EFFECTS ON IN MICROCARRIER BIOREACTORS BY SHANE CROUGHAN

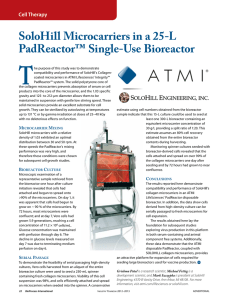

advertisement