2 - BioReactor Sciences

advertisement

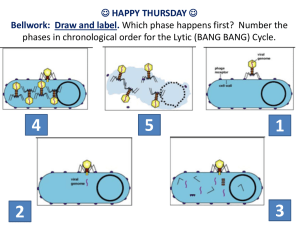

Production of Avian Influenza H1N1 Virus using TideCell Bioreactor System www.bioreactorsciences.com A case study of Virus Prodcution using MDCK cells Comparison study Due to significant difference in characteristics of virus strain and host cell line, the optimal process of virus production can be significantly different. In the following slides are requirement of conditions for this specific case of study, on which comparison of TideCell/BelloCell system and other commonly used systems are based. High cell density is required to achieve high virus titer. TdeCell: High surface area provided increase cell density. Cell density reach around 4 x106 cells/ml. Roller bottle: The surface area is limited. Cell density reach around 0.5~1x106cells/ml Microcarrier system: The bead density is limited. Cell density reach around 1~2x106 cells/ml Cell attachment efficiency is low due to long term trypsinization. TideCell: Extremely low shear enviorment enables high attachment rate even the cells have been over-trypsinized. Roller bottle:A rolling culture status increases the difficulties of cell attachment, especially in serum-free culture medium. Microcarrier system: Agitated environment increases the difficulties of cell attachment. The cell attachment efficiency will become lower when the scale is increased. Cells tend to detach after infection TideCell: Extremely low shear stress environment enables cells not easy to detach after infection and increase the productivity. Roller bottle: A rolling culture environment enhances cell detach after infection. Microcarrier system: Agitated environment enhances cell detach after infection. Low DNA and host cell protein are required TideCell: Low shear stress culture environment enables cells retaining in the matrix without being flushing out. DNA and host cell protein residues are relatively low in the harvest. Roller bottle: A rolling agitated environment causes cell disruption and release of DNA and host cell protein directly into harvest. Microcarrier system: Agitated environment causes cell disruption and release of DNA and host cell protein directly into harvest. Nutrient supply and medium exchange are required to minimize cell interference and dilution of virus titer. TideCell: Directly exchange culture medium from the mixing tank without interfere cells in the matrix vessel Roller bottle: Exchange culture medium directly from the bottle causing detach of cells. Microcarrier system: Culture has to be stopped temperarily and allow the microcarriers to settle before medium exchange. Cell Density before Infection Summary of results Production profile Purification profile Conclusion TideCell: Virus HA titer: 512~1024 Roller Bottle: HA titer: 256 Microcarrier system: HA titer: 256~512 Thank you for watching. Please visit us@ www.bioreactorsciences.com or www.cescobioproducts.com