AquaSorb MP23 TECHNICAL

advertisement

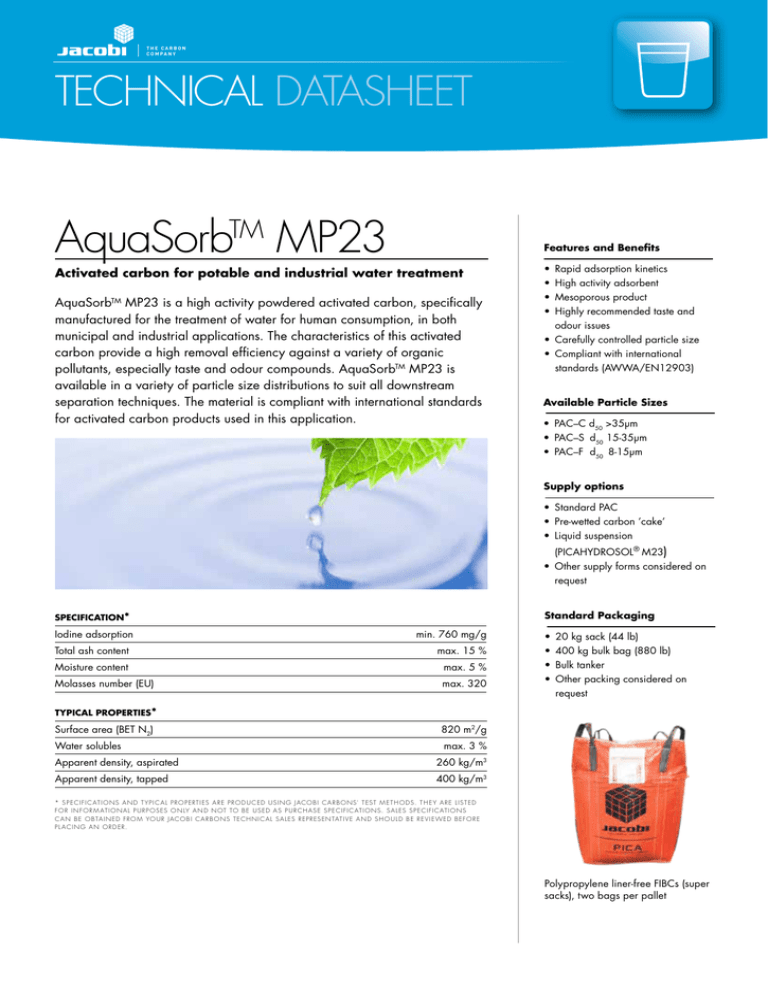

THE CARBON C O M PA N Y TECHNICAL DATASHEET AquaSorbTM MP23 Features and Benefits Activated carbon for potable and industrial water treatment AquaSorbTM MP23 is a high activity powdered activated carbon, specifically manufactured for the treatment of water for human consumption, in both municipal and industrial applications. The characteristics of this activated carbon provide a high removal efficiency against a variety of organic pollutants, especially taste and odour compounds. AquaSorbTM MP23 is available in a variety of particle size distributions to suit all downstream separation techniques. The material is compliant with international standards for activated carbon products used in this application. • Rapid adsorption kinetics • High activity adsorbent • Mesoporous product • Highly recommended taste and odour issues • Carefully controlled particle size • Compliant with international standards (AWWA/EN12903) Available Particle Sizes • PAC–C d50 >35µm • PAC–Sd50 15-35µm • PAC–Fd50 8-15µm Supply options • Standard PAC • Pre-wetted carbon ’cake’ • Liquid suspension (PICAHYDROSOL® M23) • Other supply forms considered on request Standard Packaging SPECIFICATION* Iodine adsorption Total ash content min. 760 mg/g max. 15 % Moisture content max. 5 % Molasses number (EU) max. 320 • 20 kg sack (44 lb) • 400 kg bulk bag (880 lb) • Bulk tanker • Other packing considered on request TYPICAL PROPERTIES* Surface area (BET N2) 820 m2/g Water solubles max. 3 % Apparent density, aspirated 260 kg/m3 Apparent density, tapped 400 kg/m3 * S P E C I FI C AT I O N S A N D T Y P I C A L P R O P ERT I ES A R E P R O D U C ED U S I N G J ACO B I C A R B O N S' T ES T M E T H O D S. T H E Y A R E L I S T ED F O R I N F O R M AT I O N A L P U R P O S ES O N LY A N D N OT TO B E U S ED A S P U R C H A S E S P E C I FI C AT I O N S. S A L ES S P E C I FI C AT I O N S C A N B E O BTA I N ED FR O M YO U R J ACO B I C A R B O N S T E C H N I C A L S A L ES R EP R ES EN TAT I V E A N D S H O U L D B E R E V I E W ED B EF O R E P L AC I N G A N O R D ER. Polypropylene liner-free FIBCs (super sacks), two bags per pallet Technical Datasheet: AquaSorbTM MP23 TASTE AND ODOUR REMOVAL Methyl-iso Borneol Influent concentration127ng/l AquaSorbTM MP23 at 10mg/l dose Effluentconcentration 76ng/l Removal efficiency 40% AquaSorbTM MP23 at 40mg/l dose Effluentconcentration 27ng/l Removal efficiency 79% Geosmin Influent concentration187ng/l AquaSorbTM MP23 at 10mg/l dose Effluentconcentration 83ng/l Removal efficiency 56% AquaSorbTM MP23 at 40mg/l dose Effluentconcentration 8ng/l Removal efficiency 96% DATA O BTA I N ED FR O M I N D EP EN D EN T T ES T I N G BY AU S T R A L I A N WAT ER Q UA L I T Y C EN T R E W I T H PAC S W ER E D O S ED A S A P R E -W E T T ED S LU R RY AT 10 A N D 4 0 M G/L I N TO 2 L I T R E VO LU M ES O F S TA B I L I S ED TA P WAT ER CO N TA I N I N G 10 0 N G/L TA R G E T CO N C EN T R AT I O N S O F M E T H Y L- I S O B O R N E O L ( M I B) A N D G E O S M I N . CO N TAC T PRODUCTION CAPABILITY Jacobi Carbons operates multiple facilities for the manufacture of activated carbons. These production plants are strategically located close to market and raw material sources. With an annual output in excess of 70 000 metric tonnes, Jacobi Carbons is able to supply product to all locations around the globe. All production units are certified according to internationally recognised standards (ISO9000 & ISO14001). Quality control is consistent throughout the group of companies and goods are always shipped in compliance with customer specifications. WA S M A I N TA I N ED BY M I X I N G F O R 20 M I N U T ES AT 10 0 R PM W I T H A FL AT- B L A D E PA D D L E S T I R R ER. T R E AT ED WAT ER WA S PA RT I T I O N ED BY FI LT R AT I O N T H R O U G H 1 µ M P O R E S I Z E PA P ER FI LT ERS A N D A N A LYS ED F O R M I B A N D G E O S M I N AGA I N S T T H E P O S I T I V E S P I K ED CO N T R O L . BURNING AND EXPLOSION CHARACTERISTICS Auto-ignition temperature 400cm3 160 ºC 6400cm3 150 ºC 12800cm3 130 ºC Smolder temperature No smoldering up to 400 ºC Dust explosion class St1 (weak explosion potential) Combustion factor BZ3: no spread of fire Minimum ignition energy >10 000 mJ (MIKE3) Minimum ignition energy 100 - 1000 J (VDI2263 Part 1) Minimum ignition temperature >400oC Lower explosion limit 250g/m3 Electrical resistivity 0.05 x 104 Ω.m Explosion severity (20l sphere) P max. 8 bar MRE (∆P) 33 bar/s Kmax or Kst 88 bar/m/s CARBON APPLICATION KNOWLEDGE The supply of activated carbon products is supported by an industry-leading technical support service. Our in-house expertise extends over many years of practical experience in the design and utilisation of activated carbon in a variety of applications. Jacobi Carbons can assist in the design, specification and method of use of our products to achieve the optimum treatment outcome required. Our laboratory facilities support our product portfolio with a extensive library of technical data. DATA P R OV I D ED I S I N D I C A AT I V E O N LY A N D B A S ED O N T H E A N A LYS I S O F M AT ER I A L U N D ER S P E C I FI C CO N D I T I O N S. T H ES E M AY N OT B E R EP R ES EN TAT I V E O F P R E VA I L I N G C I R C U M S TA N C ES D U R I N G T H E H A N D L I N G A N D U S E O F T H I S AC T I VAT ED C A R B O N G R A D E. NOTICE Due to the progressive nature of the Jacobi Carbons Group and the continually improving design and performance of our products, we reserve the right to change product specifications without prior notification. The information contained in this datasheet is intended to assist a customer in the evaluation and selection of products supplied by Jacobi Carbons. The customer is responsible for determining whether products and the information contained in this document are appropriate for customer’s use. Jacobi Carbons assumes no obligation or liability for the usage of the information in this datasheet, no guarantees or warranties, expressed or implied, are provided. Jacobi Carbons disclaims responsibility and the user must accept full responsibility for performance of systems based on this data. © Copyright 2012. Jacobi, Jacobi Carbons, PICA and the Jacobi and PICA logos are registered trademarks and AquaSorb, EcoSorb, ColorSorb, DioxSorb, AddSorb, ReSorb, PICACTIF, PICAPURE, PICATOX, PICACARB, PICAGOLD, PICARESP, PICAHYDRO and PICACLEAN are trademarks of Jacobi Carbons, all of which may or may not be used in certain jurisdictions. JACOBI-TDS-AQUASORB-MP23-A4-ENG-F0215 Lenntech info@lenntech.com Tel. +31-152-610-900 www.lenntech.com Fax. +31-152-616-289