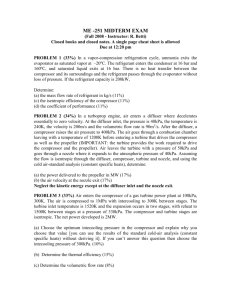

A STUDY OF DYNAMIC COMPRESSOR SURGE ... STRATEGIES FOR A GAS TURBINE ENGINE

advertisement