Lean Aircraft Initiative Implementation Workshop:

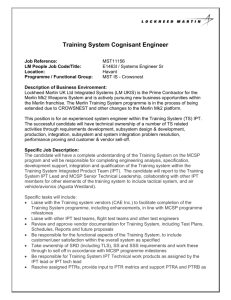

advertisement