INVESTIGATION OF CHEMICAL AND PHYSICAL PROPERTIES OF SOUTHWESTERN WISCONSIN MAPLE SYRUP

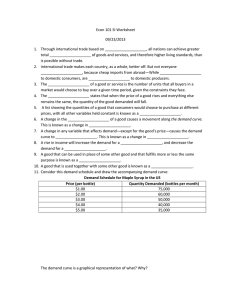

advertisement