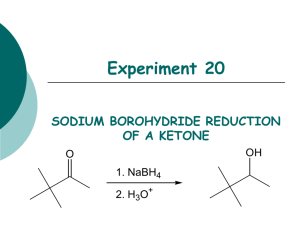

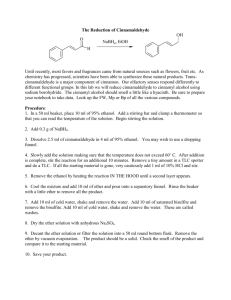

Hydrodehalogenation of Aromatic Halogens Using Sodium Borohydride and Palladium under Ambient Conditions Zach M. Rousslang, Alyssa Russo and Dr. David B. Cordes Department of CHEMISTRY | Pacific University | 2043 College Way | Forest Grove, OR 97116 | cordes@pacificu.edu Abstract: Using sodium borohydride as the reducing agent and catalyzed by activated palladium on carbon, the reductive dehalogenation of aromatic halides is observed under room temperature and pressure. This heterogeneous reaction mixture employs isopropyl alcohol as the solvent and provides high conversion yields within an hour reaction time. The effects of the local electronic environment on yields are currently being studied using halogenated benzonitriles, toluenes, anisoles, and benzenes. BACKGROUND: The reductive hydrogenation of organic molecules is a cornerstone of synthetic chemistry. This tool allows chemists to manipulate the polarity, reactivity, and overall composition/structure of unsaturated hydrocarbons. Since its advent, hydrogenation has developed niches in many fields such as material science, natural products research, and in both food and medicinal chemistry. Due to the ubiquitous importance of unsaturated hydrocarbons many methods have been developed for their reduction. Some of the existing methodologies require expensive reagents, complex multiphase systems, and produce harmful byproducts RESULTS: Selective Reduction of α-β Unsaturated Compounds: NaBH4 (4 equiv), CH3COOH (2 equiv) 2.5% Pd/C R R Toluene or IPA, 1.5 hour, open air Halogens are one of the most reactive chemical families due to their high nuclear charge. Their reactivity and polar nature are of critical importance for many biological and chemical processes, yet they can also be extremely toxic in the wrong environment. Aromatic compounds are notorious for electron delocalization and thus these conjugated systems are susceptible to halogen interaction. The stabilizing effects of this interaction can produce highly inert compounds, which can pose a problem for waste management. Hydrodehalogenation is a sub-field of hydrogenation chemistry where a halogen is effectively replaced with hydrogen and has significant applications in many of the same areas as basic hydrogenation. Yield Product Substrate NH2 NH2 O O 98% O O 99% N N O O BOROHYDRIDE REDUCTIONS: 99% Borohydride reagents are ordinarily used for the reduction of polar functional groups, especially with carbonyl-containing compounds such as ketones, aldehydes, and esters. Among the borohydride reagents, sodium borohydride in particular is valued for its low cost, mild nature, and ease of handling. Surprisingly, however, this green reagent has found only limited use in the reduction of less polar functional groups. O O 99% Hydrodehalogenation of Aromatic Compounds: The hydrolysis of borohydride produces hydrogen gas. In the presence of hydrogen gas, reduced metals are found to catalyze the reduction of alkenes. Simple Reductions Using Pd/C and NaBH4: Initial research was conducted using our method for the hydrogenation of alkenes and alkynes. High conversion yields have been obtained for many simple unsaturated hydrocarbon. A solvent study indicated that isopropyl alcohol (IPA) was the most effective solvent. ALKENE or ALKYNE 4 NaBH4, 2 CH3COOH, catalytic Pd/C IPA, RT, open air ALKANE 90% or higher conversion Aromatic halogen (1mmol) Substrate 4 mmol NaBH4, 5 mL IPA 5% mol Pd/C, 1 hour, open air Product Yield CN CN Cl CN Substrate CN Product CN 93.3 % CN 95.8 % 96.1 % Br Cl CN CN Yield CN Br 57.2 % CN Hydrodehalogenated aromatic CN CN 98.0 % 99.0 % I Br Substrate Product Yield Substrate Product F Cl Reactions occurred rapidly under ambient conditions. Molar percent catalyst ranged from 1 to 5%. Yield 7.4 % 1.6 % 16.1 % 3.1 % F Cl OUR STANDARD PROCEDURE: Current Procedure: 1. An air-dried round bottom flask with stir bar is charged in open air with the alkene, α-β unsaturated compounds, or aromatic halogen, (1 mmol), 5 mol % Pd/C, and 5 mL isopropyl alcohol (IPA) . 2. Solid NaBH4 (4 mmol) is added in a single portion directly to the stirring heterogeneous solution. (Note: Addition of the NaBH4 causes the rapid evolution of small hydrogen gas bubbles.) 3. The contents of the reaction flask are left to stir in open air at room temperature. 4. Workup is conducted by quenching the reaction mixture or reaction aliquot with 0.1 M HCl until no further hydrogen evolution is observed. The solution is then made basic with saturated NaHCO3. The products are then extracted from the basic solution with ether, dried over anhydrous MgSO4 and filtered. The solvent can be removed by evaporation at reduced pressure. 5. Reactions are typically analyzed by GC/MS. 11.9 % 3.7 % F Cl Substrate OCH3 Cl Product Yield OCH3 99.8 % OCH3 OCH3 Substrate Product OCH3 Br OCH3 OCH3 OCH3 94.9 % 87.2 % 99.9 % Br Cl OCH3 OCH3 OCH3 OCH3 99.9 % Cl Yield 99.9 % Br FUTURE DIRECTIONS: Acknowledgements: Pacific University and the Department of Chemistry; The Murdock Charitable Trust; Vincent Huynh and Anthony Tran -Conclude systematic survey of reduction in simple aromatic halides. -Perform mechanistic studies to develop probable reaction scheme. -Fully optimize a method using water as the solvent. -Devise methods for the isolation, purification and yield calculation of select halogenated aromatics.