August T24/M07043/EE/20150824 2015

advertisement

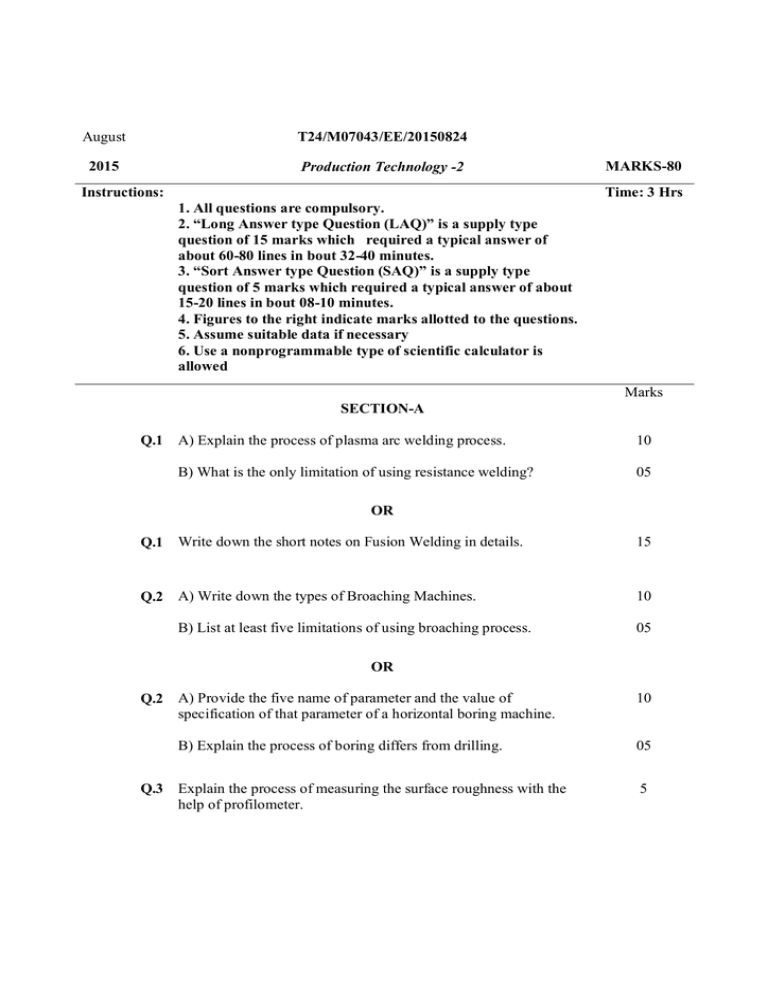

August T24/M07043/EE/20150824 2015 Production Technology -2 Instructions: MARKS-80 Time: 3 Hrs 1. All questions are compulsory. 2. “Long Answer type Question (LAQ)” is a supply type question of 15 marks which required a typical answer of about 60-80 lines in bout 32-40 minutes. 3. “Sort Answer type Question (SAQ)” is a supply type question of 5 marks which required a typical answer of about 15-20 lines in bout 08-10 minutes. 4. Figures to the right indicate marks allotted to the questions. 5. Assume suitable data if necessary 6. Use a nonprogrammable type of scientific calculator is allowed Marks SECTION-A Q.1 A) Explain the process of plasma arc welding process. B) What is the only limitation of using resistance welding? 10 05 OR Q.1 Write down the short notes on Fusion Welding in details. 15 Q.2 A) Write down the types of Broaching Machines. 10 B) List at least five limitations of using broaching process. 05 OR Q.2 A) Provide the five name of parameter and the value of specification of that parameter of a horizontal boring machine. B) Explain the process of boring differs from drilling. Q.3 Explain the process of measuring the surface roughness with the help of profilometer. 10 05 5 Q.4 Explain the following terms:I) wheel dressing II) wheel truing 5 SECTION-B Q.5 A) Which components used for making jigs and fixtures.. B) What is super finishing? 10 05 OR Q.5 A) Give at least 8 principles to be used while designing jigs & fixtures. 10 05 B) Give the difference between jigs and fixtures. Q.6 A) With the help of diagram explain the process of cup drawing and rolling. 10 05 B) Which metal forming process is used to make coins and how? OR Q.6 A) Explain advantages and disadvantages of the powder metallurgy process. 10 05 B) What is metal forming process? Q.7 Explain in brief the differences between micro finishing and grinding processes. 5 Q.8 Name the principle involved in the process of metal cutting. 5 Computer Generated Random Question Paper dated: 21-07-2015 13:16:48 ***BEST OF LUCK***