Document 10816872

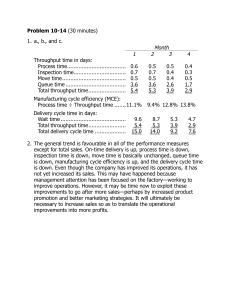

advertisement