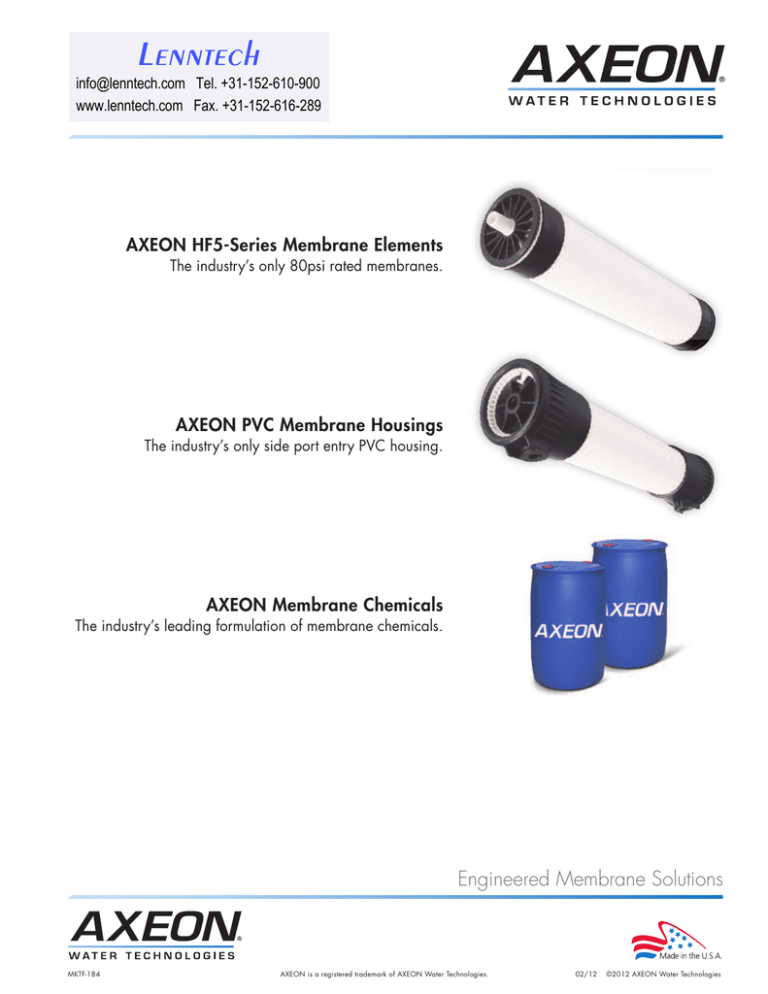

Lenntech AXEON HF5-Series Membrane Elements AXEON PVC Membrane Housings AXEON Membrane Chemicals

advertisement